Académique Documents

Professionnel Documents

Culture Documents

Lubricant Properties and The Role of Additives

Transféré par

Anonymous vyUisZImrTitre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Lubricant Properties and The Role of Additives

Transféré par

Anonymous vyUisZImrDroits d'auteur :

Formats disponibles

Servicios de Noria Latín América, S.A. de C.V.

Blvd. San Pedro 245-1, 2° Piso

Confiabilidad León, GTO, México 37530

Lubricant Properties and the Role of Additives

Some of the most important properties necessary for satisfactory lubricant

performance are:

1. Low volatility under operating conditions. Volatility characteristics are

essentially inherent in the choice of base oil for a particular type of service and

cannot be improved by the use of additive materials.

2. Satisfactory flow characteristics in the temperature range of use. Flow

characteristics largely depend on the choice of base oil; however, they can be

improved modifiers. The former improve low-temperature flow properties, while

the latter enhance high-temperature viscosity characteristics.

3. Superior stability or ability to maintain desirable characteristics for a reasonable

period of use. While these characteristics depend to some extent on the base

materials, which enhance base fluid properties in this area. Lubricant stability is

affected by the environment in which it operates. Such factors as temperature,

oxidation potential and contamination with water, unburned fuel fragments, and

corrosive acids limit the useful life of a lubricant. This is the area where additives

have made a major contribution in improving the performance characteristics and

extending the useful life of lubricants.

4. Compatibility with other materials in the system. Compatibility of lubricants

with seals, bearings, clutch plates, etc., may also be partially associated with the

base oil. However, additive chemistry can have a major influence on such

characteristics. Additives can be classified as materials that impart new properties

to or enhance existing properties of the lubricant or fuel into which they are

incorporated. (Lubrizol)

Detergents:

Although these compounds are commonly called detergents, their function

appears to be the dispersing of particulate matter rather than cleaning up existing

dirt and debris. Therefore, it is more appropriate to categorize them as

dispersants. The following is a brief outline of the representative types of metallic

dispersants.

Sulfonates: Sulfonates are the products of the neutralization of a sulfonic acid

with a metallic base. Commercially available sulfonates are of two types:

petroleum sulfonates and synthetic sulfonates. Petroleum (or natural) sulfonates

are metal salts of sulfonic acids that were formerly byproducts of the sulfuric acid

treatment of oil fractions in the manufacture of white oils. Currently, with the high

demand for detergent oils, sulfonates rather than white oils have become the

principal product. The structure of the organic portion of petroleum sulfonates is

not completely known. Depending on the crude oil source, the structure can have

varying proportions of aliphatic, naphthenic, and aromatic hydrocarbon groups.

Artículos Técnicos Página 1

Servicios de Noria Latín América, S.A. de C.V.

Blvd. San Pedro 245-1, 2° Piso

Confiabilidad León, GTO, México 37530

Synthetic sulfonates are metal salts of acids produced from the sulfonation of

alkylated aromatics by reaction with sulfur trioxide. Most metallic cations of

sulfonate detergents are calcium, magnesium, and sodium. Oil-soluble sulfonates

containing metal in excess of the stoichiometric amount are called basic

sulfonates. Among the advantages of basic sulfonates is a greater ability to

neutralize acidic bodies in addition to serving as a dispersant for contaminants.

Salicylates: Salicylates are generally prepared from alkyl phenols by a chemical

scheme known as the Kolbe reaction. The potassium salicylate may be

metathesized with calcium chloride or magnesium chloride. The resulting salts are

then overbased to form highly basic detergents that have proven effective in

diesel engine oil formulations.

Phenates and Phenol Sulfide Salts: The broad class of metal phenates includes

the salts of alkylphenols, alkylphenol sulfides, and alkylphenol aldehyde products.

Oil solubility is provided by alkylating the phenol with olefins that generally

contain seven or more carbon atoms. Sulfur is incorporated into the phenates by

reacting the alkylphenol with sulfur chloride or elemental sulfur. The introduction

of sulfur and the presence of a methylene bridge lowers the corrosivity of the

products toward bearing materials and improves their antioxidant characteristics.

