Académique Documents

Professionnel Documents

Culture Documents

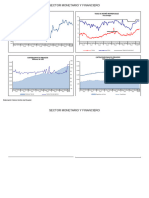

Curva Tiempo-Corriente

Transféré par

toriz123Titre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Curva Tiempo-Corriente

Transféré par

toriz123Droits d'auteur :

Formats disponibles

CURRENT IN AMPERES

10000

1000

2000

3000

4000

5000

6000

7000

8000

9000

100

200

300

400

500

600

700

800

900

10

20

30

40

50

60

70

80

90

.5 .6 .7 .8 .9 1 2 3 4 5 6 7 8 9

1000 1000

900 900

800 800

700 700

600 600

500 500

400 400

102

101

103

300 300

200 200

100 100

90 90

80 80

70 70

60 60

50 50

40 40

30 30

20 20

10 10

9 9

8 8

7 7

6 6

5 5

TIME IN SECONDS

TIME IN SECONDS

4 4

3 3

2 2

1 1

.9 .9

.8 .8

.7 .7

.6 .6

.5 .5

.4 .4

.3 .3

.2 .2

.1 .1

.09 .09

.08 .08

.07 .07

.06 .06

.05 .05

.04 .04

.03 .03

.02 .02

.01 .01

.5 .6 .7 .8 .9 1 2 3 4 5 6 7 8 9

10

20

30

40

50

60

70

80

90

100

200

300

400

500

600

700

800

900

1000

2000

3000

4000

5000

6000

7000

8000

9000

10000

CURRENT IN AMPERES

MINIMUM MELTING TIME-CURRENT CHARACTERISTIC CURVES

POSITROL® FUSE LINKS—S&C COORDINATING SPEED

BASIS—These fuse links are tested in accordance with the proce- It is advisable to replace unblown silver-tin or cast-tin element If close coordination is to be achieved, overloading must be

dures described in ANSI Standard C37.41-1981. As required by fuse links in single-phase or three-phase installations when one or avoided since it causes a significant shift in time-current character-

this standard, the minimum melting curves are based on tests more fuse links have blown, since they may be damaged by tran- istics.

starting with the fuse link at an ambient temperature of 25°C and no sient overcurrents.

Because of the damageability of silver-tin and cast-tin element

initial load.

fuse links, setback allowances must be used in coordinating these

CONSTRUCTION—Fusible elements for fuse links rated 101 amperes fuse links as “protected” devices. These are applied by reducing the

COORDINATION—Any preloading reduces melting time. The effect of

are silver-tin; fusible elements for fuse links rated 102 and 103 current value in the above curves by 10%.

preloading (as described in S&C Data Bulletin 350-195) must be

amperes are cast tin. All are of solderless construction.

determined for the fuse links represented by these curves and

TOLERANCES—Curves are plotted to minimum test points. Max- adjustments to these curves must be made:

imum variations within the coordinating range (melting times less 1. When close coordination is required; FUSE LINKS AVAILABLE—

than 10 seconds) expressed in current values are plus 20%. 2. When automatic circuit reclosers or three-shot cutouts are Style Ampere Ratings

involved; Universal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 101, 102, and 103

APPLICATION—These fuse links should never be exposed to loading

3. When, regardless of the preciseness of coordination, the fuse

in excess of the peak-load capabilities listed in S&C Data Bulletin

link is subjected to temporary overloads.

350-190.

Supersedes TCC No. 172-6 dated 5-28-84 c1984

TCC NUMBER 172-6

s S&C ELECTRIC COMPANY • Chicago

S&C ELECTRIC CANADA LTD. • Toronto

Page 1 of 1

December 17, 1984

Vous aimerez peut-être aussi

- Sistemas Seguros de Acceso y Trans. de Datos (MF0489_3): SEGURIDAD INFORMÁTICAD'EverandSistemas Seguros de Acceso y Trans. de Datos (MF0489_3): SEGURIDAD INFORMÁTICAÉvaluation : 5 sur 5 étoiles5/5 (1)

- Curva Tiempo-CorrienteDocument1 pageCurva Tiempo-CorrienteNabhi BrunoPas encore d'évaluation

- Curvas Max K PDFDocument1 pageCurvas Max K PDFyorsPas encore d'évaluation

- Fusible Tipo K - TDocument5 pagesFusible Tipo K - TEmmanuel PugaPas encore d'évaluation

- Fusible Tipo K - TDocument5 pagesFusible Tipo K - Tzoprairving0% (1)

- A-A View: S130-TWNDocument1 pageA-A View: S130-TWNNadir Khattak Jr.Pas encore d'évaluation

