Académique Documents

Professionnel Documents

Culture Documents

The Acid Number and Base Number of In-Service Oils

Transféré par

HARVY19Titre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

The Acid Number and Base Number of In-Service Oils

Transféré par

HARVY19Droits d'auteur :

Formats disponibles

OIL ANALYSIS

A New Approach for

Determining

Base Number of Used Oils

the Acid and

B Y CRAIG WINTERFIELD, FLUID L IFE, FREDERIK VAN DE VOORT, MCGILL UNIVERSITY

The acid number and base number of in-service oils are The acid number and base number are also sometimes reported

considered key indicators of oil quality and are used to using a variety of partial least squares (PLS) direct-read Fourier

monitor the accumulation of acid and the depletion of transform infrared (FTIR) methods, which estimate the acid and

the base additive package. A significant rise in acid number or base number of used oils by directly measuring the spectrum of

decrease in base number may reflect a deterioration in oil quality undiluted oil.

either due to chemical reactions, oxidation, incorrect oils, additive

depletion and contamination. Tables 1 and 2 summarize common Quantitative FTIR Spectroscopy

acid number and base number methods. FTIR spectroscopy has been touted as a potential alternative

ASTM methods, including D664, D974, D2896 and D4739, are means of obtaining quantitative acid number and base number

the current industry standard methods for measuring the acid and data. However, there previously had been no solid evidence that

base number. These titration-based methods are slow and expen- FTIR was viable or reliable in commercial practice. FTIR has

sive to execute, require significant volumes of sample and solvent, predominantly been utilized as an automated fingerprint-based

and are prone to interferences. As a result, these methods have survey technique, as per ASTM D7418-07 or the Joint Oil Analysis

relatively wide repeatability and reproducibility limits, accounting Program, which is typically used for screening and trending changes

for their significant inter-laboratory variability. The high cost and in lubricant parameters such as moisture, glycol, soot, oxidation,

poor accuracy of these methods limit their usefulness and applica- antioxidants and wear additives. As such, FTIR condition moni-

tion to routine oil monitoring. toring analysis provides a rapid, automated means of screening a

ACID NUMBER METHOD TYPE REAGENT CALIBRATION NOTES

Potassium

ASTM D664 Titration Stoichiometric Slow, high uncertainty

hydroxide

Potassium

ASTM D974 Titration Stoichiometric Dark oils interfere with measurement

hydroxide

PLS-FTIR FTIR direct read None PLS calibration Subject to interferences

FTIR acid/base PLS and

Stoichiometric-FTIR IR active base Improved precision over ASTM D664

reaction based stoichiometric

Table 1. Common Acid Number Test Methods

BASE NUMBER METHOD TYPE REAGENT CALIBRATION NOTES

Perchloric acid in Slow, labor-intensive, used for new oil

ASTM D2896 Titration Stoichiometric

glacial acetic acid quality control

ASTM D4739 Titration Hydrochloric acid Stoichiometric Slow, high uncertainty

PLS-FTIR FTIR direct read None PLS calibration Subject to interferences

FTIR acid/base PLS and

Stoichiometric-FTIR IR active acid Improved precision over ASTM D4739

reaction based stoichiometric

Table 2. Common Base Number Test Methods

22 | May- June 2015 | www.machinerylubrication.com

FTIR CALIBRATION TYPE CALIBRATION SAMPLES NOTES

• Fast analysis

In-service oil samples with correspond-

• Easy-to-set-up calibration

PLS (partial least squares) ing ASTM acid number or base number

• Subject to interferences

data

• Estimate ASTM D664 and D4739

• Accurate and precise

• Calibration is anchored to stoichiometric chemical

Gravimetrically prepared standards of reactions

Stoichiometric – linear fit

organic acid/base diluted in mineral oil • Results cannot be directly compared to ASTM D664 or

D4739

• Results are a direct match to ASTM D664 and D4739/

Gravimetrically prepared standards and D2896

Mixed mode = PLS +

samples of used oil with corresponding • Accurate and precise

stoichiometric

ASTM D664 or D4739 data • High initial development cost

Table 3. Summary of Calibration Types for FTIR Acid Number and Base Number Methods

large number of oil samples, in part to determine if additional approach, the analytical principles are similar to the ASTM

quantitative analyses, such as acid or base number determinations, methods, e.g., acid/base reactions, but instead of titrating to deter-

are required. mine the end point, the acid/base reaction is monitored and

measured spectrally.

