Académique Documents

Professionnel Documents

Culture Documents

High Temperature Behaviour of Similar and Dissimilar of Welded p22 and p91 Steels

Transféré par

zebCopyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

High Temperature Behaviour of Similar and Dissimilar of Welded p22 and p91 Steels

Transféré par

zebDroits d'auteur :

Formats disponibles

5th International Conference on Mechanics and Materials in Design

REF: A0405.0407

HIGH TEMPERATURE BEHAVIOUR OF SIMILAR AND DISSIMILAR

WELDED COMPONENTS OF STEEL GRADE P22 AND P91

P. Seliger1, and A. Thomas

Siempelkamp Pruef-und Gutachter-Gesellschaft mbH

P.O. 10 02 63, D-01072 Dresden, Germany

Email: (1)peter.seliger@siempelkamp.com

SYNOPSIS

The service of energy production plants would be impossible without the professional

designing, manufacturing and monitoring of welded joints. Particularly with the increase of

the steam parameters pressure and temperature the integrity of creep-exposed welded joints

continues to move into the focus of the technical designers, operators and supervisors of

energy-technical plants. The lifetime assessment factors of welded components, implemented

in the Design Codes, must be urgently updated for the modern materials and the advanced

steam parameters used in the piping construction.

INTRODUCTION

Within the European research project WELDON [1] the Siempelkamp Pruef- und Gutachter-

Gesellschaft mbH (SPG) is performing component-like tests at higher temperatures. On the

one hand it concerns tests at inner pressurised pipes, whose circumferential weldments are

stressed additionally by external axial load. The pipes from steel grade P22 and P91 are

equipped with sensors for the on-line monitoring of temperatures, deformations and strains.

Metallographic investigations are monitoring the damage development in the individual zones

of the weld relevant for the creep strength behaviour. Further creep-rupture tests at large

tensiles are accomplished, in order to be able to examine the geometry size effect. For

observance of similar axial and hoop stresses pre-calculation of specimen geometry and

loading have been done before manufacture. For creep testing special test rigs were designed

and built. All testing data will be implemented as inputs for the numeric FE analysis. In the

context of the project the determined research results flow into a methodology for the

estimation of the welding seam behaviour.

RESULTS

2 EXPERIMENTAL DETAILS

2.1 Welding of similar and dissimilar pipe materials,

Forged pipes of 145 mm outer diameter and 45 mm wall thickness were produced from

material grades P22 and P91 according to ASTM A 369 [2]. Similar butt welds were

manufactured of P22-P22 and P91-P91 as well as dissimilar butt welds of P22-P91. The

dissimilar welds were welded with P22-like electrodes (2,25 % Cr).

The macro- and microstructure of the P91-P91 and P22-P91 welds are shown in Figure 1 and

Figure 2.

Chapter IV: Welds at High Temperature (WELDON) in Design 1

Porto-Portugal, 24-26 July 2006

P9 P9 P9

1BM W

1 1BM

M

10

Fig. 1 Macrostructure of similar weld P91-P91, microstructure P 91 base metal (BM)

P22 P22 P91

BM WM BM

10 mm

Fig. 2 Macrostructure of dissimilar weld P22-P91, microstructure P22 base metal (BM)

The microstructure of P22 pipes contains ferritic-bainitic microstructure. The microstructure

of the P91 pipes show needle shaped martensite of average grain size and indicates a regular

heat treatment at a sufficient austenitic temperature. All welded pipes were subjected to

appropriate post weld heat treatment (PWHT). The details of welding and PWHT are

presented in Table 1. After the PWHT, the pipes were examined non-destructively employing

ultrasonic (UT) and Magnetic Particle Inspection (MPI) techniques, without indications for

presence of welding defects or cracks.

