Académique Documents

Professionnel Documents

Culture Documents

Fontaine Quinta Rueda

Transféré par

Hamilton MirandaCopyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Fontaine Quinta Rueda

Transféré par

Hamilton MirandaDroits d'auteur :

Formats disponibles

MAINTENANCE MANUAL

Fontaine Fifth Wheel 19

Maintenance SAE Standard King Pin

Steam clean fifth wheel and mounting brackets every

thirty days or 17,000 km (10,000 miles), whichever

occurs first.

Inspection

1. Inspect mounting brackets and fifth wheel assembly

for cracks, loose nuts and bolts.

2. Inspect safety lock latch for free operation.

3. Inspect all springs for secure fastening.

4. Inspect wedge adjustment.

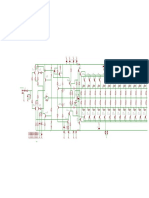

a. Open kingpin lock and insert vertically a 5 cm Figure 19-1

(2 in.) diameter shaft.

b. Release the lock by tripping the release latch at

bottom of throat.

c. Adjust wedge stop to 6 mm (1/4 in.) clearance

from end of wedge.

NOTE: When kingpin is worn, adjust with no clear-

ance between wedge and stop.

5. Oil all fifth wheel moving parts.

6. Grease the two zerk fittings for bracket bearings.

Figure 19-2

7. Grease top plate.

8. Inspect SAE standard kingpin. See Figure 19-1.

IMPORTANT: Do not grease jaw and wedge. Grease

between the jaw and wedge collects dirt and abrasive

matter which cause undue wear.

Proper Cotter Pin Installation

The cotter pin retains the lower bracket pin on the Fon-

taine Model 5000 Fifth Wheel. The proper method of

installing the cotter pin is illustrated in Figure 19-2.

Available from Fontaine is a new retainer pin that

Figure 19-3

replaces the cotter pin. See Figure 19-3.

Before Coupling

1. For adjustable fifth wheel, slide fifth wheel to desired

position and engage securely the locking plungers.

NOTE: Aft

er coupling, check position by setting trailer brakes and

"rocking" trailer.

(04/96) KM819006 Page 1 of 2

MAINTENANCE MANUAL

Fontaine Fifth Wheel 19

2. Inspect fifth wheel jaw, wedge and handle for open After Coupling

position.

1. Inspect handle for position behind safety latch.

IMPORTANT: Do not try to couple a closed fifth wheel. 2. Inspect kingpin for position ahead of the locked jaw

Damage to mechanism could result in trailer loss. and wedge.

WARNING! Failure to follow these instructions could

lead to a hazardous operating condition.

Troubleshooting

PROBLEM POSSIBLE CAUSE REMEDY

Difficult coupling. 1. Kingpin too high to trip latch. 1. Check that upper fifth wheel rides

on lower fifth wheel when cou-

pling.

2. Damaged trailer plate or kingpin. 2 Check trailer plate for flatness.

Check kingpin for squareness

with trailer plate.

Excessive wear on fifth wheel top 1. Kingpin welded improperly with 1. Check plate and kingpin for

plate. welds contacting top plate. proper installation. Grind smooth

any contact points.

Difficult uncoupling. 1. Pressure on locking mechanism 1. Back up tractor and set brakes.

caused by truck rolling slightly Tap wedge near setscrew.

away from trailer.

Slack. 1. Wedge not adjusted correctly. 1. Open kingpin lock and insert verti-

cally a 5 cm (2 in.) diameter shaft.

Relase lock by tripping release

latch at bottom of throat. Adjust

setscrew to approximately 3 mm

(1/8 in.) clearance from end of

wedge.

2. Squirting of wedge. 2. Wash jaw and wedge with solvent

to remove grease.

3. Undersize kingpin. 3. Replace kingpin if greater than 35

mm (1/8 in.) wear at 5 cm (2 in.)

diamter.

4. Wear shaft and brackets. 4. Rotate the shaft 180° at the

square end.

