Académique Documents

Professionnel Documents

Culture Documents

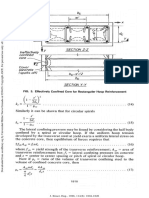

Test Unit Preparation: Fig. 5 - Posítions Oí Electrícal Resístance Straín Gages For 8-And 12-Bar Uníts

Transféré par

Ronal J Clavijo R0 évaluation0% ont trouvé ce document utile (0 vote)

15 vues1 pageTitre original

p05.pdf

Copyright

© © All Rights Reserved

Formats disponibles

PDF, TXT ou lisez en ligne sur Scribd

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

© All Rights Reserved

Formats disponibles

Téléchargez comme PDF, TXT ou lisez en ligne sur Scribd

0 évaluation0% ont trouvé ce document utile (0 vote)

15 vues1 pageTest Unit Preparation: Fig. 5 - Posítions Oí Electrícal Resístance Straín Gages For 8-And 12-Bar Uníts

Transféré par

Ronal J Clavijo RDroits d'auteur :

© All Rights Reserved

Formats disponibles

Téléchargez comme PDF, TXT ou lisez en ligne sur Scribd

Vous êtes sur la page 1sur 1

strain gage positions were as shown in Fig. 5.

For the 2

tests conducted at the fast strain rate, only the gages

numbered 2 and 10 were present at one one-third 8 3 8 3

point, 4 and 11 at midheight, and 7 and 12 at the other

one-third point. The strain gages used had a gage

length of 5 mm (0.20 in.). 7 4

For tests conducted at the low strain rate 4

(0.0000033/sec), the loads and strains were recorded

manually. For tests conducted at the higher strain rates

(0.00167 /sec or 0.0167 /sec), all measurements were re- Fig. 5 - Posítions oí electrícal resístance straín gages

corded electronically. for 8- and 12-bar uníts

Test unit preparation

The concentrically loaded test uníts had thin layers

V

of plaster placed between their ends and the steel plates Buck/1ng of ~/24mm (0.941n.!

at the ends of the testíng machine. The spherical seat-

ing normally located at the top platen was removed

long1rud1nal Dar

Dend1ng supporr --- d1a Dar

Dar w1rh 11 ~ 16mm !0.63in)d1a

since it was considered that a more uniform compres- <::;¡

"' supporr bar

sion strain would be maintained at high strains if ro- ~

tation of the platen could not occur.

For the concentrically loaded test units, a steel roller

bearing was inserted at each end of the unit between

-- -- -- ~

the end plates and the platens of the testing machine.

The roller bearings were set at a predetermined eccen- Fíg. 6 - Bendíng oí bar to which linear potentiometers

tricity of 49 mm (1.93 in.) for the 12-bar units and 33 were attached

mm (1.30 in.) for the 8-bar units. The eccentric loading

produced a strain gradient which varied as the test pro-

gressed, since the distribution of concrete compressive and supported the linear potentiometers had often de-

stress depended on the shape of the concrete stress- formed near one end, indicating that initially plane sec-

strain curve which changed as the test progressed. For tions were not remaining plane for the duration of the

the chosen end eccentricity (the end eccentricity was test. This occurred despite the fact that the end sections

held constant during the test), the straín was O at one of the test units remained plane. It was noticed that

face of the concrete core when the compressive strain the horizontal bars bent only if they were near a buckle

at the opposite face was about 0.01. Generally, rather in the longitudinal bars, as illustrated in Fig. 6. It ap-

than zero strain, there was initially a small compressive peared that the very high localized strains associated

strain and then a small and eventually a high tensile with longitudinal bar buckling caused local distortion

strain at one face, while the compressive strain in- of the concrete section. However, beca use this phe-

creased at the opposite face. nomenon occurred toward the end of testing, errors in

the longitudinal strains measured were not considered

to be great.