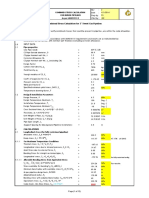

Table 1: Details of welding technology

Filler Root

Joint type Post weld heat treatment

Process Material Process Material

P22 - P22 SMAW SHCromo2KS GTAW UnionICrMo910 690 °C/ 2h /air

P91 - P91 SMAW Chromo9V GTAW Thermanit MTS3 760 °C/ 2h/ air

P22 - P91 SMAW SHCromo2KS GTAW UnionICrMo910 725 °C/ 2h/ air

2 Editors: J.F. Silva Gomes and Shaker A. Meguid

5th International Conference on Mechanics and Materials in Design

2.2 Finite Element Calculation

For the determination of the loading conditions finite element calculations were made. The

specimen dimension and loading conditions were chosen such that the applied stresses in the

hoop and axial directions (i.e. equivalent or v. Mises stress σv) at the outer side will be the

same for the pipe and will correspond to the axial load σa applied to the large tensile

specimen. An open question was concerning the level of the inner pressure and loads to reach

the target test times. Therefore at first an elastic FE computation of the real component was

made using ANSYS. Figure 3 illustrates the FE mesh.

1

ELEMENTS

APR 3 2003

14:10:06

PLOT NO. 1

Z X

Figure 3: FE mesh

The reference stress was calculated in the weld cross section to compare the stresses with the

creep rupture strength of the materials. As example, for the 10.000 hours feature test a

reference stress of 85 MPa for P91-weld and about 106 MPa for P22 weld was chosen (Figure

4). This corresponds to a weld strength factor of about 85 % related to the mean value of the

base material.

1 1

NODAL SOLUTION NODAL SOLUTION

APR 3 2003 APR 3 2003

STEP=1 12:20:14 STEP=1 12:20:03

SUB =1 PLOT NO. 6 SUB =1 PLOT NO. 3

MN TIME=1

TIME=1

SEQV (AVG) SEQV (AVG)

DMX =.02132 DMX =.132323

SMN =72.567 SMN =.588765

SMNB=72.564 SMX =462.887

SMX =113.73 SMXB=845.515

SMXB=113.736 MX

MN

MX

Y

X Z

Y

X Z

72.567 81.714 90.861 100.009 109.156 .588765 103.322 206.055 308.788 411.52

77.14 86.288 95.435 104.582 113.73 51.955 154.688 257.421 360.154 462.887

Figure 4: Calculation results of initial reference stress (equivalent stress; v. Mises)

Chapter IV: Welds at High Temperature (WELDON) in Design 3

Porto-Portugal, 24-26 July 2006

2.3 Manufacture of feature test

Large tensile specimens (20 x 50 mm cross section, length 700 mm) and pipes (100 mm inner

diameter, 12 resp. 15 mm wall thickness) were machined from larger welded pipes. The pre-

test examination of the components includes geometrical measurements, NDE (X-ray

radioscopy, MPI), replica examination and hardness measurements across the weld zone

surface.

2.4 Test rig for high temperature component testing

The components are tested in specially designed high temperature test rigs (Figure 5).

800

Gripping

device

Furnace

1850

1340

Feature pipe or

large tensile

Hydraulic

cylinder

Fig. 5 High temperature test rig for pipe creep tests Fig.6-Sensor application

on test pipe P22-P91

Pipes have been tested under simultaneous application of constant internal pressure using

argon and an axial loading. Electrical heating elements are used for heating the component to

the test temperatures. Capacitive strain gages type HT-DMS (gage length 20 mm) were

installed on the pipes to measure the integral strain on different locations (base metal BM,

weld metal WM, heat affected zone HAZ) and orientations (longitudinal and circumferential),

as shown in Figure 6. Additionally, a number of reference marks (creep pips) were fixed on

the pipe surface for intermittent extensometer measurements during test stops. The accuracy

of pressure and temperature measurements during the test duration was kept within the ECCC

recommendations [3] for creep tests.

3 RESULTS AND DISCUSSIONS

3.1 Creep test and Metallographic examination

In P22-P91 dissimilar weld, a carbon/carbide depleted zone was formed due to carbon

diffusion from P22 weld metal to the higher Cr containing P91 BM. This migration had let to

the formation of a dark seam of carbides adjacent to the weld interface, as shown in Figure 7.