Types of FTIR Calibrations One of the consequences of using weaker organic acids and

Currently, there are three distinct quantitative approaches avail- bases is that the predicted analytical FTIR acid number/base

able for acid number or base number analysis by FTIR. One is number values obtained will be significantly lower than those

based on direct neat-oil analysis solely using partial least squares obtained using the titration methods. Until recently, this divergence

(PLS) chemometrics. Another is based on the use of ASTM-like of FTIR acid number and base number values from those obtained

acid/base stoichiometric reactions. A third approach, called a using titration procedures was a major impediment to laboratories

mixed-mode calibration, combines the advantages of both the PLS wishing to make use of the stoichiometric approach. Oil analysis

and stoichiometric calibrations. and reliability clients are naturally reluctant to change their familiar

analytical frame of reference, and a shift in expected acid number

PLS-only Calibrations and base number values could lead to confusion. This problem was

A PLS-only calibration is created by comparing ASTM D664 solved by the development of a “mixed-mode” stoichiometric cali-

and D4739 data to the undiluted FTIR spectra of a representative bration with the concurrent implementation of PLS.

set of in-service oils. Partial least squares is then used to correlate

variations in these spectra to the acid number and base number Mixed-mode Calibrations

results measured by titration. The spectrum of unknown samples The mixed-mode method combines the advantages of both types

can then be used to predict or estimate the acid number or base of FTIR calibration. This calibration is anchored using gravimetri-

number result. cally prepared ideal standards to define the fundamental acid/base

PLS-based spectral methods rely solely on non-specific spec- relationship. Hundreds of in-service oil samples are then used to

tral changes that can become problematic when dealing with

used oil samples because they have significant and tricky interfer-

ences that can be difficult to model adequately. These older

direct-read methods have trouble accounting for real-life variables

such as soot, water, incorrect lubricant or mixtures of lube and oil

degradation products.

Stoichiometric Calibrations

The stoichiometric calibration relies on acid/base reactions that

are directly measured using the absorbance of infrared light. This is

made possible through the use of weaker but “IR active” organic

Figure 1. An example of a system used for the FTIR determina-

acids and bases rather than stronger inorganic potassium hydroxide tion of ASTM-identical acid number and base number results for

(KOH) or hydrochloric acid (HCl), as per ASTM methods. With this in-service mineral oils

24 | May- June 2015 | www.machinerylubrication.com

OIL ANALYSIS

further account for the spectral variability induced by real samples The performance of the mixed-mode calibrations was moni-

and to align the data with the corresponding ASTM method. PLS tored over a six-month period. Some 177 acid number samples and

serves only to refine the measurement and to ensure that the results 284 base number samples were analyzed using both the FTIR

match the ASTM reference method used in its development. method and the corresponding ASTM titration methods (D664

A variety of mixed-mode PLS calibrations were recently devel- and D4739). Samples included a mixture of new and used oils from

oped and assessed. The bulk of the samples analyzed for the PLS a wide variety of components, including hydraulic systems, gear-

component of the base number calibration were in-service engine boxes, transmissions, engines, turbines and compressors.

