Académique Documents

Professionnel Documents

Culture Documents

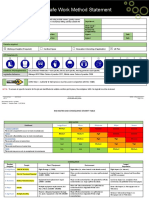

Safe Work Method Statement - Formwork and Concreting

Transféré par

Anonymous gmNTrHsTitre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Safe Work Method Statement - Formwork and Concreting

Transféré par

Anonymous gmNTrHsDroits d'auteur :

Formats disponibles

Prepared by: Muhammed Shabin

Project Engineer 12/19/2017

SAFE WORK METHOD STATEMENT FOR CONCRETE FORMWORK

Possible Safety or

Task Breakdown RB Task Breakdown RA Task Breakdown

Environment hazards

NOTE: RB = Risk Rating before controls implemented - RA = Risk Rating after controls are implemented

Design Personal Injury F Designers must L Engineer

Specifications - Crushing - Fully describe all features of design

- Falls - Provide SWMS for installation and stripping

- Being struck by falling - Define load cases

object - Define Acceptance criteria

- Provide for field adjustment

- Describe location of weep, vibrator and clean out

holes and inspection openings

- Detail sequence of concrete placement, including

any slopes, direction of pore and time between pores

- Describe strength stability and stiffness of system

- Detail foundation materials

- Details of surface type (filling, compaction, drainage)

- Allow for loads during construction (such as workers

materials, wind, false decks, rain, water runoff) reduce

fall risks where pracricable

Certification of design must be provided by a competent

Person

All formwork materials ( timber/plywood, prefab modules, aluminum,

steel or plastic) must meet quality design testing criteria as defined in

codes or standard practices

All exposed rebars must contain end caps

- Correct size for rebar

- Fitted correctly

- Regular inspections are undertaken to check conditions of

endcaps and to ensure no caps are missing

Document No. 007 Activity : Concrete Formwork Review No. 000 Date: 19th December 2017

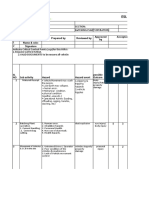

Prepared by: Muhammed Shabin

Project Engineer 12/19/2017

SAFE WORK METHOD STATEMENT FOR CONCRETE FORMWORK

Possible Safety or

Task Breakdown RB Task Breakdown RA Task Breakdown

Environment hazards

NOTE: RB = Risk Rating before controls implemented - RA = Risk Rating after controls are implemented

Preparation Personal Injury F Project documentation must be available on site and include at least L Engineer Site

- Crushing - design specifications Supervisor

- Falls - drawings

- Being struck by falling - loading calculations

object - plans/Elevations

Collapse of structure - general arrangements

- maximum point loadings

- component types and spacings

- methods of securing structure and components

- formply size

- minimum stripping times

- edge protection

- back propping where required

- any variation from design and subsequent certification of

variations

- safe load bearings

- time frames between pour and pour rates

Personal Personal Injury F Competency based training L Site Supervisor

Requirements - Crushing - site induction

- Falls - nature of hazards and emergency plan

- Being struck by falling - requirements from HSE Plan

object - operation of heavy equipments as required

Collapse of structure - PPE (use, maintanence, storage)

- specific SWMS

Risk Control Personal Injury F consider: L Site Supervisor

- Crushing - edge protection and netting to prevent falling objects

- Falls - fit for purpose work platforms/scaffolding

- Being struck by falling - traffic management, mechanical lifting, adequate lighting

object - PPE and house keeping

Document No. 007 Activity : Concrete Formwork Review No. 000 Date: 19th December 2017

Prepared by: Muhammed Shabin

Project Engineer 12/19/2017

SAFE WORK METHOD STATEMENT FOR CONCRETE FORMWORK

Possible Safety or

Task Breakdown RB Task Breakdown RA Task Breakdown

Environment hazards

NOTE: RB = Risk Rating before controls implemented - RA = Risk Rating after controls are implemented

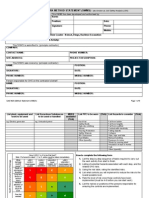

Formwork erection Personal Injury F all framing must be carried out so that it complies with on site design L All

- Crushing documentation and any manufacturers' requirements

- Falls inspect all formwork components to ensure acceptable conditions

- Being struck by falling as per

object Traditional

Collapse of structure Foundation:

- ensure stable base

- ensure base plates are provided under props and standards

- ensure suitable sole boards are provided

Note: Base plates and sole boards may not be required if

competent persons deems them unnecessary

Note: If Lapped planks are used, they must be secured against

uplifting and slipping

Pre pour inspection Personal Injury F Inspection must be undertaken by qualified person to ensure L Site Supervisor

