Académique Documents

Professionnel Documents

Culture Documents

API 620 Design

Transféré par

rsubramaniCopyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

API 620 Design

Transféré par

rsubramaniDroits d'auteur :

Formats disponibles

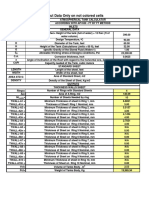

Item Tag: 2000-FB-01/02

Item Description: 15000 MT PROPANE / BUTANE / PROPELENE STORAGE TANK

Project Name: SHV SUPER GAS

API 620 DOUBLE WALL FULL CONTAINMENT STORAGE TANK DESIGN

INNER TANK OUTER TANK

TANK DIAMETER D 45200 46800 mm

TANK HEIGHT HT 18600 20000 mm

PRODUCT STORED Propane Propane

DESIGN LIQUID LEVEL H 17625 16440 mm

DESIGN PRESSURE Pi 0 2000 mm wc

SPECIFIC GRAVITY OF THE LIQUID G 0.59175 0.59175

DESIGN TEMPERATURE T 50 50 °C

EXTERNAL PRESSURE Pe 0 50 mm wc

CORROSION ALLOWANCE Ca 0 1.5 mm

ROOF TYPE SELF SUPPORTED DOME

ROOF RADIUS R 37440 mm

BOTTOM TYPE FLAT

MATERIAL SA537CL1 SA537CL1

DESIGN STRESS API 620 Table 5-1 Sts 21000 21000 psi

YIELD STRESS Sy 50000 50000 psi

Minimum Tensile Strength ST 70000 70000 psi

Modulus of elasticity E 29200000 29200000 psi

DENSITY OF THE MATERIAL 7.85 7.85 g/cm³

DESIGN WIND PRESSURE Pd 3991 N/m²

INSULATION THICKNESS 300 mm

INSULATION DENSITY 40 kg/m³

PREPARED BY TECHNIP INDIA LTD. 1/27

Preliminary calculation

Item Tag: 2000-FB-01/02

Item Description: 15000 MT PROPANE / BUTANE / PROPELENE STORAGE TANK

Project Name: SHV SUPER GAS

ROOF DESIGN AS PER API 620

Roof plate thickness assumed initially tr 8 mm

Min Tank Wall thickness 3/16 in + Ca tmin 6.26364 mm 5.10.4.1.a

Joint Efficiency (API 620 Table 5-2) E 0.7

Summation of vertical components of the forces in any and all internal or external ties F 0 kg

braces, diaphragms, trusses, columns, skirt

Minimum Roof Live load (API 620 5.4.1) Lr 20 lb/ft²

Minimum Platform Load (specification requirement) PL kg/m²

Weight of external accessories on Roof (platforms, insulation, Nozzles, Suspended deck & Structure) W1 216260 kg

Calculation

Roof plate thickness assumed initially tr 0.315 in

Corrosion allowance for roof plate Ca 0.0591 in

Joint Efficiency (API 620 Table 5-2) E 0.7

Maximum allowable tensile stress for Tension Sts 21000 psi Table 5-1

Allowable tensile stress in Test Condition min (85% Sy, 55% ST) Stt 38500 psi

Roof Radius Rs 1474.0157 in

Tank Diameter D 1842.5197 in

Roof Height Rs-sqrt(Rs²-(D/2)²) Hr 323.363 in

Roof Surface area 2 x PI x Rs x Hr Af 2994830.883 in²

Crosssectional area of tank At 2666331.60973 in²

Roof Plate material density Rd 0.2836 lb/in³

Roof Plate weight tr x Af x Rd Wr 267540.222102 lb

Roof Support Weight (Rafter weight) 76 kg/m² 0.1080948 lb/in² Wrs 288216.582088 lb

Weight of external accessories on Roof (platforms, insulation, Nozzles) W1 476637.04 lb

Total Weight of Roof Wr+Wrs+Wcr+W1 W 1173207 lb

Summation of vertical components of the forces F 0 lb

Design internal Pressure Pi 2.8446 lb/in²

Design External Pressure Pe 0.0711 lb/in²

Test Pressure Pt 3.55575 lb/in²

Pressure due to Roof and Accessories Weight (W+F)/At Pw 0.44001 lb/in²

Thickness calculation at the center of the Roof for Design Internal Pressure

Meridional unit force Rs/2(Pi+(W+F)/Af) T1 1807.7741 lb/in 5.10.2.5 (4)

Latitudinal unit Force Rs(Pi+W/Af)-T1 T2 1807.7742 lb/in 5.10.2.5 (5)

the Roof is in Tension T 1807.7742 lb/in

Required Thickness T/(StsE)+Ca t 0.1821 in 5.10.3.2 (16)

t 4.63 mm

Assumed thickness is sufficient

Thickness calculation at the Edge of the Roof for Design Internal Pressure

Meridional unit force Rs/2(Pi+(W+F)/At) T1 1772.2032 lb/in 5.10.2.5 (4)

sin-1(D/(2Rs) Alpha 0.6751 rad

Latitudinal unit Force Rs(Pi+W/At*Cos(alpha))-T1 T2 1914.4726 lb/in 5.10.2.5 (5)

the Roof is in Tension T 1914.4726 lb/in

Required Thickness T/(StsE)+Ca t 0.189 in 5.10.3.2 (16)

t 4.8 mm

Assumed thickness is sufficient

PREPARED BY TECHNIP INDIA LTD. 2/27

Preliminary calculation

Item Tag: 2000-FB-01/02

Item Description: 15000 MT PROPANE / BUTANE / PROPELENE STORAGE TANK

Project Name: SHV SUPER GAS

ROOF DESIGN AS PER API 620

Thickness calculation of the Roof for only Gas (internal) Pressure and if (W+F)/At is negligible

Meridional unit force 1/2*Pi*Rs T1 2096.4925 lb/in 5.10.2.5 (7)

Latitudinal unit Force 1/2*Pi*Rs T2 2096.4925 lb/in 5.10.2.5 (7)

the Roof is in Tension T 2096.4925 lb/in

Required Thickness T/(StsE)+Ca t 0.2017 in 5.10.3.2 (16)

t 5.12 mm

Assumed thickness is sufficient

Thickness calculation at the center of the Roof for Test Pressure

Meridional unit force Rs/2(Pt+(W+F)/Af) T1 2331.8973 lb/in 5.10.2.5 (4)

Latitudinal unit Force Rs(Pt+W/Af)-T1 T2 2331.8972 lb/in 5.10.2.5 (5)

the Roof is in Tension T 2331.8973 lb/in

Required Thickness T/(SttE)+Ca t 0.1456 in 5.10.3.2 (16)

t 3.7 mm

Assumed thickness is sufficient

Thickness calculation at the Edge of the Roof for Test Pressure

Meridional unit force Rs/2(Pt+(W+F)/At) T1 2296.3264 lb/in 5.10.2.5 (4)

sin-1(D/(2Rs) Alpha 0.6751 rad

Latitudinal unit Force Rs(Pt+W/At*Cos(alpha))-T1 T2 2438.5957 lb/in 5.10.2.5 (5)

the Roof is in Tension T 2438.5957 lb/in

Required Thickness T/(Stt*E)+Ca t 0.15 in 5.10.3.2 (16)

t 3.81 mm

Assumed thickness is sufficient

Thickness calculation of the Roof for only Gas (Test) Pressure and if (W+F)/At is negligible

Meridional unit force 1/2*Pt*Rs T1 2620.6157 lb/in 5.10.2.5 (7)

Latitudinal unit Force 1/2*Pt*Rs T2 2620.6157 lb/in 5.10.2.5 (7)

the Roof is in Tension T 2620.6157 lb/in

Required Thickness T/(Stt*E)+Ca t 0.1563 in 5.10.3.2 (16)

t 3.97 mm

Assumed thickness is sufficient

Thickness calculation at the center of the Roof for Design External Pressure

Live Load Lr 0.1389 lb/in²

Platform Load PL 0 lb/in²

Meridional unit force Rs/2(-Pe-(W+F)/Af-Lr-PL) T1 -443.4901 lb/in 5.10.2.5 (4)

Latitudinal unit Force Rs(-Pe-W/Af-Lr-PL)-T1 T2 -443.49 lb/in 5.10.2.5 (5)

Thickness calculation shall be as per 5.10.3.5

Allowable compressive stress Sca 173.607 lb/in²

T' 443.4901 lb/in

T'' 443.49 lb/in

Required Thickness Sqrt(T'+0.8T'')R)/1342+Ca t 0.867 in 5.10.3.5(18)

sqrt(T''Rs)/1000+Ca t 0.8677 in 5.10.3.5 (19)

Step 2

For thickness determined by equation 18 (t-c)/Rs 0.00055

For Thickness determined by equation 19 (t-c)/Rs 0.00055

Larger thickness calculated by Equation 18 or 19 is the required thickness. Further calculations using Steps 3 through 6 are unnecessary

PREPARED BY TECHNIP INDIA LTD. 3/27

Preliminary calculation

Item Tag: 2000-FB-01/02

Item Description: 15000 MT PROPANE / BUTANE / PROPELENE STORAGE TANK

Project Name: SHV SUPER GAS

ROOF DESIGN AS PER API 620

t 22.04 mm

Assumed thickness is not sufficient, recheck with revised thickness or design with rafter supports

PREPARED BY TECHNIP INDIA LTD. 4/27

Preliminary calculation

Item Tag: 2000-FB-01/02

Item Description: 15000 MT PROPANE / BUTANE / PROPELENE STORAGE TANK

Project Name: SHV SUPER GAS

ROOF DESIGN AS PER API 620

Thickness calculation at the Edge of the Roof for Design External Pressure

Live Load Lr 0.1389 lb/in²

Platform Load PL 0 lb/in²

sin-1(D/(2Rs) Alpha 0.6751 rad

Meridional unit force Rs/2(-Pe-(W+F)/At-Lr-PL) T1 -479.0609 lb/in 5.10.2.5 (4)

