Académique Documents

Professionnel Documents

Culture Documents

Chapter01 Electinst

Transféré par

Chidiebere Samuel OkogwuTitre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Chapter01 Electinst

Transféré par

Chidiebere Samuel OkogwuDroits d'auteur :

Formats disponibles

SITP Electrical Installation

1.0 ELECTRICAL DISTRIBUTION SYSTEM.

Most consumers in Nigeria receive an electricity supply derive from a high voltage

three-phase 50 Hz distribution system. Industrial consumers with heavy load

demands are given a supply at a higher voltage that is either used for a works

distribution system with step-down transformer substations at different points, or is

stepped down in one main substation feeding a low distribution system.

1.1 Supply voltages

For the largest industrial plants, the incoming supply may be derived from a local

transmission system operating at, say 33kV or 66kV, and is stepped down to a lower

high voltage for the works distribution system. In some cases, the distribution system

voltage of, say, 6.6kV or 11kV is used directly for high voltage motors and

equipment, or is stepped down to about 3.3kV.

The low voltage (e.g. 415V) supply is derived from the star-connected secondary

winding of the step-down transformer and it may be distributed by either a three-wire

system (Fig. 1) or a four-wire system (Fig. 2). With the three-wire system the voltage

is the same between any two phases so that it can be used to supply both three-

phase and single -phase equipment at the same voltage. With the four-wire system

the voltage between one phase and neutral is that produced by one phase of the

transformer secondary winding so that the phase voltage equals 3 times the

phase-to-neutral voltage. Therefore, with the standard low voltage of 415V between

415

phases, the phase-to-neutral voltage is = 240V.

3

Omoigui, M Page 1 of 23 ©Univation

SITP Electrical Installation

In general, the three-wire system is used only to supply three-phase loads while the

four-wire system provides both for 415V three-phase loads and 240V single-phase

loads. A four-wire 415/240V supply is given to premises where there is a

requirement for three-phase equipment or where the demand is high enough to

necessitate the introduction of the 415V system into the consumer's premises. In the

interests of safety, this is avoided when possible and the supply is given by a 240V

phase-and-neutral cable.

Low voltage (l.v.) is defined as voltages corresponding to 500-600V a.c. between

conductors and earth or 50-1000V ac. between conductors, or for 120-900V d.c.

between conductors and earth or 120-1500V d.c. between conductors.

Voltages above l. v. are considered high voltage. Extra-Iow voltages (e.l.v) are those

not above 50V a.c. or 120V d.c.

To enable electricity to be used safely and efficiently, a distribution system must be

planned and installed in accordance with whatever statutory regulations applicable to

the use of electricity in the premises involved.

1.2 Industrial distribution systems

A typical arrangement of a distribution system for a large industrial plant is shown in

Figure 3. The high-voltage switchboard could be supplied from the ring-main 11 k V

feeders forming part of the network of the local electricity authority or it could be

located in one substation of a number supplied from a ring main, providing an 11 k V

distribution system around the plant. In the latter case the 11 k V supply would be

derived from a main substation stepping down from 33kV, 66kV or 132kV. The

Omoigui, M Page 2 of 23 ©Univation

SITP Electrical Installation

magnitude of the load demand, determines from which system the incoming supply

would be provided.

With the arrangement of Figure 3., each of the transformers would have a capacity

of, say 1000k V A. The h. v. switchboard forms part of a ring main system with one

circuit breaker controlling the incoming supply and the other the outgoing supply. A

bus-section circuit breaker is normally closed but would be opened, together with the

appropriate feeder circuit breaker to isolate a transformer from the h. v. system.

Low-voltage circuit-breakers control the output from each transformer and each of

the four feeders, and the I. v. switchboard includes a bus-section circuit-breaker that

is normally open to limit the short-circuit current in the event of a fault on the I. v.

system. When the total load is such that it can be carried by one transformer, the

bus-section circuit-breaker is closed and one transformer is switched out.

In many industrial plants the load is such that only one substation is needed and this

may contain only one transformer. Similarly, only one transformer may be installed in

each of the substations fed from a works high-voltage ring main. The arrangement of

the system depends on whether it is imperative to maintain continuously a supply to

all parts of an industrial plant. If this is the case, then a complicated distribution

system is necessary.