- Crushing - safe work practices were followed

- Falls - system complies with requirement of design and project

- Being struck by falling documentation

object - is adequately braced

Collapse of structure - is strippable

- has adequate connections

- correct spacing of frames, props and timbers

- correct joists and bearer sizes

- accectable jack extensions

- adequate bracing to ensure stability

The engineer should suppliy an inspection certificate to verify the

structural integrity of the support structure and formwork system

Document No. 007 Activity : Concrete Formwork Review No. 000 Date: 19th December 2017

Prepared by: Muhammed Shabin

Project Engineer 12/19/2017

SAFE WORK METHOD STATEMENT FOR CONCRETE FORMWORK

Possible Safety or

Task Breakdown RB Task Breakdown RA Task Breakdown

Environment hazards

NOTE: RB = Risk Rating before controls implemented - RA = Risk Rating after controls are implemented

During Concrete Personal Injury F Ensure L All

Pour - Crushing - continuous supervision of the formwork assembly and

- Falls concrete placement

- Being struck by falling - Communication between supervising personnel and

object the placing crews

Collapse of structure - Monitor indicators if installed

- if any failure, undue settlement or distortion of the

formwork develops, work should cease and

- the affected formwork assembly or component

strengthened or replaced

- Concrete is placed and compacted in a matter that

ensures specified quality of surface finish

Dismantling Personal Injury F Concrete should be inspected prior to dismantle L Site Supervisor

formwork - Crushing Check for unacceptable:

(Stripping) - Falls - warping

- Being struck by falling - twisting

object - cracks

Collapse of structure - blowholes

- deviations as per

Emergency Plan Personal Injury M Must include at least M All

- Crushing - rescue procedures

- Falls - evacuation points

- Being struck by falling - roles/responsibilities

object - communication procedures

Collapse of structure - first aid

- use and location of fire protection equipments

Document No. 007 Activity : Concrete Formwork Review No. 000 Date: 19th December 2017

Prepared by: Muhammed Shabin

Project Engineer 12/19/2017

SAFE WORK METHOD STATEMENT FOR CONCRETE FORMWORK

SAFE WORK METHOD STATEMENT - part 2

Training in the following safe work procedures/

Formal training, Licenses required for workers

Duties of workers undertaking this task: SWMS/ training modules is required:

undertaking this task:

All workers to be trained in relevant procedures

- License to perform high risk work (heavy Name Operator Site specific Inductions

equipments like Crane, forklift, Man lift) Name Rigger Training in SWMS

- TUV certificate for Equipment and Name Supervisor Nature of hazards/risks

operator Emergency procedures

Duties of regulatory permits/licenses,

Details of Supervisory Agreements for workers

Engineering details/Certificates/Work Cover Relevant Codes of Practice

undertaking this tasks:

Approvals

- Competent supervisors for job - Local council permits

- Direct on site-supervision - Building Approvals

- Remote site - communication systems/ - EPA approvals/ Permits

schedule - 3rd party attestation

- Audits - PPE to comply with standards

- Spot checks, etc

- Reporting systems

Tools/ Equipments Maintanence details for tools/ equipments used on job

Example

- Electric jack Hammer As per manufacture recommendation, Electrical tested/ Tagged every 3 months

-

Document No. 007 Activity : Concrete Formwork Review No. 000 Date: 19th December 2017

Prepared by: Muhammed Shabin

Project Engineer 12/19/2017

SAFE WORK METHOD STATEMENT FOR CONCRETE FORMWORK

Part 3 - SIGN OFF

This SWMS has been developed in consultation and cooperation with the workers and relevant persons from the prestigious Organization. I have read the above

SWMS and understand its contents. I confirm that I have skills and training, including relevant certifications to conduct the task as described. I agree to comply

safety requirements within this SWMS including safe work instructions and Personal Protective Equipments described

Name Qualification Signature Date Time Organization

Review No. 1 2 3 4 5 6 7

Name and initials

Date

Document No. 007 Activity : Concrete Formwork Review No. 000 Date: 19th December 2017

Prepared by: Muhammed Shabin

Project Engineer 12/19/2017

Vous aimerez peut-être aussi

- SWMS DemolitionDocument18 pagesSWMS Demolitionalee0007100% (1)

- SWMS - PlumberDocument7 pagesSWMS - PlumberSiddiqueShaikhPas encore d'évaluation

- Safe Work Method Statement TemplateDocument3 pagesSafe Work Method Statement TemplateJonasPas encore d'évaluation

