Académique Documents

Professionnel Documents

Culture Documents

Assignment 1 (Perot, Ikea, CPM)

Transféré par

Aditya WibisanaCopyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Assignment 1 (Perot, Ikea, CPM)

Transféré par

Aditya WibisanaDroits d'auteur :

Formats disponibles

I Gde Nyoman Aditya Wibisana

29117424

YP 58 A

Chapter 3: Number 11

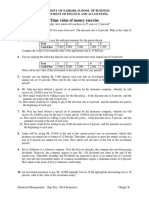

Development Cost $20,000,000.00

Pilot Testing $5,000,000.00

Debug $3,800,000.00

Ramp-up Cost $3,000,000.00

Advance Marketing $6,600,000.00

Marketing and Support $1,000,000.00 per year

Unit Production Cost Year 1 $655.00

Unit Production Cost Year 2 $545.00

Unit Price Year 1 $820.00

Unit Price Year 2 $650.00

Sales and Production Volume Year 1 250

Sales and Production Volume Year 2 150

Interest Rate 10%

This table explains about Patay2 Chip Product Estimates, and the next table will explain about

Patay2 Chip project timing from development until production and sales.

Year 1 Year 2 Year 3 Year 4

Patay2 Chip

1st Half 2nd Half 1st Half 2nd Half 1st Half 2nd Half 1st Half 2nd Half

Development

Pilot Testing

Debug

Ramp-up

Advance Marketing

Marketing and Support

Production and Sales

February 8th, 2018 1

a. What are the yearly cash flows and their present value (discounted at 10%) of this project? What is the net present value?

Year 1 Year 2 Year 3 Year 4

Patay2 Chip

1st Half 2nd Half 1st Half 2nd Half 1st Half 2nd Half 1st Half 2nd Half

Development

Pilot Testing

Debug

Ramp-up

Advance Marketing

Marketing and Support

Production and Sales

Year 1 Year 2 Year 3 Year 4

Patay2 Chip

1st Half 2nd Half 1st Half 2nd Half 1st Half 2nd Half 1st Half 2nd Half

Development -$5,000,000.00 -$5,000,000.00 -$5,000,000.00 -$5,000,000.00

Pilot Testing -$2,500,000.00 -$2,500,000.00

Debug -$1,900,000.00 -$1,900,000.00

Ramp-up -$3,000,000.00

Advance Marketing -$6,600,000.00

Marketing and Support -$500,000.00 -$500,000.00 -$500,000.00 -$500,000.00

Unit Production Cost -$655.00 -$655.00 -$545.00 -$545.00

Production Volume 125,000 125,000 75,000 75,000

Production Cost -$81,875,000.00 -$81,875,000.00 -$40,875,000.00 -$40,875,000.00

Sales Volume 125,000 125,000 75,000 75,000

Unit Price $820.00 820 650 650

Sales Revenue $102,500,000.00 $102,500,000.00 $48,750,000.00 $48,750,000.00

Period Cash Flow -$5,000,000.00 -$5,000,000.00 -$9,400,000.00 -$19,000,000.00 $20,125,000.00 $20,125,000.00 $7,375,000.00 $7,375,000.00

PV Year 1 (r = 5% per semester) -$4,761,904.76 -$4,535,147.39 -$8,120,073.43 -$15,631,347.02 $15,768,464.10 $15,017,584.86 $5,241,274.81 $4,991,690.29

Time 1 2 3 4 5 6 7 8

Project NPV $7,970,541.46

Based on the table, in the first 2 years the period cash flow is minus because Parot Corp. has not started sales and the value of project

NPV is $7.970.541,46 it means the project should be accepted as it will increase profit and therefore value of the company.

February 8th, 2018 2

b. Perot’s engineers have determined that spending $10 million more on development will allow them to add even more advance

features. Having a more advanced chip will allow them to price the chip $50 higher in both years. Is it worth the additional

investment?