TEST OBSERVATIONS In the tests, a marked degradation in the strength of

The appearance of vertical cracks in the concrete the concrete core was always initiated by fracture of

cover was always the first sign of any distress in the an inner hoop. Generally, a considerable number of

test units. These cracks spread rapidly as crushing of hoops fractured befare testíng was complete, and the

the concrete cover caused the cover to become ineffec- concrete was still able to carry a significant load after

tive. As expected, this was particularly evident for the the fracture of three or four hoops. Thus, it would be

units with closely spaced hoops, since closely spaced reasonably conservative to define the limit of useful

transverse steel causes a plane of weakness between the concrete compressive strain as that strain at which

core and cover concrete. However, with the cover con- fracture of a hoop first occurs. It should be noted that

crete lost, the load still continued to increase as the fracture of the outer (perimeter) hoops occurred later,

core concrete became confined by arching between the if at all, than fracture of the inner hoops. This was

hoops and longitudinal bars. Eventually this load de- due to the loss of bond at the outer hoops, caused by

creased. Buckling of the longitudinal bars occurred at the loss of the concrete cover, allowing an averaging

higher strains; this was invariably associated with frac- of the outer hoop strain across the width of the con-

ture of the hoops at or near the buckle. As the hoops crete core. Fracture of an inner hoop, and the subse-

snapped, the core concrete in the near vicinity was re- quent local degradation of the strength of the concrete

duced to fine rubble and flowed or was ejected from core, also caused a loss of anchorage at the embedded

the core. ends of the outer hoop bars, resulting in a tendency

After the tests, it was found that the horizontal bars for the outer hoop bar to unwind rather than to frac-

which passed through the units at the one-third points ture.

ACI JOURNAL / January-February 1982 17

Vous aimerez peut-être aussi

- 10 1 1 875 5824 PDFDocument33 pages10 1 1 875 5824 PDFحمودي معزPas encore d'évaluation

- In-Plane Fatigue Strength of Plates With Laminar DiscontinuitiesDocument8 pagesIn-Plane Fatigue Strength of Plates With Laminar DiscontinuitiesalbertoxinaPas encore d'évaluation

- Ada453908 PDFDocument30 pagesAda453908 PDFDani Quirante Flaaut EtcPas encore d'évaluation

- TRIAXIAL Stress Gauge Measures Rock StressDocument9 pagesTRIAXIAL Stress Gauge Measures Rock StressEduardo MorinPas encore d'évaluation

- Column Capacity With Site Imperfection Splice WeldDocument8 pagesColumn Capacity With Site Imperfection Splice WeldRaja GopalPas encore d'évaluation

- Shear Transfer in Concrete Having Reinforcement at An Angle To Shear PlaneDocument26 pagesShear Transfer in Concrete Having Reinforcement at An Angle To Shear PlanePremasiri Karunarathna100% (1)

- ELASTIC STRESSES IN SINGLE MITRED BENDSDocument22 pagesELASTIC STRESSES IN SINGLE MITRED BENDSWang Kin HuiPas encore d'évaluation

- Composite Beams: P. AnsourianDocument27 pagesComposite Beams: P. AnsourianLeonardoMadeira11Pas encore d'évaluation

- FRPConfinedCircularolumnsUnderSmallEccentricLoading Ghali Kassen FawzyDocument10 pagesFRPConfinedCircularolumnsUnderSmallEccentricLoading Ghali Kassen FawzyAhmd MhmdPas encore d'évaluation

- Behavior of Corbels With External Prestressing Bars - Experimental StudyDocument21 pagesBehavior of Corbels With External Prestressing Bars - Experimental StudyMaurício FerreiraPas encore d'évaluation

- Torsional Properties of Fabricated I-Beam and Box Sections 1941Document36 pagesTorsional Properties of Fabricated I-Beam and Box Sections 1941Reinaldo Chohfi Jr.Pas encore d'évaluation

