Académique Documents

Professionnel Documents

Culture Documents

Tray Data Sheet

Transféré par

ecsuperalTitre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Tray Data Sheet

Transféré par

ecsuperalDroits d'auteur :

Formats disponibles

TRAY DATA SHEET

JOB NO.: BY DATE REV.

ITEM NO.:

SERVICE:

CUSTOMER:

PLANT LOCATION:

TOWER TRAY LOADINGS

SECTION

CASE

NO. OF TRAYS IN SECTION

TRAY NO. FROM TOP OF TOWER

VAPOR TO TRAY:

RATE, Kg/Hr

DENSITY, Kg/M3 (@T & P)

MOLECULAR WT.

TEMPERATURE, oC

PRESSURE, Kg/cm2 abs

LIQUID FROM TRAY

RATE, Kg/Hr

DENSITY, Kg/M3 (@T)

TEMPERATURE, oC

SURFACE TENSION, Dynes/cm

VISCOSITY, cps

MAX DP / TRAY, mm Hg

DESIGN LOAD % OF FLOOD

MAX. GUARANTEED % FLOOD

% OVER CAPACITY

MECHANICAL DESIGN

TOWER DIAMETER, mm

MANWAY DIAMETER (I.D.), mm

TYPE TRAY

TRAY SPACING, mm

NO. PASSES

MATERIAL & THICKNESS: DECK/DOWNCOMER

VALVE

BOLTING

SUPPORTS

Trap Off Trays: Loc. Below Tray No.

NOTES

n 1. Design operation to be 50 to 100% of loads shown. Trays are not to be limited to loads shown but designed to full capacity

consistent with stable and efficient operation at above loads, with vapor and liquid ratios in same proportion as above.

Tray fabricator to advise percent overload the trays can handle.

n 2. Necessary bottom and intermediate tray seal pan assemblies are to be furnished.

n 3. Accumulator (trap off) trays must be liquid tight.

n 4. Tray support rings to be designed by tray fabricator and furnished by Vessel MFG

n 5. Abbreviations: CS - carbon steel, 410 SS-12% chromium alloy.

VEI Job No. 4494-011 Sheet 1 of 4 02/19/2018 09:20:50

TRAY DATA SHEET

JOB NO.: BY DATE REV.

ITEM NO.:

SERVICE:

CUSTOMER:

PLANT LOCATION:

TOWER TRAY LOADINGS

SECTION

CASE

NO. OF TRAYS IN SECTION

TRAY NO. FROM TOP OF TOWER

VAPOR TO TRAY:

RATE, Kg/Hr

DENSITY, Kg/M3 (@T & P)

MOLECULAR WT.

TEMPERATURE, oC

PRESSURE, Kg/cm2 abs

LIQUID FROM TRAY

RATE, Kg/Hr

DENSITY, Kg/M3 (@T)

TEMPERATURE, oC

SURFACE TENSION, Dynes/cm

VISCOSITY, cps

MAX DP / TRAY, mm Hg

DESIGN LOAD % OF FLOOD

MAX. GUARANTEED % FLOOD

% OVER CAPACITY

MECHANICAL DESIGN

TOWER DIAMETER, mm

MANWAY DIAMETER (I.D.), mm

TYPE TRAY

TRAY SPACING, mm

NO. PASSES

MATERIAL & THICKNESS: DECK/DOWNCOMER

VALVE

BOLTING

SUPPORTS

Trap Off Trays: Loc. Below Tray No.

NOTES

VEI Job No. 4494-011 Sheet 2 of 4 02/19/2018 09:20:50

TRAY DATA SHEET

JOB NO.: BY DATE REV.

ITEM NO.:

SERVICE:

CUSTOMER:

PLANT LOCATION:

TOWER TRAY LOADINGS

SECTION

CASE

NO. OF TRAYS IN SECTION

TRAY NO. FROM TOP OF TOWER

VAPOR TO TRAY:

RATE, Kg/Hr

DENSITY, Kg/M3 (@T & P)

MOLECULAR WT.