In failed P22-P91 dissimilar weld a noticeable hardness reduction was seen which is due to

the decarburised zone in P22 WM, as shown in Figure 8. More microstructure data on pre-test

material characterisation of feature test components are presented in [4]. Figure 9 shows the

creep curves of the two large tensile specimens of P22-P91 dissimilar weld, tested at different

axial loads σa. The fracture location is the decarburised zone of P22 weld metal, which

corresponds to the hardness drop in figure 8.

4 Editors: J.F. Silva Gomes and Shaker A. Meguid

5th International Conference on Mechanics and Materials in Design

Figure 8: Hardness scan across weld, zero distance

Fig. 7 P22-P91 dissimilar weld, Decarburised zone in is weld interface, hardness peak in the P91 HAZ

P22 WM adjacent to P91 BM, dark carbide zone on and small hardness drop in decarburised zone of

fusion line P22 weld metal metal [4]

2,0

l0

P22-P91; 550°C; 125 MPa

P22-P91; 550°C; 105 MPa

1,6

integral strain [%]

1,2

0,8

0,4

0,0

0 500 1000 1500 2000 2500 3000 3500 4000

test duration [h]

Figure 9: P22-P91 dissimilar weld, creep curves of large tensile specimens,

Failure location in decarburised zone of P22-weld metal

The fracture of the large tensile specimens made from P22-P22 similar welds occurred in P22

fine grained HAZ (Type IV) after 10.191 h (σa=125 MPa) and 1.276 h (σa=150 MPa) of test

durations, respectively.

Figure 10 illustrates the measured creep curves of the different weld zones of P91-P91

similar welded test pipe. Only the primary and secondary stages of the creep curve had been

monitored by the capacitive strain gages applied on the weld surface. But, the creep crack

initiation and fracture had occurred on the opposite side of the test pipe, where no sensor was

installed. A small necking zone was found in circumferential direction in the HAZ were the

crack had initiated (Type IV cracking).

For the P22-P22 test pipe the crack initiation and fracture was very well monitored by the

strain gage fixed across the HAZ region, as indicated in Figure 11 and Figure 12. The creep

curves of this sensor show the typical tertiary stage.

Chapter IV: Welds at High Temperature (WELDON) in Design 5

Porto-Portugal, 24-26 July 2006

0,4

HAZ, longitudinal

WM, longitudinal

BM, longitudinal

BM, circumferential

0,3

integral strain [%]

0,2

0,1

0,0

0 500 1000 1500 2000 2500 3000 3500 4000

test duration [h]

Figure 10: Pipe P91-P91 (σv= 102 MPa); creep curves of different weld zones, Type IV cracking

7,0

HAZ, longitudinal

6,0 BM, longitudinal

BM, circumferential

5,0

integral strain [%]

4,0

3,0

2,0

1,0

0,0

0 2000 4000 6000 8000 10000 12000

test duration [h]

Figure 11: Pipe P22-P22 (σv= 128 MPa); creep curves of different weld zones, Type IV cracking

7,0

HAZ, longitudinal

BM, longitudinal

6,0 BM, circumferential

5,0

integral strain [%]

4,0

3,0

2,0

1,0

0,0

0 5000 10000 15000 20000 25000

test duration [h]

Figure 12: Pipe P22-P22 (σv= 106 MPa); creep curves of different weld zones, Type IV cracking

6 Editors: J.F. Silva Gomes and Shaker A. Meguid

5th International Conference on Mechanics and Materials in Design

3.2 Creep rupture strength – Comparison standard (uniaxial) lab tests and pipe tests

One of the main project topics was to investigate the influence of size and component type on

creep rupture strength or lifetime. Figure 13 shows the results of feature tests (large tensiles/

pipes) for P22 similar weld in comparison to those of the standard uniaxial specimen, which

were tested by the project partner CESI [5]. The failure points of large tensiles and standard

specimens are closed together in the range of mean values of creep rupture strength. The

results of the pipes seems to be better, but in the diagram the Mises-reference stress at the

beginning of test is used, which leads to an overvaluation.