- ResumenDocument32 pagesResumenDiana RicardiPas encore d'évaluation

- Proyecto de instalación eléctrica industrialDocument1 pageProyecto de instalación eléctrica industrialJAZMIN OSCULLOPas encore d'évaluation

- WWTP Cap.1200 RDocument11 pagesWWTP Cap.1200 Rsupri yatnoPas encore d'évaluation

- Monitoreo y pronóstico de caudales en las cuencas de los ríos Ilave y CoataDocument27 pagesMonitoreo y pronóstico de caudales en las cuencas de los ríos Ilave y CoataRoger Chullunquia TisnadoPas encore d'évaluation

- Tarea 1 - Recuperación MejoradaDocument2 pagesTarea 1 - Recuperación MejoradaLuis E Famous YankeePas encore d'évaluation

- Bomba HidráulicaDocument2 pagesBomba HidráulicaJuan Amador SanchezPas encore d'évaluation

- Termodinamica - Cengel 7th - Espanhol-951Document1 pageTermodinamica - Cengel 7th - Espanhol-95147 RoninPas encore d'évaluation

- SUB ESTACION 14-Nueva Configuracion-ModelDocument1 pageSUB ESTACION 14-Nueva Configuracion-Modeljuan jesus baldeon chuquihuaPas encore d'évaluation

- 2019 Esquema Hidraulico IntegralDocument1 page2019 Esquema Hidraulico IntegralJhxncxrlx MxzxPas encore d'évaluation

- Pipe Rack Tramo 2 Cuerda Superior Pipe Rack Tramo 3 Cuerda Superior Pipe Rack Tramo 1 Cuerda Superior Pipe Rack Tramo 5 Cuerda InferiorDocument1 pagePipe Rack Tramo 2 Cuerda Superior Pipe Rack Tramo 3 Cuerda Superior Pipe Rack Tramo 1 Cuerda Superior Pipe Rack Tramo 5 Cuerda InferiorJOSE MANUEL ORTIZ ARRIETA LUJANPas encore d'évaluation

- Mapa de comunidades 1 AMAZONAS, ARENAL. CABENO, DASHINO, EL BLANCO, EL CISNE, LA LAGUNA, LOS SHIRIS, LUMBAQUI, NUEVO PARAISO, PARAISO, PLAYASECA, SAN FRANCISCO, SAN JOSE DE AGUARICO, SAN SALVADOR, SARDINAS Y UNION INDEPENDIENTE.Document1 pageMapa de comunidades 1 AMAZONAS, ARENAL. CABENO, DASHINO, EL BLANCO, EL CISNE, LA LAGUNA, LOS SHIRIS, LUMBAQUI, NUEVO PARAISO, PARAISO, PLAYASECA, SAN FRANCISCO, SAN JOSE DE AGUARICO, SAN SALVADOR, SARDINAS Y UNION INDEPENDIENTE.CONSERVACION Y DESARROLLO SOSTENIBLEPas encore d'évaluation

- 23af-001-Plp-01 PozasDocument1 page23af-001-Plp-01 PozasRoy SifuentesPas encore d'évaluation

- P1007 - Orica - E001Document1 pageP1007 - Orica - E001CesarPas encore d'évaluation

- Programa y Plan de Mantención PreventivaDocument3 pagesPrograma y Plan de Mantención PreventivaJhousep steven Mesia gonzalesPas encore d'évaluation

- Neptuno Pumps® - Bombas Horizontales Multietapa (HR) Poster PDFDocument1 pageNeptuno Pumps® - Bombas Horizontales Multietapa (HR) Poster PDFFreddy Cachumba100% (1)

- Plano - Zona de VidaDocument1 pagePlano - Zona de VidaCARLOS CIRINEO URETAPas encore d'évaluation

- 1096 0766 Ask Ask-Mk EsDocument28 pages1096 0766 Ask Ask-Mk EsNick OchoaPas encore d'évaluation

- Cabaña 2Document1 pageCabaña 2YAMRO WORKBOATPas encore d'évaluation

- Diagrama TS AguaDocument1 pageDiagrama TS AguaVale Ignacia TapiaPas encore d'évaluation

- Econ Pol 17 Politica FiscalDocument9 pagesEcon Pol 17 Politica FiscalDaniel Perdomo CabreraPas encore d'évaluation

- Situación Epidemiológica de Sarampión Rubeola y PFA Lima y Callao 17junio2021Document48 pagesSituación Epidemiológica de Sarampión Rubeola y PFA Lima y Callao 17junio2021cdc.inmunopreveniblesPas encore d'évaluation