Thiophosphonates: Commercial products of this type are generally derived from

acidic components produced by the reaction from acidic components produced by

the reaction between polybutene (500 to 1000 molecular weight range) and

phosphorus pentasulfide. However, these materials have almost vanished from

use. (Lubrizol)

Dispersants:

A major development in the additive field was the discovery and use of ashless

dispersants. These materials may be categorized into two broad types: high-

molecular weight polymeric dispersants used to formulate multigrade oils and

lower molecular weight additives for use where viscosity modification is not

necessary. These additives are much more effective than the metallic types in

controlling sludge and varnish deposits that result from intermittent and low-

temperature gasoline engine operation. Compounds useful for this purpose are

again characterized by a polar group attached to a relatively high molecular

weight hydrocarbon chain. The polar group generally contains one or more of the

elements nitrogen, oxygen and phosphorus. The solubilizing chains are generally

higher in molecular weight than those in detergents; however, they may be quite

similar in some instances. (Lubrizol)

Polymeric Dispersants:

These ashless dispersants may serve the dual function of dispersant and viscosity

modifier. They have two different structural features: those that are similar to

materials employed as viscosity modifiers and those of polar compounds (which

impart dispersancy). (Lubrizol)

Artículos Técnicos Página 2

Servicios de Noria Latín América, S.A. de C.V.

Blvd. San Pedro 245-1, 2° Piso

Confiabilidad León, GTO, México 37530

Oxidation and Bearing Corrosion Inhibitors:

The function of an oxidation inhibitor is to prevent deterioration of the lubricant

associated with oxygen attack. These inhibitors either destroy free radicals (chain

breaking) or interact with peroxides involved in the oxidation mechanism. Among

the widely used antioxidants are phenolic types and zinc dithiophosphates. The

former are considered to be of the chain-breaking variety, whereas the latter are

believed to be peroxide destroyers. The corrosion of bearing metal is generally

considered of the bearing metal. In engine operation, these acids to be due

largely to reaction of the acid with the oxides either originate from products of

incomplete fuel combustion that find their way into the lubricant as blowby gases

or are produced from lubricant oxidation. Oxidation inhibitors can significantly

reduce this tendency. Detergents can reduce bearing corrosion by neutralizing the

corrosive acids. Other inhibitors such as zinc dithiophosphates and

phosphosulfurized olefins not only inhibit oxidation but also form a protective film

on the bearing surface, making it impervious to acid attack.

Phenolic Inhibitors (Chain-breaking):

The inhibitor efficiency of phenol is markedly increased by substituting alkyl

groups in the two ortho and para positions. It is particularly enhanced when the

ortho para substituent is a primarily alkyl group. A variety of hindered phenols are

produced commercially and employed as inhibitors in transformer, turbine, and

engine oils.

Zinc Dithiophosphates (Peroxide-destroying):

Of greatest commercial importance in engine lubricants are the zinc

dithiophosphates, which not only serve as antioxidants but also provide both

antiwear and bearing corrosion protection. Stability increases with the length of

the alkyl chain and is lower for secondary alkyl groups with the same number of

carbon atoms. It should be noted, however, that the overall performance

characteristics of ZDPs are not related to the decomposition temperature.

(Lubrizol)

Antiwear Additives:

Wear is the loss of metal with subsequent change in clearance between surfaces

moving relative to each other. If continued, particulate matter, and attack of

corrosive acids can occur. Metal-to-metal contact can be prevented by adding

film-forming compounds that protect the surface either by physical absorption or

chemical reaction. Dithiophosphates are widely used for this purpose and are

particularly effective in reducing wear in valvetrain mechanisms. These

compounds are described under oxidation and bearing corrosion inhibitors. Other

effective additives contain phosphorus, sulfur, or sulfur, or abrasive wear can be

prevented by effective removal of particulate matter by filtration of both the air

entering the engine and the lubricant during engine operation. Corrosive wear is

largely the result of acidic blowby products formed during fuel combustion. This

Artículos Técnicos Página 3

Servicios de Noria Latín América, S.A. de C.V.

