Académique Documents

Professionnel Documents

Culture Documents

Design and Construction of A Vegetable Drier: Aminusaleh Mohammed

Transféré par

viktorija bezhovskaTitre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Design and Construction of A Vegetable Drier: Aminusaleh Mohammed

Transféré par

viktorija bezhovskaDroits d'auteur :

Formats disponibles

The International Journal Of Engineering And Science (IJES)

||Volume||2 ||Issue|| 9||Pages|| 88-94||2013||

ISSN(e): 2319 – 1813 ISSN(p): 2319 – 1805

Design and construction of a Vegetable Drier

AminuSaleh Mohammed

Hydraulic Equipment Development Institute, Kumbotso Kano

--------------------------------------------------------------ABSTRACT-------------------------------------------------------

With the subsequent increase of food growing especiallyin rural areas, there is an accompanying need for

preservation method. This has led to a substantial increase in the number of driers, yet expensive for local farmers

to acquire.This paper condensed and comprehensive work done with the aim of reducing the cost of drying and

also for practical demonstration of some of the theoretical knowledge acquired. It was discovered that the drier is

efficient since the heat leakage was found to be very low.

KEYWORDS: Drier efficiency, microbiological growth, heat leakage, coefficient of thermal conductivity and

convection heat transfer

----------------------------------------------------------------------------------------------------------------------------------------

Date of Submission: 28, August, 2013 Date of Acceptance: 30, September 2013

---------------------------------------------------------------------------------------------------------------------------------------

I. INTRODUCTION

The preservation of vegetable by drying is (1) believed to be one of the best post harvest operation thathas

been practiced for a long time in Nigeria. This gives room for storage and future consumption or use.The success

of any drying operation depends on removing enough moisture from food (vegetable) to achieve a water activity

too low not to allow microbiological growth to take place. This in turn means that there must be sufficient transfer

of heat to provide the latent of vaporizationneeded.Most people particularly farmers expose their crops to the sun

by spreading them widely to dry before storage- Example of some of the vegetable are: Okro, tomatoes, pepper,

carrot and spinach. Sun drying still remains the most widespread method of food preservation due to its simplicity

and low cost. This is conveniently done in dry season because rainy season makes it difficult and domestic animals

disturb the spreaded product hence making drying a difficult task especially in the rural area:

The method used for drying may be conviently classified as follows:

(i) Drying by healed air, the food (vegetable are placed in contact with a moving streamheated air. Heat is

supplied to the product mainly by convection.

(ii) Drying by the application of energy from a radiating microwave or dielectric source.

(iii) Drying by direct contact with a heated surface heat is supplied to the product mainly by conduction

(iv) Freeze - drying; the moisture in fee food is froze and then sublimed to vapour,usually, by the application

of heat under very low pressure conditions.

There are modem dryers that uses convectional fuel which are expensive for local farmers to acquire,

operate and maintain, then, therefore a simple and mobile small scale drier which uses fuel available in the rural

area will be of great help to our local farmer-

This project "Design and construction of a prototype vegetable drier" would use kerosine as fuel for the heat

generation which can be obtained even in rural areas.

1.2 Literature Review

One of the longest established methods of food preservation is drying. It combines the benefits of

micro-biological and physio-chemical stability with reduction in weight and transport costs and has other

advantages in handling and storage. It is of wide application, covering fish and meats, fruit and vegetables and

many part or wholly prepared food products. Example of preserved food included tea, coffee, granulated sugar,

soft fruits, vine fruits, legumes, root vegetable, ready - meals, and herbs and spices.The success of any drying

depends on removing enough moisture from the food to achieve a water activity too low to allow microbiological

growth to take place. In order to achieve successful drying there must be sufficient input and transfer of heat to

provide the latent heat of vaporization needed,As all moisture must be lost from exposed surfaces, normally to the

air, it follows that the relative humidity of the air used for drying are critical factors, as will be the manner in which

the food is supported during the drying operation, that is, the extent to which potential exposed surface are covered

by contact with other food particles, trays or conveyors,

www.theijes.com The IJES Page 88

Design and construction of a Vegetable Drier…

1.2.1 Drying Temperature

Most of the countries which dry fruits commercially have sunny climate that favours sun dry methods.

Sun drying of fruit gives the required range of drying temperature and therefore it is still the method of drying

fruits. The suitable drying temperature for fruit is 60°C - 80° C. Example Banana dries at (60°C - 7^C) until it is

hard brittle. Avoid over heating to prevent darkening, vegetable are dried at (55°C - 60°C) until the legumes are

brittle and crisp onion dries at (5f C ' 70°C) until crisp.

1.2.2 Method Used for the Drying of Foodstuff

This may be conviently classified as follows:

(i) Drying by direct contact with a heated surface. Heat is supplied to the product mainly by conduction.

(ii) Freeze dry: the moisture in the food is frozen and then sublimed to vapour usually by the application of heat

under very low - pressure condition.

(iii) Drying by heated air: The product is placed in contact with the heated air. Heat is supplied to the product

mainly by convection.

(iv) Drying by application of energy a radiating microwave or electric source.