Latitudinal unit Force Rs(-Pe-(W/At+Lr+PL)cos(alpha))-T1 T2 -291.8806 lb/in 5.10.2.5 (5)

Thickness calculation shall be as per 5.10.3.5

Allowable compressive stress Sca 173.607 lb/in²

Step 1

Maximum of ABS(T1), ABS(T2) T' 479.0609 lb/in

Minimum of ABS(T1), ABS(T2) T'' 291.8806 lb/in

Required Thickness Sqrt(T'+0.8T'')R)/1342+Ca t 0.823 in 5.10.3.5(18)

sqrt(T''Rs)/1000+Ca t 0.715 in 5.10.3.5 (19)

Step 2

For thickness determined by equation 18 (t-c)/Rs 0.00052

For Thickness determined by equation 19 (t-c)/Rs 0.00045

Larger thickness calculated by Equation 18 or 19 is the required thickness. Further calculations using Steps 3 through 6 are unnecessary

t 20.9 mm

Assumed thickness is not sufficient, recheck with revised thickness or design with rafter supports

DESIGN OF COMPRESSION-RING REGION

Shell Radius Rc 921.25985 in

Roof Radius Rs= R2 1474.0157 in

Design Internal Pressure Pi 2.8446 lb/in²

Design External Pressure Pe 0.0711 lb/in²

Test Pressure Pt 3.55575 lb/in²

Corrosion allowance C 0.059 in

Thickness of the cylindrical sidewalls at and near the junction of the roof tc 40 mm 1.575 in

Thickness of the roof plate at and near the Juncture of the sidewall th 40.000 mm 1.575 in

Extension of Roof Compression ring outside the shell Wall L 350.000 mm 13.780 in 5.12.5.8

(Does not exceed 16 times its thickness) #MACRO?

Actual Width of Roof Compression ring inside the shell wall L1 1050.000 mm 41.339 in

Surface area of Roof Compression ring 315290.760 in²

Weight of roof compression ring Wcr 140813.322 lb

Width of the roof plate considered to participate 0.6sqrt(R2(th-c) Wh 28.360 in 5.12.4.2 (24)

in resisting the circumferential force

Corresponding width of participating sidewall plate 0.6sqrt(Rc(tc-c) Wc 22.421 in 5.12.4.2 (25)

Angle between the direction of T1 and a vertical line cos-1(Rc/R2) a 0.896 rad

COMPRESSION RING CALCULATION FOR INTERNAL PRESSURE

Since the term (W+F)/At is negligible compared to design pressure, Equation 7 and 13 shall be used in calculating T1 & T2 & T2s 5.10.2.5

Meridional unit force in the roof 1/2*Pi*R2 T1 2096.493 lb/in 5.10.2.5 (7)

Latitudinal unit force in the roof 1/2*Pi*R2 T2 2096.493 lb/in 5.10.2.5 (7)

Circumferential unit force in the cylindrical side wall Pi*Rc T2s 2620.616 lb/in 5.10.2.5 (13)

PREPARED BY TECHNIP INDIA LTD. 5/27

Preliminary calculation

Item Tag: 2000-FB-01/02

Item Description: 15000 MT PROPANE / BUTANE / PROPELENE STORAGE TANK

Project Name: SHV SUPER GAS

ROOF DESIGN AS PER API 620

Total circumferential force acting on a vertical T2*Wh+T2s*Wc-T1*Rc*sina Q -1401248.023 lb 5.12.4.3 (26)

cross section

PREPARED BY TECHNIP INDIA LTD. 6/27

Preliminary calculation

Item Tag: 2000-FB-01/02

Item Description: 15000 MT PROPANE / BUTANE / PROPELENE STORAGE TANK

Project Name: SHV SUPER GAS

ROOF DESIGN AS PER API 620

Required Net cross section area Q/15000 Ac 93.417 in² 5.12.4.3 (27)

Available cross sectional area Wh*th+Wc*tc+L*th Aa 97.854 in²

the horizontal projection of the effective compression-ring region width shall be not less than 0.015 times the radius of the tank wall 5.12.5.1

Okay

The net cross-sectional area provided in the compression region is sufficient

COMPRESSION RING CALCULATION FOR TEST PRESSURE

Since the term (W+F)/At is negligible compared to design pressure, Equation 7 and 13 shall be used in calculating T1 & T2 & T2s 5.10.2.5

Meridional unit force in the roof 1/2*Pt*R2 T1 2620.616 lb/in 5.10.2.5 (7)

Latitudinal unit force in the roof 1/2*Pt*R2 T2 2620.616 lb/in 5.10.2.5 (7)

Circumferential unit force in the cylindrical side wall Pt*Rc T2s 3275.770 lb/in 5.10.2.5 (13)

Total circumferential force acting on a vertical T2*Wh+T2s*Wc-T1*Rc*sina Q -1736871.009 lb 5.12.4.3 (26)

cross section

Required Net cross section area Q/20000 Ac 86.844 in² 5.12.4.3 (27)

Available cross sectional area Wh*th+Wc*tc+L*th Aa 97.854 in²

the horizontal projection of the effective compression-ring region width shall be not less than 0.015 times the radius of the tank wall 5.12.5.1

Okay

The net cross-sectional area provided in the compression region is sufficient

COMPRESSION RING CALCULATION FOR EXTERNAL PRESSURE

Since the external pressure and Weight of roof plate acts down wards, - Sign shall be considered in the calculation

Meridional unit force in the roof R2/2(Pe+(W+F)/At) T1 -376.692 lb/in 5.10.2.5 (4)

Latitudinal unit force in the roof Rs*Pe-T1 T2 271.890 lb/in 5.10.2.5 (5)

Circumferential unit force in the cylindrical side wall Pe*Rc T2s -65.502 lb/in 5.10.2.5 (13)

Total circumferential force acting on a vertical T2*Wh+T2s*Wc-T1*Rc*sina Q 277143.460 lb 5.12.4.3 (26)

cross section

Required Net cross section area Q/1.3Sts*E Ac 14.503 in² 5.12.4.3 (27)

Available cross sectional area Wh*th+Wc*tc+L*th Aa 97.854 in²

The net cross-sectional area provided in the compression region is sufficient

SUSPENDED DECK

Suspended Deck plate thickness 8 mm

Suspended Deck Plate OD 46.790 mm

Suspended Deck weight 107990.000 kg

Suspended Deck structure weight 30 kg/m² 51590.000 kg

insulation thickness on suspended Deck 350 mm

Insulation Density 65 kg/m³

Insulation weight 39120.000 kg

PREPARED BY TECHNIP INDIA LTD. 7/27

Preliminary calculation

Item Tag: 2000-FB-01/02

Item Description: 15000 MT PROPANE / BUTANE / PROPELENE STORAGE TANK

Project Name: SHV SUPER GAS

ROOF DESIGN AS PER API 620

SUMMARY OF REPORT

Required thickness of roof plate for internal Design Pressure 5.120 mm

Required thickness of roof plate for Test Pressure 3.970 mm

Required thickness of Roof Plate for External Pressure 22.040 mm

Provided Thickness of Roof Plate 8.000 mm

Required Thickness of Roof Plate in Compression Ring 40.000 mm

Min Required Width of Roof Plate in Compression Ring inside the shell wall 720.349 mm

Provided Width of Roof Plate in Compression Ring outside the shell wall 350.000 mm

Required Thickness of Shell Plate in Compression Ring 40.000 mm

Min Required Width of Shell Plate in Compression Ring 569.486 mm

Weight of Roof Plate 121333 kg

Weight of Roof Plate in Compression Ring 63861 kg

Weight of Roof Structure considered in Design 130710 kg

Suspended Deck weight of thick 8 mm 107990 kg

Suspended Deck structure weight 51590 kg

Weight of Insulation above suspended Deck 39120 kg

PREPARED BY TECHNIP INDIA LTD. 8/27

Preliminary calculation

Item Tag: 2000-FB-01/02

Item Description: 15000 MT PROPANE / BUTANE / PROPELENE STORAGE TANK

Project Name: SHV SUPER GAS

INNER TANK DESIGN AS PER API 620

Roof Weight (including Roof Structure, Top Platform and external accessories) w 0 kg

Weight of vertical components of the forces F 0 kg

Calculation

Radius of Tank Shell Rc 22600 mm

Corrosion Allowance Ca 0 mm

Design Liquid Level H 17625 mm

Specific Gravity of Liquid G 0.59175

Design internal Pressure Pg 0 psi

Design External Pressure Pe 0 psi

Test Pressure Pt 0 psi R.6.2

Maximum allowable tensile stress Sts 21000 psi

Allowable tensile stress in Test Condition min (85% Sy, 55% ST) Stt 38500 psi R.6.2

Min Tank Wall thickness 3/16 in + Ca 4.7625 mm 5.10.4.1.a

Nominal Thickness of Tank Wall in erection Condition 7.9375 mm TABLE 5.6

Density of material 0.2836 lb/in³

DESIGN CASE - INTERNAL PRESSURE WITH DESIGN LIQUID LEVEL

Radius of Tank Shell R=R2=Rc 889.7638 in

Cross-sectional area of the interior of the tank At 2487134.878 in²

Corrosion allowance Ca 0 in

Course # 1- For Latitudinal unit force T2

Pressure resulting from the Liquid head at level under consideration Pl 14.8339 psi

Total Pressure Pg+Pl P 14.8339 psi

Latitudinal unit force of meridional arc P*Rc T2 13198.66723 lb/in 5.10.2.5 (11)

Joint Efficeincy E 1

Required Thickness T2/(Sts*E)+Ca t 0.6285 in 5.10.3.2 (16)

Min thickness of bottom shell Course max(5.10.4.1.a,Table 5.6, 5.10.3.2 (16)) t 15.9639 mm