1000

Stress in N/mm²

100

crossweld_standard_specimens

crossweld_large_tensiles

Pipes_butt_weld

10

100 1.000 10.000 100.000

Time in hours

Fig. 13 Creep rupture strength, uniaxial tests and pipe tests, P22-P22 at 550 °C

It is well known, that the reference stress distribution is changing during service due to

relaxation of high stressed areas. Therefore, the failure points of pipes in figure 13 should

shift to lower stress levels. The amount of shifting depends on the test duration, the absolute

stress level and the test temperature. The calculation of relaxation and redistribution was

done by the project partner UNOTT and will be presented specially.

The crossweld standard specimens of P91 have an expected creep rupture level at the lower

scatter band, like seen in figure 14. The large tensile test results are showing a non-

explainable behaviour, but probably they do not differ from cross weld specimen so much.

1000

Stress in N/mm²

100

crossweld_standard_specimens

crossweld_large_tensiles

Pipes_butt_welded

10

100 1.000 10.000 100.000

Time in hours

Fig. 14 Creep rupture strength, uniaxial tests and pipe tests, P91-P91 at 625 °C

Chapter IV: Welds at High Temperature (WELDON) in Design 7

Porto-Portugal, 24-26 July 2006

For the pipes the same restrictions concerning the used reference stresses are valid like for

P22-tests.

The results for the dissimilar welds P22/P91 are definitely worse then for similar P22/P22-

tests. All the crossweld specimens have a strength level at the lower bound of the scatterband

(Figure 15). The reason is the weakness of the decarburised zone in P22 weld metal, which is

the failure location as well.

1000

Stress in N/mm²

100

crossweld_standard_specimens

crossweld_large_tensiles

Pipes_butt_welded

10

100 1000 10000 100000

Time in hours

Fig. 15 Creep rupture strength, uniaxial tests and pipe tests, P22-P91 at 550 °C

4 CONCLUSIONS AND OUTLOOK

Within this EU 5th Framework research project ‘WELDON’, feature tests at high temperatures

are performed on component-like specimens like welded pipes and large tensile specimens in

addition to laboratory specimens in order to study the geometry and size effects on the

damage evaluation methodology which is being developed. The observed carbide depletion in

the P22 weld metal adjacent to the fusion line of P91-P22 dissimilar welds and its effect on

the weld strength reduction have to be taken into account.

No size effects or significant differences between standard crossweld and large crossweld

results were observed.

The strength level of similar P22-welds at 550 °C is in the mean range of base material. On

the other hand the dissimilar weld at the same temperature shows a strength at the lower

bound of scatterband due to the different failure location.

Also the similar welded P91-specimens have a strength level in the range of lower scatter

band, but this is due the (for P91) very high temperature of 625 °C.

Based on the weld combinations, the component geometry and the loading conditions, the

concentration of strain in the different weld regions on feature test specimens and its relation

to the failure location and strain measured in standard creep testing of crossweld specimens

will be investigate within the project.

ACKNOWLEDGMENT

The authors gratefully acknowledge the financial support provided by the European

Commission to the RTD project ‘WELDON’ (Contract No. G5RD-CT-2001-00596).

8 Editors: J.F. Silva Gomes and Shaker A. Meguid

5th International Conference on Mechanics and Materials in Design

REFERENCES

1. Weld Strength for high temperature components design and operation (WELDON).

European Project No. GRD2-2000-30363.

2. ASTM A 369. Standard specification for carbon and ferritic alloy steel forged and bored

pipe for high-temperature service. ASTM International, 2002

3. ECCC Recommendations. Data acceptability criteria and data generation:

Recommendations for creep testing of post exposed (ex-service) materials. Volume 3 Part III

[Issue 2], 2001

4. Agyakwa P. Yaghi A. Becker AA. Current state of metallurgical examination of the test

welds and failed notched cross weld creep samples. Report WELDON/UNOT-009/TRP-

005/R0

5. S. Concari WP2 “Material supply” and WP5 “Creep tests”. CESI-Report WELDON/

CESI-011/WPR-004/00

Chapter IV: Welds at High Temperature (WELDON) in Design 9

Vous aimerez peut-être aussi

- Clamp FEM AnalysisDocument27 pagesClamp FEM AnalysisRicardo Paz SoldanPas encore d'évaluation