Figures 4 and 5 show the differences between the individual

oils covering most major lubricant suppliers and representing a

ASTM and FTIR results for acid number and base number, respec-

wide range of equipment applications (mining, transport, genera-

tively. The analytical differences between the two methods are

tors, marine, etc.), with nearly 70 percent using diesel fuel and the

normally distributed in both cases, with each having an overall

balance natural gas. In the case of acid number, a mix of new and mean difference of almost zero. This indicates on-average similarity

in-service oils covering a wide range of suppliers and grades was in their results, with the variability around the mean difference

considered, including oils from engines, compressors, hydraulic reflecting the reproducibility of the ASTM reference methods.

systems, turbines, transmissions and gearboxes. These extended production results clearly demonstrated that the

Figures 2 and 3 illustrate the typical cross-validated FTIR cali- FTIR acid number/base number methods are capable of delivering

brations obtained for acid number and base number, respectively. ASTM-identical results.

50

Acid Number

Sample Frequency 40

30

20

10

0

-0.4 -0.2 0 0.2 0.4

AN Difference (ASTM - FTIR); mg KOH/g

Figure 2. A cross-validation chart of the mixed-mode calibration

comparing acid number data for in-service oil samples analyzed Figure 4. Comparing the differences between ASTM and FTIR

by ASTM D664 and the FTIR acid number method acid number results obtained for random operational samples

120

Base Number

100

Sample Frequency

80

60

40

20

0

-0.8 -0.6 -0.4 -0.2 0 0.2 0.4 0.6 0.8 1.0

Figure 3. A cross-validation chart of the mixed-mode calibration

BN Difference (ASTM - FTIR); mg KOH/g

comparing base number data for in-service oil samples analyzed

by ASTM D4739 and the FTIR base number method Figure 5. Comparing the differences between ASTM and FTIR

base number results obtained for random operational samples

26 May- June 2015 | www.machinerylubrication.com

ML

ASTM D664 FTIR ACID NUMBER ASTM D4739 FTIR BASE NUMBER

Sample 120 seconds per 60 seconds per Sample 120 seconds per 60 seconds per

preparation time sample sample preparation time sample sample

Samples per Samples per

4-6 60 4-6 60

hour hour

Daily startup Daily startup

and preventative Variable (up to 1 and preventative Variable (up to 1

< 15 minutes < 15 minutes

maintenance hour) maintenance hour)

time time

Waste disposal Waste disposal

~130 ml ~25 ml ~90 ml ~25 ml

volume volume

Table 4. Comparison of Key Performance Characteristics Between the ASTM and FTIR Methods

MIXED-MODE BASE MIXED-MODE ACID

BASE NUMBER FTIR ASTM D4739 ACID NUMBER FTIR ASTM D664

NUMBER REPRODUCIBILITY REPRODUCIBILITY NUMBER REPRODUCIBILITY REPRODUCIBILITY

6 1.3 3.55 1 0.20 0.44

10 1.3 4.52 2 0.20 0.88

15 1.3 5.46 3 0.20 1.32

Table 5. Reproducibility Comparison of Acid and Base Number Results

FTIR Calibration Pros and Cons

Based on the recent two-year assessment, the mixed-mode calibra-

tion can deliver statistically ASTM-identical data at rates roughly

equivalent to operating nine to 10 dedicated titrators for each analysis

type. Tables 4 and 5 summarize and compare the key variables of the

two analytical approaches (ASTM and FTIR). With one analyst

capable of analyzing nearly 500 samples by FTIR per 8-hour shift, the

advantage is clearly in favor of the FTIR system.

Although the mixed-mode calibration was developed to produce

results statistically identical to ASTM D664 and D4739, accuracy is

intrinsically limited by the uncertainty of these reference methods. The

uncertainty and bias in the FTIR methods can be minimized by using a

large set of in-service oil samples (more than 200). The FTIR methods

also benefit from excellent precision in contrast to the more compli-

cated indirect titration-based methods.

While the stoichiometric approach was found to be superior in

accuracy relative to the neat-oil PLS-only approach, this does not

mean the PLS-only method should be completely discounted as a

potentially useful procedure. It is possible that this method may serve

to provide adequate tracking estimates of ASTM parameters in more

limited situations. Unfortunately, there is no published information or

performance data available for the chemometric PLS-only approach.

