Académique Documents

Professionnel Documents

Culture Documents

CTT11934 - Scope of Work

Transféré par

Waqas WaqasDescription originale:

Titre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

CTT11934 - Scope of Work

Transféré par

Waqas WaqasDroits d'auteur :

Formats disponibles

ANNEXURE “A1”

SCOPE OF WORK

1. Introduction

The Petroleum Oil & Gas Corporation of South Africa, hereinafter referred to as

PetroSA, is the national oil company of the Republic of South Africa. PetroSA

owns, operates and manages the South African Government’s assets in the

Petroleum Industry.

PetroSA seeks to establish a three year or five year contract [commencing 01

July 2015] with a suitable and competent Supplier for the retubing of heat

exchanger bundles and / or for the manufacturing of complete heat exchangers,

i.e. shells and bundles. The majority of the exchangers are required to be

designed, fabricated or retubed in accordance with ASME VIII Div 1 and TEMA.

The contract shall be based on rates for labour / machining and cost plus

percentage mark-up for materials.

2. Services

2.1. Scope of work, but not necessarily limited to:

Design, Procure, Manufacture, Inspect and Test

Supply, Packing, Transport and Deliver to PetroSA Mossel Bay Site

Supply of consumables / material to execute the Contract works

Rigging and Rigging Equipment to load and off load equipment at

supplier’s works

Project Management, Supervision and Quality Assurance

Inspection and Testing through-out Construction

Data Package

Performance and Acceptance test of workmanship

Defects Liability Period

Any other items not covered by the foregoing, but forming part of

the Supplier’s obligations and responsibilities, including all ancillary

equipment and services required to make heat exchangers supplied

a fully comprehensive working system, until such time as the heat

exchanger has been Accepted by PetroSA.

2.2. Mechanical Scope

2.2.1. The Supplier shall supply PetroSA with, in the case retubing:

a) Off-loading, dismantle / strip tube bundle complete at

Supplier Works and clean components.

b) Inspect and assess material and tolerances, machining,

welding, heat treatment and associated fabrication testing

requirements. Submit detailed cost estimate to PetroSA.

c) Forming of U-tubes and heat treatment when applicable.

d) Assemble heat exchanger tube bundle, attaching tubes to

tube sheet(s), as per PetroSA approved Supplier QA/QC

procedures and PetroSA Engineering specifications and

other support documentation.

e) Preparation of tube bundle after reinstatement

The Supplier shall take appropriate action to protect

and prevent internal and external corrosion of all tube

bundle components after final inspection and approval

by PetroSA.

The Supplier shall take suitable precaution to protect

tube bundles from physical damage during

transportation and handling.

The Supplier shall clearly and suitably mark the lifting

points and tube bundle weight shall be prominently

displayed.

Each assembled tube bundle or new heat exchanger

shall be clearly identified with the tag number hard

stamped at a suitable location on the tubesheet[s].

Specific painting requirements shall be completed

before delivery.

2.2.2. The Supplier shall supply PetroSA with, in the case

replacement heat exchanger:

a) Design new heat exchanger in accordance with existing

equipment information given, using the latest code of

manufacture, and submit to PetroSA for approval.

b) Compile new drawings and submit to PetroSA for

approval.

c) Compile QCP and accompanying QC documents, i.e.

WPS, technique sheets and submit to PetroSA for

approval.

d) Compile purchase specifications for materials and submit

to PetroSA for approval.

e) Purchase materials for new manufacture

f) Manufacture new shells and bundles as per PetroSA

Specifications.

g) Assemble heat exchanger tube bundle, attaching tubes to

tube sheet(s), as per PetroSA approved Supplier QA/QC

procedures and PetroSA Engineering specifications and

other support documentation.