- A Quick PCB Thermal Calculation For Power Electronic Devices With Exposed Pad Packages PDFDocument14 pagesA Quick PCB Thermal Calculation For Power Electronic Devices With Exposed Pad Packages PDFwnaciPas encore d'évaluation

- Failure PDFDocument101 pagesFailure PDFManuel GasparPas encore d'évaluation

- Stress Analysis of Reactor Nozzle To HeadDocument5 pagesStress Analysis of Reactor Nozzle To HeadKagira Drawing SoltuionPas encore d'évaluation

- Design and Performance of Buried PVC Pipe SystemsDocument57 pagesDesign and Performance of Buried PVC Pipe Systems이동욱100% (1)

- Combined Stress Calc Rev. 2Document12 pagesCombined Stress Calc Rev. 2babu75% (4)

- Foundation Design Calculations for Cairn Oil & Gas Pipe SupportsDocument79 pagesFoundation Design Calculations for Cairn Oil & Gas Pipe SupportsaanchaljasujaPas encore d'évaluation

- Design Calculation Report For CCT Tank: TitleDocument15 pagesDesign Calculation Report For CCT Tank: TitleghansaPas encore d'évaluation

- Solns 3cmosDocument16 pagesSolns 3cmosramprakash_rampelliPas encore d'évaluation

- Boiler Materials: P.Sundaramoorthy BHEL, TiruchirappalliDocument47 pagesBoiler Materials: P.Sundaramoorthy BHEL, Tiruchirappalliteddy tavaresPas encore d'évaluation

- Solder Joint Reliability - A Unified Thermo-Mechanical Model Approach PDFDocument83 pagesSolder Joint Reliability - A Unified Thermo-Mechanical Model Approach PDFQUALITY LABORATORYPas encore d'évaluation

- MOS Integrated Circuit DesignD'EverandMOS Integrated Circuit DesignE. WolfendalePas encore d'évaluation

- Stress ElbowsDocument8 pagesStress Elbowssanjeettirkey0% (1)

- Mathcad - MWD056g - Glass Wall With Feature1Document36 pagesMathcad - MWD056g - Glass Wall With Feature1MichaeluiMichaeluiPas encore d'évaluation

- Design of Helical SpringsDocument14 pagesDesign of Helical SpringsSerdar ArslanPas encore d'évaluation

- 000000000001002094Document142 pages000000000001002094Dante FilhoPas encore d'évaluation

- Material TestingDocument7 pagesMaterial TestingkimsonPas encore d'évaluation

- HTLS Conductors - Mechanical CalculationDocument25 pagesHTLS Conductors - Mechanical CalculationJorge Pinto RochaPas encore d'évaluation

- Engineering ManualDocument57 pagesEngineering ManualCes Rico-CepriaPas encore d'évaluation

- Dental Amalgam: A Concise History and ReviewDocument182 pagesDental Amalgam: A Concise History and ReviewPayal Batavia100% (1)

- Concrete Mechanics and Design - Solution ManualDocument277 pagesConcrete Mechanics and Design - Solution Manualramya_an241167% (3)

- Surface Characterization Methods: Principles, Techniques and ApplicationsDocument429 pagesSurface Characterization Methods: Principles, Techniques and ApplicationsMarcia Gaby CruzPas encore d'évaluation

- Astm F2947-14Document7 pagesAstm F2947-14Augusto MedeirosPas encore d'évaluation

- Is Code 1343 For Pre Stressed ConcreteDocument64 pagesIs Code 1343 For Pre Stressed ConcreteGuntiMuralidhar100% (9)

- Creep Behaviour in Cracked Sections of Fibre Reinforced ConcreteDocument244 pagesCreep Behaviour in Cracked Sections of Fibre Reinforced ConcreteMohamed MoawadPas encore d'évaluation

- Julian F. V. Vincent (Auth.) - Structural Biomaterials-Macmillan Education UK (1982) PDFDocument218 pagesJulian F. V. Vincent (Auth.) - Structural Biomaterials-Macmillan Education UK (1982) PDFArjan van BreemenPas encore d'évaluation