The advantage of this method is that it can make use of FTIR instru-

mentation that many laboratories already have in place.

Neither the FTIR PLS-only nor the stoichiometric acid number/base

number approaches are sanctioned by any governing bodies, ASTM or

otherwise. Therefore, any laboratory using either of these methods can

only present the results to their clients as an accurate, precise and

cost-effective means of obtaining acid and base number data.

www.machinerylubrication.com | May- June 2015 | 27

reported in the technical data sheet of the

candidate oil. The higher the viscosity index

value, the less the viscosity changes with a

change in temperature. This is a crucial

factor to consider when looking to switch to

a different type or brand of oil.

Kinematic viscosity is the measurement

of a fluid’s resistance to flow due to the

effects of gravity. It is the viscosity that most

people are accustomed to in terms of how

thick a fluid is. This will be one of the most

noted changes as the oil is heated, the

viscosity drops and the oil flows more

readily. For all tribosystems, the oil’s ability

to flow and support loads is what protects

the component from surface degradation

and ultimately the loss of usefulness and

failure of the machine.

The viscosity at 100 degrees C is critical,

not just for vacuum pumps but for all

machines. It is important to understand the

viscosity requirements of the bearings or

gearsets at the operating temperatures and

to ensure that they are being met by the

lubricant in use. By verifying that the

viscosity is appropriate, you will be gener-

ating less wear and prolonging the life of

your machines.

If you have a question for one of Noria’s experts,

email it to editor@noria.com.

www.machinerylubrication.com | May- June 2015 | 53

Vous aimerez peut-être aussi

- Spectro 5200 Trivector Analyzer & OilView Manual - Rev ADocument446 pagesSpectro 5200 Trivector Analyzer & OilView Manual - Rev AAnonymous srwHCpA100% (2)

- D2893Document3 pagesD2893rimi7alPas encore d'évaluation

- D6443Document7 pagesD6443rimi7al100% (1)

- PH Stat Titration Workstations Reference Manual PDFDocument254 pagesPH Stat Titration Workstations Reference Manual PDFmuszeres.petrikPas encore d'évaluation

- User Manual 3000 Systems V2.0 - TN TSDocument169 pagesUser Manual 3000 Systems V2.0 - TN TSMọt SáchPas encore d'évaluation

- Certified Lubrication SpecialistDocument4 pagesCertified Lubrication SpecialistHARVY19Pas encore d'évaluation

- Lista de Verbos Irregulares en InglésDocument5 pagesLista de Verbos Irregulares en Inglésaleslo8100% (3)

- Lista de Verbos Irregulares en InglésDocument5 pagesLista de Verbos Irregulares en Inglésaleslo8100% (3)

- Lista de Verbos Irregulares en InglésDocument5 pagesLista de Verbos Irregulares en Inglésaleslo8100% (3)

- Habanera Botolena & Carinosa (Gas-A)Document8 pagesHabanera Botolena & Carinosa (Gas-A)christian100% (4)

- Got GottmanDocument3 pagesGot GottmanaalcantaraPas encore d'évaluation

- Sale Deed Document Rajyalakshmi, 2222222Document3 pagesSale Deed Document Rajyalakshmi, 2222222Madhav Reddy100% (2)

- ASTM - D7684 EditedDocument10 pagesASTM - D7684 Editedanandagholap100% (1)

- Astm D2414-21Document9 pagesAstm D2414-21Rajdeep MalPas encore d'évaluation

- C-S 209-141-001Document48 pagesC-S 209-141-001Manuel G Rodriguez100% (1)

- E 334 - 01 (2013)Document12 pagesE 334 - 01 (2013)ruben carcamoPas encore d'évaluation

- Astm d1319 2003 PDFDocument10 pagesAstm d1319 2003 PDFJeffreyChelePas encore d'évaluation

