Académique Documents

Professionnel Documents

Culture Documents

Engine and Hydraulic Pump Controller: Pantalla Anterior

Transféré par

Hamilton MirandaTitre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Engine and Hydraulic Pump Controller: Pantalla Anterior

Transféré par

Hamilton MirandaDroits d'auteur :

Formats disponibles

320B & 320B L TRACK-TYPE EXCAVATORS 6CR00001-UP (MACHINE) POW...

Page 1 of 5

Pantalla anterior

Producto: EXCAVATOR

Modelo: 320B L EXCAVATOR 6CR

Configuración: 320B & 320B L TRACK-TYPE EXCAVATORS 6CR00001-UP

(MACHINE) POWERED BY 3066 ENGINE

Operación de Sistemas

308B, 311B, 312B, 315B, 317B, 318B, 320B, 322B, 325B, 330B, M325B and W330B

Excavators Engine and Pump Control

Número de medio -RENR1998-06 Fecha de publicación -01/10/2004 Fecha de actualización -06/10/2004

i01239582

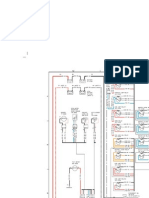

Engine and Hydraulic Pump Controller

SMCS - 1931

Illustration 1 g00662501

Diagram Of The Engine Control and Hydraulic Pump Control

(1) Controller

(2) Connector 2

mhtml:file://C:\Documents and Settings\Pesados\Configuración local\Archivos tempo... 29/05/2009

320B & 320B L TRACK-TYPE EXCAVATORS 6CR00001-UP (MACHINE) POW... Page 2 of 5

(3) Connector 1

Table 1

Engine And Hydraulic Pump Control (Connector 2) (1)

No.1 Function Type

Front Pump

2 Sensor Input (Freq.)

Pressure Sensor

Proportional Reducing

3 Solenoid Output (Pulsed)

Valve (+)

Proportional Reducing

4 Solenoid Output (Pulsed)

Valve (-)

6 AUX Pressure Switch Input (Operational)

7 Implement Pressure Switch Input (Operational)

8 Boom Raise Pressure Switch Input (Operational)

9 GOV Actuator Feedback Sensor Input (PWM)

10 Governor Actuator (+) Solenoid Output (Pulsed)

12 Trenching Solenoid Solenoid Output (On/Off)

13 Engine Coolant Temp. Sensor Input (PWM)

15 Coolant Level Switch Input (Operational)

18 Travel Pressure Switch Input (Operational)

20 Governor Actuator (-) Solenoid Output (Pulsed)

21 Level Finish Solenoid Solenoid Output (On/Off)

22 Travel Speed Solenoid Solenoid Output (On/Off)

24 Engine Speed (+) Sensor Input (Freq.)

25 Engine Speed (-) Sensor Return

26 Engine Oil Pressure Switch Input (Operational)

27 Swing Brake Solenoid Solenoid Output (Pulsed)

29 Fuel Level Sensor Input (PWM)

30 Hydraulic Oil Temp. Sensor Input (PWM)

31 Travel Alarm Solenoid Output (On/Off)

34 Alternator R Terminal Sensor Input (Voltage)

35 Air Cleaner Switch Input (Operational)

mhtml:file://C:\Documents and Settings\Pesados\Configuración local\Archivos tempo... 29/05/2009

320B & 320B L TRACK-TYPE EXCAVATORS 6CR00001-UP (MACHINE) POW... Page 3 of 5

36 Engine Oil Level Switch Input (Operational)

38 Monitor (+) Power

40 Hydraulic Oil Level Switch Input (Operational)

(1) The connector contacts that are not listed are not used. The connector has 40 contacts.