Blvd. San Pedro 245-1, 2° Piso

Confiabilidad León, GTO, México 37530

type of wear can be controlled by using alkaline additives such as basic phenates

and sulfonates. (Lubrizol)

Viscosity Modifiers:

Viscosity modifiers, or viscosity index improvers as they were formerly known,

comprise a class of materials that improves the viscosity/temperature

characteristics of the lubricant. This modification of rheological properties results

in increased viscosity at all temperatures. The viscosity increase is more

pronounced at high temperatures which significantly improves the viscosity index

of the lubricant.

Viscosity modifiers are generally oil-soluble organic polymers. The polymer

molecule in solution is swollen by the lubricant, and the volume of the swollen

entity determines the degree to which the polymer increases viscosity. The higher

the temperature, the larger the volume and the greater the "thickening" effect of

the polymer. Hence, the oil tends to "thin" less due to increased temperature. In

addition to viscosity improvement, the performance of these polymers also

depends on shear stability or resistance to mechanical shear and on their chemical

and thermal stability.

With a given polymer system, shear stability decreases with an increase in

molecular weight. The loss due to shear is reflected in a loss in lubricant viscosity.

On the other hand, the "thickening power" of the viscosity modifier increases with

an increase in molecular weight for a given polymer type. A performance balance

must then be established which takes into consideration shear stability and

viscosity needs as well as thermal and oxidative stability in actual engine

operation. (Lubrizol)

Pour Point Depressants:

Pour point depressants prevent the congelation of oil at low temperature. This

phenomenon is associated with crystallization of the paraffin wax that is present

in mineral oil fractions. To provide low pour points, the refiner removes wax

constituents, which solidify at relatively high temperatures, in a process known as

dewaxing. Complete dewaxing would reduce the yield of lube oil to an

uneconomical level. Therefore, the dewaxing process is supplemented by using

additives that lower the pour point of the oil. Pour point depressants do not

prevent wax from crystallizing in the oil. Rather, they are absorbed on the wax

crystals and, thus, reduce the amount of oil occluded on the crystal. Reducing the

crystal volume permits lubricant flow. (Lubrizol)

Miscellaneous Additives:

This category includes antirust compounds and foam inhibitors. Chemicals

employed as rust inhibitors include sulfonates, alkenyl succinic acids, substituted

imidazolines, amines, and amine phosphates. A considerable amount of

Artículos Técnicos Página 4

Servicios de Noria Latín América, S.A. de C.V.

Blvd. San Pedro 245-1, 2° Piso

Confiabilidad León, GTO, México 37530

information on these additives is contained in patent literature. Antifoam agents

include silicones and miscellaneous organic copolymers.

Additive Use:

While the general nature of additives may be the same for various types of

lubricants, the specific types of additives chosen will depend upon the service in

which the lubricant will be used and the characteristics of the base fluid. (Lubrizol)

Artículos Técnicos Página 5

Vous aimerez peut-être aussi

- Second 274 288Document15 pagesSecond 274 288Anonymous vyUisZImrPas encore d'évaluation

- Role of Alien and Native Birds in The Dissemination of FiretreeDocument7 pagesRole of Alien and Native Birds in The Dissemination of FiretreeAnonymous vyUisZImrPas encore d'évaluation

- Role of Alien and Native Birds in The Dissemination of FiretreeDocument7 pagesRole of Alien and Native Birds in The Dissemination of FiretreeAnonymous vyUisZImrPas encore d'évaluation

- Firetree (Myrica Faya) Distribution in Hawai'I: Louis D. Whiteaker and Donald E. GardnerDocument16 pagesFiretree (Myrica Faya) Distribution in Hawai'I: Louis D. Whiteaker and Donald E. GardnerAnonymous vyUisZImrPas encore d'évaluation

- SHP19 E EditionDocument302 pagesSHP19 E EditionAnonymous vyUisZImrPas encore d'évaluation

