Académique Documents

Professionnel Documents

Culture Documents

SIP Direnc

Transféré par

Mustapha DemirCopyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

SIP Direnc

Transféré par

Mustapha DemirDroits d'auteur :

Formats disponibles

Resistor Networks SIP Series

page 1/3

INSTRUCTION

Thick film resistor networks have metal glaze element on the ceramic substrates with strong clip

construction terminal, and are coated with special epoxy resin. They are the most suitable to

meet the requirement of high density circuit assembling.

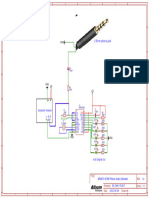

How to order : SIP 08 G 472 A

Part Number designation: SIP 08 G 472 A

SIP TYPE

08 PIN NUMBER

G TOLERANCE

472 RESISTANCE

A CIRCUIT

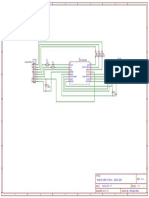

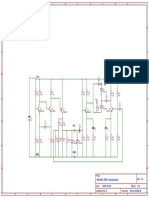

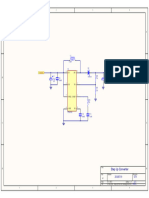

CONSTRUCTION & DIMENSIONS

Pin One Indicated

L T

Type L H T C d f

(max) (max) (max) ±0.05 ±0.05 ±0.2

H 4pin 10.2

A 472G 5pin 12.7

6pin 15.3

7pin 17.8

1 2 3 …………. C 8pin 20.4 5.08 2.50 3.50 0.50 2.54

9pin 22.9

f d 0.25±0.05 10pin 25.4

11pin 28.0

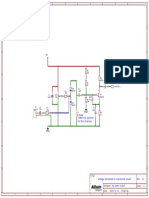

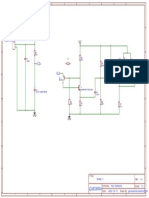

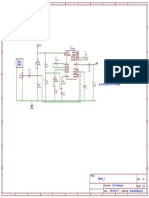

CIRCUIT DIAGRAM 12pin 30.5

A B C D

R1 R2 R3 Rn

R1 R2 R3 Rn R1 R2 Rn R1 Rn

1 2 31 41 n+1 1 2 3 4 2n-1 2n n/2+1 n+1 1 2 3 4 n+1

R1=R2=···········=Rn R1=R2=···········=Rn R1=R2=···········=Rn R1=R2=···········=Rn

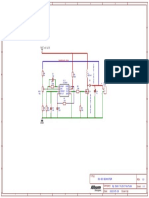

E P T R

R1 R1 R1 R1 R1 R1 R2 R2 R2 R2

R1 R2 Rn

R2 R2 R2 R2 R2 R2 R1 R1 R1 R1

1 2 3 4 5 n n+1 1 2 3 4 5 n n+1 1 2 3 n+1 n+2 1 2 3 4 n/2+2

R1=R2=···········=Rn

Resistor Networks SIP Series

page 2/3

CHARACTERISTICS

1. POWER RATING:

SERIES CIRCUIT STYLE POWER RATING

B 0.2 W

SIP

Others 0.125W

2 MECHANICAL CHARACTERISTICS

ITEM REQUIREMENT TEST METHODS

R esistance to soldering △R With 350±5℃, for 3 seconds.

heat ≦ ± (0.5% + 0.05Ω)

Over 95% of termination After immersing flus,dip in th230±5 ℃

Solderability must be covered with new solder bath for 3±0.5 sec.

solder.

Terminal Strength △R Tensile: 1 Kg for 30 sec.

(Tensiles Strength) ≦ ± (1.0% + 0.05Ω) Bending; 500g for 2 times

No mechanical damage.

Exterior No mechanical defect. Visual

Size Within specification Calipers

3. ELECTRICAL CHARACTERISTICS

ITEM REQUIREMENT TEST METHODS

Temperature Coefficient TCR( PPM/℃ ) =

(ppm/ ℃) R < 50Ω ±250 PPM/℃

R2 - R1 1

X

50Ω≦ R < 2.2MΩ, R1 T 2 - T1

±100 PPM/℃ T1= 25 ℃

T2= TEST TEMPERATURE

R≧ ( -55 ℃ ~ +125 ℃ )

2.2MΩ ±250 PPM/℃ R1: RESISTANCE AT TEMP. T1

R2: RESISTANCE AT TEMP. 2

2.5 x Rated Voltage for 5 sec.

Short-Time Overload △R (200V max.)

