Académique Documents

Professionnel Documents

Culture Documents

RLC4PCING

Transféré par

Kaiser IqbalCopyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

RLC4PCING

Transféré par

Kaiser IqbalDroits d'auteur :

Formats disponibles

RLC4

ELECTRONIC RELAY FOR FUEL LEVEL AND PUMP CONTROL

FUEL LEVEL CONTROL

SINPLIFIES THE INSTALLATION OF THE TRANSFER SYSTEMS FOR

SUPPLYING GENERATING SETS

ONLY ONE FLOAT AS A LEVEL INDICATING INSTRUMENT

MANUAL AND AUTOMATIC DRIVE OF THE POMP

VISUALIZATION OF THE SYSTEM’S STATE

FILE VER. DATE LANGUAGE PAGE

RLC4PCING B/03 24/01/0706/03/01 ING 1 of 5

COMPOSITION

RLC4 consists in an electronic circuit board, which controls the levels of pump performance. The

following is found on the front of the RLC4 instrument:

1. A bar of 12 LED which indicate the fuel level (each LED is equal to 1/12 of the maximum level);

2. System status indicator LED;

3. A three-position switch for the operating mode selection.

On the back of the instrument:

1. Two jumpers for the selection of the type of maximum level marker contact;

2. DIP switch for the pump starting and stopping levels selection;

3. Two trimmers to adjust the minimum and maximum level of the tank (preset and to be adjusted

only if necessary);

4. Two jumpers to select the type of float (VDO or VEGLIA BORLETTI);

5. A 10-pole connector for its connection and a 500mA safety fuse.

OPERATING PRINCIPLES

RLC4 is designed to operate in two modes, which can be selected using the following switches:

AUTOMATIC: automatic operating;

0: the pump is completely disconnected;

MANUAL: manual operating. This is not a fixed position. The system returns to the 0 position

as soon as the switch is released.

AUTOMATIC OPERATING MODE

An electric signal associated with an electric circuit is received by the float, which controls the level

indicating instrument and activates a relay and three transistor outputs depending on the level.

These outputs supply the following commands:

• Pump starting and stopping (transistor);

• Reserve level (transistor);

• No fuel level (transistor);

• Safety solenoid valve (16A relay).

The above commands have the following performance sequence:

When the level falls between 8 and 4/12 (2/3 and 1/3) of the maximum level, the pump power

transistor is activated (pump command), together with the pilot relay of the safety solenoid valve;

If the pump does not start in correspondence to 3/12 (1/4) of the level, the level continues to fall,

which enables the fuel reserve transistor pre-alarm when the level reaches 2/12 (1/6) of the level;

When the pump starts, the level is restored until it reaches 9/12 - 12/12 (3/4 - 1) of the maximum

level: the pump is then stopped and the solenoid valve disabled.

MANUAL OPERATING MODE

When the switch is set in the MANUAL position, the pump is started and stops automatically when

the switch is released. A safety device is active, which controls the stoppage of the pump as soon

as the maximum level is reached even if the switch is pressed.

FILE VER. DATE LANGUAGE PAGE

RLC4PCING B/03 24/01/0706/03/01 ING 2 of 5

SIGNALS

SYMBOLS DESCRIPTION

MAXIMUM LEVEL

PUMP ON

PUMP OFF

THERMAL RELEASE

FUEL RESERVE

NO FUEL

FUEL LEVEL: indicates the level by means of the 12 yellow LED bar.

MAXIMUM LEVEL: indicates the status by means of a red LED; the safety stoppage of the

pump is also performed.

POMP ON: indicates that the pump is working by means of a green LED.

POMP OFF: indicates that the pump is not working by means of a red LED.

THERMAL RELEASE: indicates that the thermal safety device is enabled by means of a red

LED and the pump stops.

FUEL RESERVE: indicates the reserve status by means of a yellow LED.

NO FUEL: indicates no fuel by means of a red LED.

CONNECTIONS

For the power and service supply to the RLC4 module, see the connection diagram in

Fig. 4

PROGRAMMING

Level selection switch: for the related setting, see the performance programming in Fig. 3.

NO/NC maximum level contact selection jumpers: if the system is supplied with the

maximum level contact normally closed, cut the two MAX LEV NC jumpers, on the back of

the RLC4 circuit board, as indicated in Fig. 2.

