Académique Documents

Professionnel Documents

Culture Documents

Mechanics of A Hydraulic Excavator PDF

Transféré par

Jayath BogahawatteDescription originale:

Titre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Mechanics of A Hydraulic Excavator PDF

Transféré par

Jayath BogahawatteDroits d'auteur :

Formats disponibles

Proceedings

rd

of the 3 International Modelica Conference,

Linköping, November 3-4, 2003,

Peter Fritzson (editor)

Peter Beater and Martin Otter

Fachhochschule Südwestfalen in Soest; DLR, Germany:

Multi-Domain Simulation: Mechanics and Hydraulics of an

Excavator

pp. 331-340

Paper presented at the 3rd International Modelica Conference, November 3-4, 2003,

Linköpings Universitet, Linköping, Sweden, organized by The Modelica Association

and Institutionen för datavetenskap, Linköpings universitet

All papers of this conference can be downloaded from

http://www.Modelica.org/Conference2003/papers.shtml

Program Committee

Peter Fritzson, PELAB, Department of Computer and Information Science,

Linköping University, Sweden (Chairman of the committee).

Bernhard Bachmann, Fachhochschule Bielefeld, Bielefeld, Germany.

Hilding Elmqvist, Dynasim AB, Sweden.

Martin Otter, Institute of Robotics and Mechatronics at DLR Research Center,

Oberpfaffenhofen, Germany.

Michael Tiller, Ford Motor Company, Dearborn, USA.

Hubertus Tummescheit, UTRC, Hartford, USA, and PELAB, Department of

Computer and Information Science, Linköping University, Sweden.

Local Organization: Vadim Engelson (Chairman of local organization), Bodil

Mattsson-Kihlström, Peter Fritzson.

Peter Beater and Martin Otter Multi-Domain Simulation: Mechanics and Hydraulics of an Excavator

Multi-Domain Simulation:

Mechanics and Hydraulics of an Excavator

Peter Beater1, and Martin Otter2

1

University of Applied Sciences Soest, Germany, pb@beater.de

2

DLR, Oberpfaffenhofen, Germany, Martin.Otter@dlr.de

Abstract 2. Modeling Choices

It is demonstrated how to model and simulate an There are several approaches when simulating a

excavator with Modelica and Dymola by using system. Depending on the task it may be necessary

Modelica libraries for multi-body and for hydrau- to build a very precise model, containing every

lic systems. The hydraulic system is controlled by a detail of the system and needing a lot of informa-

“load sensing” controller. Usually, models con- tion, e.g., model parameters. This kind of models is

taining 3-dimensional mechanical and hydraulic expensive to build up but on the other hand very

components are difficult to simulate. At hand of the useful if parameters of a well defined system have

excavator it is shown that Modelica is well suited to be modified. A typical example is the optimiza-

for such kinds of system simulations. tion of parameters of a counterbalance valve in an

excavator (Kraft 1996).

1. Introduction The other kind of model is needed for a first

study of a system. In this case some properties of

The design of a new product requires a number of

the pump, cylinders and loads are specified. Re-

decisions in the initial phase that severely affect

quired is information about the performance of that

the success of the finished machine. Today, digital

system, e.g., the speed of the pistons or the neces-

simulation is therefore used in early stages to look

sary input power at the pump shaft, to make a deci-

at different concepts. The view of this paper is that

sion whether this design can be used in principle

a new excavator is to be designed and several can-

for the task at hand. This model has therefore to be

didates of hydraulic control systems have to be

“cheap”, i.e., it must be possible to build it in a

evaluated.

short time without detailed knowledge of particular

Systems that consist of 3-dimensional me-

components.

chanical and of hydraulic components – like exca-

The authors intended to build up a model of

vators – are difficult to simulate. Usually, two dif-

the second type, run it and have first results with a

ferent simulation environments have to be coupled.

minimum amount of time spent. To achieve this

This is often inconvenient, leads to unnecessary

goal the modeling language Modelica (Modelica

numerical problems and has fragile interfaces. In

2002), the Modelica simulation environment Dy-

this article it is demonstrated at hand of the model

mola (Dymola 2003), the new Modelica library for

of an excavator that Modelica is well suited for

3-dimensional mechanical systems “MultiBody”

these types of systems.

(Otter et al. 2003) and the Modelica library of hy-

The 3-dimensional components of the exca-

draulic components HyLib (Beater 2000) was

vator are modeled with the new, free Modelica

used. The model consists of the 3-dimensional me-

MultiBody library (Otter et. al. 2003). This allows

chanical construction of the excavator, a detailed

especially to use an analytic solution of the kine-

description of the power hydraulics and a generic

matic loop at the bucket and to take the masses of

“load sensing” controller. This model will be

the hydraulic cylinders, i.e., the “force elements”,

available as a demo in the next version of HyLib.

directly into account. The hydraulic part is mod-

eled in a detailed way, utilizing pump, valves and

cylinders from HyLib, a hydraulics library for 3. Construction of Excavators

Modelica. For the control part a generic “load In Figure 1 a schematic drawing of a typical exca-

sensing” control system is used, modeled by a set vator under consideration is shown. It consists of a

of simple equations. This approach gives the re- chain track and the hydraulic propel drive which is

quired results and keeps the time needed for ana- used to manoeuvre the machine but usually not

lyzing the problem on a reasonable level. during a work cycle. On top of that is a carriage

The Modelica Association Modelica 2003, November 3-4, 2003

Peter Beater and Martin Otter Multi-Domain Simulation: Mechanics and Hydraulics of an Excavator

