Académique Documents

Professionnel Documents

Culture Documents

Top 25 Causes of Container Claims

Transféré par

Jack0 évaluation0% ont trouvé ce document utile (0 vote)

37 vues21 pagesContainer claims

Copyright

© © All Rights Reserved

Formats disponibles

PDF ou lisez en ligne sur Scribd

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentContainer claims

Droits d'auteur :

© All Rights Reserved

Formats disponibles

Téléchargez comme PDF ou lisez en ligne sur Scribd

0 évaluation0% ont trouvé ce document utile (0 vote)

37 vues21 pagesTop 25 Causes of Container Claims

Transféré par

JackContainer claims

Droits d'auteur :

© All Rights Reserved

Formats disponibles

Téléchargez comme PDF ou lisez en ligne sur Scribd

Vous êtes sur la page 1sur 21

ewer

FE omeoey

eon

SSCA tary

UAC

pre

s

E

Nl

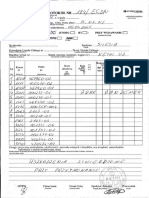

The types of incidents that

occur to containerised cargo

Thisis quick reference breaking down of types of incidents that

‘cour to containarisad cargo, isting the incidents, the cause of

incidents, identifying any documentation needed, and identtying

any loss proventatve steps that can ba taken,

1, Damage to the container and potentially tha cargo inside.

2. Damages and losses to cargo inside a sound container.

3, Wet damage to the cargo inside a container,

4, Temperature damage to reefer cargo,

Key references to note

‘Sub-Contractor could be: The Merchant under the bill

> The barge owners. of lading could be:

> The container freight station, > The noliy party.

> The oad port torinal. > The shipper

> The transhipment port terminal, > The consigner,

7 The discharge port tina, “> The consignee,

9 The raitway company. “> The owner and receiver

af he goods.

> The road havoge % > The holder of the original bill

> Tha ctevedores company. of iading,

ny or pty seg on

Chater Party coulda win; > ARV pay aig on

> Owners of ocean vessel.

9 Ovmurstteedervessé, The mandatory Clim

~ Joint service porter as vessel POcuments should bo:

Provider > The statement of claim.

> Joint service partner as space > Copy ofthe orignal ba of lacing.

charterer. > Proof of tie to the goods.

> Chatterars, > The commercial invoice,

> The packing list,

> An independent expen report,

Coe

omer

Clr eee memes ey ne

Broken > Poor handling of Fi Gote in EIR at origin A! HRY © Chack condition of container frames at torminal in gate.

Sontainer hoawy 1 Gato out et 1 asus nate to sbinper advising them of damages

doors Fa equipment discharge zy FRY Personnel present on quayside curing handling operations to

PRIA Road Trafic gs connactr's 1" ineividvaly obsorve container condition.

ecient) damagefoss report 1 rmgy_ © Container maintenance scheduo established in order to confirm the

> Pillorage CrSibconvactars MES ISM unite good condtion spon deopatch rom the solar yocd,Wrerted

contaciwihMenbec 4 tn, docurens provided to confirm container mainionance/nspetion

CD Gontainertreck AE IR _ Pr tovoleasetoloadng ocaton,

Copy of bil oftading |= Repair effected Gf possible) prior to container being loaded to vesset

ci 4 ir i

i Itunrepsirable, extent of damage established prior to loading to

5 Wiiness statement = INI © cing vce to conte seu werhians oft Poste ocean.

Coe ay

any ‘evan of cargo either prior to or subsequent to shipment.

11 Road havage

documents =

Detivary Notes

1 Police Reports

1D Equipment

interchange repon es ta

Collapse > Bad weather © Sub-contractor's = B Diligont passage planning to minimise chances of vessel grounding!

at stow 5 Colson damagelloss report TS geting caughtinbad weather

andiossof Grounding 1D Sub-contractor's i i Receive and act on atest weather forecasts fo avoid severe weather.

onbonda gantcact vith ME) ESI ty to vat excoste vesse ations by tray aterafon of coves og

vessel, 2 Sinking Membor 1 speed or both.

> forestowageby 1 Copy of bil of acing BEE! J 1 Fottow Catogs to iinise chances of colisions.