- Shipping Instructions For CDC Legionella Testing: A. Before Initial ShipmentDocument2 pagesShipping Instructions For CDC Legionella Testing: A. Before Initial ShipmentAnonymous vyUisZImrPas encore d'évaluation

- Controlling Fire Tree (Myrica Faya) in HawaiiDocument6 pagesControlling Fire Tree (Myrica Faya) in HawaiiAnonymous vyUisZImrPas encore d'évaluation

- Iran Advisory 09032019Document7 pagesIran Advisory 09032019Anonymous vyUisZImrPas encore d'évaluation

- R-12 Rocket SchematicDocument1 pageR-12 Rocket SchematicAnonymous vyUisZImrPas encore d'évaluation

- Sensors: Toward Digitalization of Maritime Transport?Document22 pagesSensors: Toward Digitalization of Maritime Transport?Anonymous vyUisZImrPas encore d'évaluation

- Requisition and Invoice/Shipping Document: Previous Edition Is ObsoleteDocument2 pagesRequisition and Invoice/Shipping Document: Previous Edition Is ObsoleteAnonymous vyUisZImrPas encore d'évaluation

- Fob Definition: Shipping Terms of SaleDocument2 pagesFob Definition: Shipping Terms of SaleAdam FathuhyPas encore d'évaluation

- Web Straight Bill of Lading-Original-Not Negotiable Call 1-800-610-6500 Scac: RdwyDocument3 pagesWeb Straight Bill of Lading-Original-Not Negotiable Call 1-800-610-6500 Scac: RdwyAnonymous vyUisZImrPas encore d'évaluation

- Rencana Anggaran Biyaya Rab Pembangunan Kandang Closed House Pusat Ternak Indonesia Kandang Closed House PDFDocument27 pagesRencana Anggaran Biyaya Rab Pembangunan Kandang Closed House Pusat Ternak Indonesia Kandang Closed House PDFSukrisworoPas encore d'évaluation

- Requisition and Invoice/Shipping Document: Previous Edition Is ObsoleteDocument2 pagesRequisition and Invoice/Shipping Document: Previous Edition Is ObsoleteAnonymous vyUisZImrPas encore d'évaluation

- Chapter 17. Shipping Contributors: Alan Simcock (Lead Member) and Osman Keh Kamara (Co-LeadDocument50 pagesChapter 17. Shipping Contributors: Alan Simcock (Lead Member) and Osman Keh Kamara (Co-LeadAnonymous vyUisZImrPas encore d'évaluation

- IMO Course From Management To Operation PDFDocument74 pagesIMO Course From Management To Operation PDFSlim100% (1)

- Surviving The Crash: Stress Reactions of Motor Vehicle Accident VictimsDocument4 pagesSurviving The Crash: Stress Reactions of Motor Vehicle Accident VictimsAnonymous vyUisZImrPas encore d'évaluation

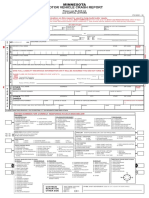

- Minnesota Motor Vehicle Accident ReportDocument2 pagesMinnesota Motor Vehicle Accident ReportAnonymous vyUisZImrPas encore d'évaluation

- Press Release ARCA LAS Electric Rocket PDFDocument3 pagesPress Release ARCA LAS Electric Rocket PDFAnonymous vyUisZImrPas encore d'évaluation

- Uenr2139uenr2139 SisDocument2 pagesUenr2139uenr2139 SisOsvaldo Lozada0% (1)

- US Market CrashesDocument14 pagesUS Market Crashesjohn2ma2Pas encore d'évaluation

- Pressrelease180702 enDocument1 pagePressrelease180702 enAnonymous vyUisZImrPas encore d'évaluation

- Fortis Release NotesDocument19 pagesFortis Release NotesAnonymous vyUisZImrPas encore d'évaluation

- Handwriting Practice PDFDocument1 pageHandwriting Practice PDFUmairAkhtarPas encore d'évaluation