THICKNESS CALCULATION FOR INTERNAL DESIGN PRESSURE WITH DESIGN LIQUID LEVEL FOR LATITUDINAL FORCE T2

Course Liquid Liquid Total Latitudinal Required Min.Require Provided New

Weld Joint Stress in

Course No. Width height Pressure Pressure force T2 Thickness d Thick as Thickness Weight

Efficiency Shell (psi)

(m) (m) (psi) (psi) (lb/in) (mm) per API 620 (mm) (lb)

1 2.4 1 17.625 14.8339 14.8339 13198.6672 15.964 7.9375 19 17644.534 112110

2 2.4 1 15.225 12.814 12.814 11401.4333 13.79 7.9375 17 17035.083 100304

3 2.4 1 12.825 10.794 10.794 9604.11046 11.616 7.9375 15 16262.96 88500

4 2.4 1 10.425 8.7741 8.7741 7806.87656 9.443 7.9375 13 15253.436 76697

5 2.4 1 8.025 6.7542 6.7542 6009.64266 7.269 7.9375 10 15264.492 58994

6 2.4 1 5.625 4.7342 4.7342 4212.31978 5.095 7.9375 8 13374.115 47193

7 2.4 0.85 3.225 2.7143 2.7143 2415.08588 3.437 7.9375 8 9021.056 47193

8 1.8 0.85 0.825 0.6944 0.6944 617.851983 0.879 7.9375 8 2307.859 35395

18.6 Total 566386

Course # 1- For Meridional unit force T1

Roof Weight (including Roof Structure, Top Platform and external accessories) Wr 0 lb

Weight of vertical components of the forces F 0 lb

Weight of Shell Plate + Roof Plate W 566386 lb

PREPARED BY TECHNIP INDIA LTD. 9/27

Preliminary calculation

Item Tag: 2000-FB-01/02

Item Description: 15000 MT PROPANE / BUTANE / PROPELENE STORAGE TANK

Project Name: SHV SUPER GAS

INNER TANK DESIGN AS PER API 620

Meridional unit force Rc/2(P+(W+F)/At) T1 6498.022 lb/in 5.10.2.5 (10)

Required Thickness T1/(Sts*E)+Ca t 7.86 mm 5.10.3.2 (16)

PREPARED BY TECHNIP INDIA LTD. 10/27

Preliminary calculation

Item Tag: 2000-FB-01/02

Item Description: 15000 MT PROPANE / BUTANE / PROPELENE STORAGE TANK

Project Name: SHV SUPER GAS

INNER TANK DESIGN AS PER API 620

THICKNESS CALCULATION FOR INTERNAL PRESSURE AND DESIGN LIQUID LEVEL FOR MERIDIONAL FORCE T1

Shell Course Shell Course Total Total Meridional Required

Weld Joint

Course No. New Weight Corroded Weight Pressure Force Thickness Result

Efficiency

(lb) Weight (lb) W (lb) P (psi) T1 (lb/in) t (mm)

1 112110 112110 566386 14.8339 1 6498.022 7.86 Okay

2 100304 100304 454276 12.814 1 5619.459 6.797 Okay

3 88500 88500 353972 10.794 1 4738.739 5.732 Okay

4 76697 76697 265472 8.7741 1 3855.952 4.664 Okay

5 58994 58994 188775 6.7542 1 2971.055 3.594 Okay

6 47193 47193 129781 4.7342 1 2082.946 2.519 Okay

7 47193 47193 82588 2.7143 0.85 1192.77 1.697 Okay

8 35395 35395 35395 0.6944 0.85 302.595 0.431 Okay

Total 566386 566386

DESIGN CASE - TEST PRESSURE WITH TEST LIQUID

Specific gravity of test Liquid G 1

Course # 1- For Meridional unit force T1 & For Latitudinal unit force T2

Pressure resulting from the Test Liquid head at level under consideration Pl 25.0679 psi

Total Test Pressure Pt+Pl P 25.0679 psi

Meridional unit force Rc/2(P+(W+F)/At) T1 11050.944 lb/in 5.10.2.5 (10)

Latitudinal unit force P*Rc T2 22304.51 lb/in 5.10.2.5 (11)

Allowable tensile stress in Test Condition Stt 38500 psi

Required Thickness max(T1,T2)/(Stt*E)+Ca t 14.72 mm 5.10.3.2 (16)

THICKNESS CALCULATION FOR TEST PRESSURE WITH DESIGN TEST LIQUID LEVEL

Provided Liquid Liquid Total Meridional Latitudinal Required

Total Weight Weld Joint Max (T1,T2)

Course No. Thickness height Pressure Pressure Force force T2 Thickness Result

W (lb) Efficiency (lb/in)

t (mm) (m) (psi) (psi) T1 (lb/in) (lb/in) t (mm)

1 19 566386 17.625 25.0679 25.0679 1 11050.944 22304.51 22304.510 14.720 Okay

2 17 454276 15.225 21.6544 21.6544 1 9552.393 19267.302 19267.302 12.720 Okay

3 15 353972 12.825 18.2409 18.2409 1 8051.731 16230.093 16230.093 10.710 Okay

4 13 265472 10.425 14.8274 14.8274 1 6548.957 13192.884 13192.884 8.710 Okay

5 10 188775 8.025 11.4139 11.4139 1 5044.071 10155.676 10155.676 6.710 Okay

6 8 129781 5.625 8.0004 8.0004 1 3536.019 7118.467 7118.467 4.700 Okay

7 8 82588 3.225 4.5869 4.5869 0.85 2025.857 4081.258 4081.258 3.170 Okay

8 8 35395 0.825 1.1734 1.1734 0.85 515.694 1044.049 1044.049 0.820 Okay

DESIGN CASE - EXTERNAL PRESSURE WITH NO LIQUID

Design External Pressure Pe 0 psi

Total Pressure P 0 psi

Course # 1- For Meridional unit force T1 & For Latitudinal unit force T2

Meridional unit force Rc/2(P+(W+F)/At) T1 -101.312 lb/in 5.10.2.5 (10)

Latitudinal unit force P*Rc T2 0 lb/in 5.10.2.5 (11)

(t-c)/R 0.00085

Allowable compressive stress 1000000*[(t-c)R] Sca 850 psi 5.5.4.3

Thickness calculation shall be as per 5.10.3.5

Step 1

PREPARED BY TECHNIP INDIA LTD. 11/27

Preliminary calculation

Item Tag: 2000-FB-01/02

Item Description: 15000 MT PROPANE / BUTANE / PROPELENE STORAGE TANK

Project Name: SHV SUPER GAS

INNER TANK DESIGN AS PER API 620

Maximum of ABS(T1), ABS(T2) T' 101.312 lb/in

Minimum of ABS(T1), ABS(T2) T'' 0 lb/in

Required Thickness Sqrt(T'+0.8T'')R)/1342+Ca t 0.224 in 5.10.3.5(18)

PREPARED BY TECHNIP INDIA LTD. 12/27

Preliminary calculation

Item Tag: 2000-FB-01/02

Item Description: 15000 MT PROPANE / BUTANE / PROPELENE STORAGE TANK

Project Name: SHV SUPER GAS

INNER TANK DESIGN AS PER API 620

sqrt(T''Rs)/1000+Ca t 0 in 5.10.3.5 (19)

Step 2

For thickness determined by equation 18 (t-c)/Rs 0.00026

For Thickness determined by equation 19 (t-c)/Rs 0

Larger thickness calculated by Equation 18 or 19 is the required thickness. Further calculations using Steps 3 through 6 are unnecessary

t 5.69 mm

UNITY CHECK AS PER 5.5.4.4

Larger computed compressive stress T'/(t-Ca) S1 135.4382 lb/in²

Smaller computed Compressive stress T''/(t-Ca) Ss 0 lb/in²

(t-c)/R 0.00085

Allowable compressive stress 1800000*[(t-c)R] Scs 1530 psi 5.5.4.2

(S1+0.8Ss)/Scs 0.0886

1.8Ss/Scs 0

THICKNESS CALCULATION FOR EXTERNAL PRESSURE WITH NO LIQUID

Provided Total Meridional Latitudinal Max (abs Min (abs t Required t Required

Total Weight

Course No. Thickness Pressure Force force T2 T1,T2) T1,T2) as per (18) as per (19)

W (lb)

t (mm) P (psi) T1 (lb/in) (lb/in) T' T'' (in) (in)

1 19 566386 0 -101.312 0 101.312 0 0.2238 0

2 17 454276 0 -81.258 0 81.258 0 0.2004 0

3 15 353972 0 -63.317 0 63.317 0 0.1769 0

4 13 265472 0 -47.486 0 47.486 0 0.1532 0

5 10 188775 0 -33.767 0 33.767 0 0.1292 0

6 8 129781 0 -23.215 0 23.215 0 0.1071 0

7 8 82588 0 -14.773 0 14.773 0 0.0855 0

8 8 35395 0 -6.332 0 6.332 0 0.056 0

THICKNESS CALCULATION FOR EXTERNAL PRESSURE WITH NO LIQUID

min Reqd

(t-c)/Rs by (t-c)/Rs by S1 Ss Scs (S1+0.8Ss)/

Course No. Thick (t-c)/R 1.8Ss/Scs Result

Eq (18) Eq (19) (lb/in²) (lb/in²) (lb/in²) Scs

t (mm)

1 0.00026 0 5.68 135.4382 0 0.00085 1530 0.0886 0 Okay

2 0.00023 0 5.09 121.4091 0 0.00076 1368 0.0888 0 Okay

3 0.0002 0 4.49 107.2168 0 0.00067 1206 0.089 0 Okay

4 0.00018 0 3.89 92.7804 0 0.00058 1044 0.0889 0 Okay

5 0.00015 0 3.28 85.7682 0 0.00045 810 0.1059 0 Okay

6 0.00013 0 2.72 73.7077 0 0.00036 648 0.1138 0 Okay

7 0.0001 0 2.17 46.9043 0 0.00036 648 0.0724 0 Okay

8 0.00007 0 1.42 20.1041 0 0.00036 648 0.0311 0 Okay

PREPARED BY TECHNIP INDIA LTD. 13/27

Preliminary calculation

Item Tag: 2000-FB-01/02

Item Description: 15000 MT PROPANE / BUTANE / PROPELENE STORAGE TANK

Project Name: SHV SUPER GAS

INNER TANK DESIGN AS PER API 620

SUMMARY OF REPORT

Course Corroded Reqd Thick Reqd thk Reqd thk Reqd thk Provided

New Weight

Course No. Width Weight API 620 INT Pres Test Pres Ext Pres Thickness Result

(lb)

