Académique Documents

Professionnel Documents

Culture Documents

Stavatti Model 1338-500 13 3-8 Cementing Head System Linecard Feb 2018

Transféré par

Stavatti Aerospace LtdCopyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Stavatti Model 1338-500 13 3-8 Cementing Head System Linecard Feb 2018

Transféré par

Stavatti Aerospace LtdDroits d'auteur :

Formats disponibles

STAVATTI™ 13 3/8

13 3/8 UNIVERSAL LIFTING

TOP DRIVE SUBSEA

CEMENTING HEAD SYSTEM

SUBSEA CEMENTING HEAD With REMOTE CONTROL

13 3/8 CEMENT HEAD OVERVIEW

The Model 1338-500 is a 13 3/8 Top Drive Universal Lifting Cement Head capable

of lifting, rotating and cementing simultaneously. The 1338-500 has been DNV cer-

tified at a working pressure of 5,000 psi combined with 500 metric tons of lift.

Designed as a top drive system, the 1338-500 is relatively light and compact while

offering the highest lifting and pressure ratings in the industry.

This 1338-500 is a rotating cementing head. The 1338-500 has no welded connec-

tions and does not require any external manifolds. Instead the design accept drill-

ing fluid and cement through the swivel at the top. This allows the continuous and

independent rotation, stroking (lifting) and high flow cementing simultaneously. An

internal cage secures the plugs and allows the flow of drilling fluid around the plugs

and down into the casing. Cement then flows into the top of the head using the

same hose used for the drilling fluid. The flow of cement takes the same internal

path as the drilling fluid. When ready to cement, the lower pin puller is retracted

releasing the bottom plug from the cage, allowing it to drop. The bottom plug is

pushed downward by the force of cement flowing through the slots in the cage and

into the casing adapter. The tattle tale is then activated by the plug as it passes

down into the casing. After the desired amount of cement is pumped through the

head, the top pin puller is retracted. The spring tub automatically pushes the top

plug into the flow of drilling fluid. Drilling fluid then pushes the top plug down into

the casing adapter, activating the tattle tale as it continues to travel down into the

casing. This mechanically operated Lever Tattle Tale is available in a Flag and an

electronic indicator versions. Indicating the passage of the plug, the Tattle Tale can

be re-cocked without removal from the head. Plugs can be loaded before the job

and dropped by a manual or remote Pin Puller.

The 1338-500 cementing head is self-cleaning. The drilling fluid that follows the

cement cleans and removes residual cement, significantly decreasing maintenance

time and effort between cementing operations. The simplicity of our cement head

designs allows the cementing heads can be serviced on-site. The cementing

heads work with interchangeable casing adapters that enable usage of a single

cementing head throughout the entire cementing operation. The 1338-500 cement-

ing head can utilize bottom adapters down to 7 inches and virtually any custom

sized adapter. Standard bottom adapter sizes include 7 in, 9 5/8 in, 10 3/4 in and

13 3/8 in. When switching cementing operations to a smaller casing, one only

needs to switch the internal cage and the bottom adapter. Plug cages are easily

changed by removing the Pin Pullers and Bull Plugs that hold the cage in place,

then the cage will easily slide out of the body cavity. Plug Cages and Bottom

Adapter can be easily changed on location to meet ever changing job requirements.

Featuring the proprietary Sure Lock™ system, this breach lock style connector

enables fast, easy and secure interchangeability of top subs and casing adapters

on the cementing head body. With only a quick insertion into the cementing head

body and 45 degree turn the components lock into position. Puck Locks secure the

components allowing up to 70,000 ft-lbs of torque through the cementing head.

Optional hydraulic remote control is available for all cementing heads, eliminating

the need for manual plug or dart release.

Produced by Stavatti Industries Ltd in Strategic Partnership with Hybrid Technology,

our cementing heads have been produced for over 30 years and are deployed

around the world in the most demanding environments. All cementing heads and

related oil field tools are certified by Det Norske Veritas (DNV) and are patent pro-

tected. From our simple internal designs and innovative features, the 1338-500

Universal Lifting cementing head presents a variety of features that will simplify

your cementing operations and reduce operating costs.