Page 2 of 2 KM819006 (04/96)

Vous aimerez peut-être aussi

- Maintenance Manual Fontaine Fifth Wheel Maintenance: SAE Standard King PinDocument2 pagesMaintenance Manual Fontaine Fifth Wheel Maintenance: SAE Standard King PinedilsonPas encore d'évaluation

- Maintenance Interval Schedule c15 MCW PDFDocument3 pagesMaintenance Interval Schedule c15 MCW PDFVictor NunezPas encore d'évaluation

- Magnum Manual Mtt20 PartsDocument40 pagesMagnum Manual Mtt20 Partsbalajiboss005Pas encore d'évaluation

- Camlift: Hydraulic Pumping Unit - 40-192 SeriesDocument2 pagesCamlift: Hydraulic Pumping Unit - 40-192 SeriesJose Jaime Garcia Reyes100% (1)

- LC168F 2H+Owner's+ManualDocument32 pagesLC168F 2H+Owner's+ManualFRANCISCO ALVARADO VERGARAPas encore d'évaluation

- Kane 458 Operating ManualDocument64 pagesKane 458 Operating ManualP_Davies0% (1)

- Electronic Unit Injector - Adjust: SMCS - 1290-025Document2 pagesElectronic Unit Injector - Adjust: SMCS - 1290-025Vago Si BeerPas encore d'évaluation

- Er-105-1-1 - Proflo No-Flow SwitchDocument10 pagesEr-105-1-1 - Proflo No-Flow SwitchJeff LPas encore d'évaluation

- TDXMDocument20 pagesTDXMJavier PalaciosPas encore d'évaluation

- Inspección de King PinDocument2 pagesInspección de King PinCarlos Felipe Orjuela RamírezPas encore d'évaluation

- Manual AJAX - 31414Document637 pagesManual AJAX - 31414Alberto Esau Reyes CruzPas encore d'évaluation

- Panel de Control Compresor ArielDocument40 pagesPanel de Control Compresor ArielTatiana GomezPas encore d'évaluation

- Lavadora Secadora LG WD15EGS6 PDFDocument100 pagesLavadora Secadora LG WD15EGS6 PDFK-Search100% (1)

- MEP 803A MEP 813A Operators Manual TM 9 6115 642 10 PDFDocument100 pagesMEP 803A MEP 813A Operators Manual TM 9 6115 642 10 PDFomoige100% (1)

- Altronic V Installation Manual (FORM AV II)Document12 pagesAltronic V Installation Manual (FORM AV II)francis_mouille_iiPas encore d'évaluation

- ZIS - 49400415A0 - MI.30628 - Gas StopDocument128 pagesZIS - 49400415A0 - MI.30628 - Gas StopFederico Maggi100% (1)

- ER-105-3 Digital No-Flow Timer (DNFT)Document8 pagesER-105-3 Digital No-Flow Timer (DNFT)EzequielPas encore d'évaluation

- Manual Stinger Mts FTDocument16 pagesManual Stinger Mts FTFabian Andres CelyPas encore d'évaluation

- Cat TdtoDocument2 pagesCat TdtoAhmed GhonimyPas encore d'évaluation

- ELITE40 Operation Manual 1210Document57 pagesELITE40 Operation Manual 1210Edgar Castañeda100% (1)

- Truc Vit Dau R90-160kw PDFDocument12 pagesTruc Vit Dau R90-160kw PDFTuấn NguyễnPas encore d'évaluation

- Alarmas y Paros Waukesha s-8382-03 PDFDocument3 pagesAlarmas y Paros Waukesha s-8382-03 PDFmdo100% (1)

- Asme Section Viii Liquidos Penetrantes CriteriosDocument2 pagesAsme Section Viii Liquidos Penetrantes CriteriosLorena JimenezPas encore d'évaluation

- Codigo de Falla - Sinotruck HowoDocument12 pagesCodigo de Falla - Sinotruck HowoJorge Antonio Ancalle AlmeidaPas encore d'évaluation

