Académique Documents

Professionnel Documents

Culture Documents

Astm - A 36 (M) (1970-1985) PDF

Transféré par

jaferrero0 évaluation0% ont trouvé ce document utile (0 vote)

61 vues11 pagesNorma ASTM

Titre original

ASTM - A 36 (M) (1970-1985).pdf

Copyright

© © All Rights Reserved

Formats disponibles

PDF ou lisez en ligne sur Scribd

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentNorma ASTM

Droits d'auteur :

© All Rights Reserved

Formats disponibles

Téléchargez comme PDF ou lisez en ligne sur Scribd

0 évaluation0% ont trouvé ce document utile (0 vote)

61 vues11 pagesAstm - A 36 (M) (1970-1985) PDF

Transféré par

jaferreroNorma ASTM

Droits d'auteur :

© All Rights Reserved

Formats disponibles

Téléchargez comme PDF ou lisez en ligne sur Scribd

Vous êtes sur la page 1sur 11

Standard Specification for

STRUCTURAL STEEI.'

‘his suas iid wee the fed desertion \ 4A AGN: the number ims losing He dsgation nus the

yes frig adeyton a inthe es of resen he yer at revson Aman in Potosi yo

rearoroval A aupereecaon

nate ana hae see lat hvssan enya

huis has bron apron for we BY etl ofthe Depot of Dene on orien the DoD Ines of

Spetecontond Sond

1. Scope

LI This specification® covers carbon stert

shapes. plates, and bars of structucal quality for

use in riveted, bolted, of welded construction oF

bridges and buildings, and for general sructural

purpeses.

1.2 Supplemental requirements are provided

where improved hotch toughness is important

These shall apply only when specified by the

purchaser inthe order.

1.3 When the stecl is to be welded, i is pre-

supposed that a welding procedure suitable for

the grade ofstel and intended vse or service will

‘be utilized,

1.4 The values stated in either ineh-pound

units or SI (metric) units are to be regarded

separately as standard, Within the text the SI

units are shown in brackets. The values stated in

each system are not exact equivalents, therefore,

each system must be used independent af the

‘other. Combining values from the two vstems

‘may result in nonconformnance with the speci

cation,

2. Applicable Documents

24 ASTM Standards:

‘AG/A6M Specification for General Require

‘ments for Rolled Steel Plates, Shapes, Sheet

Piling, and Bars for Structural Use?

A27 Specification for Steel Castings, Carbon,

for General Appticationt

‘A283, A283M Specification for Low and In-

Cerrvediate Tensile Swength Carbott Steel

Plates, hayes, and Bars?

AX01 Specification for Carhon Steel Exter-

nally Thrended Standard Fasteners?

‘A325 Specification for High Strength ols for

‘Structural Stel Joint

4.500 Specification for Cokt-Formed Welded

and Seamess.Carbon Steel Struetural Tub-

ing ie Rounds and Shapes?

‘A501 Specification for Hot Formed Welded

and Seamless Carbon. Steel Structural

Tubing?

A502 Specification for Stel Structaral Rivets?

‘A.363 Specification for Carbon and Alloy St

Nats"

A570 Specification for Hot-Rolled Carbon

Steel Sheet and Strip, Structural Quality?

‘A 66S Specification for Steet Forgings. Carbon

and Alloy, for General Indusitial Use®

3. Aon eins

Uns there rosie in the

ection ie creat AS

thd tae ah cn the hey

Stee upd ma se a

theresa tm ed yh psn

wh eed wi a prised on

Uisipitnn Uns aes pi

Dia nd ened wn ach pr

poste ope wc es ed

"This recication unde the joriaition of ASTM Con

se ted Suvihtne Shion Son ota

REA HERS aS

bs

ASTM

ci

shall contoen 10 the tensile requirements of Sec-

finn 8: hese bolts use for anchorage purposes

shaft conform to Specification 4 307jan all nuts

shall conform to the requirements of Specitica

tion 563, Grade A.