Omoigui, M Page 3 of 23 ©Univation

SITP Electrical Installation

Figure.4 shows a system designed to ensure the availability of a works supply in all

circumstances except the complete loss of the incoming supply. Distribution is by a

h. v. ring main with automatic circuit-breakers to provide for switching sections as

required in the event of faults or the need to carry out maintenance. With appropriate

fault protection schemes the system can be operated as a closed ring main so that in

the event of cable fault the section involved is disconnected at each end without loss

of supply.

Alternatively, the system can be operated as an open ring main, with simpler fault

protection. The ring main would be opened at a point where each out-going feeder

would be equally loaded. A cable fault would interrupt the supply to certain

substations but after the operation of the appropriate circuit-breakers to isolate the

faulty section, supply would be restored by closing the circuit-breaker that is normally

open to divide the ring main. As a further safeguard there are three transformers in

each substation and if necessary the I. v. supply to a particular I. v. switchboard can

be maintained by an interconnection with the I. v. switchboard in another substation.

Omoigui, M Page 4 of 23 ©Univation

SITP Electrical Installation

This interconnection also permits all the h. v. switch gear and transformer in a

substation to be isolated for maintenance while the supply is still available from the I.

v. switchboard

Every circuit requires a circuit protective conductor (c.p.c.) connected to the

consumer's terminals. This provision also applies to all outlet points including lighting

circuits, which must have a c.p.c. run to all switch and light outlets. To enable them

to be connected to the protective conductor, an earth terminal must be provided in all

insulated switch boxes and also in metal switch boxes where there is not a solid

conduit connection to the box and cover plate.

1.3 Low-voltage distribution circuits

In industrial distribution systems three-wire and four-wire circuits supply three-phase

and single phase low-voltage power to the production plant. These circuits may be

used to feed main distribution boards; or as sub-mains to sub-distribution boards

supplying two or more final circuits; or as final circuits.

In practice, some main three-phase circuits may serve as final circuits supplying

large motors or other individual loads (Figure. 5.) or, as shown in Figure. 6, a sub-

main may supply a group motor control board when this is a convenient unit to

Omoigui, M Page 5 of 23 ©Univation

SITP Electrical Installation

provide centralized starting and control facilities for motors that operate together to

power a production process. It is a particularly suitable unit when motors have to be

started in a certain sequence and must all be shut down if one fails. To provide a

supply for lighting and other equipment in the area used for the production process,

a sub-distribution board can be connected to the busbars of the group motor control

board.

For the single-phase supplies, the arrangement shown in Figure.7 can be used;

protective conductors are omitted for clarity .The broken line represents that part of

the system where the main I. v. switchboard is located. From the three-phase four-

wire board, the single-phase circuits are taken to switch-fuse boards each feeding a

distribution fuse board. This is known as the TN-S supply system. T stands for earth

and N for neutral, while S denotes that the protective (earth) and neutral conductors

are separate.

Omoigui, M Page 6 of 23 ©Univation

SITP Electrical Installation

1.4 Methods of System Earthing

Electrical supplies entering premises vary slightly with the type of earthing provision

adopted. The lEE Wiring Regulations outline five different systems, however, one of

these requires special authorization before use and another cannot be used at all for

public supplies. The three most popular systems are shown in Figure 8. The systems

are classified with a three or a four-letter designation; the meaning of which is as

follows.

The first letter denotes the supply earthing arrangement:

T -Earth; one or more points connected to earth;

I -All parts isolated from earth or one point connected to earth through a high

impedance.

The second letter denotes the installation earthing arrangement:

T -All exposed conductive parts connected directly to earth;

N -All exposed conductive parts connected directly to the earthed conductor (which

for AC is usually the neutral).

Omoigui, M Page 7 of 23 ©Univation

SITP Electrical Installation

The third and fourth letters denote the arrangement of neutral and protective

conductors:

S -Neutral and protective conductors separate;

Omoigui, M Page 8 of 23 ©Univation

SITP Electrical Installation

C -Neutral and protective conductors combined.

Prior to the above classification system being introduced, other ways of classifying

these conductors were employed and as these classifications are still used it would

be useful to take a look at these:

PME -This refers to protective multiple earthing (now known as TN-C-S), for which

permission for its use is required.