- Experimental Investigation On Internally Ring-Stiffened Joints of Offshore PlatformsDocument5 pagesExperimental Investigation On Internally Ring-Stiffened Joints of Offshore Platformssm8575Pas encore d'évaluation

- Failure Characteristics and Critical Punching Perimeter of High Strength Concrete PanelsDocument6 pagesFailure Characteristics and Critical Punching Perimeter of High Strength Concrete PanelsYusuf Ali SamiPas encore d'évaluation

- 5 - KhanDocument39 pages5 - KhanMuthu SaravanaPas encore d'évaluation

- Base Plate & Stiffener 3Document13 pagesBase Plate & Stiffener 3cu1988Pas encore d'évaluation

- Elastic Stress Parameters in Simply Supported Skew Plates in FlexureDocument9 pagesElastic Stress Parameters in Simply Supported Skew Plates in Flexureluna luneraPas encore d'évaluation

- Nishino 1966 ResDocument52 pagesNishino 1966 ResSeymur AkbarovPas encore d'évaluation

- Load Transfer Behavior of Full-Scale Instrumented Helical PilesDocument10 pagesLoad Transfer Behavior of Full-Scale Instrumented Helical PilesWimpsPas encore d'évaluation

- Hancock Et Al 1994 DB Curves PaperDocument18 pagesHancock Et Al 1994 DB Curves Paperclam2014Pas encore d'évaluation

- Liu2006 2Document1 pageLiu2006 2ebiPas encore d'évaluation

- Dong 2017Document24 pagesDong 2017fabianobertoni4025Pas encore d'évaluation

- Investigation of Load Transfer Characteristics of DowelsDocument5 pagesInvestigation of Load Transfer Characteristics of Dowelsnima sarPas encore d'évaluation

- 2001 - Rasmussen - Tests of X - and K - Joints in SHS Stainless Steel TubesDocument11 pages2001 - Rasmussen - Tests of X - and K - Joints in SHS Stainless Steel TubesFelipe CoutinhoPas encore d'évaluation

- Cable Anchors: A Prestressed Cable Anchor Is A High Strength Steel Tendon, Fitted With ADocument13 pagesCable Anchors: A Prestressed Cable Anchor Is A High Strength Steel Tendon, Fitted With AAnonymous RBDKAkBPoFPas encore d'évaluation

- Behaviour of Welded Wire Fabric Under Cyclic LoadsDocument30 pagesBehaviour of Welded Wire Fabric Under Cyclic LoadsMatias GaitanPas encore d'évaluation

- MILD STEEL TORSION TESTDocument5 pagesMILD STEEL TORSION TESTShweta Pradhan100% (1)

- Module 2 Tension Members PDFDocument26 pagesModule 2 Tension Members PDFjomarie apolinarioPas encore d'évaluation

- CRACK PREDICTIONDocument12 pagesCRACK PREDICTIONAnonymous XVEucVMsEPas encore d'évaluation

- O o Fig. 4 - Stress-Strain Curves For Steel ReinforcementDocument1 pageO o Fig. 4 - Stress-Strain Curves For Steel ReinforcementRonal J Clavijo RPas encore d'évaluation

- Fatigue Life of Double Angle Tension MembersDocument10 pagesFatigue Life of Double Angle Tension MembersalbertoxinaPas encore d'évaluation

- Regan 2004Document8 pagesRegan 2004Ghazi Bahroz JumaaPas encore d'évaluation

- Repairing Damaged Prestressed Concrete BridgesDocument28 pagesRepairing Damaged Prestressed Concrete Bridges20MC06 - SORNAMUGI KPas encore d'évaluation

- Bending Test of Reinforcing Steel BarDocument6 pagesBending Test of Reinforcing Steel BarErol Josef AporaPas encore d'évaluation

- Reinforcedconcrete Beam-Column Jointsfor Seismic Loading P A R T II - Experimental ResultsDocument12 pagesReinforcedconcrete Beam-Column Jointsfor Seismic Loading P A R T II - Experimental Resultssaikat mondalPas encore d'évaluation