> Shipper's miss 1D Witness statomont | ‘© Check that each container has been assigned a Verified Gross Mase

aeeeniee itany MRE Gq] VOM nko vt SOLAS regs toh ca ofc Tt ty 2016,

weight St D Educate shippers not to load containers asymmetrically or over

> Shippers improper iq lead containers,

stowage ofearga EBD cook mck andteshing forces using clas approved ishing pogrom.

insid the container _. Gi Check that fashings have been applied correctly by stevedores,

Ec crow shoud naval check ad ghentshings as require.

aq 7 Constion of lasting equipment should be monitored and any damaged

Ea] or worn gear shoud be replaced

© Check condtion of container frames and corner casings ot terminal

ria to loading.

1 GRY Surveyors! attendance at devanning location # reserves aro raised

| TTT tegaring damagedmissing cargo and aigaton

Fag ss0e vote to shippor it damage noted pir to daspatch

Joad containers,

1 Educa shippers how to corey stow cargo ina conianer. Reference

@ OM Sno si NE Pre

{ Packing of Cargo Transport Units (CTU Code) and MSC.1/Circ, 1498

my llounabo stra eaten i Prot

= s {or Packing of Cargo Transport Units (CTU Code)

Dertedand > Poorhandiegat CLGstin ER stofain BRE AE Gauss rem 80 mone

scratched heavy liteadpmest 2 Ga wa pase i topped if necessary ASAP fr devancever).

containers aaa Road nates Pathe 1 RY VWhock condition of container amos at erninal in gare

Accident) Svb-contractr’s issue note to shipper advising them of damages,

ddamage/loss report

© Sub-contractor's

‘contract with Member

1D Container track

Copy of bit of fading

1 Witness statoment

ifany

= i NY! 1 Educate shippers not to load contsnors asymmeticsly or over

a

i oven.

1 fag 2 Wot ett,

>Faulyheayit §=—VGM = 1 Look for pata shipper re weigh dstbuton i provious

joment | Historyenste, m

eauipme O Weight tisets ny as,

> Cargo overweight TE ® 85] check condiéon of ‘conlainer corner castings at terminal ie gate,

bs | oinemewamenenrane asi

> Uneven distributed 4 DG educate shi ners esymena

6 ;Ppers nat to load containers ssymurelically or over

‘weight inside the = load containers.

onlaner

HE Bag 9 Escate shippers how to coreaty stow cargo ina conlainen

Refernce IMO MSG Gk mk Cade of

| Rilerplo usc. ie i areca

ts te ea or

e 3 oof aston to go Tame

{CTU Code}.

>Poortaangt Cina amnen A

heavy ft equipment any

Pee

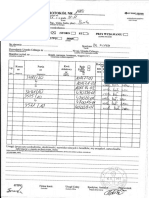

Heat damage — > Miss-declared 0G Manifest 5 INYP Look for paricuar shipper re number of claims (previous history),

Dangerous goods WG Gods I ‘F.Compiiance vith IMOG Code regulations fr seqregaionhheat sources,

ote cnbeed 1G Spocifoadices trom EE! AY C1 Permission to work on board (0 hot work).

shipper/consignee | GHot area stowage (Engine rooms/heated fuel tanks).

Oy dine

oer me

> Poor hand DGatein ERatosgin MA LP cPersonnel present on quayside andr main hub daring handling

hoary Et equipment 2 Gite os Ete ot ‘operations to individually observe container condition.

> Hitby a movi discharge {ARGO Containor maintenance schedule established in order to confi the

eee ay ME) IS SR wenr nnty

Ch Me-cntactn’s | Sens povdercsege tone contin yard rnd

> Hit another damagesioss report BE? ERY tortoroease a ostnglaaton

container during D Subcontractors

Of reported/kniown before loading to carrying vessel or ‘subsequent to

Se Ee skies tna

oomane va smitpsn np pune cheeses

Soapetbotatag | iret op dvmtan seu boconsuoe oot

stat a

pgm ME ERD can opnan nant oy ce

el ca ston cnein

£3

> Truck going too fest Witness statement | 5 Consider Bul of Ladingynvoice terms regarding responsibilty for

> shippersinprper any a

stowage of cargo 0 Police Reporte ] {llntegrty quality and professionalism of road haulers used by castor

inside the container 6 Tachograph Data =: ‘dependent upon terms),

> Weather conditions 5 vars statement | Sail ifprior to foading to carying vessol, extent of damage estimated end

‘ancderaon given to devarrovan of cong

“3 Poor rod conditions a

en Trac da HE! 85) 0 Sineyfotowing incident to eotabish, possi, whether cargo was