4. Load Sensing System

Excavators have typically one Diesel engine, two

hydraulic motors and three cylinders. There exist

different hydraulic circuits to provide the consum-

ers with the required hydraulic energy. A typical

design is a Load Sensing circuit that is energy effi-

cient and user friendly. The idea is to have a flow

rate control system for the pump such that it deliv-

ers exactly the needed flow rate. As a sensor the

pressure drop across an orifice is used. The refer-

Figure 1 Schematic drawing of excavator

ence value is the resistance of the orifice. A sche-

where the operator is sitting. It can rotate around a

matic drawing is shown in figure 4, a good intro-

vertical axis with respect to the chain track. It also

duction to that topic is given in (anon. 1992).

holds the Diesel engine, the hydraulic pumps and

The pump control valve maintains a pressure

control system. Furthermore, there is a boom, an

at the pump port that is typically 15 bar higher than

arm and at the end a bucket which is attached via a

the pressure in the LS line (= Load Sensing line). If

planar kinematic loop to the arm. Boom, arm and

the directional valve is closed the pump has there-

bucket can be rotated by the appropriate cylinders.

fore a stand-by pressure of 15 bar. If it is open the

Figure 2 shows that the required pressures in

pump delivers a flow rate that leads to a pressure

the cylinders depend on the position. For the

drop of 15 bar across that directional valve. Note:

“stretched” situation the pressure in the boom cyl-

The directional valve is not used to throttle the

inder is 60 % higher than in the retracted position.

pump flow but as a flow meter (pressure drop that

Not only the position but also the movements have

is fed back) and as a reference (resistance). The

to be taken into account. Figure 3 shows a situation

circuit is energy efficient because the pump deliv-

where the arm hangs down. If the carriage does not

ers only the needed flow rate, the throttling losses

rotate there is a pulling force required in the cylin-

are small compared to other circuits.

der. When rotating – excavators can typically ro-

If more than one cylinder is used the circuit

tate with up to 12 revolutions per minute – the

becomes more complicated, see figure 5. E.g. if the

force in the arm cylinder changes its sign and now

boom requires a pressure of 100 bar and the bucket

a pushing force is needed. This change is very sig-

a pressure of 300 bar the pump pressure must be

nificant because now the “active” chamber of the

above 300 bar which would cause an unwanted

cylinder switches and that must be taken into ac-

count by the control system. Both figures demon-

strate that a simulation model must take into ac-

count the couplings between the four degrees of

freedom this excavator has. A simpler model that

uses a constant load for each cylinder and the

swivel drive leads to erroneous results (Jansson et

al. 1998).

Figure 2 Different working situations

Figure 3 Effect of centrifugal forces Figure 4 Schematics of a simple LS system (Zähe)

The Modelica Association Modelica 2003, November 3-4, 2003

Peter Beater and Martin Otter Multi-Domain Simulation: Mechanics and Hydraulics of an Excavator

movement of the boom cylinder. Therefore com-

pensators are used that throttle the oil flow and

5. Model of Mechanical Part

thus achieve a pressure drop of 15 bar across the In Figure 6, a Modelica schematic of the mechani-

particular directional valve. These compensators cal part is shown. The chain track is not modeled,

can be installed upstream or downstream of the i.e., it is assumed that the chain track does not

directional valves. An additional valve reduces the move. Components “rev1”, ..., “rev4” are the 4

nominal pressure differential if the maximum revolute joints to move the parts relative to each

pump flow rate or the maximum pressure is other. The icons with the long black line are “vir-

reached (see e.g. Nikolaus 1994). tual” rods that are used to mark specific points on a

part, especially the mounting points of the hydrau-

lic cylinders. The light blue spheres (b2, b3, b4,

b5) are bodies that have mass and an inertia tensor

and are used to model the corresponding properties

of the excavator parts.

The three components “cyl1f”, “cyl2f”,

and “cyl3f” are line force components that describe

a force interaction along a line between two at-

tachment points. The small green squares at these

components represent 1-dimensional translational

connectors from the Modelica.Mechanics.Trans-

lational library. They are used to define the 1-

dimensional force law acting between the two at-

tachment points. Here, the hydraulic cylinders de-

scribed in the next section are directly attached.

The small two spheres in the icons of the “cyl1f,

cyl2f, cyl3f” components indicate that optionally

Figure 5 Schematic drawing of a LS system two point masses are taken into account that are

attached at defined distances from the attachment

Figure 6 Modelica schematic of mechanical part of excavator

The Modelica Association Modelica 2003, November 3-4, 2003

Peter Beater and Martin Otter Multi-Domain Simulation: Mechanics and Hydraulics of an Excavator

points along the connecting line. This allows to In a first step, the mechanical part of the excavator

easily model the essential mass properties (mass is simulated without the hydraulic system to test

and center of mass) of the hydraulic cylinders with this part separatly. This is performed by attaching

only a very small computational overhead. translational springs with appropriate spring con-

The jointRRR component (see right part of stants instead of the hydraulic cylinders. After the

Figure 6) is an assembly element consisting of 3 animation looks fine and the forces and torques in

revolute joints that form together a planar loop the joints have the expected size, the springs are

when connected to the arm. A picture of this part replaced by the hydraulic system described in the

of an excavator, a zoom in the corresponding next sections.