- Ad SLX CableDocument2 pagesAd SLX CableJose VazPas encore d'évaluation

- A Pictorial History of RocketsDocument12 pagesA Pictorial History of RocketsDiaz Ing ToretoPas encore d'évaluation

- Niall Ferguson. The War of The World: Twentieth-Century Con Ict and The Descent of The West .:the War of The World: Twentieth Century Con Ict and The Descent of The WestDocument3 pagesNiall Ferguson. The War of The World: Twentieth-Century Con Ict and The Descent of The West .:the War of The World: Twentieth Century Con Ict and The Descent of The WestAnonymous vyUisZImrPas encore d'évaluation

- Uenr2139uenr2139 SisDocument2 pagesUenr2139uenr2139 SisOsvaldo Lozada0% (1)

- Fault Code Cumminc QSM11Document26 pagesFault Code Cumminc QSM11artmehr100% (12)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeD'EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeÉvaluation : 4 sur 5 étoiles4/5 (5794)

- The Yellow House: A Memoir (2019 National Book Award Winner)D'EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Évaluation : 4 sur 5 étoiles4/5 (98)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryD'EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryÉvaluation : 3.5 sur 5 étoiles3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceD'EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceÉvaluation : 4 sur 5 étoiles4/5 (895)

- The Little Book of Hygge: Danish Secrets to Happy LivingD'EverandThe Little Book of Hygge: Danish Secrets to Happy LivingÉvaluation : 3.5 sur 5 étoiles3.5/5 (400)

- Shoe Dog: A Memoir by the Creator of NikeD'EverandShoe Dog: A Memoir by the Creator of NikeÉvaluation : 4.5 sur 5 étoiles4.5/5 (537)

- Never Split the Difference: Negotiating As If Your Life Depended On ItD'EverandNever Split the Difference: Negotiating As If Your Life Depended On ItÉvaluation : 4.5 sur 5 étoiles4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureD'EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureÉvaluation : 4.5 sur 5 étoiles4.5/5 (474)

- Grit: The Power of Passion and PerseveranceD'EverandGrit: The Power of Passion and PerseveranceÉvaluation : 4 sur 5 étoiles4/5 (588)

- The Emperor of All Maladies: A Biography of CancerD'EverandThe Emperor of All Maladies: A Biography of CancerÉvaluation : 4.5 sur 5 étoiles4.5/5 (271)

- On Fire: The (Burning) Case for a Green New DealD'EverandOn Fire: The (Burning) Case for a Green New DealÉvaluation : 4 sur 5 étoiles4/5 (74)

- Team of Rivals: The Political Genius of Abraham LincolnD'EverandTeam of Rivals: The Political Genius of Abraham LincolnÉvaluation : 4.5 sur 5 étoiles4.5/5 (234)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaD'EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaÉvaluation : 4.5 sur 5 étoiles4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersD'EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersÉvaluation : 4.5 sur 5 étoiles4.5/5 (344)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyD'EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyÉvaluation : 3.5 sur 5 étoiles3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreD'EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreÉvaluation : 4 sur 5 étoiles4/5 (1090)

- The Unwinding: An Inner History of the New AmericaD'EverandThe Unwinding: An Inner History of the New AmericaÉvaluation : 4 sur 5 étoiles4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)D'EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Évaluation : 4.5 sur 5 étoiles4.5/5 (121)

- Her Body and Other Parties: StoriesD'EverandHer Body and Other Parties: StoriesÉvaluation : 4 sur 5 étoiles4/5 (821)

- CHAPTER ONE Structural GeologyDocument46 pagesCHAPTER ONE Structural GeologyAfolabi Eniola AbiolaPas encore d'évaluation

- Ch03 Kinetics of Particles - Energy&Momentum Methods - Part 1Document48 pagesCh03 Kinetics of Particles - Energy&Momentum Methods - Part 1Mehmet Fatih SunçaPas encore d'évaluation