- Stress Relaxation of Prestressing Steel - DIN EN 1992-1-1: Benchmark Example No. 23Document9 pagesStress Relaxation of Prestressing Steel - DIN EN 1992-1-1: Benchmark Example No. 23Batuhan DerPas encore d'évaluation

- Gusset 3.1. in Tension 3.1.1 TenDocument6 pagesGusset 3.1. in Tension 3.1.1 TenKARTHIK SGPas encore d'évaluation

- Fatigue FailureDocument8 pagesFatigue FailureAhmed AymanPas encore d'évaluation

- 1994 - 3D Finite Element Simulation of The Cold Forging of Helical GearsDocument13 pages1994 - 3D Finite Element Simulation of The Cold Forging of Helical GearsNguyen Hoang DungPas encore d'évaluation

- Numerical Simulation On The Dynamic Response of Buried Pipelines Subjected To Blast Loads by Xu 2013Document5 pagesNumerical Simulation On The Dynamic Response of Buried Pipelines Subjected To Blast Loads by Xu 2013C SzetoPas encore d'évaluation

- REVISION A: ANODE SLED BOLTING ANALYSISDocument4 pagesREVISION A: ANODE SLED BOLTING ANALYSISejim2Pas encore d'évaluation

- EDM Process Parameters Affect Surface Roughness and Removal RateDocument7 pagesEDM Process Parameters Affect Surface Roughness and Removal RateAli AliPas encore d'évaluation

- Critical Remarks On The Application of The Yield Line Method On MasonryDocument13 pagesCritical Remarks On The Application of The Yield Line Method On MasonryRadekPas encore d'évaluation

- Application of The Taguchi Technique For Wedm Parameters For Tungsten CarbideDocument10 pagesApplication of The Taguchi Technique For Wedm Parameters For Tungsten CarbideTJPRC PublicationsPas encore d'évaluation

- 2SMPP-03: User's ManualDocument16 pages2SMPP-03: User's ManualAbdallah AbdelrehimPas encore d'évaluation

- ZnO Conference Paper - 718692Document9 pagesZnO Conference Paper - 718692सागर अग्रवालPas encore d'évaluation

- Transient Temperature Distribution in A Steel Rod Subjected To Friction WeldingDocument11 pagesTransient Temperature Distribution in A Steel Rod Subjected To Friction WeldingMuhammad Fatka FirmansyahPas encore d'évaluation

- Stress Analysis of Reactor Nozzle to Head JunctionDocument5 pagesStress Analysis of Reactor Nozzle to Head JunctionMohamed Rafeek0% (1)

- Midterm Answers 2019Document9 pagesMidterm Answers 2019sohail parachaPas encore d'évaluation

- Thermal Fatigue Analysis of Solder JointsDocument5 pagesThermal Fatigue Analysis of Solder JointsBrijeshPas encore d'évaluation

- Technical Comment - Wall Formwork - CommentsDocument19 pagesTechnical Comment - Wall Formwork - CommentsYazan AmlehPas encore d'évaluation

- 46 - 2.vendor Claim Notice No. HB8242-2019-001 - 0001Document30 pages46 - 2.vendor Claim Notice No. HB8242-2019-001 - 0001karthikaPas encore d'évaluation

- ML 013200198Document101 pagesML 013200198SachiPas encore d'évaluation

- Flat Platewitha Hole Analysisby AbaqusDocument7 pagesFlat Platewitha Hole Analysisby AbaqusMuhammad MalikPas encore d'évaluation

- Applied Moment, Shear and Axial LoadsDocument8 pagesApplied Moment, Shear and Axial LoadsMallesh NenkatPas encore d'évaluation

- Application for Design of Members in Tension and BendingDocument48 pagesApplication for Design of Members in Tension and BendingVictor TvvPas encore d'évaluation

- Stresses Analysis of Petroleum Pipe Fini PDFDocument7 pagesStresses Analysis of Petroleum Pipe Fini PDFYOGESH YADAVPas encore d'évaluation