- Factor de fricción en función del número de ReynoldsDocument1 pageFactor de fricción en función del número de ReynoldsLeonela RodríguezPas encore d'évaluation

- Diagrama de Moody PDFDocument1 pageDiagrama de Moody PDFLeonela Rodríguez100% (2)

- Diagrama de Moody PDFDocument1 pageDiagrama de Moody PDFLeonela Rodríguez100% (1)

- Diagrama de MoodyDocument1 pageDiagrama de MoodyLeonela RodríguezPas encore d'évaluation

- Diagrama de ModdyDocument1 pageDiagrama de ModdyMARÍA YANELA DIAZ RAMIREZPas encore d'évaluation

- Diagrama de Moody PDFDocument1 pageDiagrama de Moody PDFLeonela RodríguezPas encore d'évaluation

- 500k Viewposter2019-1Document1 page500k Viewposter2019-1Jonathan MercadoPas encore d'évaluation

- PAUTA Mantencion Workstar MixersDocument2 pagesPAUTA Mantencion Workstar MixersGonzalo SepulvedaPas encore d'évaluation

- Modelo Estructural - Desnivel - 2023 - Plano - A126 - Sin NombreDocument1 pageModelo Estructural - Desnivel - 2023 - Plano - A126 - Sin NombreJhonata Jose Marquez LopezPas encore d'évaluation

- Flyerlancio E6NVX ES - CompressedDocument2 pagesFlyerlancio E6NVX ES - CompressedMiguel Angel Guevara GuerreroPas encore d'évaluation

- SF102Document1 pageSF102MohanadElAtribyPas encore d'évaluation

- Kranbau Es Komplett PDFDocument73 pagesKranbau Es Komplett PDFJavier Alejandro Cuellar MoraPas encore d'évaluation

- 2 G Finanzas Publicas-EDocument1 page2 G Finanzas Publicas-EJose Luis SolanoPas encore d'évaluation

- Diseño de losas de cubierta y pilares paralelos al eje de trazadoDocument2 pagesDiseño de losas de cubierta y pilares paralelos al eje de trazadoingjhonlopezPas encore d'évaluation

- Plano-Magdalena-CurvasNivelDocument1 pagePlano-Magdalena-CurvasNivelTulio Guillén SheenPas encore d'évaluation

- Plan de Mantenimiento Nissan NavaraDocument1 pagePlan de Mantenimiento Nissan NavaraLuis Angel ChiloPas encore d'évaluation

- DIagrama MoodyDocument1 pageDIagrama MoodyPablo EduardoPas encore d'évaluation

- AtenciónDocument1 pageAtenciónCatalina PeñaPas encore d'évaluation

- Evolución distritos provincia Urubamba 150000-220000Document1 pageEvolución distritos provincia Urubamba 150000-220000Veronica PradozPas encore d'évaluation

- Crecimiento población distritos provincia Urubamba 2000-2017Document1 pageCrecimiento población distritos provincia Urubamba 2000-2017Veronica PradozPas encore d'évaluation

- Mg-03 Mapa de Zonas UrbanasDocument1 pageMg-03 Mapa de Zonas UrbanasVeronica PradozPas encore d'évaluation

- Md-13 Mapa de Vulnerabilidad Agricola Por Peligro de InundacionDocument1 pageMd-13 Mapa de Vulnerabilidad Agricola Por Peligro de InundacionVeronica PradozPas encore d'évaluation

- Crecimiento población distritos provincia Urubamba 2000-2017Document1 pageCrecimiento población distritos provincia Urubamba 2000-2017Veronica PradozPas encore d'évaluation

- Md-11 Mapa de Vulnerabilidad de Zonas Edificadas Por Peligro de InundacionDocument1 pageMd-11 Mapa de Vulnerabilidad de Zonas Edificadas Por Peligro de InundacionVeronica PradozPas encore d'évaluation

- Plan de Mantenimiento Fuso RosaDocument2 pagesPlan de Mantenimiento Fuso RosaLuis Angel Chilo67% (3)

- Infografía Línea Del Tiempo Timeline Historia Moderno Creativo MulticolorDocument1 pageInfografía Línea Del Tiempo Timeline Historia Moderno Creativo MulticolorYuvicza CervantesPas encore d'évaluation

- Hyr 23048 A01Document1 pageHyr 23048 A01David BorjaPas encore d'évaluation

- Isoyetas de EcuadorDocument1 pageIsoyetas de EcuadorJhon Tayson AlavaPas encore d'évaluation