> Driver fatigue FI CMRATransit correctly siowedisocured, partiulaly vith regard to cargo distribution

document i oy (lop heavy) and, to establish appropriate actions to titigate any toss.

i EAD co ttonvto gots vajootad corns tary inspection a shippers

Brorises (cbjct to lineout oh eee

HE £59) 0 susagepotertato teenies

pare

Train going too fast

> Poor rail

maintenance

> Diver fatigue

> Evtrems Weather

Deo ee

1 Witness statement

itary

Diver stotement

5 Pelco report

Rail company

siatemont

‘surveyors roport

ES acon Ce

‘C1 Consider Bil of Lading terms regarding responsibiy for prelpost

shipment transi.

‘prior to teasing to carying vessel, extent of darnage estimated and

consideration given to devan-revan of cargo.

D Survey folowing incident to eslabish, if possible, wither cargo was

cortecly stowed/seoured, particulary wih regard te cargo ditibution

(top heaw), to investigate citcumstancos surrounding the incident (iain

‘peed etc} and to establish appropriate actions to migate ery losses

Salvage potential to be explored.

Contamination

> Shippor's improper

stowage of cargo

inside the container

> Preloasing cargo

infestaion

> Taining by previous

cargo

> Thinting by floor

presenatve

> Taining by paiet

preservative

Taint rom other

cargo (samo!

adjacent containers)

> Wetting (damaged

Ccontsine:)

> Cargo leakage

1 Stowage plans from

shipper

DMO Guide for

‘container stuting

(CTU Guide)

4

Cargo manifest

(updated)

1 Material Safety Data

‘Shoot (f relevant)

1D Fumigation

Cerificatos

(GF appropriate)

1G Phytosanitary?

Veterinary

Cortfcates

Gfretevari)

ERY Educato shippers not to load containors asymmeticaty or

+n overload containers.

ing 1 Educate shippers how to conrectly stow cargo in a container Referenco

Ni MSG.Gie 1497 MONO) ice for

acting of Cargo Transport Unita (GTL} Code) and MSO.1/CGiro, 1498.

SRE erPbnact ane tant Uae toes

1D Surveyors instucted quickly once cargo damage reported so to

ERM stabs nature of cargo stowrage/securng. Even ifeargo de-vanned,

zermants of securing matorial may provide en insight.

Bigg Estobioh if panera has emarged with cargo damage tom parioular

ae shippers. fo, surveyors’ attendance at shippers premises to observe

fand if necessary, assist in safo stowage.

(aK

Aw 0 Compatibility of eargo witin same container (LOL containers).

E]QJ_ Pee shipment inspection during loaing high value cargo).

SSN Documents obisined from source (ental carpany /contsinar yard)

gg Confirming that containers have been cleaned / furigated prio 10,

ERE) loasa. This should include confirmation tat noinectauone ‘present

‘and thal any “sit” has been eliminated, Once allegations have been

made regarding “sat, attempts coud be made to esteiish the

BMD totrectpreiou cargo to confem vay of cn

{Immediate surveyors’ attendance to confirm ary presence of int”

HAR] 20d whether this coud be removed through ventlation

{1 Tainting by lor preservative is eiicut. How could one estabish

‘what has been used? Could this possibly be a locality issuo? Le,

mare stringent rules on preservatives used in Australasian areas than

others, Or, could ths be epory used to fitrepair floors, Again, this

Could be controled trough cleaning / fumigation and ventlafon at

‘S0urc0, porto the container boing delivered to loading locations

1 Patt preservative taint would be unusual. Athough pallets are

often treated with methyl bromide, the concentration used shoud

be insufcient to produce significant odour Falegations aro made.

regarding pall znt, we vould recommend immediate attendance by

Survoyors fo confi, assuming tho cargo is sited as “shippers load,

‘stow and court” on the relevant Bils of Lading, thatthe pallet tants,

of pre shipment orig

oie

Pearce

> Collision

> Grounding

+ Fire on board

> Ship's slot availabilty

> Engine fale

> Contzinar stowed

‘near a heated area

on board

Heat damage

Infestation

> Shipper improper

storage of car inside

the conser

> Shipp improper

packaging ofthe cargo

Leakages

ene aca

: a

DDG Manifest

DIMDG Code

1D Specific advices from

shipper/consignee

1 Matosiat Safety Data

‘Sheet for DG goods

Eunigation

Certificates

{appropriate}

Phytosanitary

cate

Veterinary Export

Coriticate

1D Shippers toad /

stow plan

[ae | SA 2 once cavers made, suneyr’s tendarce inode to exabih th

Ld

fine sonsitvamaturo of any cargo subjected to delay andthe measures

xy _kenby cargo eceivors to mitigate loss,

EA oigenpssage ring orn chances vessel goundnt

gottng delayed duo o bad weathor,

TRY 2 Receve and act on test weather forecast to avoid sovere weather

1 Fottow Colregs to mininice chances of colons,

TERY © Moctor mackinery in order to pre-empt failure,

A © Follow planned maintenanca systems to minimise chances of

say _mactiney ats.