FEB 2018 OIL TOOLS

STAVATTI™ 13 3/8

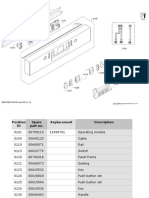

FLOW AROUND PLUG CAGE ASSEMBLIES

Cement Head Specifications

Model: 1338-500

Type: Super Sub Sea Lifting Cement Head

Casing Adapter Size: 13 3/8 in

Recommended Crossover Size: 13.750 to 7.000

Max Hook Load Capacity: 500 MT

Max Combined Hook & Pressure: 500 MT @ 5,000 psi

Max Working Pressure: 5,000 psi

Max Testing Pressure: 7,500 psi

Max Swivel RPM: 60 RPM

Min Operating Temperature: 0° C

Max Torque Through Sure Lock™: 70K RH & 70K LH

Flow Around Plug Cages: 13 3/8 in to 6 5/8 in

FLOW AREAS

Upper Sub Bore Size 4 1/4 in: 14.19 sq in

Upper Sub Flow Slots (4 Total): 15.35 sq in 13 3/8 in 9 5/8 in 7 in

Circulation Fittings-2 x 2 in 1502 (1.87 in ID): 5.49 sq in BOTTOM SUB CASING ADAPTERS

Body: Around Cage Inside 14.43 in Body Bore

7 in Thread Lower Sub (6.095 Bore): 29.16 sq in

9 5/8 in Thread Lower Sub (8.535 Bore): 57.18 sq in

10 3/4 in Thread Lower Sub (9.66 Bore): 73.25 sq in

13 3/8 in Thread Lower Sub (12.347 Bore): 119.67 sq in

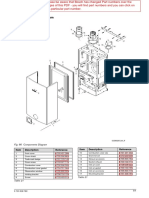

DIMENSIONS & WEIGHTS

Max Length-Triple Body Assembly: 154.4 in

Max Length-Double Body Assembly: 137.4 in

Max Weight-Triple Body Assembly: 4,581 lbs

Max Weight-Double Body Assembly: 3,918 lbs

13 3/8 in 9 5/8 in 7 in

Manufacturer: Stavatti Industries Ltd

Mail: 1443 S. Gage Street, San Bernardino, CA 92408

Tel: 909-800-6985 & 651-238-5369

STAVATTI INDUSTRIES LTD Web: www.stavatti.com/industries

FEB 2018 OIL TOOLS

Vous aimerez peut-être aussi

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)D'EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Évaluation : 4.5 sur 5 étoiles4.5/5 (119)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaD'EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaÉvaluation : 4.5 sur 5 étoiles4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingD'EverandThe Little Book of Hygge: Danish Secrets to Happy LivingÉvaluation : 3.5 sur 5 étoiles3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryD'EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryÉvaluation : 3.5 sur 5 étoiles3.5/5 (231)

- Grit: The Power of Passion and PerseveranceD'EverandGrit: The Power of Passion and PerseveranceÉvaluation : 4 sur 5 étoiles4/5 (587)

- Never Split the Difference: Negotiating As If Your Life Depended On ItD'EverandNever Split the Difference: Negotiating As If Your Life Depended On ItÉvaluation : 4.5 sur 5 étoiles4.5/5 (838)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeD'EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeÉvaluation : 4 sur 5 étoiles4/5 (5794)

- Team of Rivals: The Political Genius of Abraham LincolnD'EverandTeam of Rivals: The Political Genius of Abraham LincolnÉvaluation : 4.5 sur 5 étoiles4.5/5 (234)

- Shoe Dog: A Memoir by the Creator of NikeD'EverandShoe Dog: A Memoir by the Creator of NikeÉvaluation : 4.5 sur 5 étoiles4.5/5 (537)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyD'EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyÉvaluation : 3.5 sur 5 étoiles3.5/5 (2219)

- The Emperor of All Maladies: A Biography of CancerD'EverandThe Emperor of All Maladies: A Biography of CancerÉvaluation : 4.5 sur 5 étoiles4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreD'EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreÉvaluation : 4 sur 5 étoiles4/5 (1090)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersD'EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersÉvaluation : 4.5 sur 5 étoiles4.5/5 (344)

- Her Body and Other Parties: StoriesD'EverandHer Body and Other Parties: StoriesÉvaluation : 4 sur 5 étoiles4/5 (821)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceD'EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceÉvaluation : 4 sur 5 étoiles4/5 (894)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureD'EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureÉvaluation : 4.5 sur 5 étoiles4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaD'EverandThe Unwinding: An Inner History of the New AmericaÉvaluation : 4 sur 5 étoiles4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)D'EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Évaluation : 4 sur 5 étoiles4/5 (98)