≦ ± (0.5% + 0.05Ω) Measure resistance after 30 minutes.

Resistor Networks SIP Series

page 3/3

ENVIRONMENT TEST

ITEM REQUIREMENT TEST METHODS

Repeat t cycles as follows:

Temperature Cycle △R -55℃ 25℃ 125℃ 25℃

≦ ± (0.5% + 0.05Ω) 30 min. 15min 30 min. 15 min.

Applied:

Rated Voltage: 1.5 hours -- " ON "

Load Life in Humidity △R 0.5 hours -- " OFF "

≦ ± (2% + 0.05Ω) Temp: 40±2℃

Humidity: 90 ~ 95 %

Duration: 1000 hours

Applied:

Rated Voltage: 1.5 hours -- " ON "

Load Life △R 0.5 hours -- " OFF "

≦ ± (2% + 0.05Ω) Temp: 70±2℃

Duration: 1000 hours

High Temperature △R Temp:125±5℃

Exposure ≦ ± (0.5% + 0.05Ω) Duration: 100 hours

Low Temperature △R Temp:-65±5℃

Exposure ≦ ± (0.25% + 0.05Ω) Duration: 24 hours

6. OUTGOING INSPECTION SAMPLING PLAN

1. MIL-STD-105D, LEVEL II, NORMAL INSPECTION

2. SINGLE SAMPLING

3. AQL: DEFECTIVE MA MI

AQL 0.1 0.65

7. PACKAGING

Standard packaging quantity: 200 pcs per bag.

Vous aimerez peut-être aussi

- Circuito-Gerador de Sinais Com 555Document1 pageCircuito-Gerador de Sinais Com 555João Pedro da Silva RodriguesPas encore d'évaluation

- Astable Multivibrator Circuit EepsitaDocument1 pageAstable Multivibrator Circuit Eepsitaspitfire_hrtPas encore d'évaluation

- Schematic - Voltage Controlled FM Transmitter Circuit - 2022-12-13 PDFDocument1 pageSchematic - Voltage Controlled FM Transmitter Circuit - 2022-12-13 PDFEvie Anindya PutriPas encore d'évaluation

- R4 Res1 R11 Res1 D1 10Mh L1: Netlabel19 13.8 V Netlabel15 12 VDocument1 pageR4 Res1 R11 Res1 D1 10Mh L1: Netlabel19 13.8 V Netlabel15 12 VHicham BoutouchePas encore d'évaluation

- Schematic MOSFET 2023-06-09Document1 pageSchematic MOSFET 2023-06-09panchal vivekPas encore d'évaluation

- R1 200K R2 1K C1 0.1uf C2 P1 P2: Audioanalyzer V2.0Document1 pageR1 200K R2 1K C1 0.1uf C2 P1 P2: Audioanalyzer V2.0joxPas encore d'évaluation

- Schematic Boost Converter Sheet 1 20191024172646Document1 pageSchematic Boost Converter Sheet 1 20191024172646NatasyaPas encore d'évaluation

- Ain0 Ain1 Ain2 Ain3 Refp0 Refn0 Avdd Avss Drdy Dout DIN SCLK CS CLK DVDD DGNDDocument1 pageAin0 Ain1 Ain2 Ain3 Refp0 Refn0 Avdd Avss Drdy Dout DIN SCLK CS CLK DVDD DGNDAbd'Errahmen MharbiPas encore d'évaluation

- Schematic Ic Vipper 22a 2024-03-15Document1 pageSchematic Ic Vipper 22a 2024-03-15Vansum NguyenPas encore d'évaluation

- TCS3200 Color SensorColor Detector Schematics PDFDocument1 pageTCS3200 Color SensorColor Detector Schematics PDFsiogPas encore d'évaluation

- Schematic - How To Make MT8870 DTMF Phone Audio Decoder - 2022-08-08Document1 pageSchematic - How To Make MT8870 DTMF Phone Audio Decoder - 2022-08-08Florencio canchePas encore d'évaluation

- Circuit Diagram of DC Motor Control Using A Single SwitchDocument1 pageCircuit Diagram of DC Motor Control Using A Single Switchravirajsinhvaja100% (1)

- Schematic - TRANSMISOR DE ONDAS - 2022-10-13Document1 pageSchematic - TRANSMISOR DE ONDAS - 2022-10-13gerson sanchez pimentelPas encore d'évaluation

- Schematic TransmitterDocument1 pageSchematic TransmitterMario Leonel Torres MartinezPas encore d'évaluation

- Schematic V1.0Document1 pageSchematic V1.0kukuhsatriowibowoPas encore d'évaluation