TEMPERATURE, oC

PRESSURE, Kg/cm2 abs

LIQUID FROM TRAY

RATE, Kg/Hr

DENSITY, Kg/M3 (@T)

TEMPERATURE, oC

SURFACE TENSION, Dynes/cm

VISCOSITY, cps

MAX DP / TRAY, mm Hg

DESIGN LOAD % OF FLOOD

MAX. GUARANTEED % FLOOD

% OVER CAPACITY

MECHANICAL DESIGN

TOWER DIAMETER, mm

MANWAY DIAMETER (I.D.), mm

TYPE TRAY

TRAY SPACING, mm

NO. PASSES

MATERIAL & THICKNESS: DECK/DOWNCOMER

VALVE

BOLTING

SUPPORTS

Trap Off Trays: Loc. Below Tray No.

NOTES

VEI Job No. 4494-011 Sheet 3 of 4 02/19/2018 09:20:50

TRAY DATA SHEET

JOB NO.: BY DATE REV.

ITEM NO.:

SERVICE:

CUSTOMER:

PLANT LOCATION:

TOWER TRAY LOADINGS

SECTION

CASE

NO. OF TRAYS IN SECTION

TRAY NO. FROM TOP OF TOWER

VAPOR TO TRAY:

RATE, Kg/Hr

DENSITY, Kg/M3 (@T & P)

MOLECULAR WT.

TEMPERATURE, oC

PRESSURE, Kg/cm2 abs

LIQUID FROM TRAY

RATE, Kg/Hr

DENSITY, Kg/M3 (@T)

TEMPERATURE, oC

SURFACE TENSION, Dynes/cm

VISCOSITY, cps

MAX DP / TRAY, mm Hg

DESIGN LOAD % OF FLOOD

MAX. GUARANTEED % FLOOD

% OVER CAPACITY

MECHANICAL DESIGN

TOWER DIAMETER, mm

MANWAY DIAMETER (I.D.), mm

TYPE TRAY

TRAY SPACING, mm

NO. PASSES

MATERIAL & THICKNESS: DECK/DOWNCOMER

VALVE

BOLTING

SUPPORTS

Trap Off Trays: Loc. Below Tray No.

NOTES

VEI Job No. 4494-011 Sheet 4 of 4 02/19/2018 09:20:50

Vous aimerez peut-être aussi

- PackingDocument1 pagePackingecsuperalPas encore d'évaluation

- Procedure Qualification Record SheetDocument2 pagesProcedure Qualification Record SheeteliiiiiiPas encore d'évaluation

- Data Sheet For Steam Desuperheater: Operating ConditionDocument1 pageData Sheet For Steam Desuperheater: Operating ConditionaquilesanchezPas encore d'évaluation

- Demister Data Sheet enDocument2 pagesDemister Data Sheet enChristos BountourisPas encore d'évaluation

- Apron Feeder Application Datasheet enDocument1 pageApron Feeder Application Datasheet enVaijayanti JoshiPas encore d'évaluation

- Plumbness ReportDocument1 pagePlumbness ReportghaithalibigaPas encore d'évaluation

- Heat Exchanger Specification Sheet03-04Document1 pageHeat Exchanger Specification Sheet03-04dennis leePas encore d'évaluation

- Loading Arm Design DatasheetDocument3 pagesLoading Arm Design Datasheetsenkuttuvan0% (1)

- Tube Move Version 6.4Document25 pagesTube Move Version 6.4edisoncontreraspPas encore d'évaluation

- 074010-M06 - GRP Pipe Butt - Wrap JointDocument1 page074010-M06 - GRP Pipe Butt - Wrap Jointaug27june16Pas encore d'évaluation

- Pedro Serio-Ventura 2020.04.0 3 10:50:17 +02'00'Document3 pagesPedro Serio-Ventura 2020.04.0 3 10:50:17 +02'00'sidiPas encore d'évaluation

- HM 30 MetersDocument16 pagesHM 30 MetersAlbert NajjarPas encore d'évaluation

- Fixed Bed ReactorDocument1 pageFixed Bed ReactorspamPas encore d'évaluation

- Vapor-Liquid ColumnDocument1 pageVapor-Liquid Columnrahmat mamuriPas encore d'évaluation

- Column Data Sheet Distillation Column (T-2010)Document12 pagesColumn Data Sheet Distillation Column (T-2010)John Patrick Sanay NunezPas encore d'évaluation