- Refrentador de Caras - Bb5000Document4 pagesRefrentador de Caras - Bb5000Marco BacianPas encore d'évaluation

- Mg550-Engine ElectricalDocument12 pagesMg550-Engine Electricalsianas1706Pas encore d'évaluation

- Programming IPC & ACCUFRAC and Uploading - Downloading Parameters Into MCBDocument6 pagesProgramming IPC & ACCUFRAC and Uploading - Downloading Parameters Into MCBPeter SnellPas encore d'évaluation

- 8008 ControlSwitches EK00 III enDocument8 pages8008 ControlSwitches EK00 III enLaurence Malanum100% (1)

- Bomba Centrifuga Frame A LD17Document56 pagesBomba Centrifuga Frame A LD17richard_580Pas encore d'évaluation

- MODELS 202E/208E Differential Pressure Recorders Installation ManualDocument48 pagesMODELS 202E/208E Differential Pressure Recorders Installation Manualcami90_384375Pas encore d'évaluation

- Link Belt Rough Terrain Cranes Spec f75124Document6 pagesLink Belt Rough Terrain Cranes Spec f75124Artur Erre Emme100% (1)

- Guia de Producto Terex Stinger - pdf1227123131Document8 pagesGuia de Producto Terex Stinger - pdf1227123131Andres BalmacedaPas encore d'évaluation

- 65590-gd Cutsheet Template gd-600 2015 LRDocument2 pages65590-gd Cutsheet Template gd-600 2015 LRjys_yanqui100% (1)

- Codigos de Averias NuevosDocument1 pageCodigos de Averias Nuevoscristian faundesPas encore d'évaluation

- HL TC Manual Operador VolvoDocument126 pagesHL TC Manual Operador VolvoVentas BeorientePas encore d'évaluation

- MID 036 - CID 0336 - FMI 02 Incorrect ECS Switch Inputs: Cerrar SIS Pantalla AnteriorDocument1 pageMID 036 - CID 0336 - FMI 02 Incorrect ECS Switch Inputs: Cerrar SIS Pantalla Anteriorvictor franco gallegosPas encore d'évaluation

- Demag CC 2800 1Document64 pagesDemag CC 2800 1Fariz Safarulla100% (1)

- ZU4 Electric PumpDocument108 pagesZU4 Electric PumpAlex VarasPas encore d'évaluation

- Ideco h25 Technical SpecsDocument20 pagesIdeco h25 Technical SpecsSergio Fabian VasicekPas encore d'évaluation

- Linkbelt HTC11100 SpecDocument16 pagesLinkbelt HTC11100 SpecDaniel Cáceres TrujilloPas encore d'évaluation

- 4150K-4160K Controladores Fisher PDFDocument40 pages4150K-4160K Controladores Fisher PDFrichardPas encore d'évaluation

- Procedimiento Parker para Prueba de CilindrosDocument7 pagesProcedimiento Parker para Prueba de Cilindrosspider3486Pas encore d'évaluation

- AVTRON LoadbankDocument2 pagesAVTRON LoadbankAris DaylagPas encore d'évaluation

- CivaCon - API Bottom Loading Adaptor - Instruction & Maintenance ManualDocument2 pagesCivaCon - API Bottom Loading Adaptor - Instruction & Maintenance Manualesham2100% (1)

- Manitex 30100C Loadchart PDFDocument36 pagesManitex 30100C Loadchart PDFazamenPas encore d'évaluation

- 07-01 MafDocument5 pages07-01 MafJuan Roberto López BetanzosPas encore d'évaluation

- Parts List 859 Series: Effective: June 15, 2009 Supersedes: HY25-2859 Dated January 2007Document20 pagesParts List 859 Series: Effective: June 15, 2009 Supersedes: HY25-2859 Dated January 2007francis_15inPas encore d'évaluation

- DS450 Shop Manual (Prelim)Document94 pagesDS450 Shop Manual (Prelim)GuruRacerPas encore d'évaluation