- 02 Datasheet Pressure TransmitterDocument2 pages02 Datasheet Pressure TransmitterFadlila MuhammadPas encore d'évaluation

- WMRT Handle DrawingDocument1 pageWMRT Handle DrawingropiPas encore d'évaluation

- 6v6gt Se 12ax7 RevaDocument1 page6v6gt Se 12ax7 RevaAntonio GomesPas encore d'évaluation

- Schematic - DC DC BOOSTER - 2022-05-20Document1 pageSchematic - DC DC BOOSTER - 2022-05-20Duzão Agnusrock Lembke BassPas encore d'évaluation

- RGB LED Driver 101D SCHDocument1 pageRGB LED Driver 101D SCHBenni SiswantoPas encore d'évaluation

- Medidor Esr A Transistores: Title: Rev: Date: Sheet: Easyeda V4.11.9 Drawn byDocument1 pageMedidor Esr A Transistores: Title: Rev: Date: Sheet: Easyeda V4.11.9 Drawn byMemoPalacioPas encore d'évaluation

- Medidor Esr A Transistores: Title: Rev: Date: Sheet: Easyeda V4.11.9 Drawn byDocument1 pageMedidor Esr A Transistores: Title: Rev: Date: Sheet: Easyeda V4.11.9 Drawn byMemoPalacioPas encore d'évaluation

- Medidor Esr A Transistores: Title: Rev: Date: Sheet: Easyeda V4.11.9 Drawn byDocument1 pageMedidor Esr A Transistores: Title: Rev: Date: Sheet: Easyeda V4.11.9 Drawn byManos MagicasPas encore d'évaluation

- Receptor AM Con Control Regenerativo SCHDocument1 pageReceptor AM Con Control Regenerativo SCHCristo CrossPas encore d'évaluation

- Cargador Autom.6-12-24Document1 pageCargador Autom.6-12-24jhonnyroaPas encore d'évaluation

- Step Up Conv 096Document1 pageStep Up Conv 096azqPas encore d'évaluation

- In Ref Out in Ref Out in Ref Out in Ref OutDocument1 pageIn Ref Out in Ref Out in Ref Out in Ref Outtoony reyesPas encore d'évaluation

- Schematic - Eco Fuel 1.1.0 - 2022-04-26Document1 pageSchematic - Eco Fuel 1.1.0 - 2022-04-26Moni Que0% (1)

- Modulador AM XR2206Document1 pageModulador AM XR2206Brandon DamianPas encore d'évaluation

- Schematic - New 12V Battery Charger Circuit! - 2023-10-26Document1 pageSchematic - New 12V Battery Charger Circuit! - 2023-10-26stellampuka5Pas encore d'évaluation

- Schematic Gerador 2022-04-09Document1 pageSchematic Gerador 2022-04-09Карлос ГорбачPas encore d'évaluation

- Schematic Equaliser 2023-03-04Document1 pageSchematic Equaliser 2023-03-04sebastinPas encore d'évaluation

- 5 - JtagDocument1 page5 - JtagHungPas encore d'évaluation

- 5.IR Board 715G8623Document2 pages5.IR Board 715G8623Ricardo VieiraPas encore d'évaluation

- Current TracerDocument1 pageCurrent TracerFlashPTPas encore d'évaluation

- Meldas 65S RS232 Cross ConnectionDocument1 pageMeldas 65S RS232 Cross ConnectionMohammad AhmadPas encore d'évaluation

- Schematic - Termometro Electronico - 2022-04-21Document2 pagesSchematic - Termometro Electronico - 2022-04-21Yuli QuelcaPas encore d'évaluation

- Schematic - LM358 AKÜ ŞARJ DEVRESİ - 2021-10-18Document1 pageSchematic - LM358 AKÜ ŞARJ DEVRESİ - 2021-10-18Med SamiPas encore d'évaluation

- Bosch Spark Plug CodesDocument1 pageBosch Spark Plug CodesRafael RosasPas encore d'évaluation

- Silowa 4 AstDocument1 pageSilowa 4 AstНиколай ИвановPas encore d'évaluation

- R6x 100 R8x 1K: 3 4 Out1 IN2 Out2Document1 pageR6x 100 R8x 1K: 3 4 Out1 IN2 Out2Nguyễn Hữu BáchPas encore d'évaluation

- Assy Bantalan PrecreasingDocument1 pageAssy Bantalan PrecreasingtututasPas encore d'évaluation