2.3. Scope of Documentation

2.3.1. Level 4 MS project schedule within 3 working days of order

placement for the manufacturing, inspection and approval of

QCP hold points

2.3.2. Mandatory Requirements

a) Design and manufacturing document review and approval

b) Quality Control Plans

c) Material purchase specifications

d) NDE Procedures

e) Procedure Qualification Records

f) Weld Procedure Specifications

g) Fabrication Drawings

h) Kick-off and pre inspection meetings

i) Inspections at appropriate stages (See attached draft IAP)

j) Heat Treatment Charts

k) NDE applicable specifications, typically ASME Vlll, Div 1

and PetroSA specifications

l) Final documentation deliverables

Per Tag or ID Number

Original Code Data Book

Certified copy of Code Data Book

Original Code Data Book on CD

Drawings in Microstation format (for new manfacture)

The Supplier shall supply PetroSA with data pack containing

the following information, not later than 2 weeks after Final

release of equipment from supplier’s works.

2.4. Summary of work excluded from the scope of this specification:

PetroSA will provide:

Engineering drawings and data sheets of existing equipment

Government approved inspection authority

Loading or off-loading at PetroSA site

Commissioning

Thermal design, if required

Finite Element Analysis (FEA), if required

2.5. APPLICATION PROCESS

Once the service contract (rates) is in place –

PetroSA will issue the Supplier with a scope of work based on a

specific heat exchanger, complete with drawings and relevant

design information.

The Supplier shall forward a detailed quotation, complete with cost

breakdown backup, per tag number, within 7 days of receipt of

scope of work / tube bundle at Suppliers Works.

The Supplier shall clearly state exclusions from its scope of supply.

Suppliers are at liberty to submit proposals that may deviate from

guidelines set by PetroSA. PetroSA shall be required to approve

these alternate proposals.

The confirmation to perform the Services will be issued to the

Supplier by PetroSA's Engineering & Design Department, with an

order number, within 7 days of receiving Supplier's quotation.

The Supplier shall then issue a level 4 MS project schedule within 3

working days which shall form the basis of the equipment delivery.

Pre-inspection meeting shall be held at the supplier’s works to

clarify and agree on the scope of work (in detail) and align AIA

requirements.

2.6. REFERENCE DOCUMENTS

Air-Cooled Heat Exchangers SP/EA001S001

Exchanger Design Criteria SP/EZ001-S001

Metrication SP/MZ001S005

Technical specification painting – Part 2 –

coating system ISM/SD/MET/002

Requirements for post weld heat treatment ISM/PR/MET/002

Heat treatment SP/UZ006S005

Specification for Category 3 Pressure

Apparatus SP/VZ001-S001

Specification for Category 1 And 2 Pressure

Vessels SP/VZ001S010

Surveillance of suppliers’ manufacturing

program ISM/PR/AIA/001

PetroSA AIA scope and design verification ISM/PR/AIA/002

Supplier quality assurance requirement ISM/PR/AIA/003

Code Data Book Review ISM/PR/AIA/004

AIA coordination and Responsibilities ISM/PR/AIA/005

Mandatory Design, Inspection and Certification

of new/repaired/modified Boiler and Pressure ISM/PR/AIA/006

Apparatus

NCR's and Corrective Actions ISM/PR/AIA/007

Proof of Inspection (C.O.C.) Certificate of

Compliance ISM/PR/AIA/008

Pre-inspection meeting procedure ISM/PR/AIA/009

PR/MRE/END/DRW/0

Engineering Supplier Drawing Supply 01

Specification Packing / marking protection and 2340-ZZ0000-21001-

storage S005

DRAFT INSPECTION ACTIVITY PLAN (IAP) GUIDELINE

THIS DRAFT IAP IS A GUIDELINE DEFINING THE MINIMUM EXTENT OF PetroSA AND/OR

OTHER PARTY ACTIVITIES

TYPE AND EXTENT OF TESTS WILL BE STRICTLY COMPLY WITH CODES AND/OR

SPECIFICATIONS

CLASS: TYPE: DATE:

HEAT EXCHANGERS TUBE BUNDLES

TYPE

OF

DESCRIPTION OF ACTIVI CERTIFICATI

POS TY ON REMARKS

REQUIREMENT REQUIRED

Petro

SA

Material certificates for

1 tubes, plate, fixed and R Yes PetroSA might specify steels origin

floating head tubesheet

Welder and NDE operator Where welded construction is

2 R Yes

qualification employed

Workmanship and fabrication

3 Fabrication monitoring RI

progress observation

4 Shop major weld repairs O Yes If any

Non destructive

5 RI Yes

examination

U-Tube heat treatment after

6 R Yes Heat charts where applicable

bending

Pressure value and hold time to be

7 Hydrostatic tests W Yes

certified

Visual and dimensional

8 W Yes

check (final inspection)

9 Inspection Register R

Rev Date Approved By LEGEND

Review by Inspector

R

Random Inspection during fabrication – Notification

RI

not required

W Witness by Inspector – Notification required

SW Spot witness by Inspector – Notification required

Observed point – the specified inspector requires

notification of the time of inspection or test. The

O inspection or test is performed as scheduled, if the

specified inspector is not present, the Supplier may

proceed to the next step.

TYPICAL VENDOR DOCUMENT REQUIREMENT LIST (VDRL)

PROJECT :

EQUIPT No. :

VENDOR DOCUMENT DATE :

REQUIREMENT LIST PREPARED :

PAGE :

REV :

THE VENDOR SHALL PROVIDE DOCUMENTATION TO SATISFY THE

REQUIREMENTS LISTED BELOW.

VENDOR'S ACCEPTANCE SIGNATURE:

.........................................................

COPIES REQUIRED

DESCRIPTION

WITH FINAL

FOR REVIEW

BID DISTRIBUTION

*AFTER PURCHASE ORDER DUE REPR

PRINT PRINT REPRO PRINT

DATE* O

Master Document List

Fabrication Schedule

Sub Vendor List

Material Technical Purchase Specifications

General Arrangement Drawings

Detail Fabrication Drawings

Design Calculations (Mechanical)

QC Plan (Typical With Bid) + Actual

NDE Procedures (To AIA)

Inspection and Test Plan

Welding Procedure Specification

Welding Procedure Qualification Record

Welding Consumables Certificates

Heat Treatment Procedures

Code Data Book Addendum

Material Test Certificates

NDE Reports / Certificates

Non Conformance Reports

Concession Requests

AIA Certification

As Built Drawings

As Built Calculations

Signed Off QC Plan

TYPICAL ENGINEERING DOCUMENT LIST (EDL)

DOCUMENT REMARK

DOCUMENT TITLE REV

NUMBER S

1. DRAWINGS & DATA SHEETS

Data Sheet TBA Included

General Arrangement Drawing TBA Included

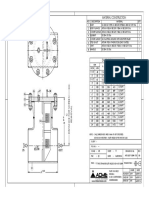

Detail Drawing C028100248 Included 0

2. SPECIFICATIONS

Shell & Tube Heat Exchanger Included

Exchanger Design Criteria Included

Metrication Included

Requirements for Vendor's Drawings & Documents Included

Painting Included

Heat Treatment SP/UZ006-S005 Included 03

Specification for Category 1 & 2 Pressure Apparatus SP/VZ001-S010 Included 00

Specification for Category 3 Pressure Apparatus SP/VZ001-S001 Included 05

Mandatory Design, Inspection & Certification of Boiler Included

SP/42001-S001 02

& Pressure Apparatus

Lad Project Engineering Bulletins 001 -009 Included

3. PROCEDURES

Vendor QA Requirements TI/P/00/027 Included

PR/MRE/END/DR Included

Engineering Supplier Drawing Supply

W/001

* Is supplied upon request

Vous aimerez peut-être aussi

- Weekly Progress ReportDocument2 pagesWeekly Progress ReportMade GileePas encore d'évaluation

- A-Mtl-Pro-730-38931 Rev A Pwps For Column Pipe To Column Pipe and 10 Inch Dia. Pipe To Pipe Welding With Gtaw + Smaw ProcessDocument4 pagesA-Mtl-Pro-730-38931 Rev A Pwps For Column Pipe To Column Pipe and 10 Inch Dia. Pipe To Pipe Welding With Gtaw + Smaw ProcessRamzi ZoghlamiPas encore d'évaluation