- TX 500 PresentationDocument9 pagesTX 500 PresentationRidho Muhammad AlattasPas encore d'évaluation

- Measurement of Hindered Phenolic Antioxidant Content in HL Turbine Oils by Linear Sweep VoltammetryDocument6 pagesMeasurement of Hindered Phenolic Antioxidant Content in HL Turbine Oils by Linear Sweep VoltammetryMohanadPas encore d'évaluation

- Determination of Metals in Lubricating Greases by Inductively Coupled Plasma Atomic Emission SpectrometryDocument7 pagesDetermination of Metals in Lubricating Greases by Inductively Coupled Plasma Atomic Emission SpectrometryNguyen Hoang QuanPas encore d'évaluation

- CCS D5293Document9 pagesCCS D5293Sofia Fasolo CunhaPas encore d'évaluation

- Profile On Ethyl AcetateDocument8 pagesProfile On Ethyl AcetateGovindanayagi Pattabiraman100% (2)

- A Study of Automotive Gear LubesDocument28 pagesA Study of Automotive Gear LubesgerardoctavaraPas encore d'évaluation

- Glass Capillary Kinematic Viscometers: Standard Specifications and Operating Instructions ForDocument24 pagesGlass Capillary Kinematic Viscometers: Standard Specifications and Operating Instructions ForJulian Felipe Noguera CruzPas encore d'évaluation

- Astm D2717 PDFDocument4 pagesAstm D2717 PDFjoao carlos protz100% (1)

- D2603Document3 pagesD2603rimi7alPas encore d'évaluation

- Organic Supplies Catalog 203-828Document32 pagesOrganic Supplies Catalog 203-828RashMidoPas encore d'évaluation

- Astm D 6079Document8 pagesAstm D 6079Jesús GarcíaPas encore d'évaluation

- SpectrOil 100 Series DatasheetDocument2 pagesSpectrOil 100 Series DatasheetClydeA.SardoncilloPas encore d'évaluation

- E2412 PDFDocument22 pagesE2412 PDFAhmad Zubair RasulyPas encore d'évaluation

- Eraspec Oil Article PinDocument3 pagesEraspec Oil Article PinHARVY19Pas encore d'évaluation

- Anton Paar ProveTec PDFDocument24 pagesAnton Paar ProveTec PDFisaacpintoPas encore d'évaluation

- D3524Document4 pagesD3524rimi7al100% (2)

- F2661 PDFDocument7 pagesF2661 PDFAhmad Zubair RasulyPas encore d'évaluation

- D5183Document5 pagesD5183engrsurifPas encore d'évaluation

- D2896 - Standard Test Method For Base Number of Petroleum Products by Potentiometric Perchloric Acid TitrationDocument10 pagesD2896 - Standard Test Method For Base Number of Petroleum Products by Potentiometric Perchloric Acid TitrationEhsan ZiaeiPas encore d'évaluation

- D 445 - 15aDocument15 pagesD 445 - 15aMayraPas encore d'évaluation

- Astm D 4628-02 AasDocument6 pagesAstm D 4628-02 AasAntony HoPas encore d'évaluation

- ASTM D 4170 Prevenção de Desgaste Por Atrito (FRETTING WEAR TEST) PDFDocument6 pagesASTM D 4170 Prevenção de Desgaste Por Atrito (FRETTING WEAR TEST) PDFIsaaq ManoelPas encore d'évaluation

- Combustion IC PDFDocument12 pagesCombustion IC PDFKhanza26Pas encore d'évaluation

- ASTM D92-05 Standard Test Method For Flash and Fire Points by Cleveland Open Cup Tester PDFDocument10 pagesASTM D92-05 Standard Test Method For Flash and Fire Points by Cleveland Open Cup Tester PDFEduarddo Ravelo NietoPas encore d'évaluation

- Astm d2597 1994Document12 pagesAstm d2597 1994Ana Genesis Moreno HernandezPas encore d'évaluation

