Académique Documents

Professionnel Documents

Culture Documents

Scope of Work For Polymer Wrapping On Caustic Lines Joints

Transféré par

anishdev6Titre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Scope of Work For Polymer Wrapping On Caustic Lines Joints

Transféré par

anishdev6Droits d'auteur :

Formats disponibles

MA-CON-SFM-00-0001

MATERIALS

Rev 0

18 NOV 09

SCOPE OF WORK FOR CONTRACTS

Page 1 of 5

TABLE OF CONTENTS

Rev.

-1 Prepared Checked Approved

-Pag Issue Date Amendment Description

By: By: By:

e 1 of

5Rev

.

POLYMER WRAPPING ON THE JOINTS OF Siraj

0 01.09.2010

CAUSTIC LINES Momin

MA-CON-SFM-00-0001 Page 1 of 5 Rev. 0

MA-CON-SFM-00-0001

MATERIALS

Rev 0

18 NOV 09

SCOPE OF WORK FOR CONTRACTS

Page 2 of 5

1. CONTRACT TITLE WITH REFERENCE NO.

POLYMER WRAPPING ON THE JOINTS OF CAUSTIC LINES

2. INTRODUCTION

Wrapping of polymers to the welding joints of caustic lines as isometric drawing list attached

3. DETAILED SCOPE OF WORK

3.1. Sequence of job Steps

3.1.1. Supply of manpower, tools, testing eqpts & etc to perform the polymer wrapping.

3.1.2. Supply of chemicals and products with MSDS

3.1.3. Arrangement of MIC gate pass of their employees

3.1.4. Surface preparation of pipe (100 mm for each joint) by wire brush grinding/Grit blasting.

3.1.5. Cleaning of pipe surface such that the base metal is clearly seen and no grease or

foreign particles is adhering to the blasted /ground surface.

3.1.6. Prepare/activate the resin and immediately apply on the prepared and clean surface.

3.1.7. Along with resin immediately spread one layer of surface veil and CSM and wet with

activated resin and rolls out any air gaps. Repeat the above for second layer also. The

same should be done to entire prepared surfaces. Also provide overlap of material at end

of each length joints.

3.1.8. Wrap the pipe joint with a polyester net such that the ends are sealed thoroughly.

MA-CON-SFM-00-0001 Page 2 of 5 Rev. 0

MA-CON-SFM-00-0001

MATERIALS

Rev 0

18 NOV 09

SCOPE OF WORK FOR CONTRACTS

Page 3 of 5

3.1.9. On curing of above layers, grind the GRP surface lightly and wet the same with

activated resin. Spread WRM (Woven roving mat) and wet the same with the resin.

Followed by 2CSM

3.1.10. Do the grinding to achieve the desired thickness of 6-8 mm.

3.1.11. Seal the end with polyester net and then entire length (100 mm for each joint) to be

wrapped tightly with polyester net.

3.1.12. Any change/addition in work scope, Qchem approval is required.

3.1.13. Number of polymer wrapping joints may increase or decrease against mentioned in

schedule of quantities.

3.2. Estimated Schedule

One Week

3.3. Acceptable work timing – General shift

3.4. Safety Requirements-Chem. Policies and procedures

3.4.1. PPE Requirements-

• Normal PPE at places where there is no leak.

• Special PPE at places where there is leak or it was temporary arrested earlier.

MA-CON-SFM-00-0001 Page 3 of 5 Rev. 0

MA-CON-SFM-00-0001

MATERIALS

Rev 0

18 NOV 09

SCOPE OF WORK FOR CONTRACTS

Page 4 of 5

Note: The contractor has to follow any additional PPE as per the review and recommendation

given by Industrial Hygienist upon review of MSDS

3.4.2. Normal PPE such as Nomex coveralls, hearing protection, hard hat, safety shoes, hand

gloves etc.

3.4.3. Special PPE such as face shield, chemical coverall, Neoprene chemical resistance hand

gloves and rubber gum boots

3.4.4. Special Precautions: Follow the Qchem PTW System

3.4.5. Waste Management: Housekeeping shall be maintained at all the times and disposal of

waste shall be carried out as per Q-chem waste management procedures. The area shall

be cleared to bring to the original wholesome status.

3.5. Proposed mile stones for Payments: Single after job completion based on actual time spent

on job

3.6. Bill of Material (BOM)

3.6.1. BOM Supplied by vendor

3.7. Special Equipments to be mobilized by Contractor: If require

3.8. Facilities to be provided by Q-Chem

3.8.1. Erection of scaffoldings

3.8.2. Arrangement of MIC gate passes requests of vendor employees.

MA-CON-SFM-00-0001 Page 4 of 5 Rev. 0

MA-CON-SFM-00-0001

MATERIALS

Rev 0

18 NOV 09

SCOPE OF WORK FOR CONTRACTS

Page 5 of 5

3.8.3. Approval of MSDS of products/Chemicals brought by Vendor

3.8.4. Arrangement of Safety training for vendor employees.

3.8.5. Inspection of Polymer wrapping done by contractor

3.9. Others

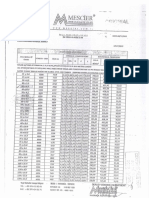

4. SCHEDULE OF QUANTITIES

NO. OF WELD NO. OF BENDS

FROM TO LINE SIZE

JOINTS

3” 7 3

2” 1 0

Caustic Storage Tank Pumps Suction

1-1/2” 25 9

¾” 4 0

1” 36 12

Pumps Discharge Injection Assembly ¾” 6 0

½” 2 0

2” 65 19

Injection Assembly 02-NA-1006-AA05-4”

¾” 7 1

5. ATTACHMENTS

5.1. List of isometric drawings of caustic lines are attached.

MA-CON-SFM-00-0001 Page 5 of 5 Rev. 0

Vous aimerez peut-être aussi

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeD'EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeÉvaluation : 4 sur 5 étoiles4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreD'EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreÉvaluation : 4 sur 5 étoiles4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItD'EverandNever Split the Difference: Negotiating As If Your Life Depended On ItÉvaluation : 4.5 sur 5 étoiles4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceD'EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceÉvaluation : 4 sur 5 étoiles4/5 (894)

- Grit: The Power of Passion and PerseveranceD'EverandGrit: The Power of Passion and PerseveranceÉvaluation : 4 sur 5 étoiles4/5 (587)

- Shoe Dog: A Memoir by the Creator of NikeD'EverandShoe Dog: A Memoir by the Creator of NikeÉvaluation : 4.5 sur 5 étoiles4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureD'EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureÉvaluation : 4.5 sur 5 étoiles4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersD'EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersÉvaluation : 4.5 sur 5 étoiles4.5/5 (344)

- Her Body and Other Parties: StoriesD'EverandHer Body and Other Parties: StoriesÉvaluation : 4 sur 5 étoiles4/5 (821)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)D'EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Évaluation : 4.5 sur 5 étoiles4.5/5 (119)

- The Emperor of All Maladies: A Biography of CancerD'EverandThe Emperor of All Maladies: A Biography of CancerÉvaluation : 4.5 sur 5 étoiles4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingD'EverandThe Little Book of Hygge: Danish Secrets to Happy LivingÉvaluation : 3.5 sur 5 étoiles3.5/5 (399)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyD'EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyÉvaluation : 3.5 sur 5 étoiles3.5/5 (2219)

- The Yellow House: A Memoir (2019 National Book Award Winner)D'EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Évaluation : 4 sur 5 étoiles4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaD'EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaÉvaluation : 4.5 sur 5 étoiles4.5/5 (265)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryD'EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryÉvaluation : 3.5 sur 5 étoiles3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnD'EverandTeam of Rivals: The Political Genius of Abraham LincolnÉvaluation : 4.5 sur 5 étoiles4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealD'EverandOn Fire: The (Burning) Case for a Green New DealÉvaluation : 4 sur 5 étoiles4/5 (73)

- The Unwinding: An Inner History of the New AmericaD'EverandThe Unwinding: An Inner History of the New AmericaÉvaluation : 4 sur 5 étoiles4/5 (45)

- Quality-I Is Safety-Ll - The Integration of Two Management Systems - Sasho Andonov (CRC, 2017)Document205 pagesQuality-I Is Safety-Ll - The Integration of Two Management Systems - Sasho Andonov (CRC, 2017)Tita Eric100% (3)

- Risk Assessment 589 Penstock RepairDocument4 pagesRisk Assessment 589 Penstock Repairanishdev6100% (4)

- ഡ്രാക്കുള ബ്രോം സ്റ്റോക്കർDocument146 pagesഡ്രാക്കുള ബ്രോം സ്റ്റോക്കർanishdev6100% (1)

- Dewatering Skip R01Document1 pageDewatering Skip R01anishdev6Pas encore d'évaluation

- Gfe Doc028 Sub 003Document43 pagesGfe Doc028 Sub 003anishdev6Pas encore d'évaluation

- Bridge For Floating Platform-ModelDocument1 pageBridge For Floating Platform-Modelanishdev6Pas encore d'évaluation

- Hose Reel ModelDocument1 pageHose Reel Modelanishdev6Pas encore d'évaluation

- Replacement of Flowmeter - Risk AssessmentDocument3 pagesReplacement of Flowmeter - Risk Assessmentanishdev650% (4)

- ഓവർക്കോട്ട് നിക്കൊളായ് ഗൊഗൊയ്Document32 pagesഓവർക്കോട്ട് നിക്കൊളായ് ഗൊഗൊയ്anishdev6Pas encore d'évaluation

- Hose Support r1Document1 pageHose Support r1anishdev6Pas encore d'évaluation

- OP410 PipingDocument1 pageOP410 Pipinganishdev6Pas encore d'évaluation

- AeratorDocument1 pageAeratoranishdev6Pas encore d'évaluation

- Inspection of Defective Penstock at Doha West Sewage Treatment WorksDocument19 pagesInspection of Defective Penstock at Doha West Sewage Treatment Worksanishdev6Pas encore d'évaluation

- Mobile Platform ModelDocument1 pageMobile Platform Modelanishdev6Pas encore d'évaluation

- Flow Losses in Flexible Hose.Document186 pagesFlow Losses in Flexible Hose.Anonymous K3FaYFlPas encore d'évaluation

- AeratorDocument1 pageAeratoranishdev6Pas encore d'évaluation

- BS L 117-1975 (2011)Document8 pagesBS L 117-1975 (2011)anishdev6Pas encore d'évaluation

- Layflat OvalHoseDocument8 pagesLayflat OvalHoseanishdev6Pas encore d'évaluation

- Reference Material Submittal - Part 8Document6 pagesReference Material Submittal - Part 8anishdev6Pas encore d'évaluation

- Bip 0071-2014Document130 pagesBip 0071-2014anishdev6Pas encore d'évaluation

- Stiffness Report GRP PIPEDocument19 pagesStiffness Report GRP PIPEanishdev6Pas encore d'évaluation

- Soft Foot-What It Is and How To Minimize It - VibrAlignDocument4 pagesSoft Foot-What It Is and How To Minimize It - VibrAlignanishdev6Pas encore d'évaluation

- Recovery Plan - Pipe Support FabricationDocument1 pageRecovery Plan - Pipe Support Fabricationanishdev6Pas encore d'évaluation

- Reference Material Submittal - Part 7 PDFDocument21 pagesReference Material Submittal - Part 7 PDFanishdev6Pas encore d'évaluation

- Reference Material Submittal - Part 5 PDFDocument21 pagesReference Material Submittal - Part 5 PDFanishdev6Pas encore d'évaluation

- Reference Material Submittal - Part 6 PDFDocument21 pagesReference Material Submittal - Part 6 PDFanishdev6Pas encore d'évaluation

- Reference Material Submittal - Part 4 PDFDocument21 pagesReference Material Submittal - Part 4 PDFanishdev6100% (1)

- Reference Material Submittal - Part 1 PDFDocument21 pagesReference Material Submittal - Part 1 PDFanishdev6Pas encore d'évaluation

- Reference Material Submittal - Part 3 PDFDocument21 pagesReference Material Submittal - Part 3 PDFanishdev6Pas encore d'évaluation

- Jafco Profile PDFDocument21 pagesJafco Profile PDFanishdev6Pas encore d'évaluation

- Land Deep Production Casings in Menengai Geothermal FieldDocument30 pagesLand Deep Production Casings in Menengai Geothermal FieldShafeeq ChappuPas encore d'évaluation

- Product and Company Identification: Safety Data SheetDocument7 pagesProduct and Company Identification: Safety Data SheetZirve PolimerPas encore d'évaluation

- (VESBO) Catalog en 100317Document55 pages(VESBO) Catalog en 100317AnhNguyen100% (1)

- Astm D1785-15Document11 pagesAstm D1785-15david franco0% (1)

- Lennox Kca090s4bn2yDocument36 pagesLennox Kca090s4bn2yGerardo ZamoranoPas encore d'évaluation

- Zuellig Pharma Corporation: Item Name of Medicine Brand Name Principal Name Quantity Unit PriceDocument2 pagesZuellig Pharma Corporation: Item Name of Medicine Brand Name Principal Name Quantity Unit PriceJZik SibalPas encore d'évaluation

- Imp of MicronutrientsDocument5 pagesImp of MicronutrientsDanish S MehtaPas encore d'évaluation

- Astm A181-2001 PDFDocument3 pagesAstm A181-2001 PDFMohammed TariqPas encore d'évaluation

- Sybron Endo Sealapex Root Canal SealerDocument7 pagesSybron Endo Sealapex Root Canal Sealerenjoy enjoy enjoyPas encore d'évaluation

- Top 305 Companies in Pune RegionDocument39 pagesTop 305 Companies in Pune RegionNiraj Thakkar0% (1)

- 20b. Global S CycleDocument15 pages20b. Global S CyclerossydaPas encore d'évaluation

- Omeprazole: by Jennica Mae V. CuicoDocument7 pagesOmeprazole: by Jennica Mae V. Cuicoジェンニカ メイPas encore d'évaluation

- Manual of Methods OF Analysis of Foods: Pesticide ResiduesDocument270 pagesManual of Methods OF Analysis of Foods: Pesticide ResiduesAnonymous XuiUo2ThPas encore d'évaluation

- Appchem 1 1Document18 pagesAppchem 1 1Fate SoteroPas encore d'évaluation

- Selig Sealing ProductsDocument60 pagesSelig Sealing Productslaurentiu29Pas encore d'évaluation

- World Fertilizer Trends and Outlook To 2020Document38 pagesWorld Fertilizer Trends and Outlook To 2020SudhirPas encore d'évaluation

- ConChem q1 m1Document28 pagesConChem q1 m1Leonora Alejo100% (1)

- ASTM D 2821 - 00 Measuring The Relative Stiffness of Leather by Means of A Torsional Wire ApparatusDocument3 pagesASTM D 2821 - 00 Measuring The Relative Stiffness of Leather by Means of A Torsional Wire Apparatusalin2005Pas encore d'évaluation

- RN FDocument52 pagesRN Fhassan SardarPas encore d'évaluation

- Vestamid L Polyamide 12 - EvonikDocument12 pagesVestamid L Polyamide 12 - EvonikHaryo Armono100% (1)

- Volcanic Eruptions NotesDocument24 pagesVolcanic Eruptions NotesKarthikesan MakPas encore d'évaluation

- Flashing CalculationsDocument8 pagesFlashing CalculationsjcmarabouPas encore d'évaluation

- NAK80 MaterialDocument3 pagesNAK80 MaterialRicky Indra DjunawanPas encore d'évaluation

- Chapter 5 CasesDocument21 pagesChapter 5 Casesejusdem generisPas encore d'évaluation

- Waterproofing: Hydrostop 4 Py-SDocument2 pagesWaterproofing: Hydrostop 4 Py-SPrashantBaruaPas encore d'évaluation

- Amarex KRT8041eDocument36 pagesAmarex KRT8041eRui Alves da Silva100% (1)

- Kluebersynth GEM 4 N GB enDocument6 pagesKluebersynth GEM 4 N GB enIvan MarijanovićPas encore d'évaluation

- Principles of Drug Administration and OrderingDocument26 pagesPrinciples of Drug Administration and OrderingManasseh Mvula33% (3)

- Makrolon® ET3137: Grades / ExtrusionDocument4 pagesMakrolon® ET3137: Grades / ExtrusionDiegoTierradentroPas encore d'évaluation

- Surgical Nursing Calculation PracticesDocument2 pagesSurgical Nursing Calculation PracticesJéssica OinonenPas encore d'évaluation