In the PME system, the protective conductor is used as a combined earth/neutral

conductor. The arrangement has some dangers but the main advantage of the

system is that any earth fault, which occurs automatically, becomes a phase to

neutral fault, and the consequent low impedance will result in the fast operation of

the protective devices. Multiple earthing of the neutral is a feature of the system and

this is employed to ensure that in the event of broken neutral, dangerous voltages do

not occur.

It should be noted however, that installation of PME is specifically prohibited in petrol

filling stations under Health and Safety Instruction.

PEN. This denotes the combined protective and neutral conductors in cables

supplying the PME system;

CNE -Sometimes the above cable is referred to as combined neutral and earth;

PNB -This stands for protective neutral bonding, used on overhead systems

employing individual transformers, where the supply authority will, by agreement,

connect an earth electrode at the consumer's premises, as well as at their

transformer.

Whichever system is provided, it is the responsibility of the consumer, or the

electrical contractor working for him, to satisfy themselves that the characteristics of

the earth fault current path, including any part of that path provided by the supply

undertaking, are suitable for the effective operation of the earth fault protection

chosen for the installation.

Omoigui, M Page 9 of 23 ©Univation

SITP Electrical Installation

It should be noted that when the neutral/ point of a supp/y, or one pole of a

transformer on the consumer's premises is earthed permanent/y it is not

permissible/e to have a fuse, non-/inked switch or circuit-breaker in the line

connected to earth.

The metering of supplies

The electric meter records the amount of energy used in a particular installation; it is

connected as shown in Fig. 11. It will be seen that the meter has current coil and a

voltage coil; the interaction of their magnetic fields causes a disc to spin. This, in

turn, is connected to gears, which operate the display, which can be either the dial or

digital type; the speed of the disc increases with an increase in load.

1.5 Tariffs

The unit of measure is the kilowatt-hour and is the result, for example, of a load of 1

kW being used for one hour or 2kW being used for a half hour. To calculate the

amount of money owing in a domestic installation, the supply authority simply deduct

the previous reading on your meter from the present one. This gives them the

number of unit used and this is multiplied by the cost per unit, to arrive at a total unit

cost. To this is added a standing or quarterly charge for provision of the service, the

total being the amount to be paid.

Omoigui, M Page 10 of 23 ©Univation

SITP Electrical Installation

Omoigui, M Page 11 of 23 ©Univation

SITP Electrical Installation

1.6 Distribution Fuseboard.

A sub-main may be used as a ring main feeding several distribution boards. A similar

arrangement controlled by a single-phase main switch-fuse is shown in Fig. 12. The

sub-main can also form a circuit looping to the bus bars of several distribution

boards. With both of these arrangements a line fuse and a neutral link may be

inserted in the connections from the sub-main to the distribution board (Fig. 12). The

insertion of fuses and links is recommended as a good practice as they enable the

board to be isolated from the rest of the circuit.

For industrial and commercial premises which do not require a three-phase supply, a

typical single-phase distribution system would be that shown in Fig. 13. The

particular arrangement of the system from the consumer's switch-fuse depends on

the load and the services that have to be supplied. The layout of the premises

determines the location of the distribution boards and the capacity and number of

ways of each board depend on what the circuits supply.

Omoigui, M Page 12 of 23 ©Univation

SITP Electrical Installation

Omoigui, M Page 13 of 23 ©Univation

SITP Electrical Installation

Various arrangements of boards and circuits are shown in Figs. 14 and 15. The

diagrams illustrate methods of connecting distribution fuse-boards which are

permitted by the lEE Wiring Regulations. The basic requirement is that every

distribution fuseboard must be connected to and controlled by the main switch- fuse,

or by a separate way on a larger distribution fuseboard or switchboard, or by a circuit

feeding several boards as in Fig. 12.

The permissible methods of connecting final circuits are shown in Fig. 15. In

industrial and commercial installations the circuits will be grouped for specific loads

so that, for example, there are four groups supplying respectively: equipment units

with a rated capacity below 15A, units with a rated capacity above 15A, an extensive

lighting system and a large motor or other unit of a rated capacity that necessitates a

direct connection to a main switch and not simply to one way of a sub-distribution

fuseboard.