(SIN GI Ensure DG cargovs correctly stowed fo avoid fia incidents,

By Implement effective planning systems to reduce instancos of alot

iB © simchtiy Good Conmsasiorbatreranesees a

vessel wil aid effoctive planning of tho containers. Any foreseeable

situations tht may impact of sot availabibty (auch as repair work to

hatch coves ete} shoud beached othe planners as ently es poosble

UR 0 Comptonce with MOG Code regulations for Sogregation/heat cources.

{Permission to work on board (re hot work).

EERO Hot area stowage (Engine roomstheated fuel tanks)

a}

LER] © Documents cbtsined fiom source (rental company / container yard)

confirming that contsiners have beon cleaned / lunigated prior

lo release, This shoud include confirmation thal no infestans

Plesent. Surveyor" attendance in order to confirm the nature of

argo, (etractveness to reported insectsAveria) extent

damage asa result and likely origin

'O Surveyors’ stiendance upon discovery of leakage to establish the

falure end extent thereof and sutabiliy of slowage/packaging.

(7 Eaubish palo has emerged wh cago darrage fom parte shipper,

{eo sunejos! atsadanc at shippers praises to aise eulabl pacaging

and assist n appropriate stowage especialy on high va cargoos,

iW

ee eo

Uncotected 2 The Morohart WE | SHE OC cststich seth the Merchant intends to receiv the cago in de

caig0 canvot receive | couse. so, charge demurago as appropri I cargo uncolected

the cargo after tezzonabe lenglh of timo, place the goods nt the ands of

>The Merchant sunyots fr sahage asponal

walla recave

‘the cargo,

> Merchant

bankrptey

> Marke issues

> Mis-described

cargo

g

g

Condensation

Container

doors with

worn rubber

soals

> Inherent vice of the Documents re

cays inate cont

2 Wonton patos win Ceci

fight conoat

> Wastes

lene

temperate

Poor maintenance

RHO Sunoyore atendane once cago de-vaned in order toconirn

“ inherent vico of cargo or high moisture content of pallet boards (both

protranatises)

Ac Attce soning cosas hao sal ventaton delta ver

side corners, These are designed to allow reasonable arfiow into the

Container and thus reduce the tisk of climatic condensation. Often

shippers choose to tape thesa ventilators closed, These could be

‘checked prio fo the containers being delivered to the shippers premises

‘and a document issued to confirm the ventlators were not sealed.

G The shippers and receivers would need to take a dogree of

responshiliy wilat stowing condensation sensitive cargoes, by the

Use of desiccant bags and Kraft liner paper over the surface of the

stowed cargo. I could also be established whether itis a limited

‘sumbr of commadtias or the goods from particular suppliers that are

subject of claim duc to climatic condensation. If this is the case, those

‘concerned could be assisted by stowage advice.

YJ © Stowage method {Space to top of stow).

Hyg, D Reaver conines inspections,

G Pea stuffing inepection at shippers premises for high value cargoes.

“jqy_ TD Sentainer maintenance schedule eetablshod. Hf rented uni, documents

INI provided to confi canisner mantenance/inepecton pio to elonee,

pq Repair etfected (f possible) prior to container being loaded to vessel,

TRI Geto of cargo damage established by surveyors following dovanning,

inorder to minimise loss,

WY F Container eomoved from service until ful repair cared out.

Container

dropped in

water

> Poor handing of 1D Witnoss statement

hheaxy Hit equipment eny

> Faulty heayy Hitt

equipment

> Cargo overwsight

Tint

2 Uneven distabuted

weight inside the

container

agg © Stk condton of consnar frames and comer eatngs ot terminal

PE prior to loaing,

i Check that each container has been essignad a Verified Gross Mass.

a {YGM) in fine with new SOLAS regs which came into force ist July

mE pois.