- 1.0 Design Criterea 1 1 Assumptions 1.1 Assumptions: 8M Clear Span Solid Slab Bridge DesignDocument10 pages1.0 Design Criterea 1 1 Assumptions 1.1 Assumptions: 8M Clear Span Solid Slab Bridge DesignAddisu Gizaw Addis Ye AbereyePas encore d'évaluation

- Nash DH Pure Leakage Analysis of Gasketed Flanged Joints Under Combined Internal Pressure and Thermal Loading Jul 2011 PDFDocument5 pagesNash DH Pure Leakage Analysis of Gasketed Flanged Joints Under Combined Internal Pressure and Thermal Loading Jul 2011 PDFCarmelo BonaccorsoPas encore d'évaluation

- Step by Step Stress Analysis of Ammonia Scrubber VDocument10 pagesStep by Step Stress Analysis of Ammonia Scrubber VBhawna GuptaPas encore d'évaluation

- Finite Element Analysis of Resistance Spot Welding ProcessDocument4 pagesFinite Element Analysis of Resistance Spot Welding ProcessAbdullah hussainPas encore d'évaluation

- Fatigue life prediction model for bellows at cryogenic temperaturesDocument7 pagesFatigue life prediction model for bellows at cryogenic temperaturesait oubella marouanePas encore d'évaluation

- Karpisz2015 Article FDTDAnalysisOfModalDispersivePDocument8 pagesKarpisz2015 Article FDTDAnalysisOfModalDispersivePHữu Nam NguyễnPas encore d'évaluation

- Esnel EquationsDocument26 pagesEsnel Equationsmt21215015 Navdeep GuptaPas encore d'évaluation

- Collapse of Thick Tubes Subjected To External Pressure: An Interpretation of Present Code RequirementsDocument8 pagesCollapse of Thick Tubes Subjected To External Pressure: An Interpretation of Present Code RequirementsAmit SharmaPas encore d'évaluation

- Optimization of 3D welding process parameters using experimental designDocument7 pagesOptimization of 3D welding process parameters using experimental designsrinathgudur11Pas encore d'évaluation

- Working Stress Method-IDocument17 pagesWorking Stress Method-IVivek SaxenaPas encore d'évaluation

- HW 1Document12 pagesHW 1peeyush_tapadiyaPas encore d'évaluation

- Propeller Blade Stress and FEADocument14 pagesPropeller Blade Stress and FEAGokul AnbazhaganPas encore d'évaluation

- ORDRE DES INGÉNIEURS DU QUÉBEC MAY 2012 SESSIONDocument6 pagesORDRE DES INGÉNIEURS DU QUÉBEC MAY 2012 SESSIONLuisAranaPas encore d'évaluation

- Vertical MembersDocument3 pagesVertical MembersARSEPas encore d'évaluation

- Combined and Composite Voltage Tests: Dr. StraussDocument7 pagesCombined and Composite Voltage Tests: Dr. StraussSergio Isaías HVtestPas encore d'évaluation

- 2015 - Fatigue Analysis of Compressor Blade With Simulated Foreign Object DamageDocument15 pages2015 - Fatigue Analysis of Compressor Blade With Simulated Foreign Object Damagemortazavi.technicalPas encore d'évaluation

- Beam-To-Beam Joints With Bolted End-Plate Connections Concerning Steel Platforms Angra 2 NPPDocument10 pagesBeam-To-Beam Joints With Bolted End-Plate Connections Concerning Steel Platforms Angra 2 NPPihpeterPas encore d'évaluation

- Summary of Stress Analysis and Design Qualification of Top End Fitting of AHWRDocument5 pagesSummary of Stress Analysis and Design Qualification of Top End Fitting of AHWRrenu raniPas encore d'évaluation

- Summary of Stress Analysis and Design Qualification of Top End Fitting of AHWRDocument5 pagesSummary of Stress Analysis and Design Qualification of Top End Fitting of AHWRrenu raniPas encore d'évaluation

- 1991 - 3-D Finite Element Modelling of The Forging Process With Automatic RemeshingDocument15 pages1991 - 3-D Finite Element Modelling of The Forging Process With Automatic RemeshingNguyen Hoang DungPas encore d'évaluation