(m) (lb) (mm) (mm) (mm) (mm) (mm)

1 2.400 112110 112110 7.9375 15.964 14.72 5.68 19 Okay

2 2.400 100304 100304 7.9375 13.79 12.72 5.09 17 Okay

3 2.400 88500 88500 7.9375 11.616 10.71 4.49 15 Okay

4 2.400 76697 76697 7.9375 9.443 8.71 3.89 13 Okay

5 2.400 58994 58994 7.9375 7.269 6.71 3.28 10 Okay

6 2.400 47193 47193 7.9375 5.095 4.7 2.72 8 Okay

7 2.400 47193 47193 7.9375 3.437 3.17 2.17 8 Okay

8 1.800 35395 35395 7.9375 0.879 0.82 1.42 8 Okay

New Weight of the Shell Plate 256981 kg

Corroded weight of the Shell Plate 256981 kg

PREPARED BY TECHNIP INDIA LTD. 14/27

Preliminary calculation

Item Tag: 2000-FB-01/02

Item Description: 15000 MT PROPANE / BUTANE / PROPELENE STORAGE TANK

Project Name: SHV SUPER GAS

OUTER TANK DESIGN AS PER API 620

Roof Weight (including Roof Structure, Top Platform and external accessories) w 569914 kg

Weight of vertical components of the forces F 0 kg

Calculation

Radius of Tank Shell Rc 23400 mm

Corrosion Allowance Ca 1.5 mm

Design Liquid Level H 16440 mm

Specific Gravity of Liquid G 0.59175

Design internal Pressure Pg 2.8446 psi

Design External Pressure Pe 0.0711 psi

Test Pressure Pt 3.55575 psi R.6.2

Maximum allowable tensile stress Sts 21000 psi

Allowable tensile stress in Test Condition min (85% Sy, 55% ST) Stt 38500 psi R.6.2

Min Tank Wall thickness 3/16 in + Ca 6.2625 mm 5.10.4.1.a

Nominal Thickness of Tank Wall in erection Condition 7.9375 mm TABLE 5.6

Density of material 0.2836 lb/in³

DESIGN CASE - INTERNAL PRESSURE WITH DESIGN LIQUID LEVEL

Radius of Tank Shell R=R2=Rc 921.2598 in

Cross-sectional area of the interior of the tank At 2666331.32 in²

Corrosion allowance Ca 0.059055118 in

Course # 1- For Latitudinal unit force T2

Pressure resulting from the Liquid head at level under consideration Pl 13.8366 psi

Total Pressure Pg+Pl P 16.6812 psi

Latitudinal unit force of meridional arc P*Rc T2 15367.71898 lb/in 5.10.2.5 (11)

Joint Efficeincy E 1

Required Thickness T2/(Sts*E)+Ca t 0.7909 in 5.10.3.2 (16)

Min thickness of bottom shell Course max(5.10.4.1.a,Table 5.6, 5.10.3.2 (16)) t 20.08886 mm

THICKNESS CALCULATION FOR INTERNAL DESIGN PRESSURE WITH DESIGN LIQUID LEVEL FOR LATITUDINAL FORCE T2

Course Liquid Liquid Total Latitudinal Required Min.Require Provided New

Weld Joint Stress in

Course No. Width height Pressure Pressure force T2 Thickness d Thick as Thickness Weight

Efficiency Shell (psi)

(m) (m) (psi) (psi) (lb/in) (mm) per API 620 (mm) (lb)

1 2.4 1 16.44 13.8366 16.6812 15367.719 20.088 7.9375 21 20017.439 128300

2 2.4 1 14.04 11.8166 14.6612 13506.7742 17.837 7.9375 18 20792.246 109965

3 2.4 1 11.64 9.7967 12.6413 11645.9215 15.586 7.9375 16 20400.442 97742

4 2.4 1 9.24 7.7768 10.6214 9785.06884 13.335 7.9375 14 19883.26 85521

5 2.4 1 6.84 5.7568 8.6014 7924.12404 11.084 7.9375 13 17501.978 79411

6 2.4 1 4.44 3.7369 6.5815 6063.27137 8.834 7.9375 13 13391.921 79411

7 2.4 1 2.04 1.7169 4.5615 4202.32658 6.583 7.9375 13 9281.66 79411

8 2.4 1 -0.36 -0.303 2.5416 2341.47391 4.332 7.9375 13 5171.603 79411

9 0.8 1 -2.76 -2.3229 0.5217 480.621238 2.081 7.9375 40 317.085 81494

20 Total 820666

Course # 1- For Meridional unit force T1

Roof Weight (including Roof Structure, Top Platform and external accessories) Wr 1256432.404 lb

Weight of vertical components of the forces F 0 lb

Weight of Shell Plate + Roof Plate W 2077098.404 lb

PREPARED BY TECHNIP INDIA LTD. 15/27

Preliminary calculation

Item Tag: 2000-FB-01/02

Item Description: 15000 MT PROPANE / BUTANE / PROPELENE STORAGE TANK

Project Name: SHV SUPER GAS

OUTER TANK DESIGN AS PER API 620

Meridional unit force Rc/2(P+(W+F)/At) T1 7325.024 lb/in 5.10.2.5 (10)

Required Thickness T1/(Sts*E)+Ca t 10.36 mm 5.10.3.2 (16)

PREPARED BY TECHNIP INDIA LTD. 16/27

Preliminary calculation

Item Tag: 2000-FB-01/02

Item Description: 15000 MT PROPANE / BUTANE / PROPELENE STORAGE TANK

Project Name: SHV SUPER GAS

OUTER TANK DESIGN AS PER API 620

THICKNESS CALCULATION FOR INTERNAL PRESSURE AND DESIGN LIQUID LEVEL FOR MERIDIONAL FORCE T1

Shell Course Shell Course Total Total Meridional Required

Weld Joint

Course No. New Weight Corroded Weight Pressure Force Thickness Result

Efficiency

(lb) Weight (lb) W (lb) P (psi) T1 (lb/in) t (mm)

1 128300 119136 2077098 16.6812 1 7325.024 10.36 Okay

2 109965 100801 1948798 14.6612 1 6416.717 9.261 Okay

3 97742 88579 1838833 12.6413 1 5505.288 8.159 Okay

4 85521 76358 1741091 10.6214 1 4591.747 7.054 Okay

5 79411 70248 1655570 8.6014 1 3676.049 5.946 Okay

6 79411 70248 1576159 6.5815 1 2759.342 4.837 Okay

7 79411 70248 1496748 4.5615 1 1842.588 3.729 Okay

8 79411 70248 1417337 2.5416 1 925.881 2.62 Okay

9 81494 78438 1337926 0.5217 1 9.173 1.511 Okay

Total 820666 744304

DESIGN CASE - TEST PRESSURE WITH TEST LIQUID

Specific gravity of test Liquid G 1

Course # 1- For Meridional unit force T1 & For Latitudinal unit force T2

Pressure resulting from the Test Liquid head at level under consideration Pl 23.3824 psi

Total Test Pressure Pt+Pl P 26.93815 psi

Meridional unit force Rc/2(P+(W+F)/At) T1 12049.683 lb/in 5.10.2.5 (10)

Latitudinal unit force P*Rc T2 24817.035 lb/in 5.10.2.5 (11)

Allowable tensile stress in Test Condition Stt 38500 psi

Required Thickness max(T1,T2)/(Stt*E)+Ca t 17.88 mm 5.10.3.2 (16)

THICKNESS CALCULATION FOR TEST PRESSURE WITH DESIGN TEST LIQUID LEVEL

Provided Liquid Liquid Total Meridional Latitudinal Required

Total Weight Weld Joint Max (T1,T2)

Course No. Thickness height Pressure Pressure Force force T2 Thickness Result

W (lb) Efficiency (lb/in)

t (mm) (m) (psi) (psi) T1 (lb/in) (lb/in) t (mm)

1 21 2077098.404 16.44 23.3825 26.93825 1 12049.729 24817.127 24817.127 17.880 Okay

2 18 1948798.404 14.04 19.969 23.52475 1 10499.533 21672.407 21672.407 15.800 Okay

3 16 1838833.404 11.64 16.5555 20.11125 1 8946.171 18527.687 18527.687 13.730 Okay

4 14 1741091.404 9.24 13.142 16.69775 1 7390.696 15382.966 15382.966 11.650 Okay

5 13 1655570.404 6.84 9.7285 13.28425 1 5833.11 12238.246 12238.246 9.580 Okay

6 13 1576159.404 4.44 6.315 9.87075 1 4274.469 9093.526 9093.526 7.500 Okay

7 13 1496748.404 2.04 2.9015 6.45725 1 2715.828 5948.805 5948.805 5.430 Okay

8 13 1417337.404 -0.36 -0.5121 3.04365 1 1157.14 2803.993 2803.993 3.350 Okay

9 40 1337926.404 -2.76 -3.9256 -0.36985 1 -401.502 -340.728 -340.728 1.280 Okay

DESIGN CASE - EXTERNAL PRESSURE WITH NO LIQUID

Design External Pressure Pe 0.0711 psi

Total Pressure P 0.0711 psi

Course # 1- For Meridional unit force T1 & For Latitudinal unit force T2

Meridional unit force Rc/2(P+(W+F)/At) T1 -391.587 lb/in 5.10.2.5 (10)

Latitudinal unit force P*Rc T2 -65.502 lb/in 5.10.2.5 (11)