4. General Requlrements for Delivery

4.1 Material furnished under this specification

shall :nnform ta the applicable requirements of

the current edition of Specification A 6/A 6M,

5.1 Unless otherwise specified, plates used as

bearing plates for bridges shall be suhjected to

‘mochanical tests and shall conform to the tensile

equirements of Section 8

5.2 Unless otherwise specified, mechanical

tests shal not be required for plates over Win:

[Ho nim} in thickness used as bearing plates in

sractures other than bridges, subject to the re-

‘quirement that they shall contain 0.20 t0 0.33 %

cearbon by heat analysis, thatthe chemical com

position shall conform to the requirements of

‘Table 2 in phosphorus and sulfur content, and

that a suicent discard shal be made from exch

wt ta secure sound plates,

6. Process

6.1. ‘The ste! shall be made by one or more of,

the following processes: open-heart, basic-ony-

en, or electricsurnace,

{6.2 No simmed or capped steel shall be used

for plates and bars ovee sin, [12.5 mm] thick or

A36j.36M

for shapes other rhan Group L

7. Chen eat Requirements

7.1 The heat analysis shall conform to the

requitenients prescribed in Table 2, except as

specificd in 5.2

7.2 The steel shall conform ow produet anal

asic to the requizements prescribed in Table 2

Subjcet to the presuct analysistoterances in Spec-

ification A 6/A 6M, except as specified in 7.3

7.3 Product analesic is not applicabte for bas

sire shapes or flat bars % in. (12.5 mm) and

tur der in thickness

7.4 When tension tests are waived in arcord-

‘nce with 8.2, chemistry consistent withthe re

‘auirements in Table 2, nd with the mechanical

properties desired! must be applied.

8, Tensile Roquivements

8.1 The material as represented by the test

specimen, except a8 specified in 5.2 and 8.2, shal

‘conform to the requirements @ to the tensile

properties prescribed in Table 3.

‘82 Shapes less than 1 in? [645 mm") in cross

section and bars, other than fats, fess than ¥ in

(12.5 man} in thickness or diameter need not be

subjected fo tension tests by the manufactures.

8.3 For material under Ya in. [8 mon] in thiek-

‘ness or diameter, a deduction from the percents

age of elongation in 8 in. [200 mm), specified in

‘Fable 3, of 1.25 % shall be made for each de-

crease of Yor in, {0-8 mn of the specified thick

ness of diameter below %¢ in. [8 mm.

Nore—The sie should testis fhe stabi of

Pine te bent or med cold

Stchihee

Highstene bls

Sketaut

Tongcmbon see

ocr set and

Cole tornad ine

ot oeea ang

ser forthe intended peti,

Son: Grate 36

00! Gate

ann

Trisha nfm)

Phowhoras mas, 04

Sito mon Bos

Siteon

Coprermin.%xhen 030,

oper tel pe:

fea

Sh azsnasn

LMM E 2 Chem

el Oe oy,

fom “Ton “Wwe ON gg Tan

Gr foe foe BAB Oat [a

a a a

PG ab-1 20 940-120 48-120 085-120

oor ont oat aot oman

0s ons 80s ns ons Ons

15-0409 18.020 015.040,

a eS a a

i

Tote Over

aD, Gat

60-090 D40.070940-

om om att

ons 8os as

on bie

“Manganese content OFOS-1.35% and siicom Gantt of 15-40% a required for shapes over 46 18/[6¥4 Ranh

TALE 3 Tene Reglromentet

Franc Sipe and Ra

“esse scre, fa 2-90 (00-550)

Vk poit p, EMP Mor

us ant a

“legate 8 (0 ma 20"

=

losin in 2. (20mm. min, 23

v

Stages

lenin in 8.200 mms, 20°

logsion in 2m [0mm min, 2

v

“ernie an 34m 0D te wet eke

tenn he nave Sto, Se 11. oF Spcicon 8)

en

“Mo wide ange shapes ove 426 1h" 634 te tense

stot mini of et 669 MPa nl at ono

Ti ao mn}ot 19% mislnum spres

"Vi pn $2 [220 MPa for ate ver

1 Bop jdt edt Dor

"ores ste han 2 in 0a}. te Sorgaon

reuerte edoced 0 perce: BO

in (200

WwW

Aaesnsem

SUPPLEMENTARY REQUIREMENTS

vents shall not apply tnless specified in the order.

Faorplementary requirements for use at the optior of the purchaser are

listed Spee Geatinn A 6/A 6M. Those that are considered suiable for vse with this

specification are listed by ttle: :

85, Charpy V-Notch Impact Test.

SIA, Bend Test,

ADDED SUPPLEMENTARY REQUIREMENTS

the following optional supplementary tequirements are also suitable for use

with this specification.

‘$1. The material supplied shall be other than $2. The material to be supplied shall be sii

immed or capped steel. con Killed fine-grain practice.