- Supersonic Axial Flow CompressorDocument11 pagesSupersonic Axial Flow CompressorAsmaa Alaa ElDeenPas encore d'évaluation

- Computer Simulation of Cumulative Fatigue Damage: Facta UniversitatisDocument9 pagesComputer Simulation of Cumulative Fatigue Damage: Facta UniversitatisBilly ChrisPas encore d'évaluation

- Couchaux Et Al-2017-Ce/papersDocument10 pagesCouchaux Et Al-2017-Ce/papersCuneyt VatanseverPas encore d'évaluation

- RC Thermal Models: Rev. 5.0 - 18 March 2021 Application NoteDocument19 pagesRC Thermal Models: Rev. 5.0 - 18 March 2021 Application NoteRaj kumarPas encore d'évaluation

- Hastelloy C-276 Alloy: Principal FeaturesDocument17 pagesHastelloy C-276 Alloy: Principal Featuresnay denPas encore d'évaluation

- Applicability of Hollomon - Jaffe Equationon Tempering of HSLA Steels - Sep - 2009 PDFDocument6 pagesApplicability of Hollomon - Jaffe Equationon Tempering of HSLA Steels - Sep - 2009 PDFzebPas encore d'évaluation

- The Ferrite Content of Austenitic Stainless Steel Weld Metal - WJ - 1973 - 07 - s281 PDFDocument17 pagesThe Ferrite Content of Austenitic Stainless Steel Weld Metal - WJ - 1973 - 07 - s281 PDFzebPas encore d'évaluation

- Accuphase Fiche DP510Document4 pagesAccuphase Fiche DP510zebPas encore d'évaluation

- Brief Review of Turbine Blade Failure FactorsDocument9 pagesBrief Review of Turbine Blade Failure FactorsTomasUreñaPas encore d'évaluation

- StressHead - Design Concept - 170223Document15 pagesStressHead - Design Concept - 170223Juan ManuelPas encore d'évaluation

- Safe Remaining Lifetime Assesment of Power Plant Steam BoilersDocument9 pagesSafe Remaining Lifetime Assesment of Power Plant Steam Boilersmuh4iminPas encore d'évaluation

- Examining Energy Dissipation of Deployable Aerospace Composites Using Matrix ViscoelasticityDocument10 pagesExamining Energy Dissipation of Deployable Aerospace Composites Using Matrix ViscoelasticitylucasPas encore d'évaluation

- Segregation-Assisted Plasticity in Ni-Based SuperalloysDocument13 pagesSegregation-Assisted Plasticity in Ni-Based SuperalloysDaniel Barba CanchoPas encore d'évaluation

- Piping Hanger Presentation1Document85 pagesPiping Hanger Presentation1Parveen Nakwal100% (1)

- Hobas FTBDocument78 pagesHobas FTBdarkroomzc100% (1)

- Determining the Linear Viscoelastic Region in PolymersDocument2 pagesDetermining the Linear Viscoelastic Region in PolymersKaustubh BhavePas encore d'évaluation

- Caea Ugm2012 NL BP PDFDocument75 pagesCaea Ugm2012 NL BP PDFAvinashRaiPas encore d'évaluation

- Failure Mechanism in SemiconductorDocument34 pagesFailure Mechanism in Semiconductormuhdsyahid100% (1)

- Aci 209 R21Document44 pagesAci 209 R21Hao LuoPas encore d'évaluation

- Life-Assessment Technology For Power-Plant Components: R. Viswanathan and S.M. GehlDocument9 pagesLife-Assessment Technology For Power-Plant Components: R. Viswanathan and S.M. GehlTalha UsmaniPas encore d'évaluation

- Suco 201900382Document12 pagesSuco 201900382emotalPas encore d'évaluation

- 18me34 - MS - Module 1Document34 pages18me34 - MS - Module 1balajiPas encore d'évaluation

- 3 Hardened Properties of Portland Cement Grouts: P.L.J.DomoneDocument36 pages3 Hardened Properties of Portland Cement Grouts: P.L.J.Domoneraahul_nPas encore d'évaluation