1.2.3 Types of Driers

There are various kind of dryer designed for drying grains grass, fruits and vegetables, Different types of

dryers are constructed with fan to remove the moisture in vegetable for better storage.

Some of the drying operations and types of dryers are listed below:

1.2.4 Field Drying and Sun Drying

This is the system of drying where the combined effects of sun and wind provide the motive forces for

effective evaporation. Effective successful 'field drying depends on local climate condition at point of harvest and

therefore, is restricted to warm/hot parts of the world where wind and air humidity are satisfactory. Sun drying of

harvest material is variable and only possible where the climate is suitable. Fruit and seeds are more frequently

dried than vegetable, but some fruits regarded as vegetables are dried successfully in this way. For example

peppers and the Sudanese slice tomato,

1.2.5 Air Drying

This may be batch wise or continuous and equipment include tunnels, trays or oven dryers, drum or roller

dryers, pneumatic, trough rotary, cascade, tower, spiral, fluidized bed bin and but aband dryers, spray dryers,

vacuum dryer etc, in most drying situations mechanical assistance isneeded over and above the-forceof nature,

this being the convectional concept of air drying. For effective drying the partial pressure of water vapour is the air

surrounding the material to be dried must be significantly lower than its saturated pressure at the operating

temperature. This can be expressed as a relative humidity ratio and the lower the ratio the more effective the

drying. As the ratio rises so fresh lower humidity air must be introduce into the system or the water vapour

removed from it by some means. In generate hot air dryer are designed to allow a high airflow in the early stage

but not so much as to move the material being dried, except where this is a requisite feature as for fluridised bed

dryer. Typically an airflow rate of 180-300mm/min is used for vegetable piece, with dry' bulb air temperature

of90°C to 100°C and wet bulb temperature 50°C.As moisture contents fall the airflow rate is reduced and drying

temperature is decreased to 55°C or less until the moisture content is below 6,0%, Separate driers may be used to

complete the final stage of drying,In fluoridised bed and air light or pneumatic driers, the airflow must be of

sufficient velocity to lift the particles to be dries from a porous plate bed and cause them to behave as a liquid. This

allows them to flow over a weir to exit the drier. Movement within the airstream provided excellentmixing and

even drying. This can be used for powders; dried vegetables and for small whole vegetable such as peas. Again the

moisture content and temperature of the air can be varied as can the airflow to suit the material being dried.

1.2.6 Vacuum Drying

These driers may be cabinet batch driers or continuous band driers with vacuum locks at infeed and outlet in either

case heat transfer is by radiation and conduction. The advantage of vacuumdrying is that evaporation of water

takes place more readily at low pressures.

1.2.7 Spray Drying

In spray drying system a spray of the material to be dried, which might for example be a pored vegetable suitable

diluted and stabilized, is dispersed, as atomized spray into a counter current of hot dry air.The droplets dry in the

airstream, falling to the bottom of unit as they do so, key elements are sufficient fan power and heating to achieve

the required velocity and temperature, the atomizer, the drying chamber and the means of removing the dried

product. The atomizer, the drying chamber may be one of the three basic types.

www.theijes.com The IJES Page 89

Design and construction of a Vegetable Drier…

1.2.8 Freeze Drying

The sublimation of frozen moisture was originally a laboratory techniques for preserving highly sensitive

products in micro-biological and mechanical works. As long as melting can be avoided, the moisture can be driven

off without damaging the structure of solid material. Freeze drying methods are used for dehydrating food

otherwise difficult of dry such as onion, coffee and certain sea foods.

The operation is carried out at the pressure below the triples point value usually about 50N/m2 and heat is

produced either by radiation or conduction from hot platens which inter-leave the trays loaded with the product.

The sublimed moisture condense on a fridge coil located at the fan end of the drying chamber.

1.2.9 Tray, Tunnel and Belt Driers

These drivers are similar in that they all use hot circulating air stream to provide the energy needed for

drying and the product being dried moves at a high velocity compared to the circulating air velocity,

The figure shown below illustrates a tray drier. In the tray drier, the product to be dried is placed on the trays in the

drying compartment. Air is heated by direct combustion with fuels or by steam or electric coils. Dampers are

installed and regulated to control the amount of air entering and leaving the drier thereby controlling the humidity

within the drier.

In tunnel driers, trays are loaded on to carts and the cart can be loaded into the drier tunnelon a

quasicontinuous basic as shown below. The air stream in a tunnel drier could be arranged to flow in the same

direction (parallel flow), opposite direction (counter flow) or at right angles (cross flow) with respect to the

direction in which the carts move through the tunnel.

1.3 Drying Rates

The drying rates of a foodstuff alter during the drying cycle reflecting the changes which are occurring in

the composition of the food " This is to be expected when one consider the complex, nature of foods. Water is an

integral component of all organic materials. It is chemically and biochemically associated with the other foodstuff

component. Moisture removal will also modify the cell structure thereby affecting the residual moisture content.