Year 1 Year 2 Year 3 Year 4

Patay2 Chip

1st Half 2nd Half 1st Half 2nd Half 1st Half 2nd Half 1st Half 2nd Half

Development

Pilot Testing

Debug

Ramp-up

Advance Marketing

Marketing and Support

Production and Sales

Year 1 Year 2 Year 3 Year 4

Patay2 Chip

1st Half 2nd Half 1st Half 2nd Half 1st Half 2nd Half 1st Half 2nd Half

Development -$7,500,000.00 -$7,500,000.00 -$7,500,000.00 -$7,500,000.00

Pilot Testing -$2,500,000.00 -$2,500,000.00

Debug -$1,900,000.00 -$1,900,000.00

Ramp-up -$3,000,000.00

Advance Marketing -$6,600,000.00

Marketing and Support -$500,000.00 -$500,000.00 -$500,000.00 -$500,000.00

Unit Production Cost -$655.00 -$655.00 -$545.00 -$545.00

Production Volume 125,000 125,000 75,000 75,000

Production Cost -$81,875,000.00 -$81,875,000.00 -$40,875,000.00 -$40,875,000.00

Sales Volume 125,000 125,000 75,000 75,000

Unit Price $870.00 $870.00 $700.00 $700.00

Sales Revenue $108,750,000.00 $108,750,000.00 $52,500,000.00 $52,500,000.00

Period Cash Flow -$7,500,000.00 -$7,500,000.00 -$11,900,000.00 -$21,500,000.00 $26,375,000.00 $26,375,000.00 $11,125,000.00 $11,125,000.00

PV Year 1 (r = 5% per semester) -$7,142,857.14 -$6,802,721.09 -$10,279,667.42 -$17,688,103.21 $20,665,502.64 $19,681,431.09 $7,906,329.80 $7,529,837.90

Time 1 2 3 4 5 6 7 8

Project NPV $13,869,752.57

February 8th, 2018 3

Perot will be spending $2.500.000 more on development every semester, then the price will be increasing from $820 to $870 for

year 1 and $650 to $700 for year 2. So, the project NPV will be increasing too from $7.970.541,46 become $13.869.752,57 and

it means the plan should be accepted and it will increase profit.

c. If sales are only 200.000 the first year and 100.000 the second year, would Perot still do the project?

Year 1 Year 2 Year 3 Year 4

Patay2 Chip

1st Half 2nd Half 1st Half 2nd Half 1st Half 2nd Half 1st Half 2nd Half

Development

Pilot Testing

Debug

Ramp-up

Advance Marketing

Marketing and Support

Production and Sales

Year 1 Year 2 Year 3 Year 4

Patay2 Chip

1st Half 2nd Half 1st Half 2nd Half 1st Half 2nd Half 1st Half 2nd Half

Development -$7,500,000.00 -$7,500,000.00 -$7,500,000.00 -$7,500,000.00

Pilot Testing -$2,500,000.00 -$2,500,000.00

Debug -$1,900,000.00 -$1,900,000.00

Ramp-up -$3,000,000.00

Advance Marketing -$6,600,000.00

Marketing and Support -$500,000.00 -$500,000.00 -$500,000.00 -$500,000.00

Unit Production Cost -$655.00 -$655.00 -$545.00 -$545.00

Production Volume 125,000 125,000 75,000 75,000

Production Cost -$81,875,000.00 -$81,875,000.00 -$40,875,000.00 -$40,875,000.00

Sales Volume 100 100 50 50

Unit Price $870.00 $870.00 $700.00 $700.00

Sales Revenue $87,000.00 $87,000.00 $35,000.00 $35,000.00

Period Cash Flow -$7,500,000.00 -$7,500,000.00 -$11,900,000.00 -$21,500,000.00 -$82,288,000.00 -$82,288,000.00 -$41,340,000.00 -$41,340,000.00

PV Year 1 (r = 5% per semester) -$7,142,857.14 -$6,802,721.09 -$10,279,667.42 -$17,688,103.21 -$64,474,801.19 -$61,404,572.56 -$29,379,566.19 -$27,980,539.23

Time 1 2 3 4 5 6 7 8

Project NPV ($225,152,828.02)

February 8th, 2018 4

If Perot reduce sales from 250 become 200 at the first year and 150 become 100 it will reduce the NPV too become -

$225.152.828,02. So, Perot will not do the project.

February 8th, 2018 5

Chapter 3: Ikea Design and Pricing

1. What are IKEA’s competitive priorities?

IKEA's competitive priority is to create quality products with low prices. they are able to

achieve this by creating a cheap product without making customers feel that the goods are

cheap. The process of minimizing costs begins at the beginning of the formation of new

products and will be carried out continuously into the entire production process undertaken.

IKEA has the slogan "Low price with meaning". this requires a balance of three things: the

whole thing, the design, and the function.