- Philippine Metal Foundries v. CADocument2 pagesPhilippine Metal Foundries v. CAMarcus AureliusPas encore d'évaluation

- Why CPVC Pipes FailDocument12 pagesWhy CPVC Pipes FailNikita Kadam100% (1)

- How To Write The Introduction of An Action Research PaperDocument8 pagesHow To Write The Introduction of An Action Research Papergw1qjewwPas encore d'évaluation

- RICS APC Candidate Guide-Aug 2015-WEB PDFDocument24 pagesRICS APC Candidate Guide-Aug 2015-WEB PDFLahiru WijethungaPas encore d'évaluation

- Share Purchase Agreement Short FormDocument7 pagesShare Purchase Agreement Short FormGerald HansPas encore d'évaluation

- Game World History PDFDocument26 pagesGame World History PDFprayudha pratriesyaPas encore d'évaluation

- Books Confirmation - Sem VII - 2020-2021 PDFDocument17 pagesBooks Confirmation - Sem VII - 2020-2021 PDFRaj Kothari MPas encore d'évaluation

- Debt RestructuringDocument4 pagesDebt Restructuringjano_art21Pas encore d'évaluation

- BDA Guide To Successful Brickwor1kDocument259 pagesBDA Guide To Successful Brickwor1kMudassar AhmadPas encore d'évaluation

- Digit Sep 09Document107 pagesDigit Sep 09dukerexPas encore d'évaluation

- Introduction To Parallel Programming 1st Edition Pacheco Solutions ManualDocument5 pagesIntroduction To Parallel Programming 1st Edition Pacheco Solutions Manualyvonnewelchdoafexwzcs100% (11)

- Union Class Dropship 3025Document1 pageUnion Class Dropship 3025A KPas encore d'évaluation

- 14.symmetrix Toolings LLPDocument1 page14.symmetrix Toolings LLPAditiPas encore d'évaluation

- ManualDocument36 pagesManual2009tamerPas encore d'évaluation

- Hear and SpellDocument3 pagesHear and Spellcarlo lastimosaPas encore d'évaluation

- Taguig City University: College of Information and Communication TechnologyDocument9 pagesTaguig City University: College of Information and Communication TechnologyRay SenpaiPas encore d'évaluation

- Research and Practice in HRM - Sept 8Document9 pagesResearch and Practice in HRM - Sept 8drankitamayekarPas encore d'évaluation

- Cover LetterDocument2 pagesCover LetterSasi Gangadhar BPas encore d'évaluation

- MS Word Lecture NotesDocument11 pagesMS Word Lecture NotesMoguriPas encore d'évaluation

- AIDTauditDocument74 pagesAIDTauditCaleb TaylorPas encore d'évaluation

- Nigeria Country Profile - 0Document4 pagesNigeria Country Profile - 0Nden SohbutPas encore d'évaluation

- Electronic Service Tool 2020C v1.0 Product Status ReportDocument6 pagesElectronic Service Tool 2020C v1.0 Product Status ReportHakim GOURAIAPas encore d'évaluation

- Manual of Infection Prevention and Control (PDFDrive)Document399 pagesManual of Infection Prevention and Control (PDFDrive)அந்தோணி சாமி100% (1)

- Smart Phone Usage Among College Going StudentsDocument9 pagesSmart Phone Usage Among College Going StudentsAkxzPas encore d'évaluation

- National Population PolicyDocument12 pagesNational Population Policymuthukumar100% (3)

- A Thermoelectric Scanning Facility For The Study of Elemental Thermocouples Robin E Bentley - Meas. Sci. Technol. 11 (2000) 538-546Document10 pagesA Thermoelectric Scanning Facility For The Study of Elemental Thermocouples Robin E Bentley - Meas. Sci. Technol. 11 (2000) 538-546Ver OnischPas encore d'évaluation

- Theories of International TradeDocument33 pagesTheories of International Tradefrediz79Pas encore d'évaluation

- Gmu Unofficial TranscriptDocument3 pagesGmu Unofficial Transcriptapi-491861804Pas encore d'évaluation