Table 2

Engine And Hydraulic Pump Control (Connector 1) (1)

No.1 Function Type

1 +Battery (Unswitched) Power

2 Ground Ground

3 +Battery (Switched) Switch Input (Keystart)

4 Key start Switch Input (Operational)

11 +Battery (Unswitched) Power

12 Ground Ground

13 Engine Speed Dial 1 Switch Input (Operational)

14 Engine Speed Dial 2 Switch Input (Operational)

15 Data Link (+) Input/Output

16 Data Link (-) Input/Output

21 AIH Indicator (2) Switch Input (Operational)

22 Fine Swing Switch Input (Operational)

23 Engine Speed Dial 3 Switch Input (Operational)

24 Enging Speed Dial 4 Switch Input (Operational)

31 RS232C (TX) Input/Output

32 RS232C (RX) Input/Output

33 RS232C (GND) Input/Output

34 Low Idle Switch Input (Operational)

39 Hydraulic Oil Filter

(1) The connector contacts that are not listed are not used. The connector has 40 contacts.

(2) Not available on the 330B.

When the controller determines that it is necessary to change the speed of the engine and the output

of the hydraulic pump, the controller will actuate the governor actuator and the proportional reducing

valve. Each input and output of the controller is connected to the machine harness through two 40-

mhtml:file://C:\Documents and Settings\Pesados\Configuración local\Archivos tempo... 29/05/2009

320B & 320B L TRACK-TYPE EXCAVATORS 6CR00001-UP (MACHINE) POW... Page 4 of 5

pin connectors.

Input/Output

The data link is a bidirectional component. The data link allows the controller to receive information

and the controller can send information. The data link is designed to allow communication between

the controller and the monitor. The data link is not a visible component. The data link consists of

internal control circuits and the connecting harness wiring. The controller sends information through

the data link. The following list contains some examples: fuel level, engine coolant temperature and

the power mode that is selected to the monitor panel. The controller also receives requested

information from the monitor panel. The following list contains some examples: power mode and

fine control mode.

Input

Each input will describe the status of the machine system. Two types of inputs exist: switch type and

sensor type. Switches and harnesses provide an open or ground to the controller. Sensors and

harnesses provide a signal that changes to the controller.

Switch Input (Keyswitch)

The input of the key start switch connects to the controller through connector 1 and contact 4. The

key start switch will provide input information to the controller about the status of the key start

switch. When the key start switch is ON this input is at +battery.

Switch Input (Operational Type)

The operational switch inputs include the following connector contacts: 2-6, 2-7, 2-8, 2-15, 2-18, 2-

26, 2-36, 2-40, 1-13, 1-14, 1-22, 1-23, 1-24, 1-34 and 1-39. Each switch input will provide

information about operator requests and machine systems. The condition of the system is sent to the

controller through each input. The status of each input will be grounded, open or +battery. Each

input of the controller will receive information from the switches that are located in the machine

systems (pressure and temperature).

Sensor Input (Frequency)

An AC signal is present for the input of the frequency sensor (connector contact 2-24). The AC

signal is used to represent the speed of a machine system. The engine speed sensor provides an AC

signal to the controller. The controller measures the frequency (Hz) of the AC signals. The resulting

speed is used by the controller to make decisions.

Sensor Input (Alternator)

The sensor input for the alternator connects to connector contact 2-34. A square wave signal is

present at this input. The signal is used to represent the speed of the alternator. The controller

measures the frequency (Hz) of the square wave signal. The controller uses this information to make

determinations and the controller uses this information to monitor the output of the alternator. When

an abnormal condition exists, the controller will alert the operator.

Sensor Input (PWM)

Each of the following contacts are a sensor input to the controller: 2-9, 2-13, 2-21 and 2-30. A PWM

mhtml:file://C:\Documents and Settings\Pesados\Configuración local\Archivos tempo... 29/05/2009

320B & 320B L TRACK-TYPE EXCAVATORS 6CR00001-UP (MACHINE) POW... Page 5 of 5

signal is present at these contacts. This signal will represent the condition of a machine system. For

example, the controller can monitor temperature. PWM sensors provide this information. The

controller measures the duty cycle of the PWM signal. This signal will represent the information that

is measured. The controller will use this information to perform decisions. When an abnormal

condition exists, the controller will alert the operator.