In the initial stage of drying of food, the rate of moisture migration from the interior of the particle to the surface is

sufficiently high to cover the surface in moisture. This period of drying is known as the constant rate period. A

critical moisture content will be reached when the moisture can no longer be drawn to the surface fast enough to

maintain a completely wet surface. This can be attributed to physical and chemical changes occurring within the

food. Once this critical moisture content has been reached, the rated of drying decreases. This second phase of the

drying cycle is termed the falling rate period. Eventually the moisture content of the food will drop to a level

where there is no driving force between the air and the surface, and drying will cease. The food is said to have

reached its equilibrium moisture content.

In practical; terms, two important points should be made which benefit any drying extension work. The

points are:-

i. For the initial drying of a commodity, the combination of high air velocity and moderatetemperature will

optimize the use of energy for drying.

ii. In the latter stages of drying, low air flow combined with high air temperature will providemore rapid drying

thana high air flow with a low temperature,

1.4 Drying Parameters

(i) The temperature of ambient air

(ii) The machine humidity of ambient air

(iii) The wind or air velocity

(iv) The initial moisture content of the product to be dried.

(v) The quantity of the product and depth of material to be dried,

1.5 Determination of Moisture Content

his may be made directly by drying the sample in an oven for a prescribed time and assuming that the

resultant loss in weight is due to moisture

1.5.1 Equilibrium Moisture Content

This is the moisture content reached by a hygroscopic product after it'svapour pressure has come to

equilibrium with that of the surrounding air.But during constant - rate drying period moisture is always present on

the surface of the vegetable being dried. The water within this vegetable is able to diffuse to the surface at a rate

faster than the rate at which it leaves the surface. This can be determined by heat transfer rate to material

www.theijes.com The IJES Page 90

Design and construction of a Vegetable Drier…

(vegetable)

Mathematically, it is expressed as:

Where;

M = drying rate, kg/s

h = convection heat transfer coefficient, kw/m2, °C

= Air stream temperature, °C

= Surface temperature

= Latent heat of vaporization evaluated at Ts, in KJ/kg

Specifically, the moisture content of vegetable determines its storability and can be expressed by a

percentage by weight on a net basic grains of the moisture per l00g sample.

where,

M = m,c net basis (%)

Wm = weight of moisture

=

Wd weight of dried material

To convert from dry to wet basis

Mn = l00md

100 + wd

1.6 Material Selection

When constructing any machine in the engineering workshop such as the vegetable drier, it is very

important to put into consideration the following factors when selecting the material. The factors are:-

i. The method by which it will be shaped,

ii. The durability of the material,

iii. The overall cost of both material and process

iv. The ability of the materials to withstand service condition.

v. The convenience of production when using the material

vi. The availability of the material

vii. Heat leakage and thermal conductivity of the material.

In construction of this drier all the above factors were considered, though may be difficult to have a

material that posses al! the properties, but yet the wood was considered most suitable since the driers and the

material combined the advantage of simplicity, portability, reduced cost, availability of material, low rate of heat

leakage and low thermal conductivity over others in existence today,

Material W/mk Cal/S cm0C Kcal/in°ks

Aluminum 209 0.499 0.0499

Copper 385 0.921 0.0921

Iron 46 0.110 0.0110

Silver 414 0.99 0.099

Brick 0.65 1.55 xl0-3 1.55 xl0-2

Concrete 1.08 2.59xl0-3 2.59xl0-2

Cardboard 0.043 1.03x10-4 1.03 xl0-5

Glass 1.00 2.4 x 10-3 2.4 x 10-2

Pine wood 0.113 2.69 xl0-4 2.69 x 10-5

5

Air 0.025 6.0 x 10- 6.0 x 10-6

Water 0.599 1.43 xl0-1 1.43 x 10-6

www.theijes.com The IJES Page 91

Design and construction of a Vegetable Drier…

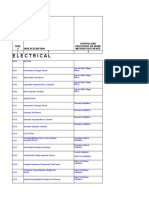

1.7 List of the Components Needed for the Construction

The table given below shows the various component and items used for the construction ofeach part.

Priority was attached to the availability of the needed materials and the cost was also put into consideration with

other factors:-

S/NO Parts Quantity Material used

1. Drier wall 3 ply wood

2. Baffles 3 aluminimum sheet

3. Door 1 plywood

4. Tray holders 4 wood

5, Nails l"&2",l'/2kgeach. standard

6. Screws 10 standard

7. Handle 1 standard

8, Chimney chamber 1 wood

9. Kerosine stove 1 standard

10, Trays 2,35x3cm wire mesh standard

11. Hinges 2 standard

12. Paints 2 tins standard

13. Insulator 4, 65cm & 65cm standard

1.7.1 Construction Processes

S/N Parts Operation Tools Used

1. The wall of the drier. The plywood was measuring planned and cut to planner, ruler, scriber, nail, saw and

size for different sides of the wall and other parts hammer,

of the body that made up the driers. Glue was put

to all the edges before nailing together in order to

form the housing.

2. The Baffles The required dimension was marked out on the Ruler, foldingmachine, scriber and

metal sheet and was cut into the number of the trysquare.

pieces needed. They werefolded to the required

angle

3. Tray holders The wood was marked out to size and after which Saw, scriber and ruler

they were cut to the required length,

4. Trays The wire mesh and the wood were marked out Hammer, scribed, assessor and

and cut to size. The wood was nailed together to saw.

form a squarewhere the wire mesh was also

nailed.