2. Describe IKEA’s process for developing a new product

a. IKEA starts the process by picking how much the new product will cost. This will help to

determine materials used, design and even the colors that are going to be used.

b.The next step is to choose a manufacturer from their network of manufactures. This is done

by determining which manufacturer can most efficiently produce the new product.

c. Next they design the product, keeping in everything in mind from the production, packaging,

and even the shipping. Every inch of the product is looked over so that they are able to get

the most out of the manufacturing, shipping, and the storage of the new product.

d. Finally they ship it. IKEA has a vast amount of nice products that do need to be assembled

once purchased because they are committed not shipping by air. They even vacuum seal

certain items to get them as flat as possible for shipping.

3. What are additional features of the IKEA concept that contribute to creating exceptional value

for customer?

The way that the company ships their products is a major contributor. By shipping flat, they

ship only 65% full containers and by strategically placing their distribution centers near ports,

railways, and highways IKEA is able to ship with great efficiency. Getting the maximum

amount of products shipped out, at the right time to the right stores keeping their prices 20 the

30 percent lower than their competition is another contributing factor to the IKEA concept.

February 8th, 2018 6

4. What should be important criteria for selecting a site for an IKEA store?’

a. adequate land area

in building the IKEA building, it takes a large area of land to cover the storefront of two

floors with the show room and market-hall above and the warehouse below. In addition to

the IKEA store there is a restaurant that sells several types of Swedish food including typical

Swedish meatball, daycare facilities and information outposts for consulting design and

product selection

b. location and access to IKEA

IKEA reduces the cost of the products imposed on its consumers by reducing the variable

costs of its products. One of them is distribution cost. by positioning its outlets in the easy

transportation path of goods then IKEA can reduce distribution costs and supply of goods.

In addition, the location can also be easily reached by consumers although the distance may

be traveled further from other similar outlets. Compensation to the consumers in the form

of the concept of facilities "one stop shopping" owned by IKEA. quantity, size, and quality

of competition also need attention. and population trends in trading areas.

Chapter 4: Number 8

ACT A M (MOST B EXPECTED

DESINATION PREDECESSOR (MINIMUM) LIKELY) (MAXIMIUM TIME

A - 1 3 5 3

B - 1 2 3 2

C A 1 2 3 2

D A 2 3 4 3

E B 3 4 11 5

F C,D 3 4 5 4

G D,E 1 4 6 4

H F,G 2 4 5 4

February 8th, 2018 7

a. Draw the network

3 5

C (2)

0 3 6 10

5 7

A (3) F (4)

3 6

7 11 11 15

2 5 D (8)

H (4)

4 7

0 2 2 7 7 11

11 15

B (2) E (5) G (4)

0 2 2 7 7 11

b. What is the critical path?

B-E-G-H

c. What is the expected project completion time?

B-E-G-H = 2+5+4+4 = 15 days

d. What is the probability of completing this project within 16 days?

PROB PROB

VAR σ Z WEEKS(D)

(EXCEL) (EXCEL)

CRITICAL

PATH B-E-G-H 2.83 1.683250823 0.594088526 16 72.38% 27.62%

The probability of completing this project within 16 days is 27.62%

February 8th, 2018 8

Vous aimerez peut-être aussi

- (USD) 2019 Q4 TikTok Global Rate Card PDFDocument3 pages(USD) 2019 Q4 TikTok Global Rate Card PDFDeryApriliansyahVaryanaddyPas encore d'évaluation

- Sarfaesi ActDocument10 pagesSarfaesi ActramyaPas encore d'évaluation

- Group Assignment Logistic and Supply Chain Management ALS2023Document29 pagesGroup Assignment Logistic and Supply Chain Management ALS2023邢益润Pas encore d'évaluation

- Questions Chapter 3 No.11: PEROT CORPORATION - Patay2 Chip ProjectDocument6 pagesQuestions Chapter 3 No.11: PEROT CORPORATION - Patay2 Chip ProjectddPas encore d'évaluation

- Midterm Exam - Saeful Aziz (29118389) PDFDocument44 pagesMidterm Exam - Saeful Aziz (29118389) PDFSaeful AzizPas encore d'évaluation

- Digital AssignmentDocument7 pagesDigital AssignmentCarol AranhaPas encore d'évaluation

- CH 3 Ed Peelen CRM As Business StrategyDocument10 pagesCH 3 Ed Peelen CRM As Business StrategyMohit AnandPas encore d'évaluation