(t-c)/R 0.00084

Allowable compressive stress 1000000*[(t-c)R] Sca 840 psi 5.5.4.3

Thickness calculation shall be as per 5.10.3.5

Step 1

PREPARED BY TECHNIP INDIA LTD. 17/27

Preliminary calculation

Item Tag: 2000-FB-01/02

Item Description: 15000 MT PROPANE / BUTANE / PROPELENE STORAGE TANK

Project Name: SHV SUPER GAS

OUTER TANK DESIGN AS PER API 620

Maximum of ABS(T1), ABS(T2) T' 391.587 lb/in

Minimum of ABS(T1), ABS(T2) T'' 65.502 lb/in

Required Thickness Sqrt(T'+0.8T'')R)/1342+Ca t 0.536 in 5.10.3.5(18)

PREPARED BY TECHNIP INDIA LTD. 18/27

Preliminary calculation

Item Tag: 2000-FB-01/02

Item Description: 15000 MT PROPANE / BUTANE / PROPELENE STORAGE TANK

Project Name: SHV SUPER GAS

OUTER TANK DESIGN AS PER API 620

sqrt(T''Rs)/1000+Ca t 0.3047 in 5.10.3.5 (19)

Step 2

For thickness determined by equation 18 (t-c)/Rs 0.00052

For Thickness determined by equation 19 (t-c)/Rs 0.00027

Larger thickness calculated by Equation 18 or 19 is the required thickness. Further calculations using Steps 3 through 6 are unnecessary

t 13.61 mm

UNITY CHECK AS PER 5.5.4.4

Larger computed compressive stress T'/(t-Ca) S1 510.0672 lb/in²

Smaller computed Compressive stress T''/(t-Ca) Ss 85.3206 lb/in²

(t-c)/R 0.00084

Allowable compressive stress 1800000*[(t-c)R] Scs 1512 psi 5.5.4.2

(S1+0.8Ss)/Scs 0.3825

1.8Ss/Scs 0.1016

THICKNESS CALCULATION FOR EXTERNAL PRESSURE WITH NO LIQUID

Provided Total Meridional Latitudinal Max (abs Min (abs t Required t Required

Total Weight

Course No. Thickness Pressure Force force T2 T1,T2) T1,T2) as per (18) as per (19)

W (lb)

t (mm) P (psi) T1 (lb/in) (lb/in) T' T'' (in) (in)

1 21 2077098.404 0.0711 -391.587 -65.502 391.587 65.502 0.5357 0.3048

2 18 1948798.404 0.0711 -369.422 -65.502 369.422 65.502 0.5236 0.3048

3 16 1838833.404 0.0711 -350.424 -65.502 350.424 65.502 0.513 0.3048

4 14 1741091.404 0.0711 -333.539 -65.502 333.539 65.502 0.5034 0.3048

5 13 1655570.404 0.0711 -318.764 -65.502 318.764 65.502 0.4948 0.3048

6 13 1576159.404 0.0711 -305.045 -65.502 305.045 65.502 0.4867 0.3048

7 13 1496748.404 0.0711 -291.326 -65.502 291.326 65.502 0.4784 0.3048

8 13 1417337.404 0.0711 -277.608 -65.502 277.608 65.502 0.47 0.3048

9 40 1337926.404 0.0711 -263.889 -65.502 263.889 65.502 0.4613 0.3048

THICKNESS CALCULATION FOR EXTERNAL PRESSURE WITH NO LIQUID

min Reqd

(t-c)/Rs by (t-c)/Rs by S1 Ss Scs (S1+0.8Ss)/

Course No. Thick (t-c)/R 1.8Ss/Scs Result

Eq (18) Eq (19) (lb/in²) (lb/in²) (lb/in²) Scs

t (mm)

1 0.00052 0.00027 13.61 510.0672 85.3206 0.00084 1512 0.3825 0.1016 Okay

2 0.00051 0.00027 13.3 568.686 100.8334 0.00071 1278 0.5082 0.1421 Okay

3 0.0005 0.00027 13.03 613.8462 114.7415 0.00062 1116 0.6323 0.1851 Okay

4 0.00049 0.00027 12.79 677.7513 133.1001 0.00054 972 0.8069 0.2465 Okay

5 0.00048 0.00027 12.57 704.0527 144.674 0.0005 900 0.9109 0.2894 Okay

6 0.00047 0.00027 12.36 673.7516 144.674 0.0005 900 0.8773 0.2894 Okay

7 0.00046 0.00027 12.15 643.4505 144.674 0.0005 900 0.8436 0.2894 Okay

8 0.00045 0.00027 11.94 613.1516 144.674 0.0005 900 0.8099 0.2894 Okay

9 0.00044 0.00027 11.72 174.0982 43.2144 0.00165 2970 0.0703 0.0262 Okay

STABILITY CHECK OF TANK SIDE WALL FOR EXTERNAL PRESSURE + WIND PRESSURE

Tank Diameter D 153.5434 ft

Design Wind Pressure Pd 3991 N/m²

Design External Pressure Pe 490.218 N/m²

Total external pressure Pd+Pe Ptd 4481.218 N/m²

Wind velocity corresponding to above sqrt(Ptd/0.6125) V 85.536 m/s

191.336 mph

Course #1 Uncorroded Condition

PREPARED BY TECHNIP INDIA LTD. 19/27

Preliminary calculation

Item Tag: 2000-FB-01/02

Item Description: 15000 MT PROPANE / BUTANE / PROPELENE STORAGE TANK

Project Name: SHV SUPER GAS

OUTER TANK DESIGN AS PER API 620

Uniform Thickness of the Side wall tuni 0.5119 in

Actual Thickness of the side wall tact 0.8268 in

Actual Course width W 7.8741 ft

Transposed course width W*sqrt(tuni/tact)^5 Wtr 2.375 ft

Maximum height of unstiffened shell 600000*tuni*sqrt((tuni/D)^3*(120/V)^2 H1 23.2561 ft

Course #1 corroded Condition

Uniform Thickness of the Side wall tuni 0.4528 in

Actual Thickness of the side wall tact 0.7678 in

Actual Course width W 7.8741 ft

Transposed course width W*sqrt(tuni/tact)^5 Wtr 2.1031 ft

Maximum height of unstiffened shell 600000*tuni*sqrt((tuni/D)^3*(120/V)^2 H1 20.5712 ft

Uncorroded Condition Corroded Condition

Uniform Provided Uniform

Width Actual Provided Transpose Transpose

Course No. thickness thickness thickness

(ft) thickness (in) Width (ft) Width (ft)

(in) (in) (in)

1 7.87410 0.8268 0.5119 2.375 0.7678 0.4528 2.1031

2 7.87410 0.7087 0.5119 3.4915 0.6497 0.4528 3.1929

3 7.87410 0.63 0.5119 4.6862 0.5709 0.4528 4.4114

4 7.87410 0.5512 0.5119 6.5448 0.4922 0.4528 6.3917

5 7.87410 0.5119 0.5119 7.8741 0.4528 0.4528 7.8741

6 7.87410 0.5119 0.5119 7.8741 0.4528 0.4528 7.8741

7 7.87410 0.5119 0.5119 7.8741 0.4528 0.4528 7.8741

8 7.87410 0.5119 0.5119 7.8741 0.4528 0.4528 7.8741

9 2.62470 1.5749 0.5119 0.1581 1.5158 0.4528 0.1281

Sum of Transposed Width 48.752 ft 47.7236 ft

Maximum height of unstiffened shell 23.2561 ft 20.5712 ft

Intermediate Girders Required

Number of intermediate stiffeners required 3 Nos

Number of Internal Stiffeners provided 4 Nos

Stiffener distance h1 2.5 m

h1 8.2021 ft

Minimum required section modulus of stiffener D²h1/10000*(v/120)² Z 49.1608 in³ API 650 5.9.7.6

Calculation of section modulus

Total width of Tank sidewall that can be included in 2*1.47(Dt)^0.5 24.5141 in

section modulus calculation

PROVIDE INVERTED "TEE" SECTION X Y X Y

WIDTH AND THICKNESS OF FLANGE 1 12 250 mm 0.354 9.724 in

2 1

WIDTH AND THICKNESS OF HUB 2 320 12 mm 12.598 0.354 in

WIDTH AND THICKNESS OF SHELL 3 0.453 24.514 in

SECTION SIZE AREA A d M =A*d Iaa I gg 3

MARKED in x in in^2 in in^3 in^4 in^4

1 0.354 x 9.724 3.4423 0.177 0.6093 286.03 0.04

2 12.598 x 0.354 4.4597 6.653 29.6704 31.07 58.98

3 0.4528 x 24.5141 11.1 13.18 146.3 167.74 0.19

Sum 19.002 176.5797 484.84 59.21

Sum(A*d)/Sum (A) y 9.293 in

PREPARED BY TECHNIP INDIA LTD. 20/27

Preliminary calculation

Item Tag: 2000-FB-01/02

Item Description: 15000 MT PROPANE / BUTANE / PROPELENE STORAGE TANK

Project Name: SHV SUPER GAS

OUTER TANK DESIGN AS PER API 620

Moment of Inertia Iaa + Igg Iyy 544.049 in^4

Section modulus Iyy / y Zyy 58.547 in^3

PROVIDED SECTION IS SUFFICIENT

WIND GRIDER WEIGHT:

FLANGE PLATE (1) 7433.221 lb

WEB PLATE (2) 9696.922 lb

Stiffeners @ 5% = 857 lb

Total weight of 4 Wind Stiffeners 32637 kg

STABILITY AND BUCKLING CHECK OF TANK SIDE WALL FOR EXTERNAL PRESSURE + WIND PRESSURE AS PER API 650 APPENDIX V

Design wind velocity (3-sec gust) V 191.336 mph

Maximum wind pressure 31 (V/120)² W 78.813 lb/ft² V.3.1

Design external pressure Pe 10.2384 lb/ft²

Modifier for the design external pressure Fpe 0.4 V.3.1

Total design external pressure for shell max (Pe, W+ Fpe*Pe) Ps 82.909 lb/ft² V.3.1