Modelica schematic and the animation view is All components of the new MultiBody li-

shown in Figure 7. When moving revolute joint brary have “built-in” animation definitions, i.e.,

“rev4” (= the large red cylinder in the lower part of animation properties are mostly deduced by default

Figure 7; the small red cylinders characterize the 3 from the given definition of the multi-body system.

revolute joints of the jointRRR assembly compo- For example, a rod connecting two revolute joints

nent) the position and orientation of the attachment is by default visualized as cylinder where the di-

points of the “left” and “right” revolute joints of ameter d is a fraction of the cylinder length L (d =

the jointRRR component are known. There is a L/40) which is in turn given by the distance of the

non-linear algebraic loop in the jointRRR compo- two revolute joints. A revolute joint is by default

nent to compute the angles of its three revolute visualized by a red cylinder directed along the axis

joints given the movement of these attachment of rotation of the joint. The default animation (with

points. This non-linear system of equations is only a few minor adaptations) of the excavator is

solved analytically in the jointRRR object, i.e., in a shown if Figure 8.

robust and efficient way. For details see (Otter et.

al. 2003).

Figure 8 Default animation of excavator

The light blue spheres characterize the center of

mass of bodies. The line force elements that visu-

alize the hydraulic cylinders are defined by two

cylinders (yellow and grey color) that are moving

in each other. As can be seen, the default anima-

tion is useful to get, without extra work from the

user side, a rough picture of the model that allows

to check the most important properties visually,

e.g., whether the center of masses or attachment

points are at the expected places.

For every component the default animation

can be switched off via a Boolean flag. Removing

appropriate default animations, such as the “center-

of-mass spheres”, and adding some components

that have pure visual information (all visXXX

components in the schematic of Figure 6) gives

quickly a nicer animation, as is demonstrated in

Figure 9. Also CAD data could be utilized for the

animation, but this was not available for the ex-

amination of this excavator.

Figure7 Foto, schematic and animation of jointRRR

The Modelica Association Modelica 2003, November 3-4, 2003

Peter Beater and Martin Otter Multi-Domain Simulation: Mechanics and Hydraulics of an Excavator

Figure 10 Overview of hydraulics library HyLib

a template for components with two ports is writ-

ten. This can be inherited for ideal models, e.g., a

laminar resistance or a pressure relief valve. While

Figure 9 Animation of excavator (start/end position) it usually makes sense to use textual input for these

basic models most of the main library models were

programmed graphically, i.e., composed from ba-

sic library models using the graphical user inter-

6. The Hydraulics Library HyLib face. Figure12 gives an example of graphical pro-

The (commercial) Modelica library HyLib (Beater gramming. All mentioned components were cho-

2000, HyLib 2003) is used to model the pump, sen from the library and then graphically con-

metering orifice, load compensator and cylinder of nected.

the hydraulic circuit. All these components are

standard components for hydraulic circuits and can

be obtained from many manufacturers. Models of

all of them are contained in HyLib. These mathe-

matical models include both standard textbook

models (e. g. Dransfield 1981, Merrit 1967,

Viersma 1980) and the most advanced published

models that take the behavior of real components

into account (Schulz 1979, Will 1968). An exam-

ple is the general pump model where the output

flow is reduced if pressure at the inlet port falls

below atmospheric pressure. Numerical properties

were also considered when selecting a model Figure 11 Pump models in HyLib

(Beater 1999). One point worth mentioning is the

fact that all models can be viewed at source code

level and are documented by approx. 100 refer-

ences from easily available literature.

7. Library Components in

After opening the library, the main win- Hydraulics Circuit

dow is displayed (Figure 10). A double click on the The composition diagram in Figure 12 shows the

“pumps” icon opens the selection for all compo- graphically composed hydraulics part of the exca-

nents that are needed to originate or end an oil flow vator model. The sub models are chosen from the

(Figure 11). For the problem at hand, a hydraulic appropriate libraries, connected and the parameters

flow source with internal leakage and externally input. Note that the cylinders and the motor from

commanded flow rate is used. Similarly the needed HyLib can be simply connected to the also shown

models for the valves, cylinders and other compo- components of the MultiBody library. The input

nents are chosen. signals, i.e., the reference signals of the driver of

All components are modeled hierarchi- the excavator, are given by tables, specifying the

cally. Starting with a definition of a connector – a diameter of the metering orifice, i.e. the reference

port were the oil enters or leaves the component – value for the flow rate. From the mechanical part

The Modelica Association Modelica 2003, November 3-4, 2003

Peter Beater and Martin Otter Multi-Domain Simulation: Mechanics and Hydraulics of an Excavator

Figure 12 Modelica schematic of hydraulic part of excavator

of the excavator only the components are shown in could be built with the components from the hy-

Figure 12 that are directly coupled with hydraulic draulics library but would require a considerable

elements, such as line force elements to which the amount of time that is usually not available at the

hydraulic cylinders are attached. beginning of a project.

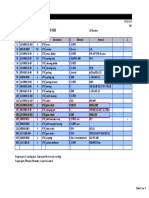

In Tables 1 and 2, the implementation of the

8. Model of LS Control LS control in form of equations is shown. Usually,

it is recommended for Modelica models to either

For this study the following approach is chosen: use graphical model decomposition or to define the

Model the mechanics of the excavator, the cylin- model by equations, but not to mix both descrip-

ders and to a certain extent the pump and metering

valves in detail because only the parameters of the Table 1 Modelica code for definition for constants,

parameters and variables for LS control system

components will be changed, the general structure

// Definition of variables,

is fixed. This means that the diameter of the bucket // parameters and constants

cylinder may be changed but there will be exactly import SI = Modelica.SIunits;

one cylinder working as shown in Figure 1. That is SI.Pressure delta_p1;

different for the rest of the hydraulic system. In SI.Pressure delta_p2;

this paper a Load Sensing system, or LS system for SI.Pressure pump_ls;

short, using one pump is shown but there are other SI.Pressure pump_ls1;

concepts that have to be evaluated during an initial SI.Pressure pump_ls2;

design phase. For instance the use of two pumps, SI.Pressure dp_ref(start = 15e5,

fixed = true);

or a separate pump for the swing. Boolean pump_q_max;