- Pile Testing - ReflectogramDocument4 pagesPile Testing - ReflectogramAnonymous FKQSDZVxPas encore d'évaluation

- Arabicpages PDFDocument85 pagesArabicpages PDFGonzalo CáceresPas encore d'évaluation

- Mechanism of Shear TransferDocument8 pagesMechanism of Shear TransferSana'a AamirPas encore d'évaluation

- 237 61 PDFDocument39 pages237 61 PDFAnonymous imkwF8N7TePas encore d'évaluation

- Failure of Chauras BridgeDocument8 pagesFailure of Chauras BridgeRitesh ChaurasiaPas encore d'évaluation

- Influence of Stirrup Distribution and SupportDocument11 pagesInfluence of Stirrup Distribution and SupportRayan MahgoubPas encore d'évaluation

- Analysis and Design For End Effects in Twisted Double TeesDocument20 pagesAnalysis and Design For End Effects in Twisted Double TeesFabrizio BisernaPas encore d'évaluation

- E EignungsprufungDocument8 pagesE EignungsprufungMehdi BakhshiPas encore d'évaluation

- Mechanics of Deformable BodiesDocument2 pagesMechanics of Deformable Bodiesmemowic458Pas encore d'évaluation

- The Anchorage Bend in The Begg TechniqueDocument7 pagesThe Anchorage Bend in The Begg TechniqueSyed Mohammad Osama AhsanPas encore d'évaluation

- Structural Characterization of Wear Debris Produced During Friction Between Two Austenitic Stainless Steel AntagonistsDocument6 pagesStructural Characterization of Wear Debris Produced During Friction Between Two Austenitic Stainless Steel AntagonistsrattayyaPas encore d'évaluation

- The Theory of Tube Producing MethodsDocument16 pagesThe Theory of Tube Producing MethodsJosé B. CorreaPas encore d'évaluation

- CRD-C90 - Test For Transverse Shear StrengthDocument3 pagesCRD-C90 - Test For Transverse Shear StrengthWeff JingPas encore d'évaluation

- Cable Bolt Anchors Performance PDFDocument8 pagesCable Bolt Anchors Performance PDFwilmerlancePas encore d'évaluation

- 2-Equation For Stress-Strain Curve (Desayi, Et Al., 1978) PDFDocument7 pages2-Equation For Stress-Strain Curve (Desayi, Et Al., 1978) PDFJhe TaguinesPas encore d'évaluation

- Imperfection, Residual Stress and Yield Slenderness Limit of Very High Strength (VHS) Circular Steel Tubes, 2003 (H Jiao, X.-L Zhao)Document17 pagesImperfection, Residual Stress and Yield Slenderness Limit of Very High Strength (VHS) Circular Steel Tubes, 2003 (H Jiao, X.-L Zhao)Phan Đào Hoàng HiệpPas encore d'évaluation

- AWS Fatigue Strength Lee06 01Document5 pagesAWS Fatigue Strength Lee06 01Jorge Ayala BacaPas encore d'évaluation

- Jse 2003Document45 pagesJse 2003^passwordPas encore d'évaluation

- Development of Is:456 Shear Design Provisions-Ii: Members With Shear ReinforcementDocument10 pagesDevelopment of Is:456 Shear Design Provisions-Ii: Members With Shear ReinforcementRabin DhakalPas encore d'évaluation

- LTB of Beams in Ebf-JcsrDocument22 pagesLTB of Beams in Ebf-Jcsrkostas formulagrPas encore d'évaluation

- (Allan, R.N., & J.W. Fisher.,1967) - Behavior of Bolted Joints With Oversize or Slotted Holes PDFDocument64 pages(Allan, R.N., & J.W. Fisher.,1967) - Behavior of Bolted Joints With Oversize or Slotted Holes PDFchristos032100% (2)