- Luces International InstalacionDocument157 pagesLuces International InstalaciondanflocaPas encore d'évaluation

- Enerpac Torque Wrench ManualDocument10 pagesEnerpac Torque Wrench ManualM Saad KhanPas encore d'évaluation

- Piezas Transmision Cargador CaseDocument2 pagesPiezas Transmision Cargador Casebiobio maquinarias100% (1)

- 6bta f1Document6 pages6bta f1Salatiel SanchezPas encore d'évaluation

- Eaton T-905 Transmission Service ManualDocument72 pagesEaton T-905 Transmission Service ManualTawfiq ZidanPas encore d'évaluation

- Iom Manual 250 Series Centrifugal Pump: M15794, Rev 0Document17 pagesIom Manual 250 Series Centrifugal Pump: M15794, Rev 0hebert perez50% (2)

- Bracket 100: If Crack or Fatigue Is Evident, Replace Control Arm, ImmediatelyDocument2 pagesBracket 100: If Crack or Fatigue Is Evident, Replace Control Arm, ImmediatelyHaingPas encore d'évaluation

- WheelHorse Snow Thrower Completing Package Manual 6-9111Document4 pagesWheelHorse Snow Thrower Completing Package Manual 6-9111Kevins Small Engine and Tractor ServicePas encore d'évaluation

- Tiger Heated GripsDocument9 pagesTiger Heated Gripschampion11311Pas encore d'évaluation

- MSA5TCD97L3692Document3 pagesMSA5TCD97L3692Mudflap CalizayaPas encore d'évaluation

- Driveline, Axle: DifferentialsDocument39 pagesDriveline, Axle: DifferentialsARIF RACHMANPas encore d'évaluation

- Manual pt19Document28 pagesManual pt19ricardoPas encore d'évaluation

- Eatonroadranger - RTLO-16918B - Despiece Con Codigos PDFDocument58 pagesEatonroadranger - RTLO-16918B - Despiece Con Codigos PDFAndre Paul MektronikPas encore d'évaluation

- EGR Cooler Cleaning Procedures - MP7 Engines PDFDocument3 pagesEGR Cooler Cleaning Procedures - MP7 Engines PDFHamilton MirandaPas encore d'évaluation

- Engine Brake Service Information SummaryDocument10 pagesEngine Brake Service Information SummaryHamilton MirandaPas encore d'évaluation

- RR Rto-14608llDocument52 pagesRR Rto-14608llHamilton MirandaPas encore d'évaluation

- Engine Power Distribution ModuleDocument1 pageEngine Power Distribution ModuleHamilton MirandaPas encore d'évaluation

- Electronic Speedometer and Tachometer SwitchDocument23 pagesElectronic Speedometer and Tachometer SwitchHamilton Miranda100% (2)

- Coolant Level Sensor and j1939 Harness SectionDocument11 pagesCoolant Level Sensor and j1939 Harness SectionHamilton Miranda0% (1)

- MBE4000 Serv ManDocument587 pagesMBE4000 Serv ManRicardo Diaz95% (20)

- Cojinetes de Arbol de Leva VolvoDocument5 pagesCojinetes de Arbol de Leva VolvoHamilton MirandaPas encore d'évaluation

- Bibracion en El Tren MotrizDocument6 pagesBibracion en El Tren MotrizHamilton MirandaPas encore d'évaluation

- Engine Remote Interface Installation and Programming InformationDocument3 pagesEngine Remote Interface Installation and Programming InformationHamilton MirandaPas encore d'évaluation

- Detroit Diesel - DDDL 7.0 Users Manual PDFDocument149 pagesDetroit Diesel - DDDL 7.0 Users Manual PDFGreenline32100% (2)

- Coneccion de Aire T300 MAckDocument11 pagesConeccion de Aire T300 MAckHamilton MirandaPas encore d'évaluation

- RR Fro-16210bDocument1 pageRR Fro-16210bHamilton MirandaPas encore d'évaluation