The hydraulic control system can be set up Boolean pump_p_max(start = false,

using meshed control loops. As there is (almost) no fixed = true);

way to implement phase shifting behavior in

purely hydraulic control systems the following ge- parameter Real k_LS = 1e-5;

neric LS system uses only proportional controllers. parameter SI.Pressure p_max = 415e5

A detailed model based on actual compo-

nents would be much bigger and is usually not

available at the begin of an initial design phase. It

The Modelica Association Modelica 2003, November 3-4, 2003

Peter Beater and Martin Otter Multi-Domain Simulation: Mechanics and Hydraulics of an Excavator

Table 2 Modelica code for LS Controller, see also Fig. 4 and 5

function conductance "Determine conductance of compensators"

input SI.Pressure dp;

output Real G;

algorithm

G := min(1e-8, max(1e-13, 1e-8 - dp*5e-14));

end conductance

equation // Set of equations to model the LS controller

// define pressure differential across the metering orifices

// for load compensator and documentation purposes

delta_p1 = if ref_boom.y[1] <= 0 then pump.port_B.p

else metOri1.port_A.p - metOri1.port_B.p;

delta_p2 = if ref_swing.y[1] <= 0 then 0.0

else metOri2.port_A.p - metOri2.port_B.p;

delta_p3 = if ref_bucket.y[1] <= 0 then pump.port_B.p

else metOri3.port_A.p - metOri3.port_B.p;

delta_p4 = if ref_arm.y[1] <= 0 then pump.port_B.p

else metOri4.port_A.p - metOri4.port_B.p;

// calculate load pressure for pump controller

pump_ls1 = if ref_boom.y[1] <= 0 then pump.port_B.p

else metOri1.port_A.p - comp1.port_B.p;

pump_ls2 = if ref_swing.y[1] <= 0 then pump.port_B.p

else metOri2.port_A.p - comp2.port_B.p;

pump_ls3 = if ref_bucket.y[1] <= 0 then pump.port_B.p

else metOri3.port_A.p - comp3.port_B.p;

pump_ls4 = if ref_arm.y[1] <= 0 then pump.port_B.p

else metOri4.port_A.p - comp4.port_B.p;

pump_ls = min([pump_ls1, pump_ls2, pump_ls3, pump_ls4);

// define Boolean state for pump controller

pump_q_max = k_LS*(15e5 - pump_ls) > 8e-3;

// set Boolean state if max. pump pressure is reached (with hysteresis)

pump_p_max = pump.port_B.p > p_max or

pre(pump_p_max) and pump.port_B.p > 0.95*p_max;

// calculate command signal for pump

pump.inPort.signal[1] = if pump_p_max then

min(7.5e-3, 7.5e-3 + k_LS*1e-2*(p_max - pump.port_B.p))

else if pump_q_max then 7.5e-3 else (k_LS*(15e5 - pump_ls));

// modify reference signal if maximum pump flow rate is exceeded

dp_ref = if pump_q_max and not pump_p_max then pump_ls else 15e5;

// calculate conductances of pressure compensators

comp1.inPort.signal[1] = conductance(delta_p1 - dp_ref);

comp2.inPort.signal[1] = conductance(delta_p2 - dp_ref);

comp3.inPort.signal[1] = conductance(delta_p3 - dp_ref);

comp4.inPort.signal[1] = conductance(delta_p4 - dp_ref);

tion forms on the same model level. For the LS circuit above and access the input and output sig-

system this is different because it has 17 input sig- nals directly. For example, ”metOri1.port_A.p”

nals and 5 output signals. One might built one used in table 2 is the measured pressure at port_A

block with 17 inputs and 5 outputs and connect of the metering orifice metOri1. The calculated

them to the hydraulic circuit. However, in this case values of the LS controller, e.g., the pump flow

it seems more understandable to provide the equa- rate “pump.inPort.signal[1] = ...” is the signal at the

tions directly on the same level as the hydraulic

The Modelica Association Modelica 2003, November 3-4, 2003

Peter Beater and Martin Otter Multi-Domain Simulation: Mechanics and Hydraulics of an Excavator

filled blue rectangle of the “pump” component, see

Figure 12).

The strong point of Modelica is that a

seamless integration of the 3-dimensional me-

chanical library, the hydraulics library and the non

standard, and therefore in no library available,

model of the control system is easily done. The

library components can be graphically connected

in the object diagram and the text based model can

access all needed variables.