Floating selection Jumper: see the related setting as in the drawing below:

FLOAT

VDO (0-180 ohm) VEGLIA BORLETTI (200-0 ohm) VDO VEGLIA

MAX 180 Ohm 0 Ohm

J1 J1

J2 J2

MIN 0 Ohm 200 Ohm

FILE VER. DATE LANGUAGE PAGE

RLC4PCING B/03 24/01/0706/03/01 ING 3 of 5

TECHNICAL FEATURES

RLC4 is ideal for reading signals received from the transducer with 0 ohm minimum level resistance and 180/200ohm

maximum level (VDO) or inverted function (VEGLIA BORLETTI). RLC4 is preset to operate without a level-indicating

instrument and is protected against a power cut-out and a power cut-out of the level conductor which control the

pump stoppage (VDO position).

• POWER SUPPLY: 12/24V

• ABSORBED POWER: 300 mA

• OUTPUT CAPACITY:

♦ 8 PUMP POWER SUPPLY 250mA

♦ 4 FUEL SUPPLY REMOTE REPEATER 250mA

♦ 5 NO FUEL REMOTE REPEATER 250mA

♦ 6 SAFETY SOLENOID VALVE 16A

• 8 LEVEL PROGRAMMING SWITCH

• FLOAT CUTOUT PROTECTION (VDO position)

• STANDARD VDO CONFIGURATION

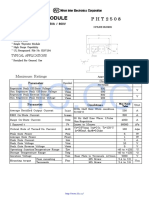

FIG. 1: FRONT VIEW RLC4 FIG. 2: REAR VIEW RLC4

CONNECTOR

JUMPERS TO BE

CUT FOR THE FUSE 1A

MAX NC LEVEL

FIG. 3: PUMP PERFORMANCE PROGRAMMING

RLC4

TABELLA SWITCH PROGRAMMING

PROGRAMMAZIONE TABLE RLC4

SWITCH

SWITCH N. 1 2 3 4 5 6 7 8

MASSIMO

MAX. 12

LIVELLO

LEVEL 1 11

1 10

1 9

1 8

1 7

1 6

1 5

1 4

3

MIN.

LIVELLO 2

LEVEL

MINIMO 1

1=ON INSERIMENTO

PUMP ARRESTO

PUMP STOP

0=OFF START

POMPA POMPA

EXAMPLE

Releasing the switch:

n. 2 the pump starts at level 5;

n. 7 the pump stops at level 10.

FILE VER. DATE LANGUAGE PAGE

RLC4PCING B/03 24/01/0706/03/01 ING 4 of 5

RLC4

RLC4 CONNECTION DIAGRAM

*NOTE: KEY

Bond 1 with 2 K1: FUEL RESERVE RELAY

for 12 Vd.c K2: NO FUEL RELAY

power K3: PUMP CONTROL RELAY

supply. EV: SAFETY SOLENOID VALVE

Supply 2 with

ML: MAX. LEVEL CONTACT

24V.

LC: LEVEL TRANSDUCER

ST: THERMAL RELEASE

ATTENTION

THE 4-5-8 OUTPUTS ARE CONTROLLED BY

TRANSISTORS (NPN) AND ARE THEREFORE

NOT PROTECTED BY OVERLOAD OR SHORT

CIRCUIT DEVICES.

MOTOR

EARTH

PUMP

FILE VER. DATE LANGUAGE PAGE

RLC4PCING B/03 24/01/0706/03/01 ING 5 of 5

Vous aimerez peut-être aussi

- Wire EDM Components For:: Brand Machine ToolsDocument15 pagesWire EDM Components For:: Brand Machine ToolsHossein VahediPas encore d'évaluation

- Hi-TECH 230-4 (9.0)Document100 pagesHi-TECH 230-4 (9.0)Ойген ЁхPas encore d'évaluation

- FI 240: Chapter 3: Axis XY-Z / UV: Scale Ls476C Z Scale Cable Pair Ofsliding 20X300Document12 pagesFI 240: Chapter 3: Axis XY-Z / UV: Scale Ls476C Z Scale Cable Pair Ofsliding 20X300ИгорьPas encore d'évaluation

- CUT - 200 300 400 MS SP - ENDocument24 pagesCUT - 200 300 400 MS SP - ENMoustaffaPas encore d'évaluation

- Tnc 135 Точка По ТочкаDocument21 pagesTnc 135 Точка По ТочкаaLexusPas encore d'évaluation

- THGT Series: Cylindrical Cased Axial Flow FansDocument42 pagesTHGT Series: Cylindrical Cased Axial Flow Fanszeljkogr100% (1)