- Boiler Data Sheet: Process Design ConditionsDocument6 pagesBoiler Data Sheet: Process Design ConditionsecsuperalPas encore d'évaluation

- Pumps Electric Driver Data SheetDocument1 pagePumps Electric Driver Data SheetAhmed GattoufiPas encore d'évaluation

- F.QC.22 Checklist Diafragma WallDocument40 pagesF.QC.22 Checklist Diafragma WallAndre SitumeangPas encore d'évaluation

- Fixed Bed ReactorDocument1 pageFixed Bed Reactorojasmainkar123Pas encore d'évaluation

- Prathna Alloys WC6 Page-2Document1 pagePrathna Alloys WC6 Page-2Kishan ChauhanPas encore d'évaluation

- P139-05-M-30-900-R00 CSU - DATASHEET (2020 - 09 - 03rd)Document6 pagesP139-05-M-30-900-R00 CSU - DATASHEET (2020 - 09 - 03rd)CongOanh PHAN100% (1)

- Leader MLA DatasheetsDocument6 pagesLeader MLA DatasheetsMEHDIPas encore d'évaluation

- Rolling LDocument1 pageRolling LAkAsH kUmAr GuPtAPas encore d'évaluation

- Hydraulic Calculation New He Line at A4 BuildingDocument24 pagesHydraulic Calculation New He Line at A4 BuildingAob AprilPas encore d'évaluation

- Questionnaire On Custome-Made Design of Crane Thyristor DriveDocument3 pagesQuestionnaire On Custome-Made Design of Crane Thyristor DriveVignesh MessiPas encore d'évaluation

- Painting Inspection ReportDocument1 pagePainting Inspection Reportعبداللة العبداللةPas encore d'évaluation

- Pipe Insulation: Qa / QC FormDocument1 pagePipe Insulation: Qa / QC FormShyam Sundar GayenPas encore d'évaluation

- QC Form 6Document1 pageQC Form 6rashid ahmadiPas encore d'évaluation

- Method Statement RC Pile Works FreeDocument6 pagesMethod Statement RC Pile Works FreePUI CHEE KHIAN100% (3)

- Anchor Channel Design ChecklistDocument3 pagesAnchor Channel Design ChecklistAniket InarkarPas encore d'évaluation

- WO Work Order 111-GeorgiaDocument16 pagesWO Work Order 111-GeorgiaDivyansh Singh ChauhanPas encore d'évaluation

- Non Routine Complicated Lift Plan For TADANO GR800EX-22032024Document60 pagesNon Routine Complicated Lift Plan For TADANO GR800EX-22032024Mujahid AyyubPas encore d'évaluation

- General Tickness BulkheadDocument13 pagesGeneral Tickness BulkheaddimasjosesmithPas encore d'évaluation

- P 100 Annex - A1Document44 pagesP 100 Annex - A1vasuPas encore d'évaluation

- WPS & PQR VVSPLDocument3 pagesWPS & PQR VVSPLBhargav BbvsPas encore d'évaluation

- Document Title: Welding Procedure Specification: Champion West Phase Iii Dev. Project C030005/ESP MSE BSP (ESP/2)Document1 pageDocument Title: Welding Procedure Specification: Champion West Phase Iii Dev. Project C030005/ESP MSE BSP (ESP/2)Ed FangPas encore d'évaluation

- Calculation Form For Circular TanksDocument1 pageCalculation Form For Circular Tanksspsingh_jmdPas encore d'évaluation

- WPQR No. 2016 02Document14 pagesWPQR No. 2016 02GANESH APas encore d'évaluation

- Anchor Channel Design ChecklistDocument3 pagesAnchor Channel Design ChecklistvinodmedaPas encore d'évaluation

- AGL CIVIL Work Check ListDocument27 pagesAGL CIVIL Work Check ListSavani BhavikPas encore d'évaluation

- ANNEXURE - III - Typical Data Sheet For Orifice PlatesDocument1 pageANNEXURE - III - Typical Data Sheet For Orifice Platesmanoj262400/2Pas encore d'évaluation