“Th meiean Sct fr Teulng and Mtv no ptionexetnth li ofan patent ree ered noms to

oe ts mest Ue ef is toad arent asd ta dereminaton Be aly of ny mh

SERS Ao onde sk ffm fh igs, oe enter vn respon ty

“hiatal revision aay tie by expr corte nd mat evened vr fe 3 ond

arte eeet wana Yar ements are imc ther ro of hs eer aes

Sai Seni adnan Ye ct ead fhe ‘ae

a a er cho nay tnd oe eto orm hve ced fa oie 0

pe eke 4$1 Commune en Stars 1916 Race St Pindeipe, Pe 18108

18

roayg “dou sete

Suinbey [2499 J9j uoneayds WOW/9 ¥

‘spuopuris WLLSY VT

stuounoog aged *Z

‘ones

-ayjoads axa yun soueuostoowoU at ynsas AeUt

Stiaises ot af WO} SOMYeA FuLUIGWOD AMO

uspaadapu pasn 3q isms waishs qo

‘quayeninbs 1982 1ou ase WaIsAs YEO

oieissonges 2g, 'TaySe1q uF UMOUS axe IU

Js 20) Xo1 219 UT “PHEpUNS se {uONRDyIoods sq, TT

adoog “T

‘popes ree wosyceds

nf pve 09 4 is

joods PUPDUNS,

{uur g} wry, woyag ssiowerp so ssou

youn payloads 21 jo [uy g'9} "UE = Jo osm019 pEEN 34 [feys fos poddeD 10 paws os

“9p YDe9 oj speur 9g joys % STI JOE IMEL sora

-Axora1s0q "yueog-uodo sossI00Nd 3

J 320ur 20 240 Sq apeus 2g res OI AHL 9

sso0mg “9

Hoan OLE ATA

3 uoH}35 J0

24a 7'§ Yl 2012 ojsuz1 ay oF wio;uod [Leys PUB AES

218 Sia BOWEL U2, FLO} parsafans 29 NYS SSIPUA 10} 5

OUD UI 9p se pase saymd “POY asi

sung. ey 40 soxdous 228

QW? yoo] ay sto de ay nebo pROPs TOE MNES

pte Ses J0 ans ue

oD uo oo

soo | soo

woe

x9 W/9 ¥ wow

beds Jo womp ru

vecwaey ae

i

\

!

|

yo monn ob HOM

np ut jaunty papas 0 ra

dese on NBEO eT, NS ORNS I

songesd wse.3-auy payer o> years pod 10 pours

ws 24) "2S WEY eNO 29 PU pagddns jeusteM 2UL “IS

498 39 RS Pan

cwoweayoads syn gs

sn so) 2yquns ose aue siw2uaunbos Cewwawtayddns euonsdo #uvsey9) 2

SLHMEIOR MIVINAWTTsAS daddy

1S] PUPA “PIS

494, 1oNAH UBION:

¢

x

a

¥

STRUCTURAL STEE

resi AROMA, earn yen

SMR Sater ea tiore

@ re

ASTEL Dentgoait

“The Stab

the tee

tina indicates the v3

cf otigin aah

ff Tast revision, A uta in pacenlomes

Seupe

1, (a) This epreification? covers carben

sted hopes, phi, and bass of stiuc-

tural uality for use in riveted, belted,

or welled constuction of bridges and

Duiltings, and foe genial structural

pparposes, When the sted) is aed in

Kelid conetructicn, welding procedure

all be stiteble for the steel ad the

intended sevice.

(B) Supplemental Requirements are

provided where improved notch tongh

ness is. fmpotant. AL apply

only when specified by the purchaser fa

the order.

Appantenant Materials

2, Unless othersise provited iol

order, the current etifn

fieations of the American Society Sur

“Testing and Materials Hsted in Table T

shall govern the delivery of otherive

unspecified appurtenart materials wh

dor the etvoelart an peor of Ha

Sock the epredetto be ater toe Jost

one te ASAT Crops AL on Boel au

Te the ditet rerpieedicty of Suhemonsttee ME

tenibteinteval Stee, A Fet af exten pen

Daeg bs fod the FCP Fear Ta

“Carrere Fey tte Bat

veal, Premera Yo

: Nstet Byes

Goa a Ceidum H of toat Cds,

jon A.36- 700

sun Sexisty for Toating sl 2 tela fesued unde

ilving the de

Ef revision, the year

‘ene of leat teapprovel

incieate U

inchured with materio} prehosed tinder

this. Speuifention for Strvctural Steel

STA Designation: A302 Unlest

herve all plein and

threaded Lars usat Tor anchorage pure

poses shall by subjected to mech»nical

fests and thall covform to the tensile

rpuicemonts of Seetion 7; headed bolts

el for at-horage purposes, 21-1 all nuts,

shall conform to the requiten

Specification (or Low-Cathon Si

ternaliy ep Internally Threaited 8

mid Fasteners (ASTM Designation:

A307

General Requirements for Dotivery

Material {eni'ted mie this speci=

fication sill conform to the eyplienble

roytieaaents of the cuntint edition of

the Specification for Generel Requite-

monis for Delivery of Ealled Steet

sy Short Piling, ard Bats

for Structural Use (ASTAE Hesignation?

AO?

Beariug Flotes

4, (a) Unless othersien speciied,

plies tse 9s bearing ples for bridges

shall bo snlsjerted to anechanical testa

ad shall conforay to the teweite require

ents of Section 7,

SB Anau Fes of ASAT Sturt ty

oa

A-36

Thitato

tess

hebets

Hoe

Coitatel

pees

fe pn atest

*

datas te

cit thn

1K fin dette ¢

Caton 8%

end

MSoppieses Bor een

Phoanhony mors eet

freer

‘i Tunder

the West

rements of the

Stor

Destin

a8 for Delivery

10 the 9

cotent

a _

Corceal Requifes

¥ of Rotkd Steet

ct Biting, and Bars

(ase vei mations

others ,

12 specitig,

ag pbtes for ihe

10 tela et

"the tensile equi

M Stantirdy, Poot 4,

aaa

Seecrereation For SreucruraL Stent (A 36) 83.

RERCIIENTIONS, (2) Unless othersine specttind, mex

wn hanced teste shall nox he seqquited for

plates over J} ia, in {hielness ted 2s

nertt noel

Piao tafe form fearing phtes in structures other than

ca Ausa.drvle ch ridges, subject (0 the reqairement thet

et en they shall contain 9.20 to 0.33 per cont

Coste 5am carom hy Tale analysts, that the chen

sh

Forsia fea ined) {cal compesition shall conform to the

Hes oho areas requirements of ‘Fable TL in phosphorus

Hottie gcc | Afoms Grade Band sulfur content, and that a euliciant

‘tio. .--0-] AS discard shall be made from each ingot

oe to seine soind plates.

pod ate ate ttt nr for Fe

reset titae Process

ET so totenniints Tenlle eg

sehen cdet, Mla HST Sicatuad 5. Tho steot shall be made by one of

Oetitys . more of the following processes: open~

1 ae Gites Bye hearth, basic-orypen, or electtiefummace.

Rant, bow -Cion Bt

Atentally hrended Stand F Ree

hp, Tiel Ete

au nig ise Nato a Fh, (a) Te eat analyst confor

ior to the requirements prescribed in Table

creat TT, execpt as specified in Section (6).

za, Colon Stoel Foren

{) Thestecl shall conform on product

‘ le Chon Sol ate and_ anys to the requrenente preserihed

rp Harta AN ‘Fable M1, subject to the product

Cold Fored Weta and, Bem? analysis tolerances in Specifiention A 6,

Gotten feedl Bkeucturat Tubing Htounda nd

Shaper wad except 98 specified below in Parngrap!

Eid eared witetand nko)

‘ett tyne lo ae

Fie ea Magenan A bated (C) Provluet analysis is not applicable

PQUIRLATENTS,

ons [7934

Gist fant

0.26 | 0.26 | 9.25 | 0.20 | 9.27

0.89 | 0:80 | 0.65

to. | te

u'b0 | 1-20 | 1.20

Phesghorwes mers ret

Bulan, es, tor

Bileom yer eon en

0,08] 901 | 0.01 | 0.04 | 0.08

0.06 | 0.09 | 0-05 | «us | 0.95

eye Va | 0:05,

io. | to

10 | 0.30

Cong, ro, rer

when ener a

sed

aed for naps

| a Srecteicariont rox Smeverurat Steet (A.36)

f for barsie shapes or Ant bars $ i. and Section, shall conform to the reaite- Section 9, exerpt t

tile in thickness enta t2 to the tensile properties pre- Te reported shen t

‘ from a heet inal

tons and shen th

described in Seth

(a) When tension tests are waived inscribed in ‘Tuble TU.

aceedence vith Section 7(3), chemistry (8) Shapos Tees than 1 sin, in erasa-

accomtent with the requirements in section and bars, other than fats, lee

than} ine nnoss-or- diameter nec

not be subjected to tenston tests by the

i WwW memufacturer. ' ‘These req'

(Q) For material under z's in. in thick-

A ut ness oF diameter, a cteduction from the SL. The mate

j Pa ia 8 fn mtn, percentage of elongation in,8 in, speci= other than rimme

por ec. 0 fied in Table TH, of 1.25 per cent ehall

loneation A be made for each decrease of #y in. of !

tre eo 8 the specified thickness or diameter below

ein. ‘

Bond Tests i

8, ‘The bend teat spechinens shall stand.

bbcing bent cold thromgh 160 deg ssithout

cracking on the outside of the bent.

partion, to fide diameter. which

hall bave a relation to the thickness of

the specimen as prescribed in ‘Table TY.

Number of Tests i

9, Tuo tensinn and two bend tests

hall he made frova each hent, unless the

‘ finished material from a heat is less than :

O ISG SEGA han oe tentow a owe bert!

test will be eufticient, However, forma: |

NEND 1

MENTS,

ave

Beet fad i terial 2 in, and ander in thickness when

at Seer 10 Mg the material froma one he \

: Over 124 to 2, nel jnore in thickness, one tension end one

yt —— ® Trash test hall be rade from bath the |

sg portores. thickest and the thinnest material rolled

yi sete Fe yeguless of the w ated. Fe \

i cilia deetcre miaterial over 2 in. thick, sehen the 1 .

i tine mperatign, trial from one lent Aifers Lin, ox more

i ment, totie: jy thickness, one tension and one bend :

| test shall be made fromm both the thickest \

and the thinnest material rolled that is

| stable U1, and with the mechanical more than 2 in. thick regardless of the

tl] properties desieed must be applied. ‘weight represented.

i Tensile Properties ‘Test Reports

| 7, (a) The material as represented by 10, Co) When test reports are required

| Oe Ene eweplees epeciied hy the piuchare over, the repent shall”

oe ion (0) and Paragraph (8) of this shout the resutts ef each Fest vegies by

i ve

to the veqires

propertics pre

1 say im, in eters

Mats, less

‘or diameter need

sion tests by the

x fg in, in (hick

J lwetion ‘from th

Hen in B in, speci

11.25 per coat shall

jstemre of dh in, of

| 0c diameter below

[> 20-deg without

aide of the bent

diameter which

to the thickness of

‘heal in Table LV,

of tests

enters the

sedate than

enston and one bend

xt Hovever, for ma-

ler in thickness, when

ne heat differs j in. or

one tension ad one

sanels from bath the

fest material rolled

tight represented. For

105; hen the ma

ds tin, o more

tery and one bevel

>from wath the thickest

iaterial rolled that is

Sees regardless of the

co ‘

reports are required

‘ke the repent hl

cach test required by

Serearicatro FoR Si

sectton 9, except that eny one test nee

De reported ashen the ensint of material

rons heat in a shipment is les than 10

Mioon endl when the ticles, variations

Goseribed in Section 9 are not exceeded

”

srnuerueat Sreet (A 36)

“the thicknees of th

may not neceisarily” he

individu:

SUPPLEMBNTARY REQU!! *MENTS

‘These requirements shall not apply unless

$1. The material supplied chall be

other than rimmed or eepped steel

intored Uhiclsness ine

tested rather than ene Or-

85,

predict testes

the sane ns AN

isthe

ev cif in the order.

52, "Hne material to be supplied shall

be siiena:killed fine-grain practice.

x20

Vous aimerez peut-être aussi

- Shoe Dog: A Memoir by the Creator of NikeD'EverandShoe Dog: A Memoir by the Creator of NikeÉvaluation : 4.5 sur 5 étoiles4.5/5 (537)

- The Yellow House: A Memoir (2019 National Book Award Winner)D'EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Évaluation : 4 sur 5 étoiles4/5 (98)

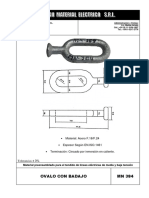

- Ovalo Con Rotula mn384Document1 pageOvalo Con Rotula mn384jaferreroPas encore d'évaluation

- Perno mn416bDocument1 pagePerno mn416bjaferreroPas encore d'évaluation

- Tirafondo mn520Document1 pageTirafondo mn520jaferreroPas encore d'évaluation

- IRAM 1605 Postes de Hormigón Pretensado para Soportes de InsDocument37 pagesIRAM 1605 Postes de Hormigón Pretensado para Soportes de InsjaferreroPas encore d'évaluation

- Productos Trifasico Hxe34Document2 pagesProductos Trifasico Hxe34jaferrero0% (1)

- VIESSMANN-Recuperador de Calor para Acs Vitocal 161-ADocument4 pagesVIESSMANN-Recuperador de Calor para Acs Vitocal 161-AjaferreroPas encore d'évaluation

- IRAM 1603 Elementos Estructurales de Hormigón - Postes de HoDocument26 pagesIRAM 1603 Elementos Estructurales de Hormigón - Postes de HojaferreroPas encore d'évaluation

- Piralac AstmDocument6 pagesPiralac AstmjaferreroPas encore d'évaluation

- Enertik Solarlake ManualDocument39 pagesEnertik Solarlake ManualjaferreroPas encore d'évaluation

- NY 1943 Variable Speed Compressor ApplicationsDocument62 pagesNY 1943 Variable Speed Compressor ApplicationsjaferreroPas encore d'évaluation

- LabJack U6 Datasheet Export 20160108Document112 pagesLabJack U6 Datasheet Export 20160108jaferreroPas encore d'évaluation

- Calculo Mecanico de Lineas de Transmision (Parte 1 de 4)Document15 pagesCalculo Mecanico de Lineas de Transmision (Parte 1 de 4)Patricio Romero100% (1)

- Storms NAEDocument10 pagesStorms NAEjaferreroPas encore d'évaluation

- High Voltage GeneratorDocument8 pagesHigh Voltage GeneratorjaferreroPas encore d'évaluation

- ION8300 8400 8500 Folleto Largo EspanolDocument8 pagesION8300 8400 8500 Folleto Largo EspanolJose Hernandez AlvaradoPas encore d'évaluation

- Ieee Recommended Practice For Determining The Electric Power Station Ground Potential Rise and InducDocument131 pagesIeee Recommended Practice For Determining The Electric Power Station Ground Potential Rise and InducjaferreroPas encore d'évaluation

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeD'EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeÉvaluation : 4 sur 5 étoiles4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingD'EverandThe Little Book of Hygge: Danish Secrets to Happy LivingÉvaluation : 3.5 sur 5 étoiles3.5/5 (400)

- Grit: The Power of Passion and PerseveranceD'EverandGrit: The Power of Passion and PerseveranceÉvaluation : 4 sur 5 étoiles4/5 (588)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureD'EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureÉvaluation : 4.5 sur 5 étoiles4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryD'EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryÉvaluation : 3.5 sur 5 étoiles3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceD'EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceÉvaluation : 4 sur 5 étoiles4/5 (895)

- Team of Rivals: The Political Genius of Abraham LincolnD'EverandTeam of Rivals: The Political Genius of Abraham LincolnÉvaluation : 4.5 sur 5 étoiles4.5/5 (234)

- Never Split the Difference: Negotiating As If Your Life Depended On ItD'EverandNever Split the Difference: Negotiating As If Your Life Depended On ItÉvaluation : 4.5 sur 5 étoiles4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerD'EverandThe Emperor of All Maladies: A Biography of CancerÉvaluation : 4.5 sur 5 étoiles4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaD'EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaÉvaluation : 4.5 sur 5 étoiles4.5/5 (266)

- On Fire: The (Burning) Case for a Green New DealD'EverandOn Fire: The (Burning) Case for a Green New DealÉvaluation : 4 sur 5 étoiles4/5 (74)

- The Unwinding: An Inner History of the New AmericaD'EverandThe Unwinding: An Inner History of the New AmericaÉvaluation : 4 sur 5 étoiles4/5 (45)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersD'EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersÉvaluation : 4.5 sur 5 étoiles4.5/5 (345)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyD'EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyÉvaluation : 3.5 sur 5 étoiles3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreD'EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreÉvaluation : 4 sur 5 étoiles4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)D'EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Évaluation : 4.5 sur 5 étoiles4.5/5 (121)

- Her Body and Other Parties: StoriesD'EverandHer Body and Other Parties: StoriesÉvaluation : 4 sur 5 étoiles4/5 (821)