Sensor Input (Voltage)

Contact 2-29 is an input for voltage sensing. A voltage is present. This voltage will represent the

condition of a machine system. For example, the level of voltage is a condition that is monitored by

the controller. Analog sensors or senders provide this information. The controller measures the

voltage, which represents the measured information. The controller uses this information to make

decisions. The controller also uses this information to monitor machine systems. When an abnormal

condition exists the controller alerts the operator.

Output

The controller responds to decisions by sending electrical signals through the various outputs. The

outputs will create an action or the outputs will provide information. Three status indicators inside

the controller that are connected to the monitor panel are outputs of the controller. These outputs are

additional to the outputs that are listed in the table for Connector Contact Description. The monitor

panel shows the operating status of the engine and pump control system and diagnostic information.

The following solenoid outputs are used by the controller to cause an action: 2-3, 2-4, 2-10, 2-12, 2-

20, 2-21, 2-22, 2-27 and. This action could be energizing a solenoid, sounding an alarm or activating

a motor.

Copyright 1993 - 2009 Caterpillar Inc.

Todos los derechos reservados.

Red privada para licenciados del SIS.

mhtml:file://C:\Documents and Settings\Pesados\Configuración local\Archivos tempo... 29/05/2009

Vous aimerez peut-être aussi

- DDEC II and III Wiring DiagramsDocument13 pagesDDEC II and III Wiring Diagramstwhiteman200682% (49)

- Electronic Control Module (Power Train) Inout OutputDocument7 pagesElectronic Control Module (Power Train) Inout OutputSayed Younis Sadaat100% (1)

- Electronic Speedometer and Tachometer SwitchDocument23 pagesElectronic Speedometer and Tachometer SwitchHamilton Miranda100% (2)

- 320C Hydraulic Excavator Electrical SchematicDocument2 pages320C Hydraulic Excavator Electrical Schematicluiscampos7792% (12)

- MBE4000 Serv ManDocument587 pagesMBE4000 Serv ManRicardo Diaz95% (20)

- 6th Central Pay Commission Salary CalculatorDocument15 pages6th Central Pay Commission Salary Calculatorrakhonde100% (436)

- 6th Central Pay Commission Salary CalculatorDocument15 pages6th Central Pay Commission Salary Calculatorrakhonde100% (436)

- E110B and E120B Excavators Electrical SystemDocument2 pagesE110B and E120B Excavators Electrical Systemedwin quiroz0% (1)

- 320B/330B Hydraulic Excavators: Service Training MalagaDocument8 pages320B/330B Hydraulic Excavators: Service Training MalagaEngr Ramez Kaawach100% (2)

- 2008 Hyundai Santa Fe GLS 2008 Hyundai Santa Fe GLS: Powertrain Control Module (PCM)Document12 pages2008 Hyundai Santa Fe GLS 2008 Hyundai Santa Fe GLS: Powertrain Control Module (PCM)Manolo RodriguezPas encore d'évaluation

- 312 BDocument2 pages312 BДрагиша Небитни Трифуновић50% (2)

- 320 BLDocument6 pages320 BLHamilton Miranda100% (1)

- Reference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2D'EverandReference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2Pas encore d'évaluation

- Section 3.7 Connectors: Figure 1. ECU 68-Pin Tyco ConnectorDocument8 pagesSection 3.7 Connectors: Figure 1. ECU 68-Pin Tyco ConnectorHamilton MirandaPas encore d'évaluation

- M 318Document2 pagesM 318Franz JW Monteza100% (2)

- Electronic Control Module - TransmissionDocument9 pagesElectronic Control Module - TransmissionFranciane Pires100% (1)

- Implement ECM: Electronic Control (Brake System) (M0111643) 2020/12/09Document23 pagesImplement ECM: Electronic Control (Brake System) (M0111643) 2020/12/09Rio AkbrPas encore d'évaluation

- Test de Presiones de Transmision 938g2Document12 pagesTest de Presiones de Transmision 938g2cristian chuquicondor torres100% (2)