- D6448Document5 pagesD6448rimi7alPas encore d'évaluation

- Carbon Black: Professor Joe Greene Csu, ChicoDocument13 pagesCarbon Black: Professor Joe Greene Csu, Chicoviluk100% (1)

- Gs Ppa: Complete, Portable Gasoline AnalysisDocument2 pagesGs Ppa: Complete, Portable Gasoline AnalysisAsep TheaPas encore d'évaluation

- Norma D4378-03 Monitoreo AceitesDocument11 pagesNorma D4378-03 Monitoreo AceitesSebastian DimianPas encore d'évaluation

- Astm D664Document20 pagesAstm D664HalanEnPas encore d'évaluation

- Parametric Design On Internal Gear of Cycloid Gear Pump With NX10.0Document6 pagesParametric Design On Internal Gear of Cycloid Gear Pump With NX10.0PanagiotisPas encore d'évaluation

- D6595Document6 pagesD6595moh_ichwanuddinPas encore d'évaluation

- ASTM D8240-22e1Document4 pagesASTM D8240-22e1saderfende100% (1)

- AN57 Used Lubricating Oil Analysis by FT-IRDocument3 pagesAN57 Used Lubricating Oil Analysis by FT-IRAzhar1109Pas encore d'évaluation

- Modal and Fatigue Analysis of Decanter Centrifuge Rotor Using ANSYSDocument3 pagesModal and Fatigue Analysis of Decanter Centrifuge Rotor Using ANSYShebsonbezerraPas encore d'évaluation

- Astm d2709 Agua CDocument3 pagesAstm d2709 Agua CDiana ÁlvarezPas encore d'évaluation

- D445 Kinematic Viscosity PDFDocument10 pagesD445 Kinematic Viscosity PDFpaty_cm2Pas encore d'évaluation

- Is 14700 4 1 2008Document20 pagesIs 14700 4 1 2008Juan Pablo Villazon RichterPas encore d'évaluation

- ASTM D4817-88 Rubber Compounding SterDocument2 pagesASTM D4817-88 Rubber Compounding SterLuisa Fernanda Carvajal RamírezPas encore d'évaluation

- Omnian PANalytical Day 2009 FinalDocument32 pagesOmnian PANalytical Day 2009 FinalAdrian ZazzPas encore d'évaluation

- G202Document5 pagesG202Gul Hassan Akhunzada100% (1)

- Relaxation of Helical Springs and Spring Steel Wires PDFDocument8 pagesRelaxation of Helical Springs and Spring Steel Wires PDFRemo StortiniPas encore d'évaluation

- Proceedings of the Metallurgical Society of the Canadian Institute of Mining and Metallurgy: Proceedings of the International Symposium on Fracture Mechanics, Winnipeg, Canada, August 23-26, 1987D'EverandProceedings of the Metallurgical Society of the Canadian Institute of Mining and Metallurgy: Proceedings of the International Symposium on Fracture Mechanics, Winnipeg, Canada, August 23-26, 1987W. R. TysonPas encore d'évaluation

- Structural Health MonitoringD'EverandStructural Health MonitoringDaniel BalageasPas encore d'évaluation

- Surface Contamination: Proceedings of a Symposium Held at Gatlinburg, Tennessee, June 1964D'EverandSurface Contamination: Proceedings of a Symposium Held at Gatlinburg, Tennessee, June 1964B. R. FishPas encore d'évaluation

- Colorimetry: Understanding the CIE SystemD'EverandColorimetry: Understanding the CIE SystemJanos SchandaPas encore d'évaluation

- Titulacion Petroleum IndustryDocument96 pagesTitulacion Petroleum Industryluis hernandezPas encore d'évaluation

- Astm D 5185 02 Icp PDFDocument7 pagesAstm D 5185 02 Icp PDFReyzza AndiaPas encore d'évaluation