- Spare Parts Catalog for Appliance RepairDocument15 pagesSpare Parts Catalog for Appliance Repairstevebow1Pas encore d'évaluation

- On Fire: The (Burning) Case for a Green New DealD'EverandOn Fire: The (Burning) Case for a Green New DealÉvaluation : 4 sur 5 étoiles4/5 (73)

- Fuel System Pressure - TestDocument7 pagesFuel System Pressure - TestHamilton MirandaPas encore d'évaluation

- Condition Monitoring of Diesel GeneratorsDocument49 pagesCondition Monitoring of Diesel GeneratorsjyotidahiyaPas encore d'évaluation

- Stavatti: The Mustang ModelDocument9 pagesStavatti: The Mustang ModelStavatti Aerospace Ltd100% (3)

- WoodPlans Online - Drill Press TableDocument6 pagesWoodPlans Online - Drill Press TableЧедомир Арнаут100% (1)

- Rod Install PDFDocument8 pagesRod Install PDFVeterano del Camino100% (1)

- JD 9965 PDFDocument625 pagesJD 9965 PDFJosé Roberto VircentsPas encore d'évaluation

- Shutdown SIS: Excavator 320C Excavator Amc 320C & 320C L Excavators AMC00001-UP (MACHINE) POWERED BY 3066 EngineDocument4 pagesShutdown SIS: Excavator 320C Excavator Amc 320C & 320C L Excavators AMC00001-UP (MACHINE) POWERED BY 3066 EngineR I SantosoPas encore d'évaluation

- Contractor Quality Control Plan For Rotary Equipment InstallationDocument4 pagesContractor Quality Control Plan For Rotary Equipment InstallationJoel SnowPas encore d'évaluation

- Dynaflo DP 60hz CatalogDocument44 pagesDynaflo DP 60hz Catalognpclap67% (3)

- Machinerycourse Outline and Hand OutDocument81 pagesMachinerycourse Outline and Hand OutKKDhPas encore d'évaluation

- Physcis Ac Generator ReportDocument15 pagesPhyscis Ac Generator ReportVishal HirrtikPas encore d'évaluation

- HHF-1600L Drilling Pump (Main Body) User ManualDocument61 pagesHHF-1600L Drilling Pump (Main Body) User ManualAhmed Saeed100% (2)

- Hilti Te70 PDFDocument13 pagesHilti Te70 PDFSIVARAMANJAGANATHAN100% (1)

- PARTES MOTOR DETROIT L-2350 AntucoyaDocument195 pagesPARTES MOTOR DETROIT L-2350 Antucoyamarcksnow100% (1)

- SM-27T Machete LC Israel Oct 2023Document2 pagesSM-27T Machete LC Israel Oct 2023Stavatti Aerospace LtdPas encore d'évaluation

- SM-31T Stiletto Linecard in A US Navy LiveryDocument2 pagesSM-31T Stiletto Linecard in A US Navy LiveryStavatti Aerospace LtdPas encore d'évaluation

- Stavatti Responds To Ussocom Armed Overwatch ProgramDocument1 pageStavatti Responds To Ussocom Armed Overwatch ProgramStavatti Aerospace LtdPas encore d'évaluation

- SM27T LC Ren Usaf 2019Document2 pagesSM27T LC Ren Usaf 2019Stavatti Aerospace Ltd100% (1)

- SM-31S Stiletto LF F125XX Taiwan Linecard 2020 MetricDocument2 pagesSM-31S Stiletto LF F125XX Taiwan Linecard 2020 MetricStavatti Aerospace LtdPas encore d'évaluation

- SM-31T Stiletto Ai-322-30f Ukraine 2019 MLCDocument2 pagesSM-31T Stiletto Ai-322-30f Ukraine 2019 MLCStavatti Aerospace LtdPas encore d'évaluation

- SM-31T Stiletto T-X F125 Linecard 2020Document2 pagesSM-31T Stiletto T-X F125 Linecard 2020Stavatti Aerospace LtdPas encore d'évaluation

- SM-31T Stiletto F125X Taiwan Linecard 2020 MetricDocument2 pagesSM-31T Stiletto F125X Taiwan Linecard 2020 MetricStavatti Aerospace LtdPas encore d'évaluation