- Eatonroadranger - RTLO-16918B - Despiece Con Codigos PDFDocument58 pagesEatonroadranger - RTLO-16918B - Despiece Con Codigos PDFAndre Paul MektronikPas encore d'évaluation

- Eatonroadranger - RTLO-16918B - Despiece Con Codigos PDFDocument58 pagesEatonroadranger - RTLO-16918B - Despiece Con Codigos PDFAndre Paul MektronikPas encore d'évaluation

- 330B System Operation Engine and Pump Control RENR1998Document51 pages330B System Operation Engine and Pump Control RENR1998DANIEL VARGAS RODRIGUEZ100% (2)

- Ajuste Inyector UnitarioDocument190 pagesAjuste Inyector UnitarioHamilton MirandaPas encore d'évaluation

- 6 Electronic Control Module (Machine) PDFDocument6 pages6 Electronic Control Module (Machine) PDFwesley candidoPas encore d'évaluation

- Governor Actuator Replace IN CAT 312bDocument2 pagesGovernor Actuator Replace IN CAT 312bbrsat82590100% (3)

- Reference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 1D'EverandReference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 1Évaluation : 2.5 sur 5 étoiles2.5/5 (3)

- 320 Cat 2Document15 pages320 Cat 2JoãoNeto100% (3)

- จูน 320b-330bDocument10 pagesจูน 320b-330bAchariya Parprom100% (3)

- Calibaracion PRVDocument4 pagesCalibaracion PRVPepe Alfred100% (1)

- Event Code 320DDocument5 pagesEvent Code 320DLuthfy100% (1)

- Testing & Adjusting Cat - Dcs.sis - Controller PDFDocument179 pagesTesting & Adjusting Cat - Dcs.sis - Controller PDFmnlar100% (7)

- 300 HEX Monitoring SystemDocument28 pages300 HEX Monitoring SystemMohamed Yousif HamadPas encore d'évaluation

- 312B PDFDocument2 pages312B PDFJesus Carhuamaca Pascual92% (13)

- Diagrama Electrico (320B) PDFDocument2 pagesDiagrama Electrico (320B) PDFjulianmata100% (1)

- Manual Calibrado Monitor Excav. 320 330 CATDocument8 pagesManual Calibrado Monitor Excav. 320 330 CAThyromec95% (59)

- Solenoid Valve (Proportional Reducing) - Calibrate - Number 1 Relief Valve and Number 2 Relief Valve - 084521Document9 pagesSolenoid Valve (Proportional Reducing) - Calibrate - Number 1 Relief Valve and Number 2 Relief Valve - 084521Juan LopezPas encore d'évaluation

- Cat 312 Monitor Indicators.Document3 pagesCat 312 Monitor Indicators.anuradha0% (1)

- Painel Monitor 320CDocument7 pagesPainel Monitor 320CMarco OlivettoPas encore d'évaluation

- Cat 320cl Schema Hydraulic SystemDocument2 pagesCat 320cl Schema Hydraulic SystemJuan Pablo Barron Marin97% (37)

- Cat Dcs Sis Controller (330BL-3DR04412)Document2 pagesCat Dcs Sis Controller (330BL-3DR04412)julianmata100% (10)

- Cat 320C Governor Actuator CalibrateDocument47 pagesCat 320C Governor Actuator CalibrateJorge Mendoza75% (4)

- EGR Cooler Cleaning Procedures - MP7 Engines PDFDocument3 pagesEGR Cooler Cleaning Procedures - MP7 Engines PDFHamilton MirandaPas encore d'évaluation

- Painel 320B CATERPILLARDocument6 pagesPainel 320B CATERPILLARMarco Olivetto100% (5)

- Electrical CircuitDocument60 pagesElectrical CircuitSumitomo Laos Sumitomo Laos100% (1)

- Controlador 320BDocument12 pagesControlador 320BJuank Jacales100% (3)