- Experiments On Cold-Formed Steel Columns With Holes: Cristopher D. Moen, B.W. SchaferDocument3 pagesExperiments On Cold-Formed Steel Columns With Holes: Cristopher D. Moen, B.W. SchaferAgung PratamaPas encore d'évaluation

- CE 581 Reinforced Concrete Structures: Lecture 4: Axial LoadingDocument36 pagesCE 581 Reinforced Concrete Structures: Lecture 4: Axial LoadingCelil OrakPas encore d'évaluation

- Ultimate Load Behaviour of Tapered Plate GirdersDocument33 pagesUltimate Load Behaviour of Tapered Plate GirdersPablo RicoPas encore d'évaluation

- Load Carrying Capacity of Z-Purlins With A.C. Sheet CladdingDocument21 pagesLoad Carrying Capacity of Z-Purlins With A.C. Sheet CladdingSRINIVAS DPas encore d'évaluation

- Derivation of Link EquationsDocument3 pagesDerivation of Link EquationsSami SyedPas encore d'évaluation

- My Favorite Destination Is The Malpelo IslandDocument2 pagesMy Favorite Destination Is The Malpelo IslandRonal J Clavijo RPas encore d'évaluation

- Derivation of Link EquationsDocument3 pagesDerivation of Link EquationsSami SyedPas encore d'évaluation

- What Is A Gaita in ColombiaDocument4 pagesWhat Is A Gaita in ColombiaRonal J Clavijo RPas encore d'évaluation

- Fema450 2 PDFDocument395 pagesFema450 2 PDFShaukat Ali KhanPas encore d'évaluation

- J. Struct. Eng., 1988, 114 (8) : 1804-1826Document1 pageJ. Struct. Eng., 1988, 114 (8) : 1804-1826Ronal J Clavijo RPas encore d'évaluation

- Appendix I. References: J. Struct. Eng., 1988, 114 (8) : 1804-1826Document1 pageAppendix I. References: J. Struct. Eng., 1988, 114 (8) : 1804-1826Ronal J Clavijo RPas encore d'évaluation

- Acelerograma Univeridad Agraria Los Santos NSDocument248 pagesAcelerograma Univeridad Agraria Los Santos NSRonal J Clavijo RPas encore d'évaluation

- p16 PDFDocument1 pagep16 PDFRonal J Clavijo RPas encore d'évaluation

- Derivation of Link EquationsDocument3 pagesDerivation of Link EquationsSami SyedPas encore d'évaluation

- Appendix Ii. Notation: J. Struct. Eng., 1988, 114 (8) : 1804-1826Document1 pageAppendix Ii. Notation: J. Struct. Eng., 1988, 114 (8) : 1804-1826Ronal J Clavijo RPas encore d'évaluation

- J. Struct. Eng., 1988, 114 (8) : 1804-1826Document1 pageJ. Struct. Eng., 1988, 114 (8) : 1804-1826Ronal J Clavijo RPas encore d'évaluation

- p18 PDFDocument1 pagep18 PDFRonal J Clavijo RPas encore d'évaluation

- Confined Strength Ratio F /FDocument1 pageConfined Strength Ratio F /FRonal J Clavijo RPas encore d'évaluation

- Jo Jo: Quasi-Static Compressive Strength of Concrete in Mpa (1 MpaDocument1 pageJo Jo: Quasi-Static Compressive Strength of Concrete in Mpa (1 MpaRonal J Clavijo RPas encore d'évaluation

- J. Struct. Eng., 1988, 114 (8) : 1804-1826Document1 pageJ. Struct. Eng., 1988, 114 (8) : 1804-1826Ronal J Clavijo RPas encore d'évaluation

- Epsfyh - (19) : J. Struct. Eng., 1988, 114 (8) : 1804-1826Document1 pageEpsfyh - (19) : J. Struct. Eng., 1988, 114 (8) : 1804-1826Ronal J Clavijo RPas encore d'évaluation