- Safe Work Method StatementDocument11 pagesSafe Work Method StatementJPas encore d'évaluation

- Concrete Formwork Work Method Statement (SWMS) V8Document5 pagesConcrete Formwork Work Method Statement (SWMS) V8pparreraPas encore d'évaluation

- Excavations: Job Safety AnalysisDocument5 pagesExcavations: Job Safety AnalysisJICKPas encore d'évaluation

- Concrete Formwork Suspended SlabDocument5 pagesConcrete Formwork Suspended SlabKate HopleyPas encore d'évaluation

- Plumbing Sewerage - Drainage Swms 10Document26 pagesPlumbing Sewerage - Drainage Swms 10Shahrin KamaruzamanPas encore d'évaluation

- Ironbark: Safe Work Method Statement No. WMS-570 Task: Work Practice - Epoxy FlooringDocument12 pagesIronbark: Safe Work Method Statement No. WMS-570 Task: Work Practice - Epoxy Flooringklp_kedarpPas encore d'évaluation

- Job Safety Analysis: Manual ExcavationDocument2 pagesJob Safety Analysis: Manual Excavationfdfddf dfsdfPas encore d'évaluation

- Safety Method StatementDocument14 pagesSafety Method StatementnayakyaPas encore d'évaluation

- Rebar Job Hazard AnalysisDocument1 pageRebar Job Hazard Analysisjoker batmanPas encore d'évaluation

- Safe Work Method Statement - PlumbingDocument4 pagesSafe Work Method Statement - PlumbingJohn KurongPas encore d'évaluation

- Master Builders SA - Safe Work Method Statement - Roof Metal InstallationDocument7 pagesMaster Builders SA - Safe Work Method Statement - Roof Metal InstallationvictorPas encore d'évaluation

- Safe Work Method StatementDocument7 pagesSafe Work Method StatementianllagasPas encore d'évaluation

- Excavations JSA Final 2015Document5 pagesExcavations JSA Final 2015jithin shankarPas encore d'évaluation

- Risk AssessmentDocument3 pagesRisk AssessmentAkinbami Olorunnifemi100% (1)

- HAZARD IDENTIFICATION & RISK ASSESSMENT FOR EXCAVATION OF ROAD WITH TLBDocument7 pagesHAZARD IDENTIFICATION & RISK ASSESSMENT FOR EXCAVATION OF ROAD WITH TLBCharles LambPas encore d'évaluation

- Safe Work Method StatementDocument4 pagesSafe Work Method StatementShahed Facebook100% (1)

- 001 JSA FormworkDocument1 page001 JSA FormworkRui Ribeiro57% (14)

- Job Safety Analysis For Rebar FixingDocument4 pagesJob Safety Analysis For Rebar FixingJayvee Baradas Valdez67% (3)

- Aha SampleDocument1 pageAha SamplekaremkokoPas encore d'évaluation

- Ohs Form 005 Safe Work Method Statement (SWMS) : This SWMS Has Been Developed and Authorised byDocument10 pagesOhs Form 005 Safe Work Method Statement (SWMS) : This SWMS Has Been Developed and Authorised byadi100% (2)

- ISC-JSA Grouting Works For Shared FenceDocument4 pagesISC-JSA Grouting Works For Shared FenceSameer AlmahboubPas encore d'évaluation

- Excavation Trenching and HorizontalDocument5 pagesExcavation Trenching and HorizontalRaed Naim Khammash100% (1)

- Steel FixingDocument5 pagesSteel Fixingrishanmulky88% (8)

- Tower Crane Dismantling JSA HSE ProfessionalsDocument2 pagesTower Crane Dismantling JSA HSE ProfessionalsnabeelPas encore d'évaluation

- Instructions For Use: Hse-Pro-006A Asbestos Management - Minor Works SwmsDocument21 pagesInstructions For Use: Hse-Pro-006A Asbestos Management - Minor Works SwmsWinstone AudiPas encore d'évaluation

- JSA for Chainsaw Tree ClearingDocument2 pagesJSA for Chainsaw Tree ClearingRetselisitsoePas encore d'évaluation

- Job Safety Analysis: JSA Reference #: DateDocument3 pagesJob Safety Analysis: JSA Reference #: DateLi QiPas encore d'évaluation

- JHA Scaffolding ErectionDocument12 pagesJHA Scaffolding ErectionChayank TiwariPas encore d'évaluation