- 00 Mapa Trazo Preliminar CarreteraDocument1 page00 Mapa Trazo Preliminar CarreteraElizabeth GalvezPas encore d'évaluation

- Plano - Cobertura VegetalDocument1 pagePlano - Cobertura VegetalCARLOS CIRINEO URETAPas encore d'évaluation

- Guia Cicloturista Carretera Anillo Del MaestrazgopdfDocument7 pagesGuia Cicloturista Carretera Anillo Del MaestrazgopdfMartin MerinoPas encore d'évaluation

- 1 G Sector MonyFin-eDocument2 pages1 G Sector MonyFin-eJose Luis SolanoPas encore d'évaluation

- NMX I 8Document1 pageNMX I 8toriz123Pas encore d'évaluation

- Pago Boleta Certificada 4243424Document1 pagePago Boleta Certificada 4243424pablo9630Pas encore d'évaluation

- 9 PDFDocument1 page9 PDFtoriz123Pas encore d'évaluation

- NMX I 9Document1 pageNMX I 9toriz123Pas encore d'évaluation

- Ejercicio GloverDocument2 pagesEjercicio Glovertoriz123Pas encore d'évaluation

- NMX I 1Document1 pageNMX I 1toriz123Pas encore d'évaluation

- NMX I 5Document1 pageNMX I 5toriz123Pas encore d'évaluation

- NMX I 7Document1 pageNMX I 7toriz123Pas encore d'évaluation

- NMX I 6Document1 pageNMX I 6toriz123Pas encore d'évaluation

- WebinarDocument1 pageWebinartoriz123Pas encore d'évaluation

- NMX I 3Document1 pageNMX I 3toriz123Pas encore d'évaluation

- Metodos InterativosDocument7 pagesMetodos Interativoscradle_of_slipknot07Pas encore d'évaluation

- NMX I 4Document1 pageNMX I 4toriz123Pas encore d'évaluation

- NMX I 2Document1 pageNMX I 2toriz123Pas encore d'évaluation

- General Ida DesDocument18 pagesGeneral Ida Despelisp4Pas encore d'évaluation

- Lista de Precios PDFDocument331 pagesLista de Precios PDFtoriz123Pas encore d'évaluation

- Qlogic 2Document35 pagesQlogic 2Cesar Elizalde SolisPas encore d'évaluation

- SolicitudBoletaCertificada PDFDocument1 pageSolicitudBoletaCertificada PDFtoriz123Pas encore d'évaluation

- Adaptación de ImpedanciasDocument18 pagesAdaptación de ImpedanciasGefry Andres Castro JimenezPas encore d'évaluation

- Dcciambt PDFDocument829 pagesDcciambt PDFEduardo Ram100% (1)

- 351 PF00444 ES WebDocument8 pages351 PF00444 ES Webtoriz123Pas encore d'évaluation

- Triptico ParralDocument2 pagesTriptico Parraltoriz123Pas encore d'évaluation

- P1 Protecciones PDFDocument5 pagesP1 Protecciones PDFtoriz123Pas encore d'évaluation

- Ensayo de Transfor M AdoresDocument16 pagesEnsayo de Transfor M AdoresJesus Salazar100% (1)

- Subestaciones Compactas Technical Document SpanishDocument18 pagesSubestaciones Compactas Technical Document SpanishMike Ballack C JPas encore d'évaluation

- Rglvig 079Document61 pagesRglvig 079IVAN RIVERA MENDIOLAPas encore d'évaluation

- Rglvig 079Document61 pagesRglvig 079IVAN RIVERA MENDIOLAPas encore d'évaluation

- Capitulo V Evaluación EconómicaDocument12 pagesCapitulo V Evaluación EconómicaJavi TiesanPas encore d'évaluation

- MetodologíaDocument10 pagesMetodologíatoriz123Pas encore d'évaluation

- Producción Minera Metálica de Oro (GRS.F) - 2019Document16 pagesProducción Minera Metálica de Oro (GRS.F) - 2019jcapaniPas encore d'évaluation

- Abordaje de Talla Baja: Dra. Gabriela Rivera Dávila Residente de Endocrinología Pediátrica Marzo 2010Document47 pagesAbordaje de Talla Baja: Dra. Gabriela Rivera Dávila Residente de Endocrinología Pediátrica Marzo 2010api-25984296Pas encore d'évaluation

- Combate a los Vampiros Eléctricos: Ahorra en tu FacturaDocument3 pagesCombate a los Vampiros Eléctricos: Ahorra en tu FacturaAaron MartinezPas encore d'évaluation