Nominal tank daimeter D 153.5434 ft

Nominal thickness of thinnest shell course tsmin 0.4528 in

Transformed height of tank shell Hts 47.7236 ft

Yield strength Fy 50000 lb/in²

Modulus of elasticity E 29200000 lb/in²

Stability Factor y 1.26192 V.8.1

Allowable Compressive stress max (15000,0.4Fy) fc 200000 lb/in² V.3.1

Buckling will occur elastically in the unstiffened cylindrical shell:

Elastic buckling (D/tsmin)^0.75 [(Hts/D)(Fy/E)^0.5 >= 0.19 1.0164 V.8.1.1

Buckling will occur elestically Proceed further

Required min shell thickness (1.23(y*Hts*Ps)^0.4*D^0.6)/E^0.4 tsmin 0.785 in V.8.1.3

The required minimum thickness is greater than the available thickness and the shell must be stiffened

Maximum height of unstiffened shell permitted 0.6*(tsmin)^2.5€/(D^1.5(Ps)y) Hsafe 12.1429 ft V.8.2.1.2

Number of stiffeners requred Hts/Hsafe-1 Ns 3 Nos V.8.2.1.3

Number of Internal Stiffeners provided 4 Nos

Actual spacing between the stiffeners Ls 8.2021 ft

Number of waves into which a shell will buckle under external pressure

sqrt(5.33*D³/(tsmin*Hts²))<=100 N² 100 V.8.2.2.1

2 < N <10 N 10

Radial load imposed on the stiffener by Shell Ps*Ls/12 Q 56.669 lb/in V.8.2.2.3

Contributing width of shell on each side of stiffener 1.47*sqrt(D*tshell) wshell 12.2571 in V.8.2.2.4

Total width of shell Contributing wshell 24.5142 in

Required moment of inertia of stiffener 648*Q*D³/(E(N²-1)) Ireqd 45.9829 in4 V.8.2.2.5

Provided stiffener is sufficient

Total area required in the stiffener region 6QD/fc Areqd 0.2611 in² V.8.2.2.6.1

Required cross-sectional area of stiffener Areqd-2.94*tshell*(sqrt(D*tshell)) Astiff 0.1306 in² V.8.2.2.6.2

Provided section is Sufficient

PREPARED BY TECHNIP INDIA LTD. 21/27

Preliminary calculation

Item Tag: 2000-FB-01/02

Item Description: 15000 MT PROPANE / BUTANE / PROPELENE STORAGE TANK

Project Name: SHV SUPER GAS

OUTER TANK DESIGN AS PER API 620

SUMMARY OF REPORT

Course Corroded Reqd Thick Reqd thk Reqd thk Reqd thk Provided

New Weight

Course No. Width Weight API 620 INT Pres Test Pres Ext Pres Thickness Result

(lb)

(m) (lb) (mm) (mm) (mm) (mm) (mm)

1 2.400 128300 119136 7.9375 20.088 17.88 13.61 21 Okay

2 2.400 109965 100801 7.9375 17.837 15.8 13.3 18 Okay

3 2.400 97742 88579 7.9375 15.586 13.73 13.03 16 Okay

4 2.400 85521 76358 7.9375 13.335 11.65 12.79 14 Okay

5 2.400 79411 70248 7.9375 11.084 9.58 12.57 13 Okay

6 2.400 79411 70248 7.9375 8.834 7.5 12.36 13 Okay

7 2.400 79411 70248 7.9375 6.583 5.43 12.15 13 Okay

8 2.400 79411 70248 7.9375 4.332 3.35 11.94 13 Okay

9 0.800 81494 78438 7.9375 2.081 1.28 11.72 40 Okay

New Weight of the Shell Plate 372353 kg

Corroded weight of the Shell Plate 337706 kg

Weight of the Stiffeners 32640 kg

PREPARED BY TECHNIP INDIA LTD. 22/27

Preliminary calculation

Item Tag: 2000-FB-01/02

Item Description: 15000 MT PROPANE / BUTANE / PROPELENE STORAGE TANK

Project Name: SHV SUPER GAS

TANK BOTTOM DESIGN AS PER API 620

ANNULAR BOTTOM PLATE WIDTH AND THICKNESS CALCULATION FOR INNER TANK

Provided Annular plate thickness tb 10 mm

Provided Annular plate Width 1100 mm

Provided Bottom plate thickness 7 mm

Nominal diamter of tank D 148.29397 ft

Design specific gravity G 0.59175

Maximum filling height of the tank for design H 57.82481 ft

Design thickness of the first shell course excluding corrosion allowance t 0.7481 in

Corrosion allowance Ca 0 in

Induced stress in first shell course (2.6*D)(HG)/t Sd 17635.5767 lb/in² Table R-6 note b

Required thickness of annular plate 0.25 + Ca 6.35 mm Table R-6

Provided annular plate thickness is sufficient

Provided Annular plate thickness tb 0.3937 in

Minimum radial width of Annular plate required 390*tb/(sqrt(H*G)) Lmin 26.2485 in R.3.5.1

inside the tank

28.9966 in R.3.5.1

Total width of Annular plate required Lmin+Shell thk+2" outside

Provided annular plate width is sufficient

Outer diameter of Annular plate OD 45340 mm

Inner diameter of Annular plate ID 43140 mm

Weight of Annular plate 12002 kg

Bottom Plate thickness

Minimum Bottom plate thickness 1/4"+ca 6.35 mm API 620 5.9.4.2

Provided Bottom plate thickness is sufficient

Outer Diameter of Bottom Plate OD 43290 mm

Weight of Bottom Plate 80879 kg

ANNULAR BOTTOM PLATE WIDTH AND THICKNESS CALCULATION FOR OUTER TANK

Provided Annular plate thickness tb 12 mm

Provided Annular plate Width 1400 mm

Provided Bottom plate thickness 8 mm

Nominal diamter of tank D 153.54331 ft

Design specific gravity G 0.59175

Maximum filling height of the tank for design H 53.93701 ft

Design thickness of the first shell course excluding corrosion allowance t 0.7678 in

Corrosion allowance Ca 0.059055118 in

Induced stress in first shell course (2.6*D)(HG)/t Sd 16595.15347 lb/in² Table R-6 note b

Required thickness of annular plate 0.25 + Ca 7.85 mm Table R-6

Provided annular plate thickness is sufficient

Provided Annular plate thickness tb 0.4724 in

Minimum radial width of Annular plate required 390*tb/(sqrt(H*G)) Lmin 32.6109 in R.3.5.1