- JHA No. 06, Manual Excavation and Instalasi Formwork For Barier Pole Dan Concrete Slab HydrantDocument4 pagesJHA No. 06, Manual Excavation and Instalasi Formwork For Barier Pole Dan Concrete Slab HydrantDarmawan OnradPas encore d'évaluation

- Job Safety Analysis (JSA) : Commercial Roofing-Membrane InstallationDocument4 pagesJob Safety Analysis (JSA) : Commercial Roofing-Membrane InstallationRakesh Chauhan100% (1)

- Painting (General Safety) SWMS 10183-4 - SAMPLEDocument6 pagesPainting (General Safety) SWMS 10183-4 - SAMPLEKunal PanchalPas encore d'évaluation

- Safe lifting operationsDocument6 pagesSafe lifting operationsvsfchanPas encore d'évaluation

- Boring & Cone Penetration test-JSA-01Document3 pagesBoring & Cone Penetration test-JSA-01Akash Shukla67% (3)

- JSA For Dismantalling of PVC Pipe (5cm) by Acetylene Gas CuttingDocument4 pagesJSA For Dismantalling of PVC Pipe (5cm) by Acetylene Gas CuttingMohammed Minhaj100% (1)

- Heights Safe Working atDocument7 pagesHeights Safe Working atHendrias Ari SujarwoPas encore d'évaluation

- Brazing (Oxygen and Acetylene)Document6 pagesBrazing (Oxygen and Acetylene)My Zain100% (1)

- HIRA Batching PlanDocument9 pagesHIRA Batching Plannitish tiwariPas encore d'évaluation

- OHS SWMS Form 005 ExcavationDocument8 pagesOHS SWMS Form 005 Excavationazlinaz100% (2)

- EARTHWORKS SAFETYDocument4 pagesEARTHWORKS SAFETYsatti100% (2)

- JSA For Concrete WorkDocument6 pagesJSA For Concrete Worklê ngọc tùng0% (1)

- SWMS 67 - Safe Use of Nail GunsDocument4 pagesSWMS 67 - Safe Use of Nail GunsJonasPas encore d'évaluation

- Concrete Placement - FootingsDocument2 pagesConcrete Placement - FootingsbashirdarakPas encore d'évaluation

- RA-02 Installation of Aco Tech PanelDocument7 pagesRA-02 Installation of Aco Tech PanelVaradaraju Thirunavukkarasan100% (1)

- Jsa - ExcavationDocument7 pagesJsa - ExcavationNOOR AISYA AMIRA ZUKAFLI100% (1)

- Sealcoating /crack Repair Parking Lots: Job Safety AnalysisDocument3 pagesSealcoating /crack Repair Parking Lots: Job Safety AnalysisRetselisitsoe0% (1)

- Site Specific Safety Plan ChecklistDocument22 pagesSite Specific Safety Plan ChecklistAnonymous y1pIqcPas encore d'évaluation

- JSA For Rebar Works Includes Working in ScaffoldingDocument4 pagesJSA For Rebar Works Includes Working in Scaffoldingyc safetyPas encore d'évaluation

- Safe Work Method StatementDocument19 pagesSafe Work Method StatementParas100% (2)

- Job Safety Analysis WorksheetDocument14 pagesJob Safety Analysis WorksheetCherry Betonio100% (2)

- RA-for Glass Installation 30-04-2022Document6 pagesRA-for Glass Installation 30-04-2022Muideen Oyedele100% (2)

- Assess and Manage Construction RisksDocument1 pageAssess and Manage Construction RisksAnonymous goXrLOI33% (3)

- SWMSElevated Work PlatformsDocument4 pagesSWMSElevated Work PlatformsRay LeePas encore d'évaluation

- RA - For Precast ChambersDocument5 pagesRA - For Precast ChambersKallem RajashekarPas encore d'évaluation

- CPF-JSA-022 Welding Cutting and Drilling of Underground and Above Pipes Night ShiftDocument3 pagesCPF-JSA-022 Welding Cutting and Drilling of Underground and Above Pipes Night Shiftaioudi100% (1)

- Sample SWMS SP003 - Margate Parade Boardwalk Concrete WorkDocument10 pagesSample SWMS SP003 - Margate Parade Boardwalk Concrete WorkHaytham S. AtiaPas encore d'évaluation

- 3.4.2 Overview of The Rigid Pavement Design ProcessDocument13 pages3.4.2 Overview of The Rigid Pavement Design ProcessAndresPas encore d'évaluation

- Nilkamal FormworkDocument23 pagesNilkamal FormworkRahul AgarwalPas encore d'évaluation