5. Bottom of the driers The Galvanized sheet of metal marked out and Steel rule, try square, cutting machine,

cut to the size before covering the bottom by service and hammer

nailing them together with thenailing them

together with the drier.

6. The door The plywood was measured cut and planned to Ruler, saw, planner and hammer.

size of the required door, Hinges were used to fix

it to"the drier wall.

7. Insulators They were placed between the inners surface ofthe Ruler hammer and saw.

wall and the sheet metal to minimize heat

Leakage.

8. Chimney area A plywood was marked out and cut to the Ruler, saw, trysquare and scriber.

dimension of 40cm x 40cm at the base and 20cm x

20cm at the top. Two of the sides were raised to

60m and cover with aplywood of 30cm x 30cm to

allow the free escape of the warm air.

9. Stand Plywood was marked out and cut into 4 pieces two Tape rule, saw, planner, hammer and

of each were equal for the production of the drilling machine.

rectangular box. Two sides were drilled to allow Tape rule, saw, planner, hammer and

the entering of air. drilling machine.

www.theijes.com The IJES Page 92

Design and construction of a Vegetable Drier…

1.7.3 Assembly of the Drier

The entire parts of the drier were assembled manually. Either through nails or screws as the case might

be. The drier is made up of a heating chamber and drying chamber with the measurement of 75cm & 70cm in

length and width respectively for proper house forming. The material used for the construction is plywood which

is internally insulated for maximum efficiency and to prevent heat lost. The openings at the top forming the

chimney allow the free escape of the warm air an was by the side of the drier or safety purpose. At the bottom by

the side of the door, drier is provided with 5cm opening to allow intake of air to move up the heat from the bottom

to the top of the drier.

II. CALCULATIONS

Calculating the rate of heart transfer per unit area of the drier.

Using the formular

Where:

Q = Rate of heat transfer

A = Area in m2

t = Temperature (0C)

K = Coefficient of thermal conductivity

l = Length (thickness) of the material

Let = Rate of heat transfer per unit area.

For 15 minutes heating (testing)

Data

Internal temperature of the drier ( ) = 590C.

Outside surface temperature of the drier wall = 280C

Data

= 590C Q = ?

= 280C A = Unit area

= 1 x 10-3

= 12 x 10-3m

= 11 x 10-3m

= 209w/mk

= 0.043w/mk

= 0.113w/mk

www.theijes.com The IJES Page 93

Design and construction of a Vegetable Drier…

Computing (Solution)

To calculate the interfaces temperature we apply fourier’s equation

i.

ii.

From the above calculation it can be seen that the drier is efficient since the heat leakage is very low.

Thus, the materials used for the construction are effective,

III. CONCLUSION

From the result of the calculation made in chapter three, the performance of the drier can be said to be

satisfactory. Instead of drying for 2-4 or weeks traditionally, this drier will be able to dry vegetable for 9-36 hours

without smoke, moisture inside and desirable market quantities. It also has the advantage of maintaining the

original colour of the vegetable, it is hygienic and no dust.However, since this project is a prototype, it could be

developed into bigger efficient vegetable drier. There can be diverse ways in which the project can be improved

upon depending on where and the quantity of the vegetable to be dried.bg

REFERENCES

[1]. D.Arthey& C, Dennis, Vegetable processing (1978)

[2]. J. Clari Batty and Steve L. Folkman, Food engineering fundamentals (1983)

[3]. Internal labourorganisation, solar drying practical methods of food preservation (1986)

[4]. P. L. Sardeson and D. D Deshmuch, Appliedphysis for polytechnic (1990).

www.theijes.com The IJES Page 94

Vous aimerez peut-être aussi

- Blooms in Glass : Unveiling the Secrets of Greenhouse HorticultureD'EverandBlooms in Glass : Unveiling the Secrets of Greenhouse HorticulturePas encore d'évaluation

- Project On Construction of Solar DryerDocument31 pagesProject On Construction of Solar DryerK-Tech SystemsPas encore d'évaluation

- Commercial Grain DryersDocument16 pagesCommercial Grain Dryerscrlion161267% (3)

- ROOT CELLARING FOR PREPPERS: Root Cellaring Techniques for Preserving Harvests and Building Self-RelianceD'EverandROOT CELLARING FOR PREPPERS: Root Cellaring Techniques for Preserving Harvests and Building Self-ReliancePas encore d'évaluation

- Battery Operated Paddy Dryer With Humidity Level SensorsDocument10 pagesBattery Operated Paddy Dryer With Humidity Level SensorsEm MendozaPas encore d'évaluation

- Fot Assin 1Document10 pagesFot Assin 1RishavPas encore d'évaluation

- Bhople Et Al (2019)Document3 pagesBhople Et Al (2019)amelia arum ramadhaniPas encore d'évaluation

- Dryers and Drying ProcessesDocument92 pagesDryers and Drying ProcessesRoem Esmerna100% (3)