- Quotation: Data SheetDocument7 pagesQuotation: Data SheeteliasPas encore d'évaluation

- FLATE Slab DesignDocument16 pagesFLATE Slab DesignNikhil Poriya100% (1)

- Contract WW300W - Sewerage Project at Highlands: Sewer Reticulation Network Approval SheetDocument18 pagesContract WW300W - Sewerage Project at Highlands: Sewer Reticulation Network Approval SheetsarwarrosunPas encore d'évaluation

- Daily Work Report - Structural Concrete: DateDocument2 pagesDaily Work Report - Structural Concrete: DateAli RazaPas encore d'évaluation

- Cyclone SeparatorDocument1 pageCyclone SeparatordadPas encore d'évaluation

- BE-WI-248-01-F05 Datasheet Rota MeterDocument3 pagesBE-WI-248-01-F05 Datasheet Rota Metermika cabelloPas encore d'évaluation

- Schematic Compeletion - AzhDocument15 pagesSchematic Compeletion - AzhHamid Reza BabaeiPas encore d'évaluation

- 63-67 F Actual Tunnel Support SheetDocument10 pages63-67 F Actual Tunnel Support SheetjitendraPas encore d'évaluation

- Method Statemetn FormDocument11 pagesMethod Statemetn FormEswar ReddyPas encore d'évaluation

- Ultrasonic Testing Thickness Measurement Report: Component DescriptionDocument2 pagesUltrasonic Testing Thickness Measurement Report: Component DescriptionPand AemonaEon100% (4)

- 761-V-103 (Vessel With Demister), PDFDocument1 page761-V-103 (Vessel With Demister), PDFAlvin SmithPas encore d'évaluation

- Handbook of Heating, Ventilating and Air ConditioningD'EverandHandbook of Heating, Ventilating and Air ConditioningÉvaluation : 4 sur 5 étoiles4/5 (6)

- Weld Quality: The Role of Computers: Proceedings of the International Conference on Improved Weldment Control with Special Reference to Computer Technology Held in Vienna, Austria, 4–5 July 1988 under the Auspices of the International Institute of WeldingD'EverandWeld Quality: The Role of Computers: Proceedings of the International Conference on Improved Weldment Control with Special Reference to Computer Technology Held in Vienna, Austria, 4–5 July 1988 under the Auspices of the International Institute of WeldingPas encore d'évaluation

- Longwall Mining at Shallow Depth of Cover in IndiaD'EverandLongwall Mining at Shallow Depth of Cover in IndiaPas encore d'évaluation

- Handbook of Railroad Construction; For the use of American engineersD'EverandHandbook of Railroad Construction; For the use of American engineersPas encore d'évaluation

- How to prepare Welding Procedures for Oil & Gas PipelinesD'EverandHow to prepare Welding Procedures for Oil & Gas PipelinesÉvaluation : 5 sur 5 étoiles5/5 (1)

- Darcy WeisbachDocument11 pagesDarcy WeisbachSudip SardarPas encore d'évaluation

- Hydro Sample Site PlanDocument1 pageHydro Sample Site PlanecsuperalPas encore d'évaluation

- Dao05 10 Cwa IrrDocument50 pagesDao05 10 Cwa IrrecsuperalPas encore d'évaluation

- Power HouseDocument1 pagePower HouseecsuperalPas encore d'évaluation

- Dam & DesanderDocument1 pageDam & DesanderecsuperalPas encore d'évaluation

- Power House 1Document1 pagePower House 1ecsuperalPas encore d'évaluation

- Penstock ManualDocument159 pagesPenstock Manualstudent_bl95% (21)

- DAO 2007-22 - Guidelines On The Requirements For Continuous Emission Monitoring Systems (CEMS) and Other Acceptable Protocols, Thereby Modifying and Clarifying Certain ProvisiDocument6 pagesDAO 2007-22 - Guidelines On The Requirements For Continuous Emission Monitoring Systems (CEMS) and Other Acceptable Protocols, Thereby Modifying and Clarifying Certain ProvisiPacific SpectrumPas encore d'évaluation

- WellpointDocument2 pagesWellpointecsuperalPas encore d'évaluation

- Env Dao 2000-81Document105 pagesEnv Dao 2000-81Francis Ruther IcaoPas encore d'évaluation