- Pines EcuDocument7 pagesPines EcuWladimir AmaguañaPas encore d'évaluation

- Detroit Diesel - DDDL 7.0 Users Manual PDFDocument149 pagesDetroit Diesel - DDDL 7.0 Users Manual PDFGreenline32100% (2)

- CAT Excavator 312B Proportional Reducing Valve Sweept - TestDocument5 pagesCAT Excavator 312B Proportional Reducing Valve Sweept - TestFabio Junior88% (8)

- Electronic Control Module (Power Train) : Operación de SistemasDocument4 pagesElectronic Control Module (Power Train) : Operación de Sistemasgalvis1020100% (2)

- Electronic Control Module 326DDocument4 pagesElectronic Control Module 326DBaron KasoziPas encore d'évaluation

- Cat 314 C ElectricoDocument2 pagesCat 314 C Electricogalvis1020100% (3)

- 320C PDFDocument2 pages320C PDFedi100% (1)

- Pines 320D Modulo HidrahulicoDocument7 pagesPines 320D Modulo Hidrahulicoehurtadof100% (1)

- Engine Brake Service Information SummaryDocument10 pagesEngine Brake Service Information SummaryHamilton MirandaPas encore d'évaluation

- Kia Picanto 1.0 Sohc 2oo9Document31 pagesKia Picanto 1.0 Sohc 2oo9Edwin Ramos100% (1)

- Machine ECM Pinout CAT TH460Document6 pagesMachine ECM Pinout CAT TH460Daniel Aguirre100% (2)

- 8999 5718 00 Diagrams and DrawingsDocument140 pages8999 5718 00 Diagrams and DrawingsMicaelPas encore d'évaluation

- 320 CDocument15 pages320 Czoetiko100% (5)

- 320D HidraulicoDocument2 pages320D Hidraulicosilvanioqueiroz100% (1)

- Variable Speed AC Drives with Inverter Output FiltersD'EverandVariable Speed AC Drives with Inverter Output FiltersPas encore d'évaluation

- Monitor 320 BL y FallasDocument8 pagesMonitor 320 BL y FallasRobin SanchezPas encore d'évaluation

- PC210LC-11 Sen06695-01 Control SystemDocument37 pagesPC210LC-11 Sen06695-01 Control Systemdatphuong100% (1)

- Caterpillar 311b 330b Excavators Engine and Pump Electronic Control SystemDocument10 pagesCaterpillar 311b 330b Excavators Engine and Pump Electronic Control Systemjohn100% (47)

- Plano Electrico Cat D6RDocument9 pagesPlano Electrico Cat D6Redhuam86% (14)

- 800 KV TL DesignDocument67 pages800 KV TL Designravi0312150% (2)

- RMP200-8 HW Mod Description - 300992BDocument28 pagesRMP200-8 HW Mod Description - 300992BTEUKU50% (8)

- Engine Power Distribution ModuleDocument1 pageEngine Power Distribution ModuleHamilton MirandaPas encore d'évaluation

- 345 Modo de ServicioDocument8 pages345 Modo de ServicioJordan RaveloPas encore d'évaluation

- Engine and Hydraulic Pump Controller 325CDocument14 pagesEngine and Hydraulic Pump Controller 325CHAmir Alberto Mojica MojicaPas encore d'évaluation

- 09.1 PLC - Technical HandbookDocument30 pages09.1 PLC - Technical HandbookSandoval Ramos Eddy100% (1)

- Electronic Control Module (ECM) : Shutdown SIS Previous ScreenDocument5 pagesElectronic Control Module (ECM) : Shutdown SIS Previous ScreenWladimir AmaguañaPas encore d'évaluation

- Electronic Control Module (Power Train)Document8 pagesElectronic Control Module (Power Train)Iginio Malaver VargasPas encore d'évaluation

- Electronic Control Module (Power Train) : Arrêter SIS Ecran PrécédentDocument4 pagesElectronic Control Module (Power Train) : Arrêter SIS Ecran Précédentamskroud brahimPas encore d'évaluation