- Activity 7 (Drying)Document21 pagesActivity 7 (Drying)Arnel SisonPas encore d'évaluation

- Drying Processes and MethodDocument21 pagesDrying Processes and Methodmirobel455kezaPas encore d'évaluation

- DryingDocument19 pagesDryingEngr Muhammad Asif JavaidPas encore d'évaluation

- Tray Dryer ExperimentDocument13 pagesTray Dryer Experimentgeek311295% (37)

- Fabrication of Solar Food Dryer Using Parabolic ReflectorDocument7 pagesFabrication of Solar Food Dryer Using Parabolic ReflectorannamalaiPas encore d'évaluation

- Review On The Design of A Tray Dryer System For Agricultural ProductsDocument10 pagesReview On The Design of A Tray Dryer System For Agricultural ProductsDwinaRahmayaniPas encore d'évaluation

- JFAV 08-012 - PERASIRIYAN - OPTIMIZATION - DRYER-with-cover-page-v2Document8 pagesJFAV 08-012 - PERASIRIYAN - OPTIMIZATION - DRYER-with-cover-page-v2Super MoelasisPas encore d'évaluation

- KhanDocument4 pagesKhanirfan hilmanPas encore d'évaluation

- SolartrocknungDocument9 pagesSolartrocknungrichard.schumacherPas encore d'évaluation

- Solar DryingDocument9 pagesSolar DryingNkem OkonkwoPas encore d'évaluation

- Units Ops 2 Midterm ProjDocument7 pagesUnits Ops 2 Midterm ProjmarielPas encore d'évaluation

- Units Ops 2 Midterm ProjDocument7 pagesUnits Ops 2 Midterm ProjmarielPas encore d'évaluation

- Hygroscopic and Nonhygroscopic MaterialDocument9 pagesHygroscopic and Nonhygroscopic Materialiresa_nuratPas encore d'évaluation

- Tray SdrywerDocument10 pagesTray SdrywerMarkbenedict AsiPas encore d'évaluation

- Tray DryerDocument22 pagesTray DryerjuaxxoPas encore d'évaluation

- Dieño de Parametros Par Un Secador BatchDocument6 pagesDieño de Parametros Par Un Secador BatchCarlos CabanillasPas encore d'évaluation

- Dryers Used in Food IndustryDocument9 pagesDryers Used in Food Industry9567592146Pas encore d'évaluation

- Solar Assisted Crop Dryers For Paddy, Flowers and Kenaf: Malaysian Agricultural Research & Development Institute (MARDI)Document22 pagesSolar Assisted Crop Dryers For Paddy, Flowers and Kenaf: Malaysian Agricultural Research & Development Institute (MARDI)Omphile MosuwePas encore d'évaluation

- Energy Efficiency in DryingDocument3 pagesEnergy Efficiency in Dryingjohnny brooksPas encore d'évaluation

- Cold Storage ReportDocument10 pagesCold Storage ReportMuneek ShahPas encore d'évaluation

- Ajeassp 2009 217 228Document12 pagesAjeassp 2009 217 228mPas encore d'évaluation

- Drum Dryer DesignDocument4 pagesDrum Dryer DesignNeuro Toxin0% (1)

- Design and Fabrication of Solar DryerDocument10 pagesDesign and Fabrication of Solar DryerAdeela Umar100% (1)

- Types of Industrial Dryers and Their Selection PDF (1) (1)Document20 pagesTypes of Industrial Dryers and Their Selection PDF (1) (1)Hari KishorePas encore d'évaluation

- Air Conditioned Palay DryerDocument6 pagesAir Conditioned Palay DryerBenien John AngelPas encore d'évaluation

- Rice Dryer ThesisDocument6 pagesRice Dryer Thesismaureennonweilertulsa100% (2)

- Chap 08 Innovative Vol 2 (2) 85-88 PoDocument4 pagesChap 08 Innovative Vol 2 (2) 85-88 Poadhroso125162Pas encore d'évaluation

- Ministry of Micro, Small & Medium Enterprises (M.S.M.E.) : Smart IOT Based Compact Dryer For Agriculture ProductsDocument12 pagesMinistry of Micro, Small & Medium Enterprises (M.S.M.E.) : Smart IOT Based Compact Dryer For Agriculture ProductsShobhit SahuPas encore d'évaluation

- Laboratory Exercise No. 3 Drying of Durable Crops (Corn)Document5 pagesLaboratory Exercise No. 3 Drying of Durable Crops (Corn)JojenPas encore d'évaluation

- Drying of Pepper With The Aid of Solar Energy Dryer: John .U. ManukajiDocument8 pagesDrying of Pepper With The Aid of Solar Energy Dryer: John .U. ManukajiInternational Journal of Engineering Inventions (IJEI)Pas encore d'évaluation

- Unesco - Eolss Sample Chapters: Solar Drying - A Technology For Sustainable Agriculture and Food ProductionDocument9 pagesUnesco - Eolss Sample Chapters: Solar Drying - A Technology For Sustainable Agriculture and Food ProductionKhloud MadihPas encore d'évaluation