- Closure Data PEDocument2 pagesClosure Data PEjowarPas encore d'évaluation

- Leak Testing and Rehabilitation PDFDocument72 pagesLeak Testing and Rehabilitation PDFjsenadPas encore d'évaluation

- L1 34258 en T Union S 2 - UV 418 TT en MDPK 5aDocument2 pagesL1 34258 en T Union S 2 - UV 418 TT en MDPK 5aKrishna VachaPas encore d'évaluation

- Vaisakh Resume of Mechanical Project Engineer With Five Years ExperienceDocument3 pagesVaisakh Resume of Mechanical Project Engineer With Five Years ExperienceEngr Tahir UL HaqPas encore d'évaluation

- G12MF TypeDocument1 pageG12MF Typeosto72Pas encore d'évaluation

- Installation ManualDocument20 pagesInstallation ManualHasan GüleryüzPas encore d'évaluation

- EIL - Specification Sheet123Document1 pageEIL - Specification Sheet123Dinesh ChougulePas encore d'évaluation

- Amair Ali (Piping) .Document3 pagesAmair Ali (Piping) .mustangPas encore d'évaluation

- AG Piping Specification SPEL en M SG 12 002 Rev0Document31 pagesAG Piping Specification SPEL en M SG 12 002 Rev0cchristt2584Pas encore d'évaluation

- National Oil Corporation: Rev Date Description Checked ApprovedDocument15 pagesNational Oil Corporation: Rev Date Description Checked ApprovedRochdi SahliPas encore d'évaluation

- Curriculumvitae: Personal ParticularDocument14 pagesCurriculumvitae: Personal ParticularBakhtiar Afendy ZaabaPas encore d'évaluation

- FRP Procedure Rev DDocument13 pagesFRP Procedure Rev DDaengkulle Firmansyah PuteraPas encore d'évaluation

- T 2171 - Diesel Storage TankDocument2 pagesT 2171 - Diesel Storage TankHuynh Thanh TamPas encore d'évaluation

- Flexible Hose Technical DataDocument7 pagesFlexible Hose Technical DataDhimas IriantoPas encore d'évaluation

- Alco ValvesDocument56 pagesAlco ValvesGuillermo de la Fuente SantiagoPas encore d'évaluation

- Product Sheet ASME Porocedure PDFDocument2 pagesProduct Sheet ASME Porocedure PDFHoang Diep PhanPas encore d'évaluation

- 003 - Exhibit A Scope of WorkDocument16 pages003 - Exhibit A Scope of WorkAF Dowell MirinPas encore d'évaluation

- MEP Draughtsman, BIM MODELERDocument2 pagesMEP Draughtsman, BIM MODELERMANISHPas encore d'évaluation

- 02 Samss 001Document6 pages02 Samss 001Florante NoblezaPas encore d'évaluation

- Fluid Dynamics: Positive Displacement PumpDocument25 pagesFluid Dynamics: Positive Displacement PumpjantskiePas encore d'évaluation

- Checksheet - Installation, Testing of Fuel Oil SystemDocument7 pagesChecksheet - Installation, Testing of Fuel Oil Systemvhin84Pas encore d'évaluation

- E25NAFLON Expansion BellowsDocument22 pagesE25NAFLON Expansion BellowsRezza Octova GochirPas encore d'évaluation

- SL No DRG No DescriptionDocument13 pagesSL No DRG No DescriptionRajesh BhadraPas encore d'évaluation

- Data Sheet For Plug ValveDocument2 pagesData Sheet For Plug ValveTauqueerAhmadPas encore d'évaluation

- D Pi 175Document2 pagesD Pi 175reza329329Pas encore d'évaluation

- Baseline Schedule Narrative PDFDocument8 pagesBaseline Schedule Narrative PDFRohit JaiswalPas encore d'évaluation