1.7 Ring Circuits

A ring circuit (Fig. 16) consists of an earth wire and two current carrying conductors

looped from one socket-outlet to another, both ends of the circuit being connected to

Omoigui, M Page 14 of 23 ©Univation

SITP Electrical Installation

the phase and neutral terminals of a single fuse or circuit breaker. It is permissible to

cut the conductors where they loop into the terminals of socket-outlets provided that

the continuity of the ring circuit is maintained by satisfactory joints. An unlimited

number of socket-outlets are permitted for a floor area not exceeding 100 m2 but the

following considerations must be taken into account. For domestic installations the

load concentration in kitchens may demand wiring by a separate ring circuit.

Separate circuits are also required for immersion heaters supplying tanks with a

capacity in excess of 15 litres, or permanently connected heating appliances forming

part of a space-heating installation.

A saving in cable can often be made by using spur circuits connected into the ring

circuit, as shown in Fig. 16. Each non-fused spur must not feed more than one single

or one twin socket-outlet or one permanently connected piece of equipment. The

Omoigui, M Page 15 of 23 ©Univation

SITP Electrical Installation

total number of fused spurs is unlimited but the number of non- fused spurs must not

exceed the socket-outlets and stationary equipment connected to the circuit. Fixed

appliances may also be connected to a ring circuit provided they are protected by

local fuses or miniature circuit-breakers with ratings not exceeding 13A and 15A

respectively. Such appliances are usually connected by means of a switched and

fused connector having a front flexible outlet. 13A sockets and plugs may be fitted to

a radial circuit, also allowing an unlimited number of points provided the looping of

socket-outlets is either wired by 4 mm2 p.v.c or 2.5 mm2 mineral insulated copper-

sheathed cable (m.i.c.c) within a floor area of 50 m2 and protected by 30A cartridge

fuses or circuit-breakers, or wired by 2.5 mm2 p.v.c. or 1.5 mm2 m.i.c.c. cable within

a floor area of 20 m2 and protected by 20A fuses or circuit breakers.

1.8 Control and protection for the consumer

1.8.1 Switching

Every electrical installation must be provided with a main switch and be protected

against short circuits, overloads and dangerous earth fault currents. Very often the

functions of switching and protection are incorporated in the same device, i.e., a

switch fuse. There are a number of ways that switch gear can be arranged before

being connected to the supply authorities meters and some of these are shown in

Information Sheet No. 5B.

In installing consumer control unit adequate precaution must be exercised in

ensuring that its insulated version are mounted on non-flammable material, because

they often have no back; they can however, be fitted with a non-flammable back-

plate (Information sheet No. 5C).

1.8.2 Protective Devices

Protection against short circuits, overloads and dangerous earth fault currents can

be obtained by use of the following:

• Semi-enclosed rewirable fuses to BS 3036;

• Cartridge fuses to BS 1361 and 1362

Omoigui, M Page 16 of 23 ©Univation

SITP Electrical Installation

• High breaking capacity (HBC) fuses to BS 88

• Miniature Circuit Breaker (MCB) to BS 3871

Omoigui, M Page 17 of 23 ©Univation

SITP Electrical Installation

Each of the above types of protection are of different construction and this is shown

in Information Sheet No. SD. They also have different advantages and

disadvantages, and it would be useful to look at some of these characteristics.

Omoigui, M Page 18 of 23 ©Univation

SITP Electrical Installation

Semi-enclosed Rewirable Fuses:

The advantages of these fuses are:

• They have a low initial cost;

• The fuse element is cheap to replace;

• They have no moving parts so there is less maintenance necessary;

• They are easy to check if they are intact.

The disadvantages of these fuses are:

• Incorrect fusewire can be used;

• They deteriorate with age;

• They cannot be replaced quickly;

• Lack of discrimination;

• They are not advisable for short circuit protection.

Cartridge Fuses:

The advantages of these fuses are:

• They have a more accurate current rating;

• There are no moving mechanical parts;

• They are not prone to deterioration;

• They are of a small physical size.