1 Educate shipprs not ta load containers asymmoticaly or over

5 en concise

> Bad weather SRE 2 Digan passage planing to minimise chancos of vse! grounding!

collapse of stow on I ~ getting caught in bad weather.

reg 7 Bsesie and act on ast weather forecasts to avoid severe weather

boord vessel

> Peer lashing 1 Ty to avoid excessive vossel mations by

ex ions by Umely alteration of course

‘collapse of stow on | orspeed orbeih

board wes

_ 1 EXD a Fetow Coreg oaininise chances of ealision.

> Collis

i” 'G Check tat each contsinar has been assigned a Vie Gross Mass

> Grounding ME RE 6H intine wth ness SOLAS regs which came into force Tet I 2018.

Sinking G Check slack and lashing forces using class approved lashing program,

12RY_T Check that tashings have tren applied co:recly by stevadares,

SY” Crow should rut check and tighten lashings a8 eequied,

FQJ_ 7 Condition of ashing equipment should bo monitored and eny damaged

NB or worn gear should be replaced.

5 Check condtion of container frames end comer castings at terminal

prior 0 Foading.

{Educate shippers not to loed containers asymmeticaly or over

2 Educate shippers how to correctly stow cargo in a container. Reference

Ciro,

~ i

a oda} and MSC.1/Gixe_ 1498.

nfunatvo Mistral lated to he MON OLUNEGE Cats ot econ

@q t ww Packi , vts (CF l.

> Bad weathor 5 Survejr’ atlonarc in oer a ellis eer and location of

an 8G arsge poston of ho continer and sully of tc, Hoek

rons to food ‘egarded a otal fas scent, low up suney ence Salanor

emer Aatveredoenewerecenersnidgaton

DD ttreguar occurenes ton sito, surveyors attendance ta establish

stan condone

~> Bed weather SST Inspect batch cover seals ora reguer basis and repair as necessary.

> Fauly hatch cover £409 speci and maintain coals on alent poite to the vessels ald.

seals TAN’ G Check and clean hold blges on a requir basis.

Hg © Check bilge alarms are functioning correctly and investigate ony alarms.

SN © Acid shipping water on dacishatches as much as possible by prudent

ship handling and cotvect weather routing,

i Surveyors’ attendance in order to establish extent and location of

terminal . damage, positon of the container and suitabitiy of facility. Follow up

‘survay, once container delivered, to eneure receivers mitigation.

SME or cegar occurence st one tein, surveyors aendancet establch

leuinal condions,

er

bm i Container holes are not usually noticed at first, and could allow rain

Wateringress > Theholss erenot Pre loading inspection

through hole usualy noticed on report water o ingress,

Ineontainer top ofthe contsnar SIN casing ptes up coud have stopped watering.

> Hobody reports the 1 Pre tans inspection of container internally and externally at source

mage RIE @ocuments obtained fom source (rental companyleonteiner yard)

> The hota et Confirming that conteners are visi undamaged prior to release

to alow waterto to shippers.

ina 2 , i

inaoss 3 5 consi rred tom onic un ul eps cain oat

Voter "> Balastwatertank Bayan pasion SUD tospct atch cover ces on a vega basi and vpar o acessary.

Gamage fal {inspect and maintsn seals on all etry point to the vessels hot

Sy foeded > Bigs tank ul .

sip hold RIB 5 k00p a watch onal of baat irks when ballatng and sto batast

> Hatch covers with Pumps when fu, Do nol continue to pump ballast int tanks onco the

wom seals tanks overfowing through ac vents.

:

> Access covers with a 1 Fellow comect ballasting procedures. Check valve, positions before

omeods Commencing betas ace

2 Burren pipes SIh heck and eon ht tiges ona regular basis

> Broken non return D Check bilge alarms are functioning correctly and investigate any

valves alarms,

> Broken souncing © Ensure ballast eystoms are well maintained (values and pipas). Follow

Dlnned maintenance stems

FB ose sooning syns ave vol mains Fotow planed

maintenance systems.