- Syntec CNC Alarm ManualDocument664 pagesSyntec CNC Alarm ManualAimanPas encore d'évaluation

- SINUMERIK 840C Software Version 6. Start-Up Difference Description OEM Version For Windows TM. Manufacturer Documentation PDFDocument112 pagesSINUMERIK 840C Software Version 6. Start-Up Difference Description OEM Version For Windows TM. Manufacturer Documentation PDFSergio Trujillo CerroPas encore d'évaluation

- Siemense CNC 48SP2Document19 pagesSiemense CNC 48SP2Xaoc KabataPas encore d'évaluation

- Add Info B-65285EN 04Document86 pagesAdd Info B-65285EN 04clausPas encore d'évaluation

- RCEG-12 Assembly Drawings and SchematicsDocument121 pagesRCEG-12 Assembly Drawings and SchematicsEnrique Martinez RojasPas encore d'évaluation

- Fbox Series Instruction Manual: 二、InstallationDocument6 pagesFbox Series Instruction Manual: 二、Installationbassit82Pas encore d'évaluation

- 4 - Torre Duplomatic ODTN-20Document33 pages4 - Torre Duplomatic ODTN-20Luiz Gustavo PastrelloPas encore d'évaluation

- MT S4000 EngDocument8 pagesMT S4000 Engsamet gozubolPas encore d'évaluation

- Set CNC machine parametersDocument3 pagesSet CNC machine parametersLio SnPas encore d'évaluation

- capto主轴标准Document87 pagescapto主轴标准中国心Pas encore d'évaluation

- Details PDF: Image Part Number Description Manufacturer QtyDocument1 pageDetails PDF: Image Part Number Description Manufacturer QtyPaulo Henrique Valério100% (1)

- AgieCharmile SP1UDocument20 pagesAgieCharmile SP1URezza KudoPas encore d'évaluation

- 1 Smart HW IntroductionDocument13 pages1 Smart HW Introductiongopikrishna.schunkPas encore d'évaluation

- Resistance Thermometer AB-E 31-17: 1 Area of ApplicationDocument3 pagesResistance Thermometer AB-E 31-17: 1 Area of Applicationhagg0% (1)

- Laser Cutting LVDDocument12 pagesLaser Cutting LVDPri HongPas encore d'évaluation

- GENOS L2000 L3000 e OEG E - 1 - 100 - Aug2017 - PDFDocument13 pagesGENOS L2000 L3000 e OEG E - 1 - 100 - Aug2017 - PDFنعيم سعيدPas encore d'évaluation

- Baldor - Spindle Drive Instructions, 7500 WD Tuning v11-4Document7 pagesBaldor - Spindle Drive Instructions, 7500 WD Tuning v11-4Asif JamilPas encore d'évaluation

- Trumatic L 2530 TRUMPF BrochureDocument9 pagesTrumatic L 2530 TRUMPF BrochureJose DiasPas encore d'évaluation

- Agiecharmilles Cut 20p 30p - enDocument20 pagesAgiecharmilles Cut 20p 30p - enMark Hahn0% (1)

- Heavy Weight Drill Pipe Data ChartDocument1 pageHeavy Weight Drill Pipe Data ChartMachx MasterPas encore d'évaluation

- 61393e OModelCD (107 197)Document91 pages61393e OModelCD (107 197)25 HanhaPas encore d'évaluation

- Gorenje Tiki TGRDocument32 pagesGorenje Tiki TGRmiroslavPas encore d'évaluation

- SF-2200H Operating ManualDocument36 pagesSF-2200H Operating ManualuripssPas encore d'évaluation

- FSG 2040 2060 2440 2460 2480adiiDocument12 pagesFSG 2040 2060 2440 2460 2480adiiMohamed ShabanPas encore d'évaluation

- Fagor 800T Manual 2 PDFDocument224 pagesFagor 800T Manual 2 PDFniksa77Pas encore d'évaluation

- Laptop For Debug: AheadtechsDocument6 pagesLaptop For Debug: AheadtechsshrusPas encore d'évaluation

- KellenbergerDocument44 pagesKellenbergerAminPas encore d'évaluation

- 6ra 2620 6d v57 1a Z Simoreg d38035 Siemens Manual 02Document18 pages6ra 2620 6d v57 1a Z Simoreg d38035 Siemens Manual 02Stefan IstratescuPas encore d'évaluation

- ALARM 998 (Rom Parity Error) : Cause and Corrective ActionDocument1 pageALARM 998 (Rom Parity Error) : Cause and Corrective ActionPalaniappan SolaiyanPas encore d'évaluation