- Energy Efficiency in The Food and Beverages IndustryDocument45 pagesEnergy Efficiency in The Food and Beverages Industrychaudhary_waqar8126Pas encore d'évaluation

- Intro Coffee DryingDocument20 pagesIntro Coffee Dryingandi aflahPas encore d'évaluation

- 608 208 PDFDocument10 pages608 208 PDF11751175Pas encore d'évaluation

- BASIC PRINCIPLES AND SYSTEMS OF GRAIN DRYINGDocument13 pagesBASIC PRINCIPLES AND SYSTEMS OF GRAIN DRYINGMary - Ann AndalPas encore d'évaluation

- Fundamentals of DryingDocument14 pagesFundamentals of DryingAlisha AnchearyPas encore d'évaluation

- Exp 2 PHTDocument12 pagesExp 2 PHTpradeep kumarPas encore d'évaluation

- Handling, Moisture Management, and Storage of Biological ProductsDocument20 pagesHandling, Moisture Management, and Storage of Biological ProductsWan RadhiahPas encore d'évaluation

- Fabrication_and_Performance_Evaluation_of_Solar_TuDocument13 pagesFabrication_and_Performance_Evaluation_of_Solar_Tuمصطفى الذاريPas encore d'évaluation

- Grain StorageDocument26 pagesGrain StorageTarsem Mittal100% (1)

- Experimental Performance Analysis of A Pilot-ScaleDocument15 pagesExperimental Performance Analysis of A Pilot-ScaleWahyudi PanggabeanPas encore d'évaluation

- A Review Drying Technology Trends and Applications in Postharvest ProcessingDocument10 pagesA Review Drying Technology Trends and Applications in Postharvest ProcessingFadli Ryan ArikundoPas encore d'évaluation

- Solar DrayerDocument12 pagesSolar Drayerfiras aliPas encore d'évaluation

- Determination of Drying Rate of Agricultural Products in A Green HouseDocument12 pagesDetermination of Drying Rate of Agricultural Products in A Green HouseAbhijeet SarathePas encore d'évaluation

- GEENA 1-5.editedDocument61 pagesGEENA 1-5.editedChineduPas encore d'évaluation

- Dryer DesignDocument39 pagesDryer DesignPrashanth Chidambaram75% (4)

- 3854 14984 1 PBDocument9 pages3854 14984 1 PBVeekhThorPas encore d'évaluation

- Solar DryingDocument15 pagesSolar Dryingasprilla100% (1)

- STORAGE: Aerating Stored GrainDocument4 pagesSTORAGE: Aerating Stored GrainMilling and Grain magazinePas encore d'évaluation

- Automated Electronic Evaporative Cooling and Fogging System For MushroomDocument14 pagesAutomated Electronic Evaporative Cooling and Fogging System For MushroomElijahx San JosePas encore d'évaluation

- Diseño de SecadoresDocument39 pagesDiseño de SecadoresJosé Helí Vallejos CoronadoPas encore d'évaluation

- Walakira Paul PDFDocument68 pagesWalakira Paul PDFviktorija bezhovskaPas encore d'évaluation

- 2015 Plastics To Fuel Developers GuideDocument74 pages2015 Plastics To Fuel Developers Guidesergioodin4851Pas encore d'évaluation

- 166-Gregor KravanjaDocument1 page166-Gregor Kravanjaviktorija bezhovskaPas encore d'évaluation

- Sustainability 12 01927 v2 PDFDocument33 pagesSustainability 12 01927 v2 PDFfesooPas encore d'évaluation

- Unclanssif"L: Nujla S SDocument314 pagesUnclanssif"L: Nujla S Sviktorija bezhovskaPas encore d'évaluation

- 10 1 1 727 3993 PDFDocument13 pages10 1 1 727 3993 PDFviktorija bezhovskaPas encore d'évaluation

- WCE2010 pp2292-2296 PDFDocument5 pagesWCE2010 pp2292-2296 PDFviktorija bezhovskaPas encore d'évaluation

- Model predicts cement plant performanceDocument17 pagesModel predicts cement plant performanceviktorija bezhovskaPas encore d'évaluation

- Zhang IEEE Transactions Industrial Electronics 2017bDocument9 pagesZhang IEEE Transactions Industrial Electronics 2017bviktorija bezhovskaPas encore d'évaluation

- Emisiones de Las RefineriasDocument21 pagesEmisiones de Las RefineriasMariaAlejandraBagurPas encore d'évaluation

- 07 Chapter2Document41 pages07 Chapter2viktorija bezhovskaPas encore d'évaluation

- Unclanssif"L: Nujla S SDocument314 pagesUnclanssif"L: Nujla S Sviktorija bezhovskaPas encore d'évaluation

- T000365Document100 pagesT000365Aditya SanyalPas encore d'évaluation

- Adsorption of Heavy Metals from Water Using Modified Jordanian ClayDocument10 pagesAdsorption of Heavy Metals from Water Using Modified Jordanian Clayviktorija bezhovskaPas encore d'évaluation

- 10.1007 s11431 016 9028 7Document11 pages10.1007 s11431 016 9028 7viktorija bezhovskaPas encore d'évaluation