The disadvantages of these fuses are:

• They are more expensive to replace than the rewirable fuses;

• They can be shorted out with silver foil (BS 1361 type );

Omoigui, M Page 19 of 23 ©Univation

SITP Electrical Installation

• The BS 1361 type can be replaced with higher rated fuse;

• They are unsuitable for very high fault current conditions.

High Breaking Capacity (HBC) fuses:

The advantages of these fuses are;

Omoigui, M Page 20 of 23 ©Univation

SITP Electrical Installation

• There are no moving parts to go wrong or maintain;

• There is no deterioration of the fuse element;

• They are reliable;

• The fuse discriminates between transient and sustained overloads.

The disadvantages of these fuses are:

• They have a high cost;

• It is not always easy to see if the fuse has blown.

Miniature Circuit Breakers:

The advantages of these fuses are :

• They are set to a predetermined rating at the factory;

• It is easy to check if the breaker has tripped or not;

• The supply to the circuit is easily reinstated;

• Multi-pole units are available;

• They discriminate between sustained and transient overloads.

The disadvantages of these fuses are:

• They have a high cost;

• They have mechanical moving parts;

• Tripping heavy overloads causes distortion due to heat;

• Ambient temperature affects their characteristics;

• Regular tests are required to ensure their satisfactory operation.

Omoigui, M Page 21 of 23 ©Univation

SITP Electrical Installation

1.9 Domestic Distribution Systems

A ring circuit is included in the domestic distribution system shown in Fig. 17. The

single-phase supply to the installation is through a consumer~ s supply control unit

which, in this case, includes the supply fuse, meter, consumers main switch, the fuse

ways for all the services and the neutral bar. Because the unit meets specified

requirements of the lEE Wiring Regulations, the consumer's main fuse is omitted,

Omoigui, M Page 22 of 23 ©Univation

SITP Electrical Installation

overall protection being given by the supply authority's fuse.

When a consumer’s control unit is not used, the incoming supply will be controlled by

the consumer’s main switch gear , which may consist of a switchfuse or a separate

switch and fuses.

As shown in Fig. 18, the switch gear must be fitted as close as possible to the supply

authority’s meter and service fuses so that the tails connecting the meter to the

switch gear are short as possible. The tails have to be provided by the consumer’s

contractor as near as possible to the meter.

For small installations, a splitter unit (Fig. 19) can provide both the main switch and

the distribution fuseboard, which has developed into the modern consumer's control

unit, thus reducing the cost of the installation.

Omoigui, M Page 23 of 23 ©Univation

Vous aimerez peut-être aussi

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeD'EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeÉvaluation : 4 sur 5 étoiles4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreD'EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreÉvaluation : 4 sur 5 étoiles4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItD'EverandNever Split the Difference: Negotiating As If Your Life Depended On ItÉvaluation : 4.5 sur 5 étoiles4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceD'EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceÉvaluation : 4 sur 5 étoiles4/5 (895)

- Grit: The Power of Passion and PerseveranceD'EverandGrit: The Power of Passion and PerseveranceÉvaluation : 4 sur 5 étoiles4/5 (588)

- Shoe Dog: A Memoir by the Creator of NikeD'EverandShoe Dog: A Memoir by the Creator of NikeÉvaluation : 4.5 sur 5 étoiles4.5/5 (537)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersD'EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersÉvaluation : 4.5 sur 5 étoiles4.5/5 (344)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureD'EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureÉvaluation : 4.5 sur 5 étoiles4.5/5 (474)

- Her Body and Other Parties: StoriesD'EverandHer Body and Other Parties: StoriesÉvaluation : 4 sur 5 étoiles4/5 (821)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)D'EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Évaluation : 4.5 sur 5 étoiles4.5/5 (121)

- The Emperor of All Maladies: A Biography of CancerD'EverandThe Emperor of All Maladies: A Biography of CancerÉvaluation : 4.5 sur 5 étoiles4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingD'EverandThe Little Book of Hygge: Danish Secrets to Happy LivingÉvaluation : 3.5 sur 5 étoiles3.5/5 (399)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyD'EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyÉvaluation : 3.5 sur 5 étoiles3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)D'EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Évaluation : 4 sur 5 étoiles4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaD'EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaÉvaluation : 4.5 sur 5 étoiles4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryD'EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryÉvaluation : 3.5 sur 5 étoiles3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnD'EverandTeam of Rivals: The Political Genius of Abraham LincolnÉvaluation : 4.5 sur 5 étoiles4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealD'EverandOn Fire: The (Burning) Case for a Green New DealÉvaluation : 4 sur 5 étoiles4/5 (73)