9. Some Simulation Results

The complete model was built using the Modelica

modeling and simulation environment Dymola Figure 14 Boom (blue) and bucket (red) piston position

(Dymola 2003), translated, compiled and simulated and swing angle (green)

for 5 s. The simulation time was 17 s using the

DASSL integrator with a relative tolerance of 10-6 Figure 15 shows the operation of the bucket cylin-

on a 1.8 GHz notebook, i.e., about 3.4 times slower der. The top figure shows the reference trajectory,

as real-time. The animation feature in Dymola i. e. the opening of the directional valve. The mid-

makes it possible to view the movements in an al- dle figure shows the conductance of the compen-

most realistic way which helps to explain the re- sators. With the exception of two spikes it is open

sults also to non-experts, see Figure 9. from t = 0 s until t = 1 s. This means that in that

Figure 13 gives the reference signals for interval the pump pressure is commanded by that

the three cylinders and the swing, the pump flow bucket cylinder. After t = 1 s the boom cylinder

rate and pressure. From t = 1.1 s until 1.7 s and requires a considerably higher pressure and the

from t = 3.6 s until 4.0 s the pump delivers the bucket compensator therefore increases the resis-

maximum flow rate. From t = 3.1 s until 3.6 s the tance (smaller conductance). The bottom figure

maximum allowed pressure is reached. shows that the flow rate control works fine. Even

though there is a severe disturbance (high pump

pressure after t = 1 s due to the boom) the com-

manded flow rate is fed with a small error to the

bucket cylinder.

Figure 13 Reference, pump flow rate and pressure

Figure 14 gives the position of the boom and the

bucket cylinders and the swing angle. It can be Figure 15 Operation of bucket cylinder

seen that there is no significant change in the pis-

ton movement if another movement starts or ends.

The control system reduces the couplings between

the consumers which are very severe for simple

throttling control.

The Modelica Association Modelica 2003, November 3-4, 2003

Peter Beater and Martin Otter Multi-Domain Simulation: Mechanics and Hydraulics of an Excavator

Modelica (2002): Modelica - A Unified Object-Oriented

10. Conclusion Language for Physical Systems Modeling. Language

For the evaluation of different hydraulic circuits a Specification. Version 2.0. http://www.Modelica.org

dynamic model of an excavator was built. It con- Nikolaus, H. W. (1994): Load Sensing - lastunabhän-

sists of a detailed model of the 3 dimensional me- gige Dosierung von Verbraucherströmen. Ölhydrau-

chanics of the carriage, including boom, arm and lik und Pneumatik, o+p, 38, pp. 196- 201.

Otter, M., Elmqvist, H., and Mattsson, S.E. (2003): The

bucket and the standard hydraulic components like

New Modelica MultiBody Library. Modelica’2003,

pump or cylinder. The control system was not 3rd International Modelica Conference, Linköping,

modeled on a component basis but the system was Nov. 2-3.

described by a set of nonlinear equations. Schulz, R. (1979): Berechnung des dynamischen Ver-

The system was modeled using the Mode- haltens hydraulischer Antriebe großer Leistung für

lica MultiBody library, the hydraulics library Hylib Umformmaschinen. PhD-Thesis. RWTH Aachen.

and a set of application specific equations. With Viersma, T. J. (1980): Analysis, Synthesis and Design of

the tool Dymola the system could be build and Hydraulic Servosystems and Pipelines. Amsterdam:

tested in a short time and it was possible to calcu- Elsevier Scientific Publishing Company.

late the required trajectories for evaluation of the Zähe, B., Gawlikowski, R, and Linden, D (1993): Load

Sensing als Mehrgrößenregelung. o+p 37, pp. 638 -

control system.

644

The animation feature in Dymola makes it

possible to view the movements in an almost real-

istic way which helps to explain the results also to

non experts.

Bibliography

anon (1992): Load Sensing Systems Principle of Opera-

tion. Eaton Corporation. Hydraulics Division. Eden

Prairie, MN, USA. (also under

http://www.hydraulics.eaton.com/products/pdfs/

03-206.pdf)

Beater, P. (1999): Entwurf hydraulischer Maschinen –

Modellbildung, Stabilitätsanalyse und Simulation hy-

drostatischer Antriebe und Steuerungen. Springer

Verlag.

Beater, P. (2000): Modeling and Digital Simulation of

Hydraulic Systems in Design and Engineering Edu-

cation using Modelica and HyLib. pp. 33 - 40.

Modelica Workshop 2000, October 23 – 24, 2000,

Lund, Sweden.

Dransfield, P. (1981): Hydraulic Control Systems - De-

sign and Analysis of Their Dynamics. Springer, Ber-

lin, Heidelberg New York.

Dymola (2003): Dymola version 5.1.

http://www.Dynasim.se

Elmqvist, H. (1978): A Structured Model Language for

Large Continous Systems. PhD-Thesis Lund Institute

of Technology, Lund, Sweden.

Jansson, A., Yahiaoui, M., and Richards, C. (1998):

Running Combined Multibody Hydraulic System

Simulations within ADAMS. International ADAMS

User Conference

HyLib (2003): HyLib version 2.1.

http://www.HyLib.com

Kraft, W. (1996): Experimentelle und analytische Un-

tersuchungen hydrostatischer Fahrantriebe am

Beispiel eines Radbaggers. PhD-Thesis RWTH

Aachen, Germany.

Merrit, H. E. (1967): Hydraulic Control Systems. New

York: John Wiley & Sons.