- Strategies For Managing Plastic Waste From Construction and Manufacturing ProjectsDocument9 pagesStrategies For Managing Plastic Waste From Construction and Manufacturing Projectsviktorija bezhovskaPas encore d'évaluation

- DissertationDocument105 pagesDissertationviktorija bezhovskaPas encore d'évaluation

- Etd1866 PDFDocument88 pagesEtd1866 PDFviktorija bezhovskaPas encore d'évaluation

- OPerations ManagementDocument25 pagesOPerations ManagementShashank PatelPas encore d'évaluation

- Comm Profile Niobium Tantalum PDFDocument27 pagesComm Profile Niobium Tantalum PDFArmandoSipiua100% (1)

- Tantalum Based Materials For Implants and Prostheses ApplicationsDocument8 pagesTantalum Based Materials For Implants and Prostheses Applicationsviktorija bezhovskaPas encore d'évaluation

- Rotary Kiln Handbook NEW PDFDocument40 pagesRotary Kiln Handbook NEW PDFNuno Monteiro100% (7)

- Synthesis, Pp. 215 218Document3 pagesSynthesis, Pp. 215 218viktorija bezhovskaPas encore d'évaluation

- The Radio Chemistry of Niobium and Tantalum - Us AECDocument63 pagesThe Radio Chemistry of Niobium and Tantalum - Us AECcolordiamondsPas encore d'évaluation

- Thesis 1966 E73sDocument75 pagesThesis 1966 E73sviktorija bezhovskaPas encore d'évaluation

- P020090909608577123244 PDFDocument5 pagesP020090909608577123244 PDFviktorija bezhovskaPas encore d'évaluation

- DissertationDocument105 pagesDissertationviktorija bezhovskaPas encore d'évaluation

- Pages From 9780820603681 - TXTDocument48 pagesPages From 9780820603681 - TXTMohammed AbdoPas encore d'évaluation

- Ubc 2007-0071aDocument153 pagesUbc 2007-0071aviktorija bezhovskaPas encore d'évaluation

- DW95 Series Dishwasher Program and Fault Troubleshooting GuideDocument56 pagesDW95 Series Dishwasher Program and Fault Troubleshooting GuidepksertzenPas encore d'évaluation

- 24 - FormworksDocument2 pages24 - FormworksRafee PiePas encore d'évaluation

- Biogas Calculation From CodDocument41 pagesBiogas Calculation From CodReuben Malambugi100% (1)

- DX100 controller service manual alarm listDocument582 pagesDX100 controller service manual alarm listIsmael50% (2)

- Mack VisionCXN603Document4 pagesMack VisionCXN603Foromaquinas50% (4)

- Two Week Look Ahead ScheduleDocument2 pagesTwo Week Look Ahead Scheduleedla371067% (3)

- Pushover Analysis ExplainedDocument62 pagesPushover Analysis ExplainedRakesh7770100% (2)

- Office of The SecretaryDocument23 pagesOffice of The Secretarykhraieric16Pas encore d'évaluation

- Log Sheet Engineering Gumaya Tower Hotel Semarang Water Storage & Pool Treatment B2 Month Of: 2018Document11 pagesLog Sheet Engineering Gumaya Tower Hotel Semarang Water Storage & Pool Treatment B2 Month Of: 2018faiz budiPas encore d'évaluation

- Thermal Power PlantDocument13 pagesThermal Power PlantSanat KumarPas encore d'évaluation

- Form Visual Inspection Pressure Pipe PDFDocument2 pagesForm Visual Inspection Pressure Pipe PDFMuhammad NawawiPas encore d'évaluation

- Cam and GrooveDocument4 pagesCam and GrooveEmnPas encore d'évaluation

- Electric Machines ManualDocument631 pagesElectric Machines ManualFarazPas encore d'évaluation

- Embedded Systems Online TestingDocument6 pagesEmbedded Systems Online TestingPuspala ManojkumarPas encore d'évaluation

- Drilling Dynamics Sensors Opt BR PDFDocument16 pagesDrilling Dynamics Sensors Opt BR PDFhamed1725Pas encore d'évaluation

- Track TractorsDocument30 pagesTrack Tractorsmdnc1985Pas encore d'évaluation

- Quality Plan For Electrical WorkDocument16 pagesQuality Plan For Electrical WorknercyPas encore d'évaluation

- Putzmeister M36 DataDocument2 pagesPutzmeister M36 DataJayath Bogahawatte67% (3)

- NBC Draft 2017 February15 Final For StaplesDocument449 pagesNBC Draft 2017 February15 Final For StaplesPrasath SivaPas encore d'évaluation

- Sa 31Document4 pagesSa 31Wagner Renato AraújoPas encore d'évaluation

- Under Review - Adani PowerDocument54 pagesUnder Review - Adani Powerkkarthi20Pas encore d'évaluation

- Pinto Pm2 Ch10Document17 pagesPinto Pm2 Ch10Focus ArthamediaPas encore d'évaluation

- Service Manual: Color Television Chassis No. SN-81Document2 pagesService Manual: Color Television Chassis No. SN-81Manuel SierraPas encore d'évaluation