2B 6 Avis stoping ator on decidhatches as much as possible by prudent

ship handing

Pipe

Cargo cannot

bbe dolivered

due to cold

treatment

fallure

> Use of containars,

vor five years old

that can only spot

ead

> Container defiosting

> Change of

equipment vehicle

caniago

> Incorrect probe

locations

> Incoreect settings

‘made on reefer

‘container by

Merchant

> Incorrect settings

‘made on reefer

‘containor by eub-

contractor

> No electricity supply

to reefer container

> Reefer cantainer unit

‘malfunction

~ Cargo warm loaded

> Late harvest

Bit ot arg

Nvoce it

applicable

Bi of aging

CContainertack

TDotaLooger ET

downto tet flo

QERGsteinatorgin Bee

TIEIR Gate ovtat

discharge :

tee

condemnation of

cargo &

D Letter placing

Merchtson sce

Letter placing sub- ‘

contactor on tice

Mandatory ctsim — ME!

docunenis (see

shave) E

1 Photographs .

Ci PTI (Container's \

pretip inspection) ME!

1 Relevant

cartespondence

with the chippor

Relevant 7

cerrespondence AE:

ath the

contractor

1 Sahage invoices

1 Scking poston re

container stackedin ME.

Por trina

Ti Stacking positon for fi:

Ny i 0 OM container used: Ensure that booking and allocation of containers

~ hava procedures In place to ensure that only newer containers are

used, and that bookings are not accepted if the correct equipinent

SH Broteraiatie,

1 Detrosting: It fore is due to USDA probe temporature deviations

Incorrect furigation

typo.

> Insutficiant

fumigation

> No fumigation

certificate issued

eH oftading

Nvocc if

applicable

D Bi oftading

Contsinr tack

© Data Logger

Sovnicad tot fe

1 Fumigation

eetifcate

Health authorities

condemnation of

‘argo

Letter placing

shipper on notice

Lotter placing sub.

‘contractor en natica

Mandatory claim

documents (28

above)

a

‘When tho cargo in potetialy damaged,

should be considered, unless

‘small amount ofthe eargo is be

the cargo is of fow value or

cing claimed as damaged.

appointing a surveyor

only a

inor'a

pre-tip inspection)

1 Relevant

‘correspondance

‘with Health

authorities

5 Relevant

correspondence:

withthe shipper

Relevant

correspondence

with the

sub-contractor

1 Sahage invoices

Sub-contractor’s

© Sub-contractor’s

contract with,

Member

1D Sub-contractor's

damage/loss report

1G Witness statement

itany

am w

a

RRR ERR

q

Incorrect satings

made on reofor

container

“Y No electricity supply

‘0 reefer container

> Reeler container unit

‘malfunction

Incorrect settings

‘mads on reefer

container

> No electricity supply

toreefer container

> Reefer containor uit

malfunction

> Cargo warm toaded

Minture of new and

‘ld cargo

> Old cargo.

> Inbevent vice of the

cargo

Late harvest

PTI (Container's

GPT (Containers i

Pre-Lip inspection) ties

0 Data Logger

dounoat ie

21 Gatoin EIR ot origin

Dereon ME

discharge

Ship's bay plans iar

{2 Sub contractor's

Semageos pot

DSibcontacio’s |

contract with Member

Ccontinsr tock — OE

1 Copy of il oflasing

Avan amement {I

itary

rest inspection) =

;a

13 Data Logger |

download

Daten Rat vin an

Gato out Ei at

discharge '

stip aye HE) SM

0 Subcontractors

demagehoss report [E'S

Subcontractors

contact wth Member [es 35g

Container track

Copy obi of ang FRE

Witness statement

ifany

NHB 5 tocorrct sotngs: investigate where the wong setting occurred,

Yihet was the root cause, and could it have been caught by monitoring

before damage ensued. Based on result, review proceduces and

ensure involved partes are following them.

‘D No electricity: Investigate root cause and consider appropriate

‘corrective action,

{G Malfunction: Investigate whether it could have boon avoided, where i

jgeourred and if more could have bean done to repair before damage

‘ensued. Inform involvediresponsible partis,

Potentially damagad, appointing a surveyor should

988 the cargo is of low value or only a small amount

of the cargo is being claimed as damaged,

"ncorrect satings: Investigate whore the wrong setting occured,

{bits the root causo, andl could it have been caught by monitoring

before damage ensued, Based on resu,reviow procedures and

ensue involved partes are following thai,

'G No electricity: Investigate root cause and consider appropri

‘couectiva action,

'D Malfunction: Investigate whether it could havo been avoided, wher it

Secured and if more cauld have been done to repair bofore damage

ensued, Inform involediresponsible

‘1 L816 points aro related tothe product itself and its proparation for

anspor. Losses caused by these factors should be discussed sith

Shippers for lee corrective action. Where a given problom persisis,

‘cceptance of such shipmenis chould be to-considered,

5 ten the cago is potently damaged, appcnting a surveyor should

be considered, unless the cargo is of low valuo or only a sina smerot

‘ofthe cargo is being claimed as domaged,

Chilled cargo.