- Strategy and CompetitionDocument88 pagesStrategy and CompetitionmeysamsafariPas encore d'évaluation

- Practice of Ratio Analysis, InterpretationDocument4 pagesPractice of Ratio Analysis, InterpretationZarish AzharPas encore d'évaluation

- Diverse Populations, Genders, Skin Types and Ethnic SpecificitiesDocument10 pagesDiverse Populations, Genders, Skin Types and Ethnic SpecificitiesAsif AliPas encore d'évaluation

- FDDGDocument7 pagesFDDGlistenkidPas encore d'évaluation

- Time Value of Money QuestionsDocument2 pagesTime Value of Money QuestionsDavidPas encore d'évaluation

- Customer Services of ICICI and HDFC BankDocument64 pagesCustomer Services of ICICI and HDFC BankShahzad Saif100% (1)

- Kapoorr@wharton - Upenn.edu: Anagement Echnology TrategyDocument8 pagesKapoorr@wharton - Upenn.edu: Anagement Echnology TrategyChaucer19Pas encore d'évaluation

- Long-Term Challenges To Food Security and Rural Livelihoods in Sub-Saharan AfricaDocument8 pagesLong-Term Challenges To Food Security and Rural Livelihoods in Sub-Saharan AfricaAgripolicyoutreachPas encore d'évaluation

- Indicator Library: How To Win in The Stock MarketDocument11 pagesIndicator Library: How To Win in The Stock MarketPeter FrankPas encore d'évaluation

- Management Assignment On Ikea: Submitted To: Academic College of LondonDocument15 pagesManagement Assignment On Ikea: Submitted To: Academic College of LondonDhruval Pradip VyasPas encore d'évaluation

- CH 11 Communicating Customer ValueDocument24 pagesCH 11 Communicating Customer ValueLuay MaaniPas encore d'évaluation

- MKT460 MID1 by Nafis Faisal Choudhury 1632855030 PDFDocument6 pagesMKT460 MID1 by Nafis Faisal Choudhury 1632855030 PDFFahim HasnatPas encore d'évaluation

- Lexus Audit 3 1Document28 pagesLexus Audit 3 1api-292900866Pas encore d'évaluation

- Airbus VS BoeingDocument8 pagesAirbus VS BoeingImaad Ali KhanPas encore d'évaluation

- Consumer Behaviour by Jayakrishnan S (CB) PDFDocument8 pagesConsumer Behaviour by Jayakrishnan S (CB) PDFRahul SinghPas encore d'évaluation

- Introduction To CBHCM - AG2-RBDocument16 pagesIntroduction To CBHCM - AG2-RBadamobirkPas encore d'évaluation

- Project Proposal (IKEA)Document4 pagesProject Proposal (IKEA)Ni007ckPas encore d'évaluation

- Communicating Value-IMP SLIDESDocument44 pagesCommunicating Value-IMP SLIDESKaran J. KikavatPas encore d'évaluation

- Production and Costs in Long RunDocument20 pagesProduction and Costs in Long RunThomas WuPas encore d'évaluation

- Unilever Unplugged Case Study 2015 - PureItDocument4 pagesUnilever Unplugged Case Study 2015 - PureItRaviSinghPas encore d'évaluation

- Chapter6 ConceptGenerationDocument47 pagesChapter6 ConceptGenerationAntaryami Mishra50% (2)

- MC Kinsey 7s Framework in Corporate Planning and Policy: Bishwajit BaishyaDocument4 pagesMC Kinsey 7s Framework in Corporate Planning and Policy: Bishwajit BaishyaAung Zaw HtwePas encore d'évaluation

- SCM - AddendumDocument13 pagesSCM - Addendumakas84Pas encore d'évaluation

- HD BM - Operations Management - Sri5151 - st20208570Document19 pagesHD BM - Operations Management - Sri5151 - st20208570Kasun WijerathnaPas encore d'évaluation

- Financial Management AssignmentDocument17 pagesFinancial Management AssignmentSagar ChhabraPas encore d'évaluation

- Ford Retrenchment Strategy 1627763841Document7 pagesFord Retrenchment Strategy 1627763841Vaibhav ManglaPas encore d'évaluation

- Oprah WinfreyDocument1 pageOprah WinfreyJean Tine MoralesPas encore d'évaluation