- The Unwinding: An Inner History of the New AmericaD'EverandThe Unwinding: An Inner History of the New AmericaÉvaluation : 4 sur 5 étoiles4/5 (45)

- 3202.31.DIES - INSTRUMENT CABLE SCHEDULE.24015 - Rev02Document6 pages3202.31.DIES - INSTRUMENT CABLE SCHEDULE.24015 - Rev02Chidiebere Samuel OkogwuPas encore d'évaluation

- Relay - Setting - P443 REV.3Document29 pagesRelay - Setting - P443 REV.3Noptana Tummasit100% (2)

- Earthing Calculation - Open ElectricalDocument11 pagesEarthing Calculation - Open ElectricalChihiya Fitria NurhayatiPas encore d'évaluation

- Alternative Source For Gas Supply To Indorama ProjectDocument4 pagesAlternative Source For Gas Supply To Indorama ProjectChidiebere Samuel OkogwuPas encore d'évaluation

- Start Time SN Job Step Hazard Harzard Controls Status CommentsDocument3 pagesStart Time SN Job Step Hazard Harzard Controls Status CommentsChidiebere Samuel OkogwuPas encore d'évaluation

- VerbalReasoningTest1 QuestionDocument12 pagesVerbalReasoningTest1 QuestionChidiebere Samuel OkogwuPas encore d'évaluation

- Dragnet Abstract Reasoning Test 1&2 SolutionsDocument10 pagesDragnet Abstract Reasoning Test 1&2 SolutionsChidiebere Samuel OkogwuPas encore d'évaluation

- 3202.31.DIES.24097 - Rev01 - Instruments Material Take-off-R0Document19 pages3202.31.DIES.24097 - Rev01 - Instruments Material Take-off-R0Chidiebere Samuel OkogwuPas encore d'évaluation

- 3202.31.DIES - INSTRUMENT TUBING SCHEDULE.24018 - Rev03Document5 pages3202.31.DIES - INSTRUMENT TUBING SCHEDULE.24018 - Rev03Chidiebere Samuel OkogwuPas encore d'évaluation

- Start Time SN Job Step Hazard Hazard Controls Status CommentsDocument3 pagesStart Time SN Job Step Hazard Hazard Controls Status CommentsChidiebere Samuel OkogwuPas encore d'évaluation

- Install PDFDocument12 pagesInstall PDFMd NazrulPas encore d'évaluation

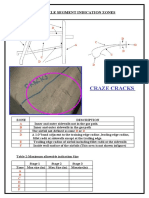

- Thin Material: Nozzle Segment Indication ZonesDocument1 pageThin Material: Nozzle Segment Indication ZonesChidiebere Samuel OkogwuPas encore d'évaluation

- PM List I&C (1258)Document6 pagesPM List I&C (1258)Chidiebere Samuel OkogwuPas encore d'évaluation

- Nozzle Segment Indication Zones: A B C B D D E FDocument1 pageNozzle Segment Indication Zones: A B C B D D E FChidiebere Samuel OkogwuPas encore d'évaluation

- TTD Setup For Ajax (2015 - 11 - 23 10 - 24 - 32 UTC)Document1 pageTTD Setup For Ajax (2015 - 11 - 23 10 - 24 - 32 UTC)Chidiebere Samuel OkogwuPas encore d'évaluation

- Bulging: Nozzle Segment Indication ZonesDocument1 pageBulging: Nozzle Segment Indication ZonesChidiebere Samuel OkogwuPas encore d'évaluation

- Kvaerner Energy LTD Thermal Power Division CSD Field Technical InstructionDocument2 pagesKvaerner Energy LTD Thermal Power Division CSD Field Technical InstructionChidiebere Samuel OkogwuPas encore d'évaluation

- Errosion: Nozzle Segment Indication ZonesDocument1 pageErrosion: Nozzle Segment Indication ZonesChidiebere Samuel OkogwuPas encore d'évaluation