- S7-1200 1215CDocument16 pagesS7-1200 1215CGeorge G100% (1)

- ToolingDocument52 pagesToolingcmgankl0% (1)

- Enable-Disable 4 Axis ParameterDocument1 pageEnable-Disable 4 Axis ParameterАндрей КузьменкоPas encore d'évaluation

- Tsugami B0205 206 III Focus BrochureDocument8 pagesTsugami B0205 206 III Focus BrochureBakhtiar Permana50% (2)

- HP-QB Manual-07Document121 pagesHP-QB Manual-07Anonymous m6yoprE9zPas encore d'évaluation

- Colchester LathesDocument7 pagesColchester LathesAndrew ParrottPas encore d'évaluation

- Fanuc Drive AlramDocument4 pagesFanuc Drive AlrammntcepplPas encore d'évaluation

- REO MFS 268 IP 20, XL, XXL Manual - NewDocument18 pagesREO MFS 268 IP 20, XL, XXL Manual - NewAlejandroPas encore d'évaluation

- DRIVE CLiQ ConnectionDocument1 pageDRIVE CLiQ ConnectionAnh HoàngPas encore d'évaluation

- Armorstart LT Distributed Motor Controllers: Selection GuideDocument60 pagesArmorstart LT Distributed Motor Controllers: Selection GuideYeltsin MunivePas encore d'évaluation

- Siemense SM 06 04 23 76Document17 pagesSiemense SM 06 04 23 76skidamdnevnoPas encore d'évaluation

- Parameter Manual Part 1Document474 pagesParameter Manual Part 1giuseppe abatiPas encore d'évaluation

- Basic 840D SL Control Manual V0 R1 (04!1!2015)Document20 pagesBasic 840D SL Control Manual V0 R1 (04!1!2015)Dawitt BadilloPas encore d'évaluation

- M.RT2261 (Without Audio) PDFDocument9 pagesM.RT2261 (Without Audio) PDFНиколайPas encore d'évaluation

- 810 GA1 Installation InstructionsDocument292 pages810 GA1 Installation InstructionstouchmemoryPas encore d'évaluation

- Bobcat - tl360 TL470Document16 pagesBobcat - tl360 TL470YakupovmmPas encore d'évaluation

- PHT2508CFDocument5 pagesPHT2508CFArnulfo Muñoz FraustoPas encore d'évaluation

- LL1302 40011-ProgramareDocument60 pagesLL1302 40011-ProgramareSzaby Kalman100% (1)

- User Manual of Macro V2.0Document31 pagesUser Manual of Macro V2.0Alex MazurPas encore d'évaluation

- Wiring Milling SZGHDocument13 pagesWiring Milling SZGHCipta Otomasi Indonesia COIPas encore d'évaluation

- User Manual-MACH3-MKX-V1.0Document40 pagesUser Manual-MACH3-MKX-V1.0Daniel NituPas encore d'évaluation

- DCS - Safety SignalsDocument25 pagesDCS - Safety SignalsJehan AICPas encore d'évaluation

- SZGH CNC 1000TDbDocument119 pagesSZGH CNC 1000TDbMaya Mayoshka0% (1)

- Instructions and Advices To Use The Electronic Controller Logik 8Document13 pagesInstructions and Advices To Use The Electronic Controller Logik 8sebastianPas encore d'évaluation

- CAT CG132 Series Gas Generator Sets - LEBE0015-01Document8 pagesCAT CG132 Series Gas Generator Sets - LEBE0015-01maggioraPas encore d'évaluation

- Oandm Manual Mec 100 Digital Voltage RegulatorDocument248 pagesOandm Manual Mec 100 Digital Voltage RegulatorKaiser IqbalPas encore d'évaluation

- How You Can Transform Yourself To The Leadership Level and Excel in Your CareerDocument30 pagesHow You Can Transform Yourself To The Leadership Level and Excel in Your CareerKaiser IqbalPas encore d'évaluation

- E0834 COP En-09 2010 PDFDocument4 pagesE0834 COP En-09 2010 PDFKaiser IqbalPas encore d'évaluation

- Dual Fuel EnginesDocument1 pageDual Fuel EnginesKaiser IqbalPas encore d'évaluation

- Engine Air Filtration (English)Document2 pagesEngine Air Filtration (English)Kaiser IqbalPas encore d'évaluation