- Rahma Putri Hapsari - 29120450 - Task 1Document4 pagesRahma Putri Hapsari - 29120450 - Task 1Rahma Putri HapsariPas encore d'évaluation

- Apple Case StudyDocument6 pagesApple Case StudySanket JadhavPas encore d'évaluation

- Performance Measurement in Decentralized OrganizationsDocument56 pagesPerformance Measurement in Decentralized OrganizationsAhmed Mostafa ElmowafyPas encore d'évaluation

- ACC3015 Accunting and Finance For Managers AS1Document26 pagesACC3015 Accunting and Finance For Managers AS1Thara DasanayakaPas encore d'évaluation

- Shailin Mohan - 6335934 Nokia Case StudyDocument3 pagesShailin Mohan - 6335934 Nokia Case StudymarwenPas encore d'évaluation

- Pestel Analysis of Tata SteelDocument9 pagesPestel Analysis of Tata SteelEshika MantriPas encore d'évaluation

- Case Study NoDocument7 pagesCase Study NoKD TricksPas encore d'évaluation

- Kelani Vs ACLDocument39 pagesKelani Vs ACLSasindu GimhanPas encore d'évaluation

- Communicating Customer Value Integrated Marketing Communications StrategyDocument24 pagesCommunicating Customer Value Integrated Marketing Communications StrategyM.WASEEM YOUSAFPas encore d'évaluation

- Strategy Corp - Case GuideDocument16 pagesStrategy Corp - Case GuideDiego BKPas encore d'évaluation

- MicroEconomics End Term ProjectDocument13 pagesMicroEconomics End Term ProjectOm PrakashPas encore d'évaluation

- Global Footprint of Pran RFL GroupDocument23 pagesGlobal Footprint of Pran RFL GroupShaffyPas encore d'évaluation

- ABC Energy LimitedDocument2 pagesABC Energy LimitedSaudamini JenaPas encore d'évaluation

- Value ChainDocument135 pagesValue ChainJunaid SabriPas encore d'évaluation

- IENG 577 Homework 3: and Payables To Be 10% of The Cost of Goods Sold. Billingham's Marginal Corporate Tax Rate IsDocument1 pageIENG 577 Homework 3: and Payables To Be 10% of The Cost of Goods Sold. Billingham's Marginal Corporate Tax Rate IsAbdu AbdoulayePas encore d'évaluation

- Al Abrar Tuition CentreDocument18 pagesAl Abrar Tuition CentreNur FahanaPas encore d'évaluation

- MBA Students Thesis 2005Document11 pagesMBA Students Thesis 2005rajansingh52Pas encore d'évaluation

- SM Strategy ExecutionDocument64 pagesSM Strategy ExecutionMaulik BuddhdevPas encore d'évaluation

- Descriptive Statistics: Case Problem: Heavenly Chocolates Website TrafficDocument4 pagesDescriptive Statistics: Case Problem: Heavenly Chocolates Website TrafficArbazuddin shaikPas encore d'évaluation

- Arla FoodsDocument2 pagesArla FoodsKumara Raja0% (2)

- Economics Essay GuideDocument7 pagesEconomics Essay GuideTarcayani PrebagaranPas encore d'évaluation

- AC7085 - ACL Cables PLCDocument16 pagesAC7085 - ACL Cables PLCDevinda HerathPas encore d'évaluation

- Conducting A Feasibility StudyDocument10 pagesConducting A Feasibility Studysignup0123456Pas encore d'évaluation

- People & Organizations Assignment 03Document3 pagesPeople & Organizations Assignment 03chaniluPas encore d'évaluation

- Competitive Analysis of AppleDocument11 pagesCompetitive Analysis of AppleSalem OmarPas encore d'évaluation

- Esquire GroupDocument3 pagesEsquire GroupNazmul Hasan OmePas encore d'évaluation

- Nepal Telcomm ServicesDocument37 pagesNepal Telcomm ServicesMadhupriya DugarPas encore d'évaluation

- Case StudyDocument3 pagesCase Studynazia malikPas encore d'évaluation

- 2Document1 page2bomzterPas encore d'évaluation

- Resource 5 (Brand Equity)Document2 pagesResource 5 (Brand Equity)golfingbossPas encore d'évaluation

- Investment CaseDocument7 pagesInvestment Caseafif12Pas encore d'évaluation

- Product Development ModelsDocument17 pagesProduct Development ModelsKUNAL PATELPas encore d'évaluation