- Common Causes of Bolted Joint LeakageDocument2 pagesCommon Causes of Bolted Joint LeakageAnonymous avGU1iPas encore d'évaluation

- Praveen Piping Field ResumeDocument5 pagesPraveen Piping Field ResumeprvnpgPas encore d'évaluation

- Taper Thread TorqueDocument1 pageTaper Thread TorqueRichardPas encore d'évaluation

- GS Ep PVV 111 enDocument30 pagesGS Ep PVV 111 ensenthil muruganPas encore d'évaluation

- Kespet Product Catalogue 2019 4Document62 pagesKespet Product Catalogue 2019 4Dovydas Prialgauskas100% (1)

- Saudi Aramco Test Report: PWHT Report Form SATR-W-2005 31-Aug-11Document1 pageSaudi Aramco Test Report: PWHT Report Form SATR-W-2005 31-Aug-11Mohammed Hamed BaganPas encore d'évaluation

- Api 602 Forged Steel Valve PDFDocument4 pagesApi 602 Forged Steel Valve PDFThomasFrenchPas encore d'évaluation

- Bolt Tightening ProcedureDocument6 pagesBolt Tightening Procedureal arabiPas encore d'évaluation

- Checklist For Piping Arrangement DrawingDocument2 pagesChecklist For Piping Arrangement DrawingRamalingam PrabhakaranPas encore d'évaluation

- MESC SPE 74-018 - 2010 - Nickel Alloy Pipe To Astm b167Document7 pagesMESC SPE 74-018 - 2010 - Nickel Alloy Pipe To Astm b167sathi11189Pas encore d'évaluation

- D LevelDocument26 pagesD LevelhussnainreflectPas encore d'évaluation

- Polymold Catalog 2020Document26 pagesPolymold Catalog 2020Sachin SampatPas encore d'évaluation

- Welding Presentation by NoreastDocument78 pagesWelding Presentation by Noreastravi00098Pas encore d'évaluation

- Piping Department Flow Chart: Final IssueDocument2 pagesPiping Department Flow Chart: Final IssueFrancisco José Hernández Gómez100% (1)

- Cladding (Metalworking) : Roll BondingDocument4 pagesCladding (Metalworking) : Roll Bondingcal2_uniPas encore d'évaluation

- Kitz Butterfly Valve Catalog PDFDocument28 pagesKitz Butterfly Valve Catalog PDFlyguyenquocduyPas encore d'évaluation

- T Type Strainer Butt Weld 1 PDFDocument1 pageT Type Strainer Butt Weld 1 PDFprashant mishraPas encore d'évaluation

- Orifice FlangeDocument70 pagesOrifice FlangePaulo SousaPas encore d'évaluation

- Specification For Fabrication and Erection ofDocument26 pagesSpecification For Fabrication and Erection ofEdgargarPas encore d'évaluation

- Bolt Tensioners CatalogDocument8 pagesBolt Tensioners CatalogAdrian StoicescuPas encore d'évaluation

- Schematic Diagram For Hydrotest.Document1 pageSchematic Diagram For Hydrotest.vsPas encore d'évaluation

- S.O.P For Hydro-Test: Ipcl-Gandhar Complex WI/GC-C&I/6.3/001 GC Maintenance Manual Hydro Test OF5Document7 pagesS.O.P For Hydro-Test: Ipcl-Gandhar Complex WI/GC-C&I/6.3/001 GC Maintenance Manual Hydro Test OF5கோகுல் இராPas encore d'évaluation

- Common Reference Guide To Piping EngineeringDocument32 pagesCommon Reference Guide To Piping EngineeringSteve WanPas encore d'évaluation

- E&I Tool Box ContentsDocument1 pageE&I Tool Box ContentsChandan RayPas encore d'évaluation

- EIL - Formats - PMI PDFDocument53 pagesEIL - Formats - PMI PDFABHISHEK SINGHPas encore d'évaluation

- EIL Scope of WorkDocument11 pagesEIL Scope of WorkManjunath VenkateshPas encore d'évaluation