- Schedule of Rates For Watermain Construction in Sarawak 2020Document35 pagesSchedule of Rates For Watermain Construction in Sarawak 2020Ryan LaiPas encore d'évaluation

- Unit 4 Role of Architect in Construction and Site Management-1Document14 pagesUnit 4 Role of Architect in Construction and Site Management-1Saloni Shah100% (1)

- Rate 69Document37 pagesRate 69Mishal Limbu100% (1)

- Precast Wall Connection Solution in 40 CharactersDocument2 pagesPrecast Wall Connection Solution in 40 CharacterskamakshiPas encore d'évaluation

- Roof Slab - MEVA Formwork CalculationDocument26 pagesRoof Slab - MEVA Formwork CalculationRicky Kusuma Hariyadi100% (1)

- Summary Bill of Quantities: Project Identifying InformationDocument15 pagesSummary Bill of Quantities: Project Identifying InformationRussel Renz de MesaPas encore d'évaluation

- Network Diagram: Engineering Field Office - 445 CDDocument7 pagesNetwork Diagram: Engineering Field Office - 445 CDJeffrey DioquinoPas encore d'évaluation

- Well Foundation MethodologyDocument20 pagesWell Foundation MethodologyKangkan Biswas75% (4)

- Construction of A 170m Long Cripple Sided Tunnel Using Variable Geometry Hydraulic Formwork in DTL 3, C927Document16 pagesConstruction of A 170m Long Cripple Sided Tunnel Using Variable Geometry Hydraulic Formwork in DTL 3, C927Batu GajahPas encore d'évaluation

- Item GuidelinesDocument34 pagesItem GuidelinesLorena AñosàPas encore d'évaluation

- Manar Cup Lock SystemDocument54 pagesManar Cup Lock Systemtarek.filePas encore d'évaluation

- Prof (1) - Zahid Ahmad Siddiqi Formwork Design-IIIDocument32 pagesProf (1) - Zahid Ahmad Siddiqi Formwork Design-IIIasdasPas encore d'évaluation

- Annexure 31.7 (A) PDFDocument8 pagesAnnexure 31.7 (A) PDFNilay GandhiPas encore d'évaluation

- Tekla - Concrete Components Reference - 1Document778 pagesTekla - Concrete Components Reference - 1sixramesh123Pas encore d'évaluation

- Construction of Surge Shaft Using Slip Form TechniqueDocument4 pagesConstruction of Surge Shaft Using Slip Form TechniqueCharumitra Singh YadavPas encore d'évaluation

- Middle East Scaffolding Calculation SheetDocument8 pagesMiddle East Scaffolding Calculation SheetissaPas encore d'évaluation

- Scrap Yard Mochia BOQDocument8 pagesScrap Yard Mochia BOQSAMEERPas encore d'évaluation

- Peri Komponentu Katalogas Klojiniams 2015 enDocument948 pagesPeri Komponentu Katalogas Klojiniams 2015 enLuôn HồPas encore d'évaluation

- BOQ Canteen BlockDocument80 pagesBOQ Canteen BlockyogeshPas encore d'évaluation

- Peri Scope 2010Document18 pagesPeri Scope 2010Nurali MamenPas encore d'évaluation

- Construction Thumb Rule BrijjDocument4 pagesConstruction Thumb Rule BrijjNaveen Bansal100% (2)

- Short Span Bridge Construction MethodDocument41 pagesShort Span Bridge Construction Method20MK06 - PUSHPA SPas encore d'évaluation

- Bondek IIDocument24 pagesBondek IIumtancw100% (3)

- U-Boot Technology Reduces Construction Costs by Lightening Concrete SlabsDocument2 pagesU-Boot Technology Reduces Construction Costs by Lightening Concrete SlabsTalmeez KundgolPas encore d'évaluation

- ESDEP Lecture 10 on Composite ConstructionDocument46 pagesESDEP Lecture 10 on Composite ConstructioniSoK11Pas encore d'évaluation

- BCN 4465 Outline-Fall 2016Document2 pagesBCN 4465 Outline-Fall 2016api-271970349Pas encore d'évaluation

- BCT593 ASSIGNMENT ESTIMATING March August 2023Document7 pagesBCT593 ASSIGNMENT ESTIMATING March August 2023MAXSWELL MANGGIE ZAMRYPas encore d'évaluation

- Item Wise Rate TenderDocument5 pagesItem Wise Rate TenderB-05 ISHA PATELPas encore d'évaluation

- MFE Accessories Brochure (Old)Document8 pagesMFE Accessories Brochure (Old)David LawPas encore d'évaluation