The Modelica Association Modelica 2003, November 3-4, 2003

Vous aimerez peut-être aussi

- Mine Fan: Prof. Satya PrakashDocument19 pagesMine Fan: Prof. Satya Prakashshivam raiPas encore d'évaluation

- Concrete Mixer DesignDocument5 pagesConcrete Mixer DesignPredrag Ilic100% (1)

- Greaves Non-Automotive Engines BrochureDocument6 pagesGreaves Non-Automotive Engines BrochureRicardo TurlaPas encore d'évaluation

- Steering and Braking SystemDocument70 pagesSteering and Braking SystemPatrick MAZIMPAKAPas encore d'évaluation

- Energy Audit For Thermic Fluid Heater: Project Report ME4422Document20 pagesEnergy Audit For Thermic Fluid Heater: Project Report ME4422Jayath Bogahawatte100% (1)

- Training Presentation: For Sales RepsDocument56 pagesTraining Presentation: For Sales RepsMageshwarPas encore d'évaluation

- Concrete Mixing Plant PDFDocument18 pagesConcrete Mixing Plant PDFereresrdf100% (2)

- Doosan DX300LC Hydraulic ExcavatorDocument8 pagesDoosan DX300LC Hydraulic ExcavatorMega Indra PermanaPas encore d'évaluation

- fUNDAMENTALS OF EARTHMOVINGDocument11 pagesfUNDAMENTALS OF EARTHMOVINGKadhim FalahPas encore d'évaluation

- Hydraulic ExcavatorDocument22 pagesHydraulic ExcavatorUjjwal ShresthaPas encore d'évaluation

- Nissan 720 L4-2.0-Z20 1983-86 Manual PDFDocument641 pagesNissan 720 L4-2.0-Z20 1983-86 Manual PDFEduardo Ariel JuarezPas encore d'évaluation

- Swing MotorDocument16 pagesSwing Motorpaulnunez9389Pas encore d'évaluation

- HPE 3PAR StoreServ 20000 Storage Service and Upgrade Guide Service EditionDocument282 pagesHPE 3PAR StoreServ 20000 Storage Service and Upgrade Guide Service Editionben boltPas encore d'évaluation

- Caterpillar M320D Wheel - ExcavatorDocument24 pagesCaterpillar M320D Wheel - ExcavatorЮлия Дам100% (5)

- Hydraulic Shovel and Backhoe ExcavatorDocument8 pagesHydraulic Shovel and Backhoe ExcavatorAndi Wardiman AnwarPas encore d'évaluation

- Efficiency Parameters of Earth Moving Equipments For Determining OutputDocument129 pagesEfficiency Parameters of Earth Moving Equipments For Determining Outputcoepcesa75% (8)

- Excavation Force CalculationDocument7 pagesExcavation Force CalculationJose FisherPas encore d'évaluation

- Design Calculation & AnalysisDocument13 pagesDesign Calculation & AnalysisAbel Meketa100% (1)

- Uputstvo Za Beton PumpuDocument155 pagesUputstvo Za Beton PumpuPredrag StojanovicPas encore d'évaluation

- Hydraulic Cylinder BucklingDocument3 pagesHydraulic Cylinder Bucklingprajakt_pie100% (1)

- Specifications of LHDS: 1St ND RD THDocument3 pagesSpecifications of LHDS: 1St ND RD THSushant0% (1)

- Road Note 31 AssignmentDocument6 pagesRoad Note 31 AssignmentJayath BogahawattePas encore d'évaluation

- MIMOA2A2M (Yellow Parts)Document6 pagesMIMOA2A2M (Yellow Parts)Gheorghe Claudiu100% (1)

- Concrete Technology For Concrete Pumps PDFDocument32 pagesConcrete Technology For Concrete Pumps PDFTran Huynh Nam100% (2)

- Optimization of Telescopic BoomDocument6 pagesOptimization of Telescopic BoomVinod YbPas encore d'évaluation

- Liebherr Plant 0001 - 04 - 05 - 16022016 - en - 820295005 - 122020 - DWDocument172 pagesLiebherr Plant 0001 - 04 - 05 - 16022016 - en - 820295005 - 122020 - DWMohamed Nasr100% (2)

- Frequency Converter English ManualDocument33 pagesFrequency Converter English Manualproduccion multipack100% (2)

- Liebher MixerDocument322 pagesLiebher MixerMohamed Nasr100% (1)

- Assembly Transmission 777DDocument62 pagesAssembly Transmission 777DKeron TrotzPas encore d'évaluation

- Volume1 Introduction To Hydraulic PressesDocument33 pagesVolume1 Introduction To Hydraulic PressesShirdish Patil100% (1)

- Volvo Hydraulic Hammer PDFDocument6 pagesVolvo Hydraulic Hammer PDFrammysi100% (1)

- DM 30 Asphalt PlantDocument4 pagesDM 30 Asphalt PlantTheodore Teddy KahiPas encore d'évaluation

- Structural Analysis-2Document2 pagesStructural Analysis-2Vinita Verma100% (1)

- JCB EscavadeiraDocument16 pagesJCB EscavadeiraExperiencia onePas encore d'évaluation

- Sany HBT80C-1818DIIIDocument1 pageSany HBT80C-1818DIIIGayashan KulathungaPas encore d'évaluation

- Bolts and Bolt TorqueDocument1 pageBolts and Bolt TorqueRichard ChuaPas encore d'évaluation

- PSM 8Document5 pagesPSM 8Salvatore MirandaPas encore d'évaluation

- KCP Heavy Industries Co., LTDDocument21 pagesKCP Heavy Industries Co., LTDPor Pengleng100% (1)

- Hydropneumatic PresentationDocument17 pagesHydropneumatic PresentationRohit SharmaPas encore d'évaluation

- BD80 PDFDocument4 pagesBD80 PDFMd Shahnawaz IslamPas encore d'évaluation

- Liebherr Truck Mounted Concrete Pumps en PDFDocument16 pagesLiebherr Truck Mounted Concrete Pumps en PDFRidwanda HimawanPas encore d'évaluation

- YK60 Portable Line BoringDocument4 pagesYK60 Portable Line BoringAnonymous Jg8w6EEBAPas encore d'évaluation