frozen

> Incorrect settings

made on reefer

ccontainar

> Poor stowage by

shipper causing a

blocked airflow

> Poor packaging

> Cold treatment

failure

PTI (Container’s

pre-tip inspection)

1 Data Logger

dowmload

1D Gate in EIR ot origin

Gate ot ERat

discharge

1 Ship's bay planls

1 Sub-contractor’s

damagofloss report

1D Subcontractors

‘contract with Member

2 Container tack

Copy of bit of fading

O Witness statement

any

aye

¥

e

|

© tacoxect satings vestigate where the vrong setting occurred,

AO Opes tonne cnt ie ee aig

mq _bolove damage ensued. Based on resul, review procedures and

RM chsurenvted prs ar olowngtar

1 Stowage and packaging: Losses caused by these factors should

Abe Secusoed wih sppere for ther comestie econ, Wher @

4 ‘ven problem persists, acceptance of such shipments should be

reconsidered.

[MEF When the cargo is potentially damaged, appointing a surveyor should

° bo considered, unless the cago is of low value or oly a small amount

ity wear ained a dae

Vous aimerez peut-être aussi

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceD'EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceÉvaluation : 4 sur 5 étoiles4/5 (895)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeD'EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeÉvaluation : 4 sur 5 étoiles4/5 (5794)

- RLMnewDocument8 pagesRLMnewJackPas encore d'évaluation

- Lashcon Gripper WLL 1000 On Deck Only ChainsDocument1 pageLashcon Gripper WLL 1000 On Deck Only ChainsJackPas encore d'évaluation

- Lashcon Gripper WLL 1000 Only Chains On Antonia B Lower HoldDocument1 pageLashcon Gripper WLL 1000 Only Chains On Antonia B Lower HoldJackPas encore d'évaluation

- 2.1 Lashing Calculation DW Mid Section (Deck)Document1 page2.1 Lashing Calculation DW Mid Section (Deck)JackPas encore d'évaluation

- 2.1 Lashing Calculation DW Mid Section (Deck)Document1 page2.1 Lashing Calculation DW Mid Section (Deck)JackPas encore d'évaluation

- Cargo Stoppers - Why They Are Critical and How To Design Them - TheNavalArchDocument5 pagesCargo Stoppers - Why They Are Critical and How To Design Them - TheNavalArchJackPas encore d'évaluation

- Securing of Coils On Ocean-Going Ships - Transport Informations ServiceDocument1 pageSecuring of Coils On Ocean-Going Ships - Transport Informations ServiceJackPas encore d'évaluation

- Principles of Processing & PreservationDocument61 pagesPrinciples of Processing & PreservationJackPas encore d'évaluation

- We Refer To Your Request, Please Be Advised That The LR/IMO No For The Vessel Is:-Remontowa Shipbuilding SA (B615/4)Document1 pageWe Refer To Your Request, Please Be Advised That The LR/IMO No For The Vessel Is:-Remontowa Shipbuilding SA (B615/4)JackPas encore d'évaluation

- Sertica Webinar - Dry Dock - Dec. 2021Document23 pagesSertica Webinar - Dry Dock - Dec. 2021JackPas encore d'évaluation

- United States Standards For Grades of Frozen Fish Fillet Blocks Scope and Product DescriptionDocument8 pagesUnited States Standards For Grades of Frozen Fish Fillet Blocks Scope and Product DescriptionJackPas encore d'évaluation

- Calculating Glaze On Frozen FishDocument8 pagesCalculating Glaze On Frozen FishJackPas encore d'évaluation

- Securing of Coils On Ocean-Going Ships - Transport Informations ServiceDocument1 pageSecuring of Coils On Ocean-Going Ships - Transport Informations ServiceJackPas encore d'évaluation

- Baltic Exchange Presentation 09-13-2021Document26 pagesBaltic Exchange Presentation 09-13-2021JackPas encore d'évaluation

- Baltic Exchange Presentation 09-13-2021Document26 pagesBaltic Exchange Presentation 09-13-2021JackPas encore d'évaluation

- MV Kethi Steel Sheets BLDocument7 pagesMV Kethi Steel Sheets BLJackPas encore d'évaluation