- FC High Strain Rate (Dynamic) :, and A Decrease in The StrainDocument1 pageFC High Strain Rate (Dynamic) :, and A Decrease in The StrainRonal J Clavijo RPas encore d'évaluation

- FIG. 6. Assumed Deterioration in Tensile Strength of Concrete Due To Prior Compression LoadingDocument1 pageFIG. 6. Assumed Deterioration in Tensile Strength of Concrete Due To Prior Compression LoadingRonal J Clavijo RPas encore d'évaluation

- J. Struct. Eng., 1988, 114 (8) : 1804-1826Document1 pageJ. Struct. Eng., 1988, 114 (8) : 1804-1826Ronal J Clavijo RPas encore d'évaluation

- p12 PDFDocument1 pagep12 PDFRonal J Clavijo RPas encore d'évaluation

- O % 17.2mpa M F U.8Mpa - TheoryDocument1 pageO % 17.2mpa M F U.8Mpa - TheoryRonal J Clavijo RPas encore d'évaluation

- Effective Lateral Confining Pressure and The Confinement Effectiveness CoefficientDocument1 pageEffective Lateral Confining Pressure and The Confinement Effectiveness CoefficientRonal J Clavijo RPas encore d'évaluation

- FC F'CCXR R-L+X Compressive Strength of Confined Concrete (Defined Later)Document1 pageFC F'CCXR R-L+X Compressive Strength of Confined Concrete (Defined Later)Ronal J Clavijo RPas encore d'évaluation

- Cover Concrete: Effectively Confined Section B-B Cover Concrete (Spalls Off) - Q-Ra Ineffectively Confined Core S/sDocument1 pageCover Concrete: Effectively Confined Section B-B Cover Concrete (Spalls Off) - Q-Ra Ineffectively Confined Core S/sRonal J Clavijo RPas encore d'évaluation

- p11 PDFDocument1 pagep11 PDFRonal J Clavijo RPas encore d'évaluation

- LC Un''unl &re I'rel: Sun-'New'Document1 pageLC Un''unl &re I'rel: Sun-'New'Ronal J Clavijo RPas encore d'évaluation

- Compressive Strength of Confined Concrete, F': SX SyDocument1 pageCompressive Strength of Confined Concrete, F': SX SyRonal J Clavijo RPas encore d'évaluation

- The Maximum Concrete Stress and The Corresponding: e e F 1 + KDocument1 pageThe Maximum Concrete Stress and The Corresponding: e e F 1 + KRonal J Clavijo RPas encore d'évaluation

- p07 PDFDocument1 pagep07 PDFRonal J Clavijo RPas encore d'évaluation

- Science: Learning Activity Sheet Quarter 4 Week 1 - 2Document5 pagesScience: Learning Activity Sheet Quarter 4 Week 1 - 2Ma.Kristine Ibarreta JazulPas encore d'évaluation

- Advanced Fluid Mechanics - Chapter 01 - IntroductionDocument26 pagesAdvanced Fluid Mechanics - Chapter 01 - Introductionhari sPas encore d'évaluation

- Mechanics Research Communications: A Note On The Mohr-Coulomb and Drucker-Prager Strength CriteriaDocument6 pagesMechanics Research Communications: A Note On The Mohr-Coulomb and Drucker-Prager Strength Criteriaமாறன் செங்கேணிPas encore d'évaluation

- Mechanical Properties of Fluids All DervationsDocument12 pagesMechanical Properties of Fluids All DervationsAmiya Kumar Das100% (1)

- Design guide for Lindab LTP150 trapezoidal sheetingDocument21 pagesDesign guide for Lindab LTP150 trapezoidal sheetingRajlić ZoranPas encore d'évaluation

- Thick Walled Cylinder - FeaDocument22 pagesThick Walled Cylinder - Feagpro123Pas encore d'évaluation

- Dynamics of Machinery Question BankDocument8 pagesDynamics of Machinery Question BankArun ShawnPas encore d'évaluation