- Kvaerner Energy LTD Thermal Power Division CSD Field Technical InstructionDocument2 pagesKvaerner Energy LTD Thermal Power Division CSD Field Technical InstructionChidiebere Samuel OkogwuPas encore d'évaluation

- Field Technical Instruction: John Brown Engineering Customer Service DivisionDocument2 pagesField Technical Instruction: John Brown Engineering Customer Service DivisionChidiebere Samuel OkogwuPas encore d'évaluation

- Kvaerner Energy LTD Thermal Power Division CSD Field Technical InstructionDocument2 pagesKvaerner Energy LTD Thermal Power Division CSD Field Technical InstructionChidiebere Samuel OkogwuPas encore d'évaluation

- Craze Cracks: Nozzle Segment Indication ZonesDocument1 pageCraze Cracks: Nozzle Segment Indication ZonesChidiebere Samuel OkogwuPas encore d'évaluation

- Kvaerner Energy LTD Thermal Power Division CSD Field Technical InstructionDocument2 pagesKvaerner Energy LTD Thermal Power Division CSD Field Technical InstructionChidiebere Samuel OkogwuPas encore d'évaluation

- Kvaerner Energy LTD Thermal Power Division C.S.D. Field Technical InstructionDocument2 pagesKvaerner Energy LTD Thermal Power Division C.S.D. Field Technical InstructionChidiebere Samuel OkogwuPas encore d'évaluation

- FTI0257Document3 pagesFTI0257Chidiebere Samuel OkogwuPas encore d'évaluation

- Kvaerner Energy LTD Thermal Power Division CSD Field Technical InstructionDocument1 pageKvaerner Energy LTD Thermal Power Division CSD Field Technical InstructionChidiebere Samuel OkogwuPas encore d'évaluation

- Technical Information Letter: Replacement of 6B ST Age-2 BucketsDocument1 pageTechnical Information Letter: Replacement of 6B ST Age-2 BucketsChidiebere Samuel OkogwuPas encore d'évaluation

- T12833-Purge Air CHK VLVDocument6 pagesT12833-Purge Air CHK VLVJEORJEPas encore d'évaluation

- Kvaerner Energy LTD Thermal Power Division CSD Field Technical InstructionDocument2 pagesKvaerner Energy LTD Thermal Power Division CSD Field Technical InstructionChidiebere Samuel OkogwuPas encore d'évaluation

- Kvaerner Energy LTD Thermal Power Division CSD Field Technical InstructionDocument2 pagesKvaerner Energy LTD Thermal Power Division CSD Field Technical InstructionChidiebere Samuel OkogwuPas encore d'évaluation

- Technical Information Letter: Five-Wire Flame Detector System ReplacementDocument1 pageTechnical Information Letter: Five-Wire Flame Detector System ReplacementChidiebere Samuel OkogwuPas encore d'évaluation

- Technical Information Letter: Excessive Gas Fuel Flow at Start-Up (F-Class)Document5 pagesTechnical Information Letter: Excessive Gas Fuel Flow at Start-Up (F-Class)Chidiebere Samuel Okogwu100% (1)

- Component Type SS21-UL Type: Speed Control MotorsDocument7 pagesComponent Type SS21-UL Type: Speed Control Motorshenry barbozaPas encore d'évaluation

- Instruction Sheet 735 3101: Industrial Frequency Converter 400 V (735 3101)Document4 pagesInstruction Sheet 735 3101: Industrial Frequency Converter 400 V (735 3101)John Philip Rosario SabaylePas encore d'évaluation

- RM8001Document2 pagesRM8001shiauyunn.yeohPas encore d'évaluation

- 4PH0 - 1P - Que - 20170112 (Q5 I-V Graph, Circuit)Document3 pages4PH0 - 1P - Que - 20170112 (Q5 I-V Graph, Circuit)superpooh-1Pas encore d'évaluation

- IndexDocument8 pagesIndexdwdawadPas encore d'évaluation

- AND9408/D Basic Principles of LLC Resonant Half Bridge Converter and DC/Dynamic Circuit Simulation ExamplesDocument9 pagesAND9408/D Basic Principles of LLC Resonant Half Bridge Converter and DC/Dynamic Circuit Simulation ExamplesFernando Sobrino-Manzanares MasPas encore d'évaluation