- Official Methods List of RefractometerDocument3 pagesOfficial Methods List of RefractometerkominooPas encore d'évaluation

- Machinery Lubrication I IIDocument12 pagesMachinery Lubrication I IIHARVY19100% (1)

- Cat Elc PDFDocument4 pagesCat Elc PDFNasser AyoubPas encore d'évaluation

- Eraspec Oil Article PinDocument3 pagesEraspec Oil Article PinHARVY19Pas encore d'évaluation

- Must Vs Have ToDocument8 pagesMust Vs Have ToHARVY19Pas encore d'évaluation

- Cat Elc PDFDocument4 pagesCat Elc PDFNasser AyoubPas encore d'évaluation

- Cat Elc PDFDocument4 pagesCat Elc PDFNasser AyoubPas encore d'évaluation

- Cat Elc PDFDocument4 pagesCat Elc PDFNasser AyoubPas encore d'évaluation

- Cat Elc PDFDocument4 pagesCat Elc PDFNasser AyoubPas encore d'évaluation

- Computerised Wear Particle Atlas For Ferrogram and Filtergram AnalysesDocument7 pagesComputerised Wear Particle Atlas For Ferrogram and Filtergram AnalysesHARVY19Pas encore d'évaluation

- Pds Detail PageDocument3 pagesPds Detail PageHARVY19Pas encore d'évaluation

- Lista de Verbos Irregulares en InglésDocument3 pagesLista de Verbos Irregulares en InglésWilliam Humberto GutierrezPas encore d'évaluation

- Taylor & Francis Materials Reference Guide: Journal PaperDocument7 pagesTaylor & Francis Materials Reference Guide: Journal PaperHARVY19Pas encore d'évaluation

- MineCare Nextgen Flyer2Document2 pagesMineCare Nextgen Flyer2HARVY19Pas encore d'évaluation

- Lista de Verbos Irregulares en InglésDocument3 pagesLista de Verbos Irregulares en InglésWilliam Humberto GutierrezPas encore d'évaluation

- WP Measuring Nitration, Oxidation and Sulfation 2017Document3 pagesWP Measuring Nitration, Oxidation and Sulfation 2017HARVY19Pas encore d'évaluation

- Whitepaper Dynamic Equilibrium Condition (DEC)Document5 pagesWhitepaper Dynamic Equilibrium Condition (DEC)HARVY19Pas encore d'évaluation

- Lista Verbos IrregularesDocument5 pagesLista Verbos IrregularesAnonymous QFC2y9h767% (3)

- Lista Verbos IrregularesDocument5 pagesLista Verbos IrregularesAnonymous QFC2y9h767% (3)

- Lista Verbos IrregularesDocument5 pagesLista Verbos IrregularesAnonymous QFC2y9h767% (3)

- FT IR SpectrometryDocument4 pagesFT IR SpectrometryHARVY19Pas encore d'évaluation

- Vickers General Hydraulic BookDocument29 pagesVickers General Hydraulic BookKarthik Sarang100% (15)

- Certified Oil Monitoring AnalystDocument2 pagesCertified Oil Monitoring AnalystHARVY19Pas encore d'évaluation

- Acid Organic Technology OAT CoolantDocument6 pagesAcid Organic Technology OAT CoolantHARVY19Pas encore d'évaluation

- Examples Present PerfectDocument2 pagesExamples Present PerfectHARVY19Pas encore d'évaluation

- Improving Self-Esteem - 08 - Developing Balanced Core BeliefsDocument12 pagesImproving Self-Esteem - 08 - Developing Balanced Core BeliefsJag KaleyPas encore d'évaluation

- Who, Summary NotesDocument12 pagesWho, Summary NotesIvan Lohr100% (2)

- CURRICULUM VITAE Kham Khan Suan Hausing, PHDDocument8 pagesCURRICULUM VITAE Kham Khan Suan Hausing, PHDCinpu ZomiPas encore d'évaluation