- Predicting Discharge Trajectories From Belt ConveyorsDocument8 pagesPredicting Discharge Trajectories From Belt ConveyorsVijay AnandPas encore d'évaluation

- Basic Food Rheology 2016Document54 pagesBasic Food Rheology 2016Syafiqah Suhaimi100% (2)

- Polymers 14 03161Document18 pagesPolymers 14 03161Ömer GezerPas encore d'évaluation

- What Is An Orbit MotorDocument10 pagesWhat Is An Orbit MotorishwarPas encore d'évaluation

- 18307apni KakshaDocument38 pages18307apni KakshaVaibhav2006Pas encore d'évaluation

- Icse X Model PaperDocument4 pagesIcse X Model Papershantanu tripathiPas encore d'évaluation

- Listrik Statis Dengan Raket NyamukDocument5 pagesListrik Statis Dengan Raket NyamukMarini Amalia OcviantiPas encore d'évaluation

- Advanced Reinforced Concrete Design IS-456-2000 by N. Krishna RajuDocument371 pagesAdvanced Reinforced Concrete Design IS-456-2000 by N. Krishna RajuVikram jare100% (1)

- Philips Affiniti 50 Ultrasound SystemDocument32 pagesPhilips Affiniti 50 Ultrasound SystemTuyen nguyen ngocPas encore d'évaluation

- Prevention of Track Buckling & Rail FractureDocument9 pagesPrevention of Track Buckling & Rail Fractureanurag3069Pas encore d'évaluation

- DPUE - Phy-2-Electric Potential and CapacitorsDocument17 pagesDPUE - Phy-2-Electric Potential and CapacitorsKomal GowdaPas encore d'évaluation

- 6-Modeling of Fluid SystemsDocument25 pages6-Modeling of Fluid SystemsAzhar AliPas encore d'évaluation

- Tensor Analysis and GeometryDocument7 pagesTensor Analysis and Geometryapi-19523062100% (1)

- St. Francis National High School SF I, Limay, Bataan Third Periodical Test in Science 7 NAME: - YR/SECTIONDocument2 pagesSt. Francis National High School SF I, Limay, Bataan Third Periodical Test in Science 7 NAME: - YR/SECTIONArvin Arne RodrigoPas encore d'évaluation

- Merancang Propeller untuk MV. CETAK MEDIADocument31 pagesMerancang Propeller untuk MV. CETAK MEDIAJustice FagPas encore d'évaluation

- Faraday Law of Electromagnetic InductionDocument5 pagesFaraday Law of Electromagnetic Inductionantex nebyuPas encore d'évaluation

- Lec 12Document4 pagesLec 12rudresh JmPas encore d'évaluation

- 05 LagrangianDynamics 3Document35 pages05 LagrangianDynamics 3Ubedullah SaeedPas encore d'évaluation

- Science NCERT Class 8 Chapter 11 Force and PressureDocument3 pagesScience NCERT Class 8 Chapter 11 Force and PressureDivyansh Kumar KarnPas encore d'évaluation

- Strength of Materials (S.O.M.) Model Question Paper (Q.P.) SolutionDocument16 pagesStrength of Materials (S.O.M.) Model Question Paper (Q.P.) SolutionProf. P. H. Jain92% (13)

- 2002, Princeton University Physics Department, Edward J. GrothDocument8 pages2002, Princeton University Physics Department, Edward J. GrothOmegaUserPas encore d'évaluation

- Mechanics of Solids: Bela I. Sandor Ryan Roloff Stephen M. Birn Maan H. Jawad Michael L. BrownDocument1 pageMechanics of Solids: Bela I. Sandor Ryan Roloff Stephen M. Birn Maan H. Jawad Michael L. BrownkprasannanPas encore d'évaluation

- Beams Sb1, Group 1 and 6Document29 pagesBeams Sb1, Group 1 and 6Wilbert Carlo RachoPas encore d'évaluation