- Aqualisa Quartz Simply A Better Shower SpreadsheetDocument6 pagesAqualisa Quartz Simply A Better Shower SpreadsheetZimam Khasin ArsyadPas encore d'évaluation

- Just Us! CafeDocument3 pagesJust Us! CafeAditya WibisanaPas encore d'évaluation

- I Gde Nyoman Aditya Wibisana Big DataDocument1 pageI Gde Nyoman Aditya Wibisana Big DataAditya WibisanaPas encore d'évaluation

- K9 Fuel BarDocument2 pagesK9 Fuel BarAditya WibisanaPas encore d'évaluation

- I Gde Nyoman Aditya Wibisana HubspotDocument2 pagesI Gde Nyoman Aditya Wibisana HubspotAditya WibisanaPas encore d'évaluation

- Aqua LisaDocument2 pagesAqua LisaAditya WibisanaPas encore d'évaluation

- Ifrs 9 - Financial Instruments Ias 38 and Ifrs 7Document43 pagesIfrs 9 - Financial Instruments Ias 38 and Ifrs 7JaaPas encore d'évaluation

- M&M (SA) StrategyDocument5 pagesM&M (SA) StrategyKavita SinghPas encore d'évaluation

- Aim6201 HW3Document2 pagesAim6201 HW3Dana Turet100% (1)

- The Macroeconomic Impact of Remittances in The PhilippinesDocument46 pagesThe Macroeconomic Impact of Remittances in The PhilippinesBrian Jason PoncePas encore d'évaluation

- Transfer To General Reserve RulesDocument2 pagesTransfer To General Reserve Rulesamey2225Pas encore d'évaluation

- On Blue Green Book - DredgingDocument19 pagesOn Blue Green Book - DredgingSandeep RaoPas encore d'évaluation

- Finland Nokia Case StudyDocument11 pagesFinland Nokia Case StudyBitan BanerjeePas encore d'évaluation

- Financial ModelingDocument6 pagesFinancial ModelingVân TrườngPas encore d'évaluation

- Project On KFCDocument24 pagesProject On KFCAk Abhi KhannaPas encore d'évaluation

- Poa - Fast Track (2 Years)Document44 pagesPoa - Fast Track (2 Years)Yenny TigaPas encore d'évaluation

- The Timing of Asset Sales and Earnings MDocument8 pagesThe Timing of Asset Sales and Earnings MRizqullazid MufiddinPas encore d'évaluation

- Exercise 1Document10 pagesExercise 1Sugim Winata EinsteinPas encore d'évaluation

- Corporate BankingDocument100 pagesCorporate Bankingvinesh1515100% (3)

- Director Report PVT LTD FinalDocument22 pagesDirector Report PVT LTD FinalKunalKumarPas encore d'évaluation

- Practice Question For Midterm Test - FA - 28.03Document4 pagesPractice Question For Midterm Test - FA - 28.03TRANG NGUYỄN THỊ HÀPas encore d'évaluation

- Chapter 6: Government Influence On Exchange Rate Exchange Rate System Fixed Exchange Rate SystemDocument5 pagesChapter 6: Government Influence On Exchange Rate Exchange Rate System Fixed Exchange Rate SystemMayliya Alfi NurritaPas encore d'évaluation

- Myanmar Business Today - Vol 2, Issue 22 PDFDocument32 pagesMyanmar Business Today - Vol 2, Issue 22 PDFMyanmar Business TodayPas encore d'évaluation

- Chapter 01 Test Bank - StaticDocument9 pagesChapter 01 Test Bank - StaticSun BluePas encore d'évaluation

- Credit OsDocument23 pagesCredit OsPatty AlayoPas encore d'évaluation

- Thu Cs CostDocument31 pagesThu Cs CostthulasikPas encore d'évaluation

- A Pathwayout of PovertyDocument57 pagesA Pathwayout of PovertyLori MayPas encore d'évaluation

- Investment Bank in BangladeshDocument13 pagesInvestment Bank in BangladeshTopu RoyPas encore d'évaluation

- Introduction of Euro As Common CurrencyDocument53 pagesIntroduction of Euro As Common Currencysuhaspatel84Pas encore d'évaluation

- Lakshwiz - D Street - AVARTAN 2022Document7 pagesLakshwiz - D Street - AVARTAN 2022Jenil RitaPas encore d'évaluation