- Turbo CargadoresDocument5 pagesTurbo CargadoresJavierPas encore d'évaluation

- Taller 14 Grado 6D Alexandercifuentes Alzate Pregunta 5Document3 pagesTaller 14 Grado 6D Alexandercifuentes Alzate Pregunta 5acifuentesalzatePas encore d'évaluation

- Revisión lección funciones cuadráticasDocument6 pagesRevisión lección funciones cuadráticasMelissa Peña SegarraPas encore d'évaluation

- A4 Taller de Controles Exixtenciales - 4491Document7 pagesA4 Taller de Controles Exixtenciales - 4491milena alapePas encore d'évaluation

- Proyecto Minero San Gabriel (Buenaventura)Document11 pagesProyecto Minero San Gabriel (Buenaventura)EA UG Adrîano100% (1)

- PsicoanaliticaDocument2 pagesPsicoanalitica3 a 1 eternoPas encore d'évaluation

- Solucionario 1er Simulacro Cpu - Sigmath 2011 - IIDocument10 pagesSolucionario 1er Simulacro Cpu - Sigmath 2011 - IIKarina Aguedo Milla100% (2)

- Ejercicios de MRUDocument5 pagesEjercicios de MRUMabe DPPas encore d'évaluation

- Evolución de Los Puentes Atirantados - Chile2014 - Sima-Stockhusen SpaDocument8 pagesEvolución de Los Puentes Atirantados - Chile2014 - Sima-Stockhusen SpaFernando SimaPas encore d'évaluation

- Teoria Del Comportamiento de La AdministracionDocument16 pagesTeoria Del Comportamiento de La Administracionmarcela acostaPas encore d'évaluation

- Transistores 151112032819 Lva1 App6891Document12 pagesTransistores 151112032819 Lva1 App6891protonicolas100% (1)

- Aprendiendo Con Todo El Cerebro Linda VerleeDocument4 pagesAprendiendo Con Todo El Cerebro Linda VerleeKELLY JOHANA MONTOYA JARAMILLOPas encore d'évaluation

- Esquema OvejeroDocument3 pagesEsquema OvejeroDiego Londoño BluzmanisPas encore d'évaluation

- Boris Pino TG Sociedad y Estado ContemporaneoDocument12 pagesBoris Pino TG Sociedad y Estado ContemporaneoBoris PinoPas encore d'évaluation

- Laboratorio Mecanica de Suelos IDocument30 pagesLaboratorio Mecanica de Suelos IJesus Alexander Saravia AguileraPas encore d'évaluation

- Desde La Corporeidad A La CulturaDocument8 pagesDesde La Corporeidad A La CulturaBelu GariPas encore d'évaluation

- Trabajo de GradoDocument96 pagesTrabajo de Gradocarmen camahoPas encore d'évaluation

- PROYECTO CHANCAdoraDocument35 pagesPROYECTO CHANCAdoraWenderGarcía50% (2)

- C.V Jenny Pacheco PDocument2 pagesC.V Jenny Pacheco PFrancisco HernandezPas encore d'évaluation

- Geografia: Geodinámica ExternaDocument4 pagesGeografia: Geodinámica ExternaAlejandra ServínPas encore d'évaluation

- Informe Práctica e InvestigaciónDocument27 pagesInforme Práctica e InvestigaciónEbelin YhanelyPas encore d'évaluation

- Ciencias Auxiliares Derecho PenalDocument7 pagesCiencias Auxiliares Derecho PenalAdry CórdovaPas encore d'évaluation

- Área de Económico-Administrativo Administración Gestión de Capital Humano Programa de Inteligencia Emocional para La Empresa para La EmpresaDocument21 pagesÁrea de Económico-Administrativo Administración Gestión de Capital Humano Programa de Inteligencia Emocional para La Empresa para La EmpresaRamirez Baltazar Monica StephaniePas encore d'évaluation

- Causas y consecuencias de la adicción a redes sociales y videojuegos en jóvenesDocument3 pagesCausas y consecuencias de la adicción a redes sociales y videojuegos en jóvenesAguirre Lopez Juan ManuelPas encore d'évaluation

- FULL Teorias de SicherDocument8 pagesFULL Teorias de SicherLuis ForlongPas encore d'évaluation

- La Población MundialDocument10 pagesLa Población MundialJeiser EspejoPas encore d'évaluation

- UDABOL Semestre VII - NuevoDocument1 pageUDABOL Semestre VII - NuevoDANIELA RODRIGUES VAILANTEPas encore d'évaluation