- Estado de Los ParametrosDocument5 pagesEstado de Los ParametrosHamilton MirandaPas encore d'évaluation

- Búsqueda Del Medio - UENR3858 - 320D2 and 323D2 ExcavatorsDocument8 pagesBúsqueda Del Medio - UENR3858 - 320D2 and 323D2 ExcavatorsErlen PolancoPas encore d'évaluation

- User Mode 325bDocument7 pagesUser Mode 325bChristian Vinueza VillavicencioPas encore d'évaluation

- Coolant Level Sensor and j1939 Harness SectionDocument11 pagesCoolant Level Sensor and j1939 Harness SectionHamilton Miranda0% (1)

- RR Rto-14608llDocument52 pagesRR Rto-14608llHamilton MirandaPas encore d'évaluation

- Bibracion en El Tren MotrizDocument6 pagesBibracion en El Tren MotrizHamilton MirandaPas encore d'évaluation

- Engine Remote Interface Installation and Programming InformationDocument3 pagesEngine Remote Interface Installation and Programming InformationHamilton MirandaPas encore d'évaluation

- Coneccion de Aire T300 MAckDocument11 pagesConeccion de Aire T300 MAckHamilton MirandaPas encore d'évaluation

- Cojinetes de Arbol de Leva VolvoDocument5 pagesCojinetes de Arbol de Leva VolvoHamilton MirandaPas encore d'évaluation

- RR Fro-16210bDocument1 pageRR Fro-16210bHamilton MirandaPas encore d'évaluation

- Illustrated Parts List: FRO-16210B November 2012Document46 pagesIllustrated Parts List: FRO-16210B November 2012Hamilton MirandaPas encore d'évaluation

- Illustrated Parts List: FRO-15210C June 2014Document46 pagesIllustrated Parts List: FRO-15210C June 2014Hamilton MirandaPas encore d'évaluation

- Illustrated Parts List: RTLO-16713A November 2012Document56 pagesIllustrated Parts List: RTLO-16713A November 2012Hamilton MirandaPas encore d'évaluation

- Conector Pasante FLD 120 PDFDocument1 pageConector Pasante FLD 120 PDFHamilton MirandaPas encore d'évaluation

- Illustrated Parts List: FRO-16210B November 2012Document46 pagesIllustrated Parts List: FRO-16210B November 2012Hamilton MirandaPas encore d'évaluation

- RR Rto-14608llDocument52 pagesRR Rto-14608llHamilton MirandaPas encore d'évaluation

- Fuller Heavy Duty Transmissions TRTS0902: Troubleshooting GuideDocument34 pagesFuller Heavy Duty Transmissions TRTS0902: Troubleshooting GuideHamilton MirandaPas encore d'évaluation

- Spicer Pso140 10s Pso150 Pso165 Lpso Llpso Series Parts ManualDocument46 pagesSpicer Pso140 10s Pso150 Pso165 Lpso Llpso Series Parts ManualHamilton Miranda100% (1)

- Speedometer PDFDocument44 pagesSpeedometer PDFHector Eugenio Henriquez Delannoy100% (1)

- Installation Instructions: 18SP548-Install Exhaust Back Pressure Sensor Kit On Series 50 or Series 60 Diesel Coach EngineDocument10 pagesInstallation Instructions: 18SP548-Install Exhaust Back Pressure Sensor Kit On Series 50 or Series 60 Diesel Coach EngineHamilton MirandaPas encore d'évaluation

- Sizing of BusbarDocument5 pagesSizing of BusbarbibinbibinPas encore d'évaluation

- 2SC3421Document4 pages2SC3421Berenice MárquezPas encore d'évaluation

- KiloVault HLX PLUS UL Datasheet 110321Document2 pagesKiloVault HLX PLUS UL Datasheet 110321xkn6brv8p8Pas encore d'évaluation

- SLM620 - Selective Level MeterDocument2 pagesSLM620 - Selective Level MeterYoga OkePas encore d'évaluation

- TD04803001E - Visual Designer Driver ListDocument8 pagesTD04803001E - Visual Designer Driver Listrogermantilla08Pas encore d'évaluation

- CATALOG Camco-Manufacturing 07843Document1 pageCATALOG Camco-Manufacturing 07843Francisco RamirezPas encore d'évaluation

- Modeling and Analysis of DC-DC Converters Under Pulse Skipping ModulationDocument6 pagesModeling and Analysis of DC-DC Converters Under Pulse Skipping ModulationJeba AntonyPas encore d'évaluation

- STK33562 Sensor LLamadaDocument37 pagesSTK33562 Sensor LLamadaR̳̿e̳̿n̳̿o̳̿s̳̿ ̳̿S̳̿a̳̿i̳̿n̳̿t̳̿Pas encore d'évaluation

- VersaBlue N 12-25-50 Liter Tank MeltersDocument2 pagesVersaBlue N 12-25-50 Liter Tank Melterseletrica_mardamPas encore d'évaluation

- Nortel OutdoorDocument7 pagesNortel OutdoorMarius TrancaPas encore d'évaluation

- IA - ASM - All Motors - c-UL - EN - 20200219Document11 pagesIA - ASM - All Motors - c-UL - EN - 20200219Fahru Rozy SunnyPas encore d'évaluation

- Parallel Operation of Ups 1Document7 pagesParallel Operation of Ups 1ZIPDASHPas encore d'évaluation

- Bioelectronics For Amperometric Biosensors - 43463Document34 pagesBioelectronics For Amperometric Biosensors - 43463Jose TrianoPas encore d'évaluation

- 33-11KV Substation Maintenance Report by Jbit Batch 1Document48 pages33-11KV Substation Maintenance Report by Jbit Batch 1jsaivardhan23Pas encore d'évaluation

- 3 Hours / 70 Marks: Seat NoDocument4 pages3 Hours / 70 Marks: Seat NoAbhishek GaykarPas encore d'évaluation

- Marvell Alaska 88E1116R: Single-Port Gigabit Ethernet Transceiver With Integrated PassivesDocument2 pagesMarvell Alaska 88E1116R: Single-Port Gigabit Ethernet Transceiver With Integrated PassivesAnton NguyễnPas encore d'évaluation

- Merged DocumentDocument25 pagesMerged DocumentAshokAbiPas encore d'évaluation

- 12V Relay Switch: Pin ConfigurationDocument2 pages12V Relay Switch: Pin ConfigurationRuhina AshfaqPas encore d'évaluation

- 2 P&ID PressDocument24 pages2 P&ID Presstes2004Pas encore d'évaluation

- Work Order Number Site Name Print Date WO Due Date C0219-CI-2502-504-3-001-A Project Name: Revision Reason: Project DescriptionDocument41 pagesWork Order Number Site Name Print Date WO Due Date C0219-CI-2502-504-3-001-A Project Name: Revision Reason: Project Descriptionjulio villaPas encore d'évaluation

- Introduction Computer Manual PDFDocument12 pagesIntroduction Computer Manual PDF77fekadu100% (1)

- Document 1 WatanabeDocument58 pagesDocument 1 WatanabeHendrik BastiwPas encore d'évaluation

- Amoud University: Faculty of EngineeringDocument4 pagesAmoud University: Faculty of EngineeringGULOED Jama JosopHPas encore d'évaluation

- FM Tuner MODEL V-2952: FeaturesDocument2 pagesFM Tuner MODEL V-2952: FeaturesAzHar HrPas encore d'évaluation

- Siprotec4 Manual b9 enDocument530 pagesSiprotec4 Manual b9 enShamik PurkayasthaPas encore d'évaluation

- Dipole Antennas - Part 01Document26 pagesDipole Antennas - Part 01Bharat ChPas encore d'évaluation

- PTU300 User's Guide in English M210796ENDocument221 pagesPTU300 User's Guide in English M210796ENAdil Khan LodhiPas encore d'évaluation