- ControlDocument1 pageControlНиколай ИвановPas encore d'évaluation

- Unipolar Stepper Motor Driver Using Transistors and L297 1Document2 pagesUnipolar Stepper Motor Driver Using Transistors and L297 1Akram BenhammouPas encore d'évaluation

- Schematic - New 12V Battery Charger Circuit - 2022-12-09Document1 pageSchematic - New 12V Battery Charger Circuit - 2022-12-09FRANCISCO SANABRIAPas encore d'évaluation

- Alimentare Sursa Astabil: VCC 9V 9VDocument1 pageAlimentare Sursa Astabil: VCC 9V 9VMares DanielPas encore d'évaluation

- Linsn Technology: Receiver RV901H SpecificationDocument6 pagesLinsn Technology: Receiver RV901H SpecificationRoberto PasicPas encore d'évaluation

- Illustrated Assembly Manual k8012Document20 pagesIllustrated Assembly Manual k8012War LinuxPas encore d'évaluation

- Slican RS232Document1 pageSlican RS232Jakub T. MakowskiPas encore d'évaluation

- How To Build 1wamp PDFDocument8 pagesHow To Build 1wamp PDFVíctor FaucheretPas encore d'évaluation

- Dual - 220V Sensing PDFDocument1 pageDual - 220V Sensing PDFvykhzkztPas encore d'évaluation

- Schematic - Baxandall 3 Tone EQ Preamp - 2021-07-28Document1 pageSchematic - Baxandall 3 Tone EQ Preamp - 2021-07-28Luan AntonyPas encore d'évaluation

- Schematic ECGPROYECTOTERMINADODIAGRAMA 2024-03-04Document1 pageSchematic ECGPROYECTOTERMINADODIAGRAMA 2024-03-04Josue Manuel Huado PalmaPas encore d'évaluation

- SEN0213 Heart Rate Monitor SchematicDocument1 pageSEN0213 Heart Rate Monitor Schematicpriyanka choudhryPas encore d'évaluation

- Digital Tilt Sensor SCH PDFDocument2 pagesDigital Tilt Sensor SCH PDFRafael Pereira AzevedoPas encore d'évaluation

- Alto A200.2 Power Amp Service ManualDocument25 pagesAlto A200.2 Power Amp Service ManualmundomusicalmeriaPas encore d'évaluation

- Vcc5V: GND P$1 GPIO - 2 P$16 D7 D8 D9 D11 D10Document2 pagesVcc5V: GND P$1 GPIO - 2 P$16 D7 D8 D9 D11 D10YimmeeePas encore d'évaluation

- Penahan Kick Starter3 BndaDocument1 pagePenahan Kick Starter3 Bndaindah permatasariPas encore d'évaluation

- 120 Top Most Current ELECTRICITY - Electrical Engineering Multiple Choice Questions and AnswersDocument59 pages120 Top Most Current ELECTRICITY - Electrical Engineering Multiple Choice Questions and AnswersEj ParañalPas encore d'évaluation

- Series and Parallel CircuitsDocument10 pagesSeries and Parallel Circuitsapi-432524972Pas encore d'évaluation

- Solar CarDocument13 pagesSolar CarcikguwanismktslPas encore d'évaluation

- 9A02306 Basic Electrical EngineeringDocument4 pages9A02306 Basic Electrical EngineeringsivabharathamurthyPas encore d'évaluation

- 3 CurrentElectricity UNACADEMY-FINALDocument59 pages3 CurrentElectricity UNACADEMY-FINALAaryan KeshanPas encore d'évaluation

- Yearly Lesson Plan Physics Form 5 2015 SmktpiDocument16 pagesYearly Lesson Plan Physics Form 5 2015 Smktpihelmi_tarmiziPas encore d'évaluation

- Homemade Magnetic Amplifiers PDFDocument8 pagesHomemade Magnetic Amplifiers PDFVjekoslav NovoselPas encore d'évaluation

- g107 Voltage DropDocument31 pagesg107 Voltage DropCharlotte WilkinsonPas encore d'évaluation

- DLP Q1 WK 8 D1 (34) Science 8Document6 pagesDLP Q1 WK 8 D1 (34) Science 8Red MarquezPas encore d'évaluation

- OCW - Control Systems - I (EE 503) - AY 2016-17 - 2017-18 PDFDocument100 pagesOCW - Control Systems - I (EE 503) - AY 2016-17 - 2017-18 PDFCiczmockingbird TsvkAdm100% (1)

- Unit IV Transient AnalysisDocument43 pagesUnit IV Transient AnalysisSaravana SelvanPas encore d'évaluation

- MP EM Ass 