- Carrier Optima (42CSH) - Wall MountedDocument8 pagesCarrier Optima (42CSH) - Wall MountedErwin Maldo50% (2)

- DAO 90-34 - Revised Water Usage and Classification Water Quality Criteria Amending Section Nos 68 and 69, Chapter III of The 1978 NPCC Rules and RegulationsDocument11 pagesDAO 90-34 - Revised Water Usage and Classification Water Quality Criteria Amending Section Nos 68 and 69, Chapter III of The 1978 NPCC Rules and RegulationsPacific Spectrum100% (4)

- Rubber Tires Racking SchemeDocument22 pagesRubber Tires Racking SchemeecsuperalPas encore d'évaluation

- Dao05 10 Cwa IrrDocument50 pagesDao05 10 Cwa IrrecsuperalPas encore d'évaluation

- Pressure Relief Valve Engineering HandbookDocument93 pagesPressure Relief Valve Engineering Handbookakrouti92% (12)

- Ambient Noise Level Std.Document1 pageAmbient Noise Level Std.ecsuperalPas encore d'évaluation

- DAO 2007-22 - Guidelines On The Requirements For Continuous Emission Monitoring Systems (CEMS) and Other Acceptable Protocols, Thereby Modifying and Clarifying Certain ProvisiDocument6 pagesDAO 2007-22 - Guidelines On The Requirements For Continuous Emission Monitoring Systems (CEMS) and Other Acceptable Protocols, Thereby Modifying and Clarifying Certain ProvisiPacific SpectrumPas encore d'évaluation

- Copper Water and Gas Tube According ASTM B 88 - Imperial UnitsDocument3 pagesCopper Water and Gas Tube According ASTM B 88 - Imperial UnitsecsuperalPas encore d'évaluation

- Electrical Test Sheet: Ele/Tss/At 300 X Commissioning E 4Document18 pagesElectrical Test Sheet: Ele/Tss/At 300 X Commissioning E 4ecsuperalPas encore d'évaluation

- Ambient Noise Level Std.Document1 pageAmbient Noise Level Std.ecsuperalPas encore d'évaluation

- Alstom HP 1103 PerformanceDocument2 pagesAlstom HP 1103 PerformanceecsuperalPas encore d'évaluation

- Electrical Test Sheet: Standard For Combined Cycle Power PlantDocument26 pagesElectrical Test Sheet: Standard For Combined Cycle Power PlantecsuperalPas encore d'évaluation

- RSCDocument3 pagesRSCecsuperalPas encore d'évaluation

- El STD08Document34 pagesEl STD08ecsuperalPas encore d'évaluation

- Flange DimensionsDocument7 pagesFlange DimensionsDave DonohuePas encore d'évaluation

- AC Induction Motor FundamentalsDocument24 pagesAC Induction Motor Fundamentalsrohtahir100% (3)

- BS4504 PN 16 Flange DimensionsDocument3 pagesBS4504 PN 16 Flange DimensionsecsuperalPas encore d'évaluation

- Tables of Flange PDFDocument5 pagesTables of Flange PDFAngel AngeleyePas encore d'évaluation

- Central Philippine University College of Engineering SECOND SEMESTER S.Y. 2005-2006 Work Term ReportDocument17 pagesCentral Philippine University College of Engineering SECOND SEMESTER S.Y. 2005-2006 Work Term ReportecsuperalPas encore d'évaluation

- Air Preheater BasicsDocument1 pageAir Preheater Basics112dharmeshPas encore d'évaluation

- Welding Metallurgy of Stainless Steels During Resistance Spot Welding Part I - Fusion Zone PDFDocument11 pagesWelding Metallurgy of Stainless Steels During Resistance Spot Welding Part I - Fusion Zone PDFKhalid HafezPas encore d'évaluation

- Family Handyman - June 2023Document68 pagesFamily Handyman - June 2023Ognjen MočevičPas encore d'évaluation

- En 764-4-2002Document44 pagesEn 764-4-2002Marija IvanovskaPas encore d'évaluation

- NFPA Fire Design GuidanceDocument6 pagesNFPA Fire Design Guidancerashal100% (1)