- WMM Plant MaconsDocument2 pagesWMM Plant Maconsharikrishna007Pas encore d'évaluation

- 9402a2803df0c0c2eb651732092f0185Document6 pages9402a2803df0c0c2eb651732092f0185Edwin TobarPas encore d'évaluation

- 1.fundamentals of Earth Moving (COMPRESSED As HANDOUT)Document3 pages1.fundamentals of Earth Moving (COMPRESSED As HANDOUT)neok3Pas encore d'évaluation

- Hydraulic Drive SystemDocument23 pagesHydraulic Drive Systemsitiajaar100% (1)

- 1 DX450 SCT Leaflet en W3636Document4 pages1 DX450 SCT Leaflet en W3636Jonathan Alexis Quispe HuamaniPas encore d'évaluation

- DESIGN AND ANALYSIS OF HYDRAULIC POWERPACK AND PUMcalculationsDocument10 pagesDESIGN AND ANALYSIS OF HYDRAULIC POWERPACK AND PUMcalculationssubhasPas encore d'évaluation

- Som-Ii Uqb 2019-20Document23 pagesSom-Ii Uqb 2019-20VENKATESH METHRIPas encore d'évaluation

- Portland Bolt Bolt Torque ChartDocument6 pagesPortland Bolt Bolt Torque ChartHtet Mrak Aung100% (1)

- Eccentric Weight Housing Oil - Change: Operation and Maintenance ManualDocument3 pagesEccentric Weight Housing Oil - Change: Operation and Maintenance ManualLuis AugustoPas encore d'évaluation

- Tunnelling ExcavatorDocument9 pagesTunnelling ExcavatortkujunPas encore d'évaluation

- Features of Calculating The Working Mechanism of An ExcavatorDocument4 pagesFeatures of Calculating The Working Mechanism of An Excavatormanjunath k sPas encore d'évaluation

- Sp4800 Sp8800 FlipbookDocument6 pagesSp4800 Sp8800 FlipbookTimothy Mcmillan100% (1)

- Control Valve (Boom Lowering)Document6 pagesControl Valve (Boom Lowering)john ayengahPas encore d'évaluation

- Linear Hydraulic CircuitsDocument11 pagesLinear Hydraulic CircuitsBetileno QuadAlexPas encore d'évaluation

- s32x s36x BrochureDocument6 pagess32x s36x Brochurebeto pagoadaPas encore d'évaluation

- 10 Mpa Single Acting Uniform Speed Rod Action 2-Stage Telescopic CylindersDocument10 pages10 Mpa Single Acting Uniform Speed Rod Action 2-Stage Telescopic CylindersĐen BáoPas encore d'évaluation

- Super Magnet Braking System (Report) PDFDocument57 pagesSuper Magnet Braking System (Report) PDFsrinivasarao katari100% (2)

- Escort Compactor Ec 5250Document2 pagesEscort Compactor Ec 5250Felix Sanders100% (3)

- Zenith-913 en PDFDocument4 pagesZenith-913 en PDFLucky TraderPas encore d'évaluation

- S36X Bro2013 PDFDocument4 pagesS36X Bro2013 PDFBagoes SetiawanePas encore d'évaluation

- Placing Systems CT4524 AUSDocument14 pagesPlacing Systems CT4524 AUSemadnaguibPas encore d'évaluation

- Concreet PlantDocument13 pagesConcreet PlantJayath BogahawattePas encore d'évaluation

- Course Elements Library AMVE 30-06-2016 - WWWDocument4 pagesCourse Elements Library AMVE 30-06-2016 - WWWJayath BogahawattePas encore d'évaluation

- Tesco 2022 Ar Primary StatementsDocument5 pagesTesco 2022 Ar Primary StatementsJayath BogahawattePas encore d'évaluation

- Robotic Process Automation in Healthcare-A ReviewDocument4 pagesRobotic Process Automation in Healthcare-A ReviewJayath Bogahawatte0% (1)

- Machine Movement Upto 30 September 2021Document79 pagesMachine Movement Upto 30 September 2021Jayath BogahawattePas encore d'évaluation

- Japan Car Database by Teoalida SAMPLEDocument50 pagesJapan Car Database by Teoalida SAMPLEJayath BogahawattePas encore d'évaluation

- MA1013B Syllabus 16S1Document1 pageMA1013B Syllabus 16S1Jayath BogahawattePas encore d'évaluation

- BF600C - Electrical DiagramDocument5 pagesBF600C - Electrical DiagramJayath BogahawattePas encore d'évaluation

- Texatherm Texaco PDFDocument4 pagesTexatherm Texaco PDFJayath BogahawattePas encore d'évaluation

- Design and Construction of An Automatic Transfer Switch For A Single Phase Power GeneratorDocument9 pagesDesign and Construction of An Automatic Transfer Switch For A Single Phase Power GeneratorJayath BogahawattePas encore d'évaluation

- Notice: Configuration MenuDocument10 pagesNotice: Configuration MenuJayath BogahawattePas encore d'évaluation

- FKS C102 PDFDocument4 pagesFKS C102 PDFJayath BogahawattePas encore d'évaluation

- Finite Lanka (PVT) LTDDocument1 pageFinite Lanka (PVT) LTDJayath BogahawattePas encore d'évaluation

- Control Diagram 2: Stop Push Button PFR Flow Switch Level Control Relay Pressure Cutoff SwitchDocument1 pageControl Diagram 2: Stop Push Button PFR Flow Switch Level Control Relay Pressure Cutoff SwitchJayath BogahawattePas encore d'évaluation