- Preferred Intern Candidates' Field of StudyDocument8 pagesPreferred Intern Candidates' Field of StudyDamien MarleyPas encore d'évaluation

- Resinas Castro CrysticDocument11 pagesResinas Castro Crysticsepe00Pas encore d'évaluation

- Shivaji University, Kolhapur: Course Part Pattern CourseDocument4 pagesShivaji University, Kolhapur: Course Part Pattern CourseDatta PanchalPas encore d'évaluation

- B 67 FceecDocument64 pagesB 67 FceecMubashir SubhaniPas encore d'évaluation

- Minimum Heights and Size Standards For Rooms Ensures That There Is Good VentilationDocument4 pagesMinimum Heights and Size Standards For Rooms Ensures That There Is Good VentilationJaved ZakhilPas encore d'évaluation

- Clay ProductsDocument40 pagesClay ProductsRaghav100% (1)

- Transocean Amirante Rig PDFDocument2 pagesTransocean Amirante Rig PDFro00tPas encore d'évaluation

- Trevor Kletz Compendium: His Process Safety Wisdom Updated for a New GenerationD'EverandTrevor Kletz Compendium: His Process Safety Wisdom Updated for a New GenerationPas encore d'évaluation

- Guidelines for Vapor Cloud Explosion, Pressure Vessel Burst, BLEVE, and Flash Fire HazardsD'EverandGuidelines for Vapor Cloud Explosion, Pressure Vessel Burst, BLEVE, and Flash Fire HazardsPas encore d'évaluation

- Functional Safety from Scratch: A Practical Guide to Process Industry ApplicationsD'EverandFunctional Safety from Scratch: A Practical Guide to Process Industry ApplicationsPas encore d'évaluation

- Perfume Engineering: Design, Performance and ClassificationD'EverandPerfume Engineering: Design, Performance and ClassificationÉvaluation : 4 sur 5 étoiles4/5 (5)

- Produced Water Treatment Field ManualD'EverandProduced Water Treatment Field ManualÉvaluation : 4.5 sur 5 étoiles4.5/5 (5)

- Piping and Pipeline Calculations Manual: Construction, Design Fabrication and ExaminationD'EverandPiping and Pipeline Calculations Manual: Construction, Design Fabrication and ExaminationÉvaluation : 4 sur 5 étoiles4/5 (18)

- Nuclear Energy in the 21st Century: World Nuclear University PressD'EverandNuclear Energy in the 21st Century: World Nuclear University PressÉvaluation : 4.5 sur 5 étoiles4.5/5 (3)

- An Introduction to the Periodic Table of Elements : Chemistry Textbook Grade 8 | Children's Chemistry BooksD'EverandAn Introduction to the Periodic Table of Elements : Chemistry Textbook Grade 8 | Children's Chemistry BooksÉvaluation : 5 sur 5 étoiles5/5 (1)

- Chemical Process Safety: Learning from Case HistoriesD'EverandChemical Process Safety: Learning from Case HistoriesÉvaluation : 4 sur 5 étoiles4/5 (14)

- Process Engineering for a Small Planet: How to Reuse, Re-Purpose, and Retrofit Existing Process EquipmentD'EverandProcess Engineering for a Small Planet: How to Reuse, Re-Purpose, and Retrofit Existing Process EquipmentPas encore d'évaluation

- Guidelines for Siting and Layout of FacilitiesD'EverandGuidelines for Siting and Layout of FacilitiesPas encore d'évaluation

- Robotics: Designing the Mechanisms for Automated MachineryD'EverandRobotics: Designing the Mechanisms for Automated MachineryÉvaluation : 4.5 sur 5 étoiles4.5/5 (8)

- Guidelines for Enabling Conditions and Conditional Modifiers in Layer of Protection AnalysisD'EverandGuidelines for Enabling Conditions and Conditional Modifiers in Layer of Protection AnalysisPas encore d'évaluation

- Well Control for Completions and InterventionsD'EverandWell Control for Completions and InterventionsÉvaluation : 4 sur 5 étoiles4/5 (10)

- Process Plant Equipment: Operation, Control, and ReliabilityD'EverandProcess Plant Equipment: Operation, Control, and ReliabilityÉvaluation : 5 sur 5 étoiles5/5 (1)

- Guidelines for the Management of Change for Process SafetyD'EverandGuidelines for the Management of Change for Process SafetyPas encore d'évaluation

- Guidelines for Developing Quantitative Safety Risk CriteriaD'EverandGuidelines for Developing Quantitative Safety Risk CriteriaPas encore d'évaluation

- Guidelines for Engineering Design for Process SafetyD'EverandGuidelines for Engineering Design for Process SafetyPas encore d'évaluation

- Bow Ties in Risk Management: A Concept Book for Process SafetyD'EverandBow Ties in Risk Management: A Concept Book for Process SafetyPas encore d'évaluation

- The HAZOP Leader's Handbook: How to Plan and Conduct Successful HAZOP StudiesD'EverandThe HAZOP Leader's Handbook: How to Plan and Conduct Successful HAZOP StudiesPas encore d'évaluation