inside the tank

35.43775512 in R.3.5.1

Total width of Annular plate required Lmin+Shell thk+2" outside

Provided annular plate width is sufficient

Outer diameter of Annular plate OD 46944 mm

PREPARED BY TECHNIP INDIA LTD. 23/27

Preliminary calculation

Item Tag: 2000-FB-01/02

Item Description: 15000 MT PROPANE / BUTANE / PROPELENE STORAGE TANK

Project Name: SHV SUPER GAS

TANK BOTTOM DESIGN AS PER API 620

Inner diameter of Annular plate ID 44144 mm

Weight of Annular plate 18870 kg

Bottom Plate thickness

PREPARED BY TECHNIP INDIA LTD. 24/27

Preliminary calculation

Item Tag: 2000-FB-01/02

Item Description: 15000 MT PROPANE / BUTANE / PROPELENE STORAGE TANK

Project Name: SHV SUPER GAS

TANK BOTTOM DESIGN AS PER API 620

Minimum Bottom plate thickness 1/4"+ca 7.85 mm API 620 5.9.4.2

Provided Bottom plate thickness is sufficient

Outer Diameter of Bottom Plate OD 44294 mm

Weight of Bottom Plate 96770 kg

PREPARED BY TECHNIP INDIA LTD. 25/27

Preliminary calculation

Item Tag: 2000-FB-01/02

Item Description: 15000 MT PROPANE / BUTANE / PROPELENE STORAGE TANK

Project Name: SHV SUPER GAS

MISCILLANEOUS WEIGHT

CAGE LADDER AND INTERMIDIATE PLATFORM FOR INNER TANK

Inner Tank height 18.6 m

Number of intermidiate platforms 4 Nos

Weight of Cage Ladder 40 kg/m 744 kg

Intermidiate Platform Weights 150 kg/m² 600 kg

Total Weight 1344 kg

CAGE LADDER AND INTERMIDIATE PLATFORM FOR OUTER TANK

Outer Tank height 20 m

Number of intermidiate platforms 4 Nos

Weight of Cage Ladder 40 kg/m 800 kg

Intermidiate Platform Weights 150 kg/m² 600 kg

Total Weight 5 No. of cage ladders 7000 kg

PERIPHERAL HANDRAIL FOR OUTER TANK

Outer Tank Diameter 46.8 m

Weight of peripheral Hand Rail 20 kg/m 2950 kg

PERIPHERAL PLATFORM OF 1 METER WIDTH FOR OUTER TANK

Outer Tank Diameter 46.8 m

Weight of peripheral platform 150 kg/m² Angle 120 7360 kg

CENTRAL PLATFORM FOR OUTER TANK

Size of Platform Length 10 m Width 10 m

Weight of platform 150 kg/m² 15000 kg

INSULATION WEIGHT ON OUTER SHELL

Outer Tank Diameter 46.8 m

Outer Tank height 20 m

Puf insulation Weight thickness 200 mm Density 40 kg/m³ 23630 kg

Mineral wool + ceramic wool Weight thickness 100 mm Density 150 kg/m³ 44580 kg

Total Insulation Weight 68210 kg

ANCHOR BOLTS

Number of anchors 120 Nos

Size of anchor length 2500 width 200 thick 20 mm

weight of anchors 9420 kg

CONCRETE WEIGHT BELOW INNER TANK

Volume concrete OD 45600 width 700 Thick 100 mm 9.87402571 m³

Density of Concrete 2000 kg/m³ Weight 19750 kg

Sand density 1800 kg/m³ Weight 276190 kg

CONCRETE WEIGHT BELOW OUTER TANK

Volume concrete OD 47200 width 1700 Thick 400 mm 97.2008767 m³

Density of Concrete 2200 kg/m³ Weight 213850 kg

Foam Glass Layers (mm) OD 43800 Thick 300 Density 128 kg/m² 57860 kg

Sand layer (mm) OD 43800 Thick 100 Density 1800 kg/m² 271220 kg

PREPARED BY TECHNIP INDIA LTD. 26/27

Preliminary calculation

Item Tag: 2000-FB-01/02

Item Description: 15000 MT PROPANE / BUTANE / PROPELENE STORAGE TANK

Project Name: SHV SUPER GAS

WEIGHT SUMMARY

INNER TANK SHELL

Shell (45200mm ID x 18600 mm Height) 256990 kg

Stiffeners 6000 kg

Internal Cage ladder with mid landing Platform + Annular Space Ladder 1350 kg

A 264340 kg

INNER TANK BOTTOM

Bottom (Annular Plate & Sketch Plates) 92890 kg

Concrete Leveling Course 295940 kg

B 388830 kg

OUTER TANK SHELL

Shell (46800mm ID x 20000 mm Height) 372353 kg

Stiffeners 32640 kg

Internal Cage ladder with mid landing Platform + Annular Space Ladder 7000 kg

Shell Insulation (PUF+CW+RW ) 68210 kg

C 480210 kg

OUTER TANK BOTTOM

Bottom (Annular plate & sketch plates) 115640 kg

Perlite Concrete blocks + fiberglass & vapour barrier felt 213850 kg

Foam Glass Layers 57860 kg

Sand layers 271220 kg

D 658570 kg

SUSPENDED DECK

Deck plates + Support of deck plates 159580 kg

Deck Fiber glass Insulation 39120 kg

E 198700 kg

DOME ROOF

Dome Roof plates 121333 kg

Dome Roof Rafters 130710 kg

Compression Ring 63861 kg

Nozzle on Dome Roof and Shell 30000 kg

External Platforms, ladders, Railing and supports 25310 kg

F 371214 kg

Anchor straps G 9420 kg

Inner Tank Operating Liquid Weight H 16735400 kg

Inner Tank Test Water Weight I 28281100 kg

EMPTY WEIGHT A+B+C +D +E+F+G 2371300 kg

EMPTY WEIGHT (Added with 2% Contigency) 2418800 kg

ERECTION WEIGHT (EXCLUDING PERLITE, FOAM GLASS, INSULATION & SAND) + 2% Contigen 1453600 kg

Operating Weight 19154200 kg

Test Weight 30699900 kg

PREPARED BY TECHNIP INDIA LTD. 27/27

Preliminary calculation

Vous aimerez peut-être aussi

- Calculation Sheet For Tank - API 620 12th EdDocument48 pagesCalculation Sheet For Tank - API 620 12th EdHamid Mansouri71% (17)

- Storage Tank CALC Api 650Document10 pagesStorage Tank CALC Api 650kuselanml100% (3)

- API 620 Tank CalculationsDocument11 pagesAPI 620 Tank CalculationsPrashant Malve64% (11)

- Sample Calc - API 620Document13 pagesSample Calc - API 620Natarajan RavisankarPas encore d'évaluation

- API 620 CalculationDocument114 pagesAPI 620 Calculationvikram100% (4)

- API 650 Tank Design 5Document44 pagesAPI 650 Tank Design 5Inamullah Khan93% (14)

- Api 620 - 2002Document12 pagesApi 620 - 2002ductaiutc100% (1)

- API 620 Tank CalculationsDocument3 pagesAPI 620 Tank CalculationsRichard Koehler0% (2)

- Tank Calc - Api650Document90 pagesTank Calc - Api650kamleshyadavmoney100% (3)

- API 650 Tank Design 1foot MethodDocument4 pagesAPI 650 Tank Design 1foot Methodjakjak67% (3)

- API 650 SheetDocument9 pagesAPI 650 SheetSalman AkramPas encore d'évaluation

- GERMANY TANK FULL REPORT-9 Updated As Per Client CommentDocument45 pagesGERMANY TANK FULL REPORT-9 Updated As Per Client CommentSalmanPas encore d'évaluation

- Storage Tank DesignDocument21 pagesStorage Tank Designravi456compPas encore d'évaluation

- Steel TankDocument75 pagesSteel Tankace1205Pas encore d'évaluation

- TD3 DIESEL API 650 Calculation ReportDocument72 pagesTD3 DIESEL API 650 Calculation ReportDaniel Gómez100% (3)

- API 650 Tank Design CalculationsDocument8 pagesAPI 650 Tank Design CalculationsVinoth Rajendra50% (4)

- Steel Storage Tanks Excel Sheet (API 650-2009) Free-09122209467Document42 pagesSteel Storage Tanks Excel Sheet (API 650-2009) Free-09122209467Hamid Mansouri100% (5)

- Tank Calc SheetDocument3 pagesTank Calc SheetHarrys Manalu100% (4)

- API2000 Tank Venting CalcsDocument5 pagesAPI2000 Tank Venting Calcsapminshull88% (8)

- API 650 Tank Design 5Document31 pagesAPI 650 Tank Design 5gon972001Pas encore d'évaluation

- API 650 Tank CalculationDocument30 pagesAPI 650 Tank Calculationsachin8389100% (2)

- Teto Api620Document3 pagesTeto Api620viniciuskurtPas encore d'évaluation

- API 620 Tank CalculationsDocument14 pagesAPI 620 Tank Calculationsblacx_rzky100% (1)

- Storage Tanks CalculationsDocument21 pagesStorage Tanks Calculationsjimallen21288% (26)

- Example Tank Calculation PDFDocument108 pagesExample Tank Calculation PDFPricop Cosmin100% (2)

- API 650 Design TanksDocument39 pagesAPI 650 Design TanksAhmedAli25% (4)

- Tank Venting According API 2000Document34 pagesTank Venting According API 2000Youssef Lagrini50% (2)

- API 650 Design TanksDocument51 pagesAPI 650 Design Tanksم.ذكى فضل ذكى100% (2)

- Supported Cone Roof (CS) Add.4Document21 pagesSupported Cone Roof (CS) Add.4skhurramq100% (2)

- Rectangular TankDocument38 pagesRectangular TankSam LowPas encore d'évaluation

- Double Deck CalDocument18 pagesDouble Deck Calranjitpandey0% (1)

- API-620 TanksDocument1 pageAPI-620 TanksMert Mengüç0% (1)

- API 620 DesignDocument19 pagesAPI 620 DesignrsubramaniPas encore d'évaluation

- Datasheet TankDocument1 pageDatasheet TankAnonymous lQiANQusxiPas encore d'évaluation

- 132KV Pi and Sa Steel Support Structures NewDocument6 pages132KV Pi and Sa Steel Support Structures NewNNANYELU CHINWUBAPas encore d'évaluation

- G225iexm08-Srp-M-Dwg-0003 - Rev A4Document55 pagesG225iexm08-Srp-M-Dwg-0003 - Rev A4BALASUBRAMANIAM MEGHANADHPas encore d'évaluation

- 4 DP VX-39 Dogis Pipe. Drift ID. With Int. Coated PipeDocument3 pages4 DP VX-39 Dogis Pipe. Drift ID. With Int. Coated Pipeyatinbhat100% (1)

- Checking of Pipe Wall Thickness API 5L X52Document1 pageChecking of Pipe Wall Thickness API 5L X52andriPas encore d'évaluation

- Final TestDocument15 pagesFinal TestSeptian FirdausPas encore d'évaluation

- Anchor LengthDocument1 pageAnchor LengthSaqib LaeeqPas encore d'évaluation

- Buried Pipe Design FinalDocument10 pagesBuried Pipe Design FinalDipesh100% (1)

- Submersible Slurry Pump Submersible Slurry Pump Submersible Slurry PumpDocument2 pagesSubmersible Slurry Pump Submersible Slurry Pump Submersible Slurry PumpErfolg SEPas encore d'évaluation

- Cold Casing Hot Casing: Ducting BOQDocument7 pagesCold Casing Hot Casing: Ducting BOQSalzPas encore d'évaluation

- F:/Aku/S V/Desain Perpipaan Thermal/Aku/Shell & Tube/Ainun Mustqaim - HtriDocument1 pageF:/Aku/S V/Desain Perpipaan Thermal/Aku/Shell & Tube/Ainun Mustqaim - HtriainunPas encore d'évaluation

- TK-TF1-001 - Calculation SheetDocument17 pagesTK-TF1-001 - Calculation SheetPhượng NguyễnPas encore d'évaluation

- Hoja de Datos para Conjunto Motor-Acople-Bomba Ansi 2196 Watercol 4X6-13 Mto 200522 Agua CorrosivaDocument4 pagesHoja de Datos para Conjunto Motor-Acople-Bomba Ansi 2196 Watercol 4X6-13 Mto 200522 Agua CorrosivaArturo Camacho SalazarPas encore d'évaluation

- BOQ Concrete Works (1) PricedDocument2 pagesBOQ Concrete Works (1) PricedAbdullah AkmalPas encore d'évaluation

- Rectangular Tank DesignDocument9 pagesRectangular Tank DesignMiguel EspañolPas encore d'évaluation

- 14-NPSHA VESSEL PR Is KnownDocument10 pages14-NPSHA VESSEL PR Is KnownAhm AnPas encore d'évaluation

- Technical Data Sheet For Shell and Tube Heat Exchager Design SpecificationDocument5 pagesTechnical Data Sheet For Shell and Tube Heat Exchager Design SpecificationSakthi VelPas encore d'évaluation

- PALL FILTER - Process Data SheetDocument2 pagesPALL FILTER - Process Data SheetThirukkumaranBalasubramanianPas encore d'évaluation