- PipingDocument11 pagesPipingAshley JacksonPas encore d'évaluation

- Site Erection Procedure For Piping InstallationDocument10 pagesSite Erection Procedure For Piping InstallationIrsan HaeruddinPas encore d'évaluation

- Enquiry ValveDocument4 pagesEnquiry ValvePradnyesh DivekarPas encore d'évaluation

- C4 Scope of WorkDocument10 pagesC4 Scope of WorkFaiz HussainPas encore d'évaluation

- Hot TappingDocument88 pagesHot TappingAlexis Pacheco100% (1)

- Fiberglass Density Current Baffles - MSTDocument10 pagesFiberglass Density Current Baffles - MSTwafikmh4Pas encore d'évaluation

- QW 381Document1 pageQW 381Waqas WaqasPas encore d'évaluation

- Request For InspDocument1 pageRequest For InspWaqas WaqasPas encore d'évaluation

- QW 453Document1 pageQW 453Waqas WaqasPas encore d'évaluation

- Bolt TighteningDocument1 pageBolt TighteningWaqas WaqasPas encore d'évaluation

- Weld Overlay Obtained by FCAW ProcessDocument2 pagesWeld Overlay Obtained by FCAW ProcessWaqas WaqasPas encore d'évaluation

- Procedure For Tank Shell To AnnularDocument1 pageProcedure For Tank Shell To AnnularWaqas WaqasPas encore d'évaluation

- ISO IQA For DDFC by AJMAL29-04-14Document52 pagesISO IQA For DDFC by AJMAL29-04-14Waqas WaqasPas encore d'évaluation

- Q235 Steel, Q235A Q235B Q235C Q235D Specification, Chemical Composition, Properties & EquivalentDocument4 pagesQ235 Steel, Q235A Q235B Q235C Q235D Specification, Chemical Composition, Properties & EquivalentWaqas WaqasPas encore d'évaluation

- Welding Procedure SummaryDocument1 pageWelding Procedure SummaryWaqas WaqasPas encore d'évaluation

- ISO 14001 Environmental Management Systems: Training, Audit & Certification ServicesDocument2 pagesISO 14001 Environmental Management Systems: Training, Audit & Certification ServicesWaqas WaqasPas encore d'évaluation

- 9.3 Qualification of WeldersDocument1 page9.3 Qualification of WeldersWaqas WaqasPas encore d'évaluation

- WPSDocument25 pagesWPSWaqas WaqasPas encore d'évaluation

- Asmesecii Partamtrverificationfinalcopy 180402033626Document47 pagesAsmesecii Partamtrverificationfinalcopy 180402033626SULTAN100% (1)

- Pakistan Ssteel Mills Mild Steel Grades SpecificationDocument3 pagesPakistan Ssteel Mills Mild Steel Grades SpecificationWaqas WaqasPas encore d'évaluation

- Air Leak TestDocument2 pagesAir Leak TestWaqas Waqas100% (1)

- Find PDF DocumentDocument1 pageFind PDF DocumentWaqas WaqasPas encore d'évaluation

- Dua Khair o AafiyatDocument1 pageDua Khair o AafiyatWaqas WaqasPas encore d'évaluation

- Loh e QuraniDocument1 pageLoh e QuraniWaqas WaqasPas encore d'évaluation

- ISO Index Welding Standards - 1Document1 pageISO Index Welding Standards - 1Waqas WaqasPas encore d'évaluation

- Process Flow Diagram of Phthalic Anhydride Via O-Xylene OxidationDocument1 pageProcess Flow Diagram of Phthalic Anhydride Via O-Xylene OxidationTalha ImtiazPas encore d'évaluation

- Formadora PMC1002Document2 pagesFormadora PMC1002superspifPas encore d'évaluation

- F110027 Engine Intake Systems 03-13 PowerCore PDFDocument16 pagesF110027 Engine Intake Systems 03-13 PowerCore PDFesequiel fernandezPas encore d'évaluation