- Booklet On Domestic WiringDocument113 pagesBooklet On Domestic Wiringpubuduclk93% (42)

- 4A Dough Rheology (2021)Document24 pages4A Dough Rheology (2021)ArinaAdilaPas encore d'évaluation

- Launceston General Hospital Expansion PlansDocument37 pagesLaunceston General Hospital Expansion PlansThe ExaminerPas encore d'évaluation

- EK Series PDFDocument8 pagesEK Series PDFImpulsora DemaPas encore d'évaluation

- D5819-05 (Reapproved 2016)Document11 pagesD5819-05 (Reapproved 2016)mithileshPas encore d'évaluation

- Thesis On Carbon FiberDocument10 pagesThesis On Carbon Fiberbrendapotterreno100% (2)

- Heat PacDocument2 pagesHeat PacTasha GutierrezPas encore d'évaluation

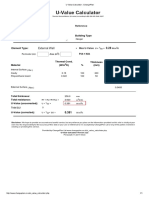

- U Value Calculator - With Liner Only1Document1 pageU Value Calculator - With Liner Only1muathPas encore d'évaluation

- Shear WallsDocument33 pagesShear Wallsmagdyamdb100% (1)

- Surface Protective Systems: Steulerflake VSMDocument3 pagesSurface Protective Systems: Steulerflake VSMfrancisca ferrerPas encore d'évaluation

- 4 App Physics 22EL Q I VDocument17 pages4 App Physics 22EL Q I VRizwan MPas encore d'évaluation

- ESTAR HVACRaterChecklistDocument4 pagesESTAR HVACRaterChecklistMeshal Al-mutairiPas encore d'évaluation

- Module 4Document25 pagesModule 4CHANDAKA TARUN SAI MALLESHPas encore d'évaluation

- Vortex Shear Mixer Product Leaflet enDocument4 pagesVortex Shear Mixer Product Leaflet enJARABA - Jean Luis ReyesPas encore d'évaluation

- LFD Box Culvert Design and Rating: User'S Manual ForDocument150 pagesLFD Box Culvert Design and Rating: User'S Manual ForMiguel valdivia rosasPas encore d'évaluation

- Truss Terminology PDFDocument3 pagesTruss Terminology PDFNerinel CoronadoPas encore d'évaluation

- Ducting Handbook 4th Ed FinalDocument56 pagesDucting Handbook 4th Ed FinalamitkdewPas encore d'évaluation

- Part RQ Qualification RequirementsDocument8 pagesPart RQ Qualification RequirementsMARCIOPas encore d'évaluation

- Fosroc Conplast CNI: Constructive SolutionsDocument2 pagesFosroc Conplast CNI: Constructive SolutionsVincent JavatePas encore d'évaluation

- Vivre Louvers by Vivre PanelsDocument83 pagesVivre Louvers by Vivre PanelsAnkit JaiswalPas encore d'évaluation

- Pressure VesselDocument26 pagesPressure VesselMohd Azharudin Mohadi100% (1)

- Materials in Construction PDFDocument20 pagesMaterials in Construction PDFGhiovani DayananPas encore d'évaluation

- Create Components of BUTTERFLY VALVE and Then Assemble ThemDocument12 pagesCreate Components of BUTTERFLY VALVE and Then Assemble Themnishantrautela1Pas encore d'évaluation

- Military Stallna N KCMSL: DD, FW 672-1 J - M-"."Document3 pagesMilitary Stallna N KCMSL: DD, FW 672-1 J - M-"."Bryan MartinezPas encore d'évaluation

- Basketball Courts Are Built Over: A 4" Thick Concrete Slab Using 3500 PSI Concrete and 1/2 Rebar Reinforcements. CDocument4 pagesBasketball Courts Are Built Over: A 4" Thick Concrete Slab Using 3500 PSI Concrete and 1/2 Rebar Reinforcements. CEugene MarcoPas encore d'évaluation

- Rail Mount Terminal Blocks With Screw and Stud Connection 2021 60449229Document36 pagesRail Mount Terminal Blocks With Screw and Stud Connection 2021 60449229Cudritescu VictorPas encore d'évaluation