- Conector Pasante FLD 120 PDFDocument1 pageConector Pasante FLD 120 PDFHamilton MirandaPas encore d'évaluation

- Eatonroadranger - RTLO-16918B - Despiece Con Codigos PDFDocument58 pagesEatonroadranger - RTLO-16918B - Despiece Con Codigos PDFAndre Paul MektronikPas encore d'évaluation

- Illustrated Parts List: RTLO-16713A November 2012Document56 pagesIllustrated Parts List: RTLO-16713A November 2012Hamilton MirandaPas encore d'évaluation

- Illustrated Parts List: FRO-15210C June 2014Document46 pagesIllustrated Parts List: FRO-15210C June 2014Hamilton MirandaPas encore d'évaluation

- Illustrated Parts List: FRO-16210B November 2012Document46 pagesIllustrated Parts List: FRO-16210B November 2012Hamilton MirandaPas encore d'évaluation

- Illustrated Parts List: FRO-16210B November 2012Document46 pagesIllustrated Parts List: FRO-16210B November 2012Hamilton MirandaPas encore d'évaluation

- RR Rto-14608llDocument52 pagesRR Rto-14608llHamilton MirandaPas encore d'évaluation

- Fuller Heavy Duty Transmissions TRTS0902: Troubleshooting GuideDocument34 pagesFuller Heavy Duty Transmissions TRTS0902: Troubleshooting GuideHamilton MirandaPas encore d'évaluation

- Installation Instructions: 18SP548-Install Exhaust Back Pressure Sensor Kit On Series 50 or Series 60 Diesel Coach EngineDocument10 pagesInstallation Instructions: 18SP548-Install Exhaust Back Pressure Sensor Kit On Series 50 or Series 60 Diesel Coach EngineHamilton MirandaPas encore d'évaluation

- Ajuste Inyector UnitarioDocument190 pagesAjuste Inyector UnitarioHamilton MirandaPas encore d'évaluation

- DDEC II and III Wiring DiagramsDocument13 pagesDDEC II and III Wiring Diagramstwhiteman200682% (49)

- Section 3.7 Connectors: Figure 1. ECU 68-Pin Tyco ConnectorDocument8 pagesSection 3.7 Connectors: Figure 1. ECU 68-Pin Tyco ConnectorHamilton MirandaPas encore d'évaluation

- 6th Central Pay Commission Salary CalculatorDocument15 pages6th Central Pay Commission Salary Calculatorrakhonde100% (436)

- Spicer Pso140 10s Pso150 Pso165 Lpso Llpso Series Parts ManualDocument46 pagesSpicer Pso140 10s Pso150 Pso165 Lpso Llpso Series Parts ManualHamilton Miranda100% (1)

- Speedometer PDFDocument44 pagesSpeedometer PDFHector Eugenio Henriquez Delannoy100% (1)

- 6th Central Pay Commission Salary CalculatorDocument15 pages6th Central Pay Commission Salary Calculatorrakhonde100% (436)

- 005 - OBA-QAC-MST-DIS-REV - R00 - Dismantling WorksDocument11 pages005 - OBA-QAC-MST-DIS-REV - R00 - Dismantling WorksDritan PeshtaniPas encore d'évaluation

- Rini - Operating Table RiEye Mk2 (Edited)Document2 pagesRini - Operating Table RiEye Mk2 (Edited)jalan jalanPas encore d'évaluation

- Auto Repair Technician Home: Home BMW Coding Auto Key Program Download & Installation DPF Tpms Shop Contact UsDocument12 pagesAuto Repair Technician Home: Home BMW Coding Auto Key Program Download & Installation DPF Tpms Shop Contact UsStefBeck BeckPas encore d'évaluation

- Power Amplifier PDFDocument2 pagesPower Amplifier PDFIordan Dan FfnPas encore d'évaluation

- Caminos, Jr. v. PeopleDocument13 pagesCaminos, Jr. v. PeoplesophiaPas encore d'évaluation

- Portsmouth City Wages 2017Document18 pagesPortsmouth City Wages 2017portsmouthheraldPas encore d'évaluation

- Urban Design Protocol ColourDocument40 pagesUrban Design Protocol ColourVươngQuốcTrungPas encore d'évaluation

- Cokaliong Vs UcpbDocument11 pagesCokaliong Vs UcpbRavenFoxPas encore d'évaluation

- TA Bill FormatDocument4 pagesTA Bill FormatBikee Yadav100% (1)

- Manual Road Side Dust Cleaning MachineDocument11 pagesManual Road Side Dust Cleaning MachineKALYAN KUMAR100% (1)

- Mux Jed MuxDocument1 pageMux Jed MuxAhsan AliPas encore d'évaluation

- Cebu City Engineering 3-YEAR PROGRAMDocument77 pagesCebu City Engineering 3-YEAR PROGRAMCebuDailyNewsPas encore d'évaluation

- Vio80U: Call For Yanmar SolutionsDocument12 pagesVio80U: Call For Yanmar SolutionsLuka BornaPas encore d'évaluation

- Detailed GuideDocument3 pagesDetailed GuideMat JonesPas encore d'évaluation

- Automotive AerodynamicsDocument3 pagesAutomotive AerodynamicsManoj PradhanPas encore d'évaluation

- Data Sheets Bettis GC Series Pneumatic Double Acting Spring Return Actuator Torque Chart Metric Bettis en en 7191530Document34 pagesData Sheets Bettis GC Series Pneumatic Double Acting Spring Return Actuator Torque Chart Metric Bettis en en 7191530rey sarPas encore d'évaluation

- Andhra Pradesh Automobile and Auto Components Policy 2015-20Document19 pagesAndhra Pradesh Automobile and Auto Components Policy 2015-20Harshith TammuPas encore d'évaluation

- Coroa e Pinhao MBDocument1 pageCoroa e Pinhao MBtoninhomelotti_53173Pas encore d'évaluation

- PT923 00111cor Inst PDFDocument15 pagesPT923 00111cor Inst PDFnazar750Pas encore d'évaluation

- BMP Min Wi G 2026 Clean Up After RainDocument13 pagesBMP Min Wi G 2026 Clean Up After RainSlamet SetyowibowoPas encore d'évaluation

- Basic Ship TheoryDocument83 pagesBasic Ship TheorySidik SetiawanPas encore d'évaluation

- Skid ResistanceDocument5 pagesSkid ResistanceMoyashi Desu100% (2)

- PDFServlet 2 PDFDocument1 pagePDFServlet 2 PDFDeepak Gupta100% (1)

- Lampiran IIb Perbup Nomor 4 Tahun 2019 Tentang Kebijakan Akuntansi Pemerintah Kabupaten BanjarDocument154 pagesLampiran IIb Perbup Nomor 4 Tahun 2019 Tentang Kebijakan Akuntansi Pemerintah Kabupaten BanjarIsro MPas encore d'évaluation

- Safety Rules and Regulations Governing LRV - Cpuc General Order 143b - California STDDocument25 pagesSafety Rules and Regulations Governing LRV - Cpuc General Order 143b - California STDJavierPas encore d'évaluation

- Rate Analysis 2 50m Test Pile R1Document15 pagesRate Analysis 2 50m Test Pile R1arif hossain labuPas encore d'évaluation

- Civil Aviation Regulations 2016 ENGLISHDocument160 pagesCivil Aviation Regulations 2016 ENGLISHSaran RamanPas encore d'évaluation

- What Does A Fishing Schooner Have To Do With STEM Education?Document1 pageWhat Does A Fishing Schooner Have To Do With STEM Education?Hartford CourantPas encore d'évaluation

- NSRP Testing ProcedureDocument502 pagesNSRP Testing Procedurecharlie limPas encore d'évaluation

- International Trade Compliance: Paris, ESGCI - 4SCM - Feb.8 2021Document48 pagesInternational Trade Compliance: Paris, ESGCI - 4SCM - Feb.8 2021Amine loubabPas encore d'évaluation