- 7203-6311-MDC-030KL TankDocument34 pages7203-6311-MDC-030KL TankDarshJhaPas encore d'évaluation

- 7 Inch TPCQDocument2 pages7 Inch TPCQRaymond Chu50% (4)

- VSL CalDocument50 pagesVSL CalEmrahCayboyluPas encore d'évaluation

- Gravity Wall (RCC) R0 (27!11!2017) 5m For TestingDocument81 pagesGravity Wall (RCC) R0 (27!11!2017) 5m For TestingLandon MitchellPas encore d'évaluation

- ER89-187-2 CL 9002 VacDocument1 pageER89-187-2 CL 9002 VacGabriel VejarPas encore d'évaluation

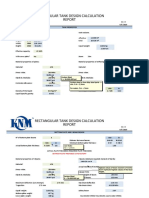

- Rectangular Tank Design Calculation: Tank Properties Tank Dimensions: Tank Volume: MM inDocument11 pagesRectangular Tank Design Calculation: Tank Properties Tank Dimensions: Tank Volume: MM inminov minovitchPas encore d'évaluation

- All Final DimensionDocument6 pagesAll Final Dimensionshailesh deshmukhPas encore d'évaluation

- Longwall Mining at Shallow Depth of Cover in IndiaD'EverandLongwall Mining at Shallow Depth of Cover in IndiaPas encore d'évaluation

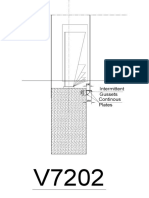

- v7202 Saddle CoverDocument1 pagev7202 Saddle CoverrsubramaniPas encore d'évaluation

- Idesa Parque Científico Tecnológico 33203 Gijón Ref Nº: 2/942-100A C/Profesor Potter Nº 105Document23 pagesIdesa Parque Científico Tecnológico 33203 Gijón Ref Nº: 2/942-100A C/Profesor Potter Nº 105rsubramaniPas encore d'évaluation

- Strong Acid System Troubleshooting: - Stick TestDocument3 pagesStrong Acid System Troubleshooting: - Stick TestrsubramaniPas encore d'évaluation

- CLip FEA AnalysisDocument12 pagesCLip FEA AnalysisrsubramaniPas encore d'évaluation

- Acid RegenerationDocument2 pagesAcid RegenerationrsubramaniPas encore d'évaluation

- Sample DrawingDocument1 pageSample DrawingrsubramaniPas encore d'évaluation

- Technology: Sulphuric Acid On The Web Technical Manual DKL Engineering, IncDocument2 pagesTechnology: Sulphuric Acid On The Web Technical Manual DKL Engineering, IncrsubramaniPas encore d'évaluation

- Storage/Loading/Unloading: Knowledge For The Sulphuric Acid Industry Sulphuric Acid On The WebDocument2 pagesStorage/Loading/Unloading: Knowledge For The Sulphuric Acid Industry Sulphuric Acid On The WebrsubramaniPas encore d'évaluation

- Cone DevelopmentDocument1 pageCone DevelopmentrsubramaniPas encore d'évaluation

- Weld Shear Stress Check For FAVID Clips Welded On CladDocument3 pagesWeld Shear Stress Check For FAVID Clips Welded On CladrsubramaniPas encore d'évaluation

- Metallurgical: Gas Cleaning Contact Section Acid System Gas CleaningDocument2 pagesMetallurgical: Gas Cleaning Contact Section Acid System Gas CleaningrsubramaniPas encore d'évaluation

- Moment Calculation Is 1893 Part4Document1 pageMoment Calculation Is 1893 Part4rsubramaniPas encore d'évaluation

- Bspd5500 Nozzle CalculationDocument24 pagesBspd5500 Nozzle CalculationrsubramaniPas encore d'évaluation

- Cone DevelopmentDocument1 pageCone DevelopmentrsubramaniPas encore d'évaluation

- External Pressure DesignDocument395 pagesExternal Pressure DesignrsubramaniPas encore d'évaluation

- API 620 DesignDocument19 pagesAPI 620 DesignrsubramaniPas encore d'évaluation

- Davit Pipe CalcDocument6 pagesDavit Pipe CalcrsubramaniPas encore d'évaluation

- Top Pipe MomentDocument2 pagesTop Pipe MomentrsubramaniPas encore d'évaluation

- NokDocument2 pagesNokrsubramaniPas encore d'évaluation

- Saddle Calc PD5500Document4 pagesSaddle Calc PD5500rsubramaniPas encore d'évaluation

- Anchor ChairDocument3 pagesAnchor ChairrsubramaniPas encore d'évaluation

- Focp SyllabusDocument23 pagesFocp SyllabusJayanthidevi PanneerselvamPas encore d'évaluation

- Bus RouteDocument5 pagesBus RoutersubramaniPas encore d'évaluation

- Thomas Turner - Mettalurgy of Iron and SteelDocument439 pagesThomas Turner - Mettalurgy of Iron and SteelrsubramaniPas encore d'évaluation

- Online Dynamic Security Assessment of Wind Integrated Power System UsingDocument9 pagesOnline Dynamic Security Assessment of Wind Integrated Power System UsingRizwan Ul HassanPas encore d'évaluation

- Watershed Conservation of Benguet VisDocument2 pagesWatershed Conservation of Benguet VisInnah Agito-RamosPas encore d'évaluation

- Bosch Injectors and OhmsDocument6 pagesBosch Injectors and OhmsSteve WrightPas encore d'évaluation

- Pressure-Dependent Leak Detection Model and Its Application To A District Water SystemDocument13 pagesPressure-Dependent Leak Detection Model and Its Application To A District Water SystemManjul KothariPas encore d'évaluation

- 240-56062705 RTV Silicone Rubber Insulator Coating and Shed Extender Supplier StandardDocument10 pages240-56062705 RTV Silicone Rubber Insulator Coating and Shed Extender Supplier StandardJane ChatsiriphatthanaPas encore d'évaluation

- The Invisible SunDocument7 pagesThe Invisible SunJay Alfred100% (1)

- Efektifitas Terapi Musik Klasik Terhadap Penurunan Tingkat HalusinasiDocument9 pagesEfektifitas Terapi Musik Klasik Terhadap Penurunan Tingkat HalusinasiAnis RahmaPas encore d'évaluation

- List of Important Books of PhysicsDocument6 pagesList of Important Books of PhysicsAbubakar Mughal0% (1)

- Astn/Ason and Gmpls Overview and Comparison: By, Kishore Kasi Udayashankar Kaveriappa Muddiyada KDocument44 pagesAstn/Ason and Gmpls Overview and Comparison: By, Kishore Kasi Udayashankar Kaveriappa Muddiyada Ksrotenstein3114Pas encore d'évaluation

- DICKSON KT800/802/803/804/856: Getting StartedDocument6 pagesDICKSON KT800/802/803/804/856: Getting StartedkmpoulosPas encore d'évaluation

- Disney - QMDocument14 pagesDisney - QMSyarifuddin Zulkifli0% (1)

- Selecting Appropriate Instructional Materials For Edukasyong Pantahanan at Pangkabuhayan/ Technology and Livelihood EducationDocument35 pagesSelecting Appropriate Instructional Materials For Edukasyong Pantahanan at Pangkabuhayan/ Technology and Livelihood EducationJhenn Mhen Yhon100% (1)

- Contoh Label Sensus 2022Document313 pagesContoh Label Sensus 2022Ajenk SablackPas encore d'évaluation

- Classroom Debate Rubric Criteria 5 Points 4 Points 3 Points 2 Points 1 Point Total PointsDocument1 pageClassroom Debate Rubric Criteria 5 Points 4 Points 3 Points 2 Points 1 Point Total PointsKael PenalesPas encore d'évaluation

- Lalkitab Varshphal Chart PDFDocument6 pagesLalkitab Varshphal Chart PDFcalvinklein_22ukPas encore d'évaluation

- 2SA1016Document4 pages2SA1016catalina maryPas encore d'évaluation

- Chen 2021Document13 pagesChen 2021Aitor UzkudunPas encore d'évaluation

- In Search of Begum Akhtar PDFDocument42 pagesIn Search of Begum Akhtar PDFsreyas1273Pas encore d'évaluation

- Hooke's LawDocument1 pageHooke's LawAnan BarghouthyPas encore d'évaluation

- Gilbert Cell Design PDFDocument22 pagesGilbert Cell Design PDFvysPas encore d'évaluation

- Reading Proficiency Level of Students: Basis For Reading Intervention ProgramDocument13 pagesReading Proficiency Level of Students: Basis For Reading Intervention ProgramSONY JOY QUINTOPas encore d'évaluation

- Sentence Diagramming:: Prepositional PhrasesDocument2 pagesSentence Diagramming:: Prepositional PhrasesChristylle RomeaPas encore d'évaluation

- Puratattva No 41Document3 pagesPuratattva No 41ultimategoonPas encore d'évaluation

- Data Sheet: Item N°: Curve Tolerance According To ISO 9906Document3 pagesData Sheet: Item N°: Curve Tolerance According To ISO 9906Aan AndianaPas encore d'évaluation

- 9300AE 10-30kseis LDN 2005 PDFDocument2 pages9300AE 10-30kseis LDN 2005 PDFDoina ClichiciPas encore d'évaluation

- Planning Theory Syllabus - 2016Document24 pagesPlanning Theory Syllabus - 2016LakshmiRaviChanduKolusuPas encore d'évaluation

- Slipform Construction TechniqueDocument6 pagesSlipform Construction TechniqueDivyansh NandwaniPas encore d'évaluation

- AZ 103T00A ENU TrainerHandbook PDFDocument403 pagesAZ 103T00A ENU TrainerHandbook PDFlongvietmt100% (2)

- ZH210LC 5BDocument24 pagesZH210LC 5BPHÁT NGUYỄN THẾ0% (1)

- Gauss' Law: F A FADocument14 pagesGauss' Law: F A FAValentina DuartePas encore d'évaluation