- Tugas, MO - REVIEW JURNAL JIT - Ikomang Aditya Prawira Nugraha (1902612010304)Document12 pagesTugas, MO - REVIEW JURNAL JIT - Ikomang Aditya Prawira Nugraha (1902612010304)MamanxPas encore d'évaluation

- Creating Literacy Instruction For All Students ResourceDocument25 pagesCreating Literacy Instruction For All Students ResourceNicole RickettsPas encore d'évaluation

- 76 ECL GuideDocument45 pages76 ECL GuideOana SavulescuPas encore d'évaluation

- IUGRDocument4 pagesIUGRMichael Spica RampangileiPas encore d'évaluation

- Class NotesDocument16 pagesClass NotesAdam AnwarPas encore d'évaluation

- BSCHMCTT 101Document308 pagesBSCHMCTT 101JITTUPas encore d'évaluation

- Dopamine What It Is, Function & SymptomsDocument7 pagesDopamine What It Is, Function & SymptomsRaj KumarPas encore d'évaluation

- RegressionDocument16 pagesRegressionchinusccPas encore d'évaluation

- Institute of Actuaries of India: Subject CT3-Probability and Mathematical Statistics May 2008 ExaminationDocument10 pagesInstitute of Actuaries of India: Subject CT3-Probability and Mathematical Statistics May 2008 ExaminationeuticusPas encore d'évaluation

- Su Jok, Twist Therapy AND Smile MeditationDocument7 pagesSu Jok, Twist Therapy AND Smile MeditationprateekPas encore d'évaluation

- Man Is Made by His BeliefDocument2 pagesMan Is Made by His BeliefLisa KireechevaPas encore d'évaluation

- Introduction To E-Business SystemsDocument19 pagesIntroduction To E-Business SystemsArtur97% (79)

- Unit 2-ED (Theory)Document13 pagesUnit 2-ED (Theory)chakramuPas encore d'évaluation

- Financial Crisis Among UTHM StudentsDocument7 pagesFinancial Crisis Among UTHM StudentsPravin PeriasamyPas encore d'évaluation

- Roman Villas at Tor Marancia and CentocelleDocument10 pagesRoman Villas at Tor Marancia and CentocelleIgor ĆirkovićPas encore d'évaluation

- VestibuleDocument17 pagesVestibuleDeepti MangalPas encore d'évaluation

- A100K10873 VSP-12-Way Technical ManualDocument20 pagesA100K10873 VSP-12-Way Technical Manualchufta50% (2)

- Canon Law Eng. Appunti Part 2Document91 pagesCanon Law Eng. Appunti Part 2noelPas encore d'évaluation

- Radiography Safety ProcedureDocument9 pagesRadiography Safety ProcedureأحمدآلزهوPas encore d'évaluation

- Oleracea Contain 13.2% Dry Matter, 15.7% Crude Protein, 5.4% Ether ExtractionDocument47 pagesOleracea Contain 13.2% Dry Matter, 15.7% Crude Protein, 5.4% Ether ExtractionJakin Aia TapanganPas encore d'évaluation

- Reflection Paper-The Elephant Man PDFDocument1 pageReflection Paper-The Elephant Man PDFCarlosJohn02Pas encore d'évaluation

- Air Augmented Rocket (285pages) Propulsion ConceptsDocument285 pagesAir Augmented Rocket (285pages) Propulsion ConceptsAlexandre PereiraPas encore d'évaluation

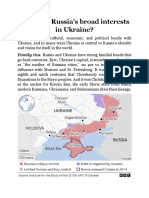

- What Are RussiaDocument3 pagesWhat Are RussiaMuhammad SufyanPas encore d'évaluation

- Registration - No Candidate Gender Category Rank/Percentage Allotment - Seat Base - Seat Course CollegeDocument166 pagesRegistration - No Candidate Gender Category Rank/Percentage Allotment - Seat Base - Seat Course CollegeCyber ParkPas encore d'évaluation