- Resistor SMD 220 OhmsDocument2 pagesResistor SMD 220 OhmsXavier G TeslaPas encore d'évaluation

- EL410 EL415 SeriesDocument5 pagesEL410 EL415 SeriesAdel KhelifiPas encore d'évaluation

- Sylvania Fluorescent Lifeline Lamps Brochure 7-1962Document6 pagesSylvania Fluorescent Lifeline Lamps Brochure 7-1962Alan MastersPas encore d'évaluation

- Rural Electrification in RwandaDocument4 pagesRural Electrification in RwandaJean-Louis KayitenkorePas encore d'évaluation

- Manual de Operación Terrometro de GanchoDocument19 pagesManual de Operación Terrometro de GanchoIsrael SanchezPas encore d'évaluation

- Small&medium ICE Motors PDFDocument3 pagesSmall&medium ICE Motors PDFeng_mhassan1Pas encore d'évaluation

- Electronic Motor Protection Relays - G - EMPR-DMPRDocument44 pagesElectronic Motor Protection Relays - G - EMPR-DMPRTruong HungPas encore d'évaluation

- Doubly-Fed Induction Machine Models For Stability Assessment of Wind FarmsDocument6 pagesDoubly-Fed Induction Machine Models For Stability Assessment of Wind FarmsArun RajendranPas encore d'évaluation

- Photovoltaic Day03 To-Day 05 Page155-250Document96 pagesPhotovoltaic Day03 To-Day 05 Page155-250ghonamyPas encore d'évaluation

- Project Report PDFDocument10 pagesProject Report PDFAnik GoyalPas encore d'évaluation

- LGES PRIME Compatible-Inverter v3.8Document5 pagesLGES PRIME Compatible-Inverter v3.8moussaPas encore d'évaluation

- Bateria de Litio Lifepo4 24v 120ah 25.6v NPP Nsfe120q10 24v120Document2 pagesBateria de Litio Lifepo4 24v 120ah 25.6v NPP Nsfe120q10 24v120Luis GutierrezPas encore d'évaluation

- 1.5.2 Hands Free Link Control Unit Input Test - Replacement - Personal Communications - AccessoriesDocument4 pages1.5.2 Hands Free Link Control Unit Input Test - Replacement - Personal Communications - AccessoriesPdindinPas encore d'évaluation

- 663 - Cockcroft-Walton GeneratorDocument27 pages663 - Cockcroft-Walton GeneratorcassioalvarengaPas encore d'évaluation

- What Is The Cause of Generator Overfluxing and Overcxcitation - QuoraDocument2 pagesWhat Is The Cause of Generator Overfluxing and Overcxcitation - QuoraCharles RobiansyahPas encore d'évaluation

- Skybox RepairDocument47 pagesSkybox RepairDomain RiderPas encore d'évaluation

- Silent Generator TFN Type Specification Model YM6700T YM7700T YM9700T YM10000TDocument1 pageSilent Generator TFN Type Specification Model YM6700T YM7700T YM9700T YM10000TElvis Culma GallegoPas encore d'évaluation

- Master VSG1Document81 pagesMaster VSG1Bình ChuPas encore d'évaluation

- Asco Series 015 Manual Reset CatalogDocument6 pagesAsco Series 015 Manual Reset Catalogpneuma110Pas encore d'évaluation

- Motor Ratings and Qualified Life Issues: Presented By: Bill Newell Schulz Electric CompanyDocument45 pagesMotor Ratings and Qualified Life Issues: Presented By: Bill Newell Schulz Electric CompanyDavid Antonio Córdova LatorrePas encore d'évaluation

- Hawkeye Prox SwitchDocument1 pageHawkeye Prox SwitchAlejandro A Ochoa VargasPas encore d'évaluation

- Practical Experiences and Lessons Learned From Connections and Planning Considerations of Grid Forming Inverters in Australia Babak BadrzadehDocument14 pagesPractical Experiences and Lessons Learned From Connections and Planning Considerations of Grid Forming Inverters in Australia Babak BadrzadehahmedPas encore d'évaluation