- Bookstore - UC Postharvest Technology CenterDocument1 pageBookstore - UC Postharvest Technology CenterJackPas encore d'évaluation

- Certificate of Classification: Ijborg 16841HDocument2 pagesCertificate of Classification: Ijborg 16841HJackPas encore d'évaluation

- Stability Book North Carrier 2020-06-23-2Document1 pageStability Book North Carrier 2020-06-23-2JackPas encore d'évaluation

- Equasis Data: Ship Name: IjborgDocument1 pageEquasis Data: Ship Name: IjborgJackPas encore d'évaluation

- Cargo Ship Safety Certificate: IjborgDocument12 pagesCargo Ship Safety Certificate: IjborgJackPas encore d'évaluation

- SEASPAN - Survey Guidance For Surveyors v2020.2Document31 pagesSEASPAN - Survey Guidance For Surveyors v2020.2JackPas encore d'évaluation

- Senior Officers Handbook Jan 20141Document30 pagesSenior Officers Handbook Jan 20141mohammad shrekyPas encore d'évaluation

- 0004Document1 page0004JackPas encore d'évaluation

- 0001Document1 page0001JackPas encore d'évaluation

- AnchorDocument1 pageAnchorJackPas encore d'évaluation

- FO-I-04 Report of Safety Inspection Revision 17Document8 pagesFO-I-04 Report of Safety Inspection Revision 17Jack100% (1)

- List of Publications Vers. 43 08.2020Document1 pageList of Publications Vers. 43 08.2020JackPas encore d'évaluation

- FO-I-11 AB Instructions For Flag State Inspectors Rev 17Document24 pagesFO-I-11 AB Instructions For Flag State Inspectors Rev 17JackPas encore d'évaluation

- MSC Reklamuje Sie Ad. Project CargoDocument8 pagesMSC Reklamuje Sie Ad. Project CargoJackPas encore d'évaluation

- The Yellow House: A Memoir (2019 National Book Award Winner)D'EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Évaluation : 4 sur 5 étoiles4/5 (98)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureD'EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureÉvaluation : 4.5 sur 5 étoiles4.5/5 (474)

- Shoe Dog: A Memoir by the Creator of NikeD'EverandShoe Dog: A Memoir by the Creator of NikeÉvaluation : 4.5 sur 5 étoiles4.5/5 (537)

- The Little Book of Hygge: Danish Secrets to Happy LivingD'EverandThe Little Book of Hygge: Danish Secrets to Happy LivingÉvaluation : 3.5 sur 5 étoiles3.5/5 (399)

- On Fire: The (Burning) Case for a Green New DealD'EverandOn Fire: The (Burning) Case for a Green New DealÉvaluation : 4 sur 5 étoiles4/5 (73)

- Never Split the Difference: Negotiating As If Your Life Depended On ItD'EverandNever Split the Difference: Negotiating As If Your Life Depended On ItÉvaluation : 4.5 sur 5 étoiles4.5/5 (838)

- Grit: The Power of Passion and PerseveranceD'EverandGrit: The Power of Passion and PerseveranceÉvaluation : 4 sur 5 étoiles4/5 (588)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryD'EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryÉvaluation : 3.5 sur 5 étoiles3.5/5 (231)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaD'EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaÉvaluation : 4.5 sur 5 étoiles4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersD'EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersÉvaluation : 4.5 sur 5 étoiles4.5/5 (344)

- The Emperor of All Maladies: A Biography of CancerD'EverandThe Emperor of All Maladies: A Biography of CancerÉvaluation : 4.5 sur 5 étoiles4.5/5 (271)

- Team of Rivals: The Political Genius of Abraham LincolnD'EverandTeam of Rivals: The Political Genius of Abraham LincolnÉvaluation : 4.5 sur 5 étoiles4.5/5 (234)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreD'EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreÉvaluation : 4 sur 5 étoiles4/5 (1090)

- The Unwinding: An Inner History of the New AmericaD'EverandThe Unwinding: An Inner History of the New AmericaÉvaluation : 4 sur 5 étoiles4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyD'EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyÉvaluation : 3.5 sur 5 étoiles3.5/5 (2259)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)D'EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Évaluation : 4.5 sur 5 étoiles4.5/5 (120)

- Her Body and Other Parties: StoriesD'EverandHer Body and Other Parties: StoriesÉvaluation : 4 sur 5 étoiles4/5 (821)