- SM-31S Stiletto LF F125XX Taiwan Linecard 2020 MetricDocument2 pagesSM-31S Stiletto LF F125XX Taiwan Linecard 2020 MetricStavatti Aerospace LtdPas encore d'évaluation

- SM-31T Stiletto F125X Linecard 2019Document2 pagesSM-31T Stiletto F125X Linecard 2019Stavatti Aerospace Ltd100% (1)

- SM-47S Super Machete Linecard With JASDF LiveryDocument2 pagesSM-47S Super Machete Linecard With JASDF LiveryStavatti Aerospace LtdPas encore d'évaluation

- SM-36 STALMA Linecard (2017)Document2 pagesSM-36 STALMA Linecard (2017)Stavatti Aerospace LtdPas encore d'évaluation

- SM-27 Machete For CASDocument6 pagesSM-27 Machete For CASStavatti Aerospace LtdPas encore d'évaluation

- SM-27S Machete Turboprop Linecard With USMC LiveryDocument2 pagesSM-27S Machete Turboprop Linecard With USMC LiveryStavatti Aerospace LtdPas encore d'évaluation

- Stavatti Model 658-500 6 5/8 Cementing Head System LinecardDocument2 pagesStavatti Model 658-500 6 5/8 Cementing Head System LinecardStavatti Aerospace LtdPas encore d'évaluation

- SM-27S Machete Turboprop Linecard With USMC LiveryDocument2 pagesSM-27S Machete Turboprop Linecard With USMC LiveryStavatti Aerospace LtdPas encore d'évaluation

- SM-27S Machete Turboprop Linecard With USAF LiveryDocument2 pagesSM-27S Machete Turboprop Linecard With USAF LiveryStavatti Aerospace LtdPas encore d'évaluation

- How A Discharge Relief Valve Controls PressureDocument6 pagesHow A Discharge Relief Valve Controls Pressureمحمد مجديPas encore d'évaluation

- Interior Components Diagram and Parts ListDocument6 pagesInterior Components Diagram and Parts ListSoluciones Tecnicas GastronomicasPas encore d'évaluation

- (DOL) Motor Starter: Instructions For Direct-On-LineDocument3 pages(DOL) Motor Starter: Instructions For Direct-On-LineVenkata Suresh MandavaPas encore d'évaluation

- Aviation Service ManualDocument28 pagesAviation Service ManualArmo MoralesPas encore d'évaluation

- Komatsu WA3203AP F4350W32.053 PageDocument2 pagesKomatsu WA3203AP F4350W32.053 PageIvan PalominoPas encore d'évaluation

- Group 11 work equipment parts and removal guideDocument4 pagesGroup 11 work equipment parts and removal guidelevinton jose tobias genesPas encore d'évaluation

- Danfoss GUY60NRb R134a 115 60Document5 pagesDanfoss GUY60NRb R134a 115 60Jhon Freddy Roldan NarvaezPas encore d'évaluation

- IgnitionDocument13 pagesIgnitionडॉ. इन्द्रसेन सिंहPas encore d'évaluation

- Dry BushingDocument5 pagesDry BushingJigar M. UpadhyayPas encore d'évaluation

- AC Low Side Installation WorksDocument1 pageAC Low Side Installation WorksNiteshPas encore d'évaluation

- 161 01-CL2Document8 pages161 01-CL2Black SmithPas encore d'évaluation

- Choose The Letter of The Best Answer and Write Your Answer On A Separate Sheet of PaperDocument10 pagesChoose The Letter of The Best Answer and Write Your Answer On A Separate Sheet of PaperJussa Leilady AlberbaPas encore d'évaluation

- Engine - VQ25DE and VQ35DE Cooling System PDFDocument27 pagesEngine - VQ25DE and VQ35DE Cooling System PDFscott glackenPas encore d'évaluation

- Parker Jet-Pipe Servovalves: Care and Handling GuideDocument9 pagesParker Jet-Pipe Servovalves: Care and Handling Guidebbkkss2Pas encore d'évaluation

- PowerKit Engine 6M26 Series SpecsDocument2 pagesPowerKit Engine 6M26 Series SpecsquocthinhPas encore d'évaluation

- Cooling System Pressure Test ProcedureDocument7 pagesCooling System Pressure Test ProcedureCristhian Samuel Yacila OrdinolaPas encore d'évaluation