- 05 Lwali LukuluDocument1 page05 Lwali LukuluNatasha Wyne100% (1)

- Gaston Batt Data SheetDocument23 pagesGaston Batt Data SheetAntony Sifuna WanjalaPas encore d'évaluation

- Travelling Water ScreenDocument11 pagesTravelling Water ScreenAnirban SinhaPas encore d'évaluation

- Carrier - Split UnitsDocument32 pagesCarrier - Split UnitsOsama.ShawkyPas encore d'évaluation

- 1 - SWE系列挖掘机综合英文样本(2017.03) 售后条款更改Document14 pages1 - SWE系列挖掘机综合英文样本(2017.03) 售后条款更改Irwan Firmansyah100% (2)

- Gasworks Profile A - History and Operation of Gasworks - FinalDocument50 pagesGasworks Profile A - History and Operation of Gasworks - FinalKrishna PatelPas encore d'évaluation

- Bombas de Doble Diafragma (00000002)Document99 pagesBombas de Doble Diafragma (00000002)gonzalotecsupplantaPas encore d'évaluation

- G5 Medium Unit Cooler Ver 1.0Document10 pagesG5 Medium Unit Cooler Ver 1.0Wawan NuryanaPas encore d'évaluation

- Mitsubishi Electric Product OverviewDocument116 pagesMitsubishi Electric Product OverviewPepes HiuuPas encore d'évaluation

- ERC-Case-No 2016-211RC-SMEC-and BILECODocument3 pagesERC-Case-No 2016-211RC-SMEC-and BILECOjjhenPas encore d'évaluation

- Note On Energy and Production - Keen - Ayres-Standish - 2019Document7 pagesNote On Energy and Production - Keen - Ayres-Standish - 2019pepePas encore d'évaluation

- Gulfpub Wo 201009Document128 pagesGulfpub Wo 201009MnesPas encore d'évaluation

- Air Cooler 2Document7 pagesAir Cooler 2Anonymous WCG2HjPybJPas encore d'évaluation

- Major Petroleum CompaniesDocument75 pagesMajor Petroleum CompaniesShaho Abdulqader MohamedaliPas encore d'évaluation

- ATC Substation Eqpt Ratings CR-0063Document39 pagesATC Substation Eqpt Ratings CR-0063kcirrenwod100% (1)

- Caso 02 Ger Oper Sims Metal ManagementDocument3 pagesCaso 02 Ger Oper Sims Metal ManagementdiegoPas encore d'évaluation

- Flyer - Hospital Visit Rev 1 PDFDocument2 pagesFlyer - Hospital Visit Rev 1 PDFckwei0910Pas encore d'évaluation

- Tugas Presentasi PKLDocument3 pagesTugas Presentasi PKLAidil AzharPas encore d'évaluation

- Knauf Insulation UAE Price ListDocument28 pagesKnauf Insulation UAE Price ListCalin SimionPas encore d'évaluation

- Hospital Directory (Metro Manila, Philippines)Document6 pagesHospital Directory (Metro Manila, Philippines)diannerized63% (8)

- Waste To Energy: Outlook For The PhilippinesDocument17 pagesWaste To Energy: Outlook For The PhilippinesMiguel CuisiaPas encore d'évaluation

- Accounting Assignment 3 - FinalDocument21 pagesAccounting Assignment 3 - FinalMiia SiddiqiPas encore d'évaluation

- R V Vessel Jacket TypesDocument2 pagesR V Vessel Jacket TypesJohan ConradiePas encore d'évaluation

- Problems Pinch TechnologyDocument2 pagesProblems Pinch TechnologyCindi RamayantiPas encore d'évaluation

- VNEM Program GuidelinesDocument25 pagesVNEM Program GuidelinesL W100% (1)

- Regulation Body of KnowledgeDocument238 pagesRegulation Body of Knowledgeshriarticles3584Pas encore d'évaluation

- Auto TrackDocument12 pagesAuto TrackSantiagoLlanosPas encore d'évaluation