- V12 Gas Engine For Cogeneration Plants: MAN Nutzfahrzeuge GroupDocument4 pagesV12 Gas Engine For Cogeneration Plants: MAN Nutzfahrzeuge GroupKaiser IqbalPas encore d'évaluation

- 6-Cylinder Gas Engine For CHP.: MAN NutzfahrzeugeDocument4 pages6-Cylinder Gas Engine For CHP.: MAN NutzfahrzeugeKaiser IqbalPas encore d'évaluation

- V12 Gas Engine For CHP.: MAN NutzfahrzeugeDocument4 pagesV12 Gas Engine For CHP.: MAN NutzfahrzeugeKaiser IqbalPas encore d'évaluation

- V8 Gas Engine Powers Cogeneration PlantsDocument4 pagesV8 Gas Engine Powers Cogeneration PlantsKaiser IqbalPas encore d'évaluation

- Highly Efficient V8 Gas Engine for CHP Plants (E2848Document4 pagesHighly Efficient V8 Gas Engine for CHP Plants (E2848Kaiser IqbalPas encore d'évaluation

- Diagrams.: 2130 Shown Connected As 4 Digital Inputs and 4 Analogue InputsDocument1 pageDiagrams.: 2130 Shown Connected As 4 Digital Inputs and 4 Analogue InputsKaiser IqbalPas encore d'évaluation

- Multi Point AnimationDocument1 pageMulti Point AnimationKaiser IqbalPas encore d'évaluation

- Guascor Special Offer Parts List Under €1 EachDocument1 pageGuascor Special Offer Parts List Under €1 EachKaiser IqbalPas encore d'évaluation

- Ddec I Ii Iii IvDocument2 pagesDdec I Ii Iii IvKaiser IqbalPas encore d'évaluation

- IG Switchboard 02-09-13 MH en Appl SampleDocument1 pageIG Switchboard 02-09-13 MH en Appl SampleKaiser IqbalPas encore d'évaluation

- 3bD8dEX Grupo GuascorDocument2 pages3bD8dEX Grupo GuascorKaiser IqbalPas encore d'évaluation

- Single PointDocument1 pageSingle PointKaiser Iqbal0% (1)

- IG Urania 02-09-13 MH en Appl - SampleDocument1 pageIG Urania 02-09-13 MH en Appl - SampleKaiser IqbalPas encore d'évaluation

- Multi PointDocument1 pageMulti PointKaiser IqbalPas encore d'évaluation

- Hs ConversionDocument4 pagesHs ConversionKaiser IqbalPas encore d'évaluation

- PLTD Tarakan: Conversion of Engines To Dual Fuel OperationDocument4 pagesPLTD Tarakan: Conversion of Engines To Dual Fuel OperationKaiser IqbalPas encore d'évaluation

- Conversion of Low Speed Engines To Dual Fuel Operation: July 2005Document4 pagesConversion of Low Speed Engines To Dual Fuel Operation: July 2005Kaiser IqbalPas encore d'évaluation

- IG Greenbird 02 09 13 MH en Appl - Sample PDFDocument1 pageIG Greenbird 02 09 13 MH en Appl - Sample PDFKaiser IqbalPas encore d'évaluation

- Ces Conversion IpsDocument8 pagesCes Conversion IpsKaiser IqbalPas encore d'évaluation

- ID-Pump HTDocument1 pageID-Pump HTKaiser IqbalPas encore d'évaluation

- Ces Alkem NigerieDocument4 pagesCes Alkem NigerieKaiser IqbalPas encore d'évaluation

- Automatic Fuel Shut Down ValveDocument2 pagesAutomatic Fuel Shut Down ValveKaiser IqbalPas encore d'évaluation

- IG Rossi 03-03-14 MH Appl - Sample 1Document1 pageIG Rossi 03-03-14 MH Appl - Sample 1Kaiser IqbalPas encore d'évaluation

- Data Sheet 06-11-10 Bs CMEDocument4 pagesData Sheet 06-11-10 Bs CMEKaiser IqbalPas encore d'évaluation

- FM200 KiddeDocument37 pagesFM200 KiddeNguyen Van TuanPas encore d'évaluation

- BA RMV-II enDocument43 pagesBA RMV-II enalejo1707Pas encore d'évaluation

- Sigma Control 2 9 - 9450 - 00use-Tcm8-285058Document204 pagesSigma Control 2 9 - 9450 - 00use-Tcm8-285058francisseePas encore d'évaluation

- ACB Protective RelayDocument6 pagesACB Protective RelayUrsula JohnsonPas encore d'évaluation

- P1457 2010apr B Relay VitalDocument226 pagesP1457 2010apr B Relay VitalElton RibeiroPas encore d'évaluation

- Test System Combitest: FeaturesDocument12 pagesTest System Combitest: FeaturesleonardoPas encore d'évaluation

- SSR-3 Installation Instructions EnglishDocument2 pagesSSR-3 Installation Instructions EnglishMaciejPas encore d'évaluation

- Siclock TC400Document4 pagesSiclock TC400RudaSepčićPas encore d'évaluation

- Automatic Voltage Stabilizer With PIC16F873ADocument21 pagesAutomatic Voltage Stabilizer With PIC16F873Atahmidmc92% (25)

- 345b Excavator Electrical System Schematic Used in Service Manual Renr1900 - Caterpillar Machinery Repair & TroubleshootingDocument5 pages345b Excavator Electrical System Schematic Used in Service Manual Renr1900 - Caterpillar Machinery Repair & TroubleshootingWilliams Burgos67% (3)

- Codigos Chrysler y Dodge 2001 en AdelanteDocument3 pagesCodigos Chrysler y Dodge 2001 en AdelanteManuel HernándezPas encore d'évaluation

- LS2000 Infrared Hydrocarbon Gas DetectorDocument2 pagesLS2000 Infrared Hydrocarbon Gas DetectorRomdhoni Widyo BaskoroPas encore d'évaluation

- PNEUMATİCDocument13 pagesPNEUMATİCAyşenur ÇetinPas encore d'évaluation

- 09b DesignDevConstructionofaLowCostAutomatic2KVAInvSyst PDFDocument13 pages09b DesignDevConstructionofaLowCostAutomatic2KVAInvSyst PDFChela MaceasPas encore d'évaluation

- VS1ST Manual de InstalaciónDocument72 pagesVS1ST Manual de InstalaciónJesus Lopez100% (1)

- b0193wv KDocument150 pagesb0193wv KRoberto MedinaPas encore d'évaluation

- LED Multifunctional Power InstrumentDocument28 pagesLED Multifunctional Power InstrumentPurevee PureveePas encore d'évaluation

- Manual LADY PIDocument5 pagesManual LADY PICameliaPas encore d'évaluation

- 2015 + Mitsubishi Mirage (Dodge Attitude) 1.2 PDFDocument248 pages2015 + Mitsubishi Mirage (Dodge Attitude) 1.2 PDFSergio GarciaPas encore d'évaluation

- ABB Pluggable Interface Relays, CR-P, CR-M & CR-U RangeDocument16 pagesABB Pluggable Interface Relays, CR-P, CR-M & CR-U RangeEliasPas encore d'évaluation

- Danfoss ECL ConfortDocument23 pagesDanfoss ECL Confortbvd360Pas encore d'évaluation

- THERMOVAC Transmitter: TTR 91, TTR 91 S TTR 96 SDocument4 pagesTHERMOVAC Transmitter: TTR 91, TTR 91 S TTR 96 Smayito12093120Pas encore d'évaluation

- Universal Relay Family: GE Consumer & IndustrialDocument22 pagesUniversal Relay Family: GE Consumer & IndustrialJulio Antonio Bastías VargasPas encore d'évaluation

- Heating Selection GuideDocument3 pagesHeating Selection GuideAdam Thong Chee HungPas encore d'évaluation

- Grounddistancerelays Residualcompensation PDFDocument13 pagesGrounddistancerelays Residualcompensation PDFShahzadmbhattiPas encore d'évaluation

- Detcon Model TP-624D: Instruction ManualDocument45 pagesDetcon Model TP-624D: Instruction ManualMarthin PurbaPas encore d'évaluation

- Honda EM 3500 XDocument56 pagesHonda EM 3500 XDokhtar SaidiPas encore d'évaluation

- BP1-R - Reverse Power RelayDocument8 pagesBP1-R - Reverse Power RelaySaasiPas encore d'évaluation

- User Manual: HGM96XX Series (HGM9610/HGM9620) Automatic Genset ControllerDocument100 pagesUser Manual: HGM96XX Series (HGM9610/HGM9620) Automatic Genset ControllerArc HiePas encore d'évaluation

- Abb Zirconia Catalogue Ss - Az20 en - 2Document20 pagesAbb Zirconia Catalogue Ss - Az20 en - 2Abhinay SuratkarPas encore d'évaluation