- Split Casing PumpDocument1 pageSplit Casing PumpJayath BogahawattePas encore d'évaluation

- Uv Installation and MaintenanceDocument8 pagesUv Installation and MaintenanceJayath BogahawattePas encore d'évaluation

- Programming: Menu StructureDocument3 pagesProgramming: Menu StructureJayath BogahawattePas encore d'évaluation

- General Stores Ledger: General Item Code General Item NameDocument2 pagesGeneral Stores Ledger: General Item Code General Item NameJayath BogahawattePas encore d'évaluation

- Breakdown Service RecordDocument1 pageBreakdown Service RecordJayath BogahawattePas encore d'évaluation

- Invertek Drives Optidrive E2 ManualDocument28 pagesInvertek Drives Optidrive E2 ManualJayath BogahawattePas encore d'évaluation

- Electrical SystemsDocument44 pagesElectrical SystemsJayath BogahawattePas encore d'évaluation

- HempalDocument1 pageHempalJayath BogahawattePas encore d'évaluation

- Engine Torque, Power and Mean Piston SpeedDocument13 pagesEngine Torque, Power and Mean Piston SpeedJayath BogahawattePas encore d'évaluation

- 1.2. Mechanical Design ConsiderationsDocument16 pages1.2. Mechanical Design ConsiderationsJayath BogahawattePas encore d'évaluation

- 1.1 Introduction To KennametalDocument40 pages1.1 Introduction To KennametalVig PankajPas encore d'évaluation

- Need For Advanced Suspension SystemsDocument10 pagesNeed For Advanced Suspension SystemsIQPC GmbHPas encore d'évaluation

- PositioningDocument2 pagesPositioningKishan AndurePas encore d'évaluation

- Ield Methods: A Typical Field Mapping Camp in The 1950sDocument4 pagesIeld Methods: A Typical Field Mapping Camp in The 1950sshivam soniPas encore d'évaluation

- 5 160 1 PBDocument13 pages5 160 1 PBLotkomoaidone Harahu TukambaPas encore d'évaluation

- Wisconsin Construction Specification 23. Aluminum or Steel Roof GuttersDocument5 pagesWisconsin Construction Specification 23. Aluminum or Steel Roof GuttersAntonio PagaPas encore d'évaluation

- Excretory Products and Their EliminationDocument13 pagesExcretory Products and Their Eliminationaravind kishanPas encore d'évaluation

- A Collection of Ideas For The Chemistry Classroom by Jeff HepburnDocument14 pagesA Collection of Ideas For The Chemistry Classroom by Jeff HepburnPaul SchumannPas encore d'évaluation

- Nitofloor NDocument3 pagesNitofloor Nkiranmisale7Pas encore d'évaluation

- What A Wonderful WorldDocument3 pagesWhat A Wonderful Worldapi-333684519Pas encore d'évaluation

- No Client Too Far: Flexible Antenna Options TDMA GPS Sync ClientDocument2 pagesNo Client Too Far: Flexible Antenna Options TDMA GPS Sync ClientFelix MartinezPas encore d'évaluation

- 4MA0 4H MSC 20140306Document14 pages4MA0 4H MSC 20140306HaiqaPervezPas encore d'évaluation

- Exploded View & Parts Listing Air Operated Double Diaphragm PumpDocument2 pagesExploded View & Parts Listing Air Operated Double Diaphragm PumpCarlos AvalosPas encore d'évaluation

- مشخصات فنی بیل بکهو فیات کوبلکو b200Document12 pagesمشخصات فنی بیل بکهو فیات کوبلکو b200Maryam0% (1)

- Air System Sizing Summary For NIVEL PB - Zona 1Document1 pageAir System Sizing Summary For NIVEL PB - Zona 1Roger PandoPas encore d'évaluation

- Commercial Kitchen Fire InvestigationsDocument6 pagesCommercial Kitchen Fire InvestigationsBen ConnonPas encore d'évaluation

- WL4000Document1 pageWL4000Laser PowerPas encore d'évaluation

- Etl 213-1208.10 enDocument1 pageEtl 213-1208.10 enhossamPas encore d'évaluation

- Pelton2014 Para-Equilibrium Phase DiagramsDocument7 pagesPelton2014 Para-Equilibrium Phase DiagramsAbraham Becerra AranedaPas encore d'évaluation

- Science: The Menstrual CycleDocument4 pagesScience: The Menstrual CycleLena Beth Tapawan YapPas encore d'évaluation

- Syllabus (402050B) Finite Element Analysis (Elective IV)Document3 pagesSyllabus (402050B) Finite Element Analysis (Elective IV)shekhusatavPas encore d'évaluation

- Lecture 1 - Reinforced Concrete - IntroductionDocument62 pagesLecture 1 - Reinforced Concrete - IntroductionChristopher PaladioPas encore d'évaluation

- Editor: Lalsangliana Jt. Ed.: H.Document4 pagesEditor: Lalsangliana Jt. Ed.: H.bawihpuiapaPas encore d'évaluation

- Radiation Formula SheetDocument5 pagesRadiation Formula SheetJakeJosephPas encore d'évaluation

- Pertanyaan TK PDBDocument4 pagesPertanyaan TK PDBHardenPas encore d'évaluation

- Sikagrout®-214 Ae: Product Data SheetDocument3 pagesSikagrout®-214 Ae: Product Data Sheetmohammed rinshinPas encore d'évaluation

- DLL - Mapeh 6 - Q2 - W8Document6 pagesDLL - Mapeh 6 - Q2 - W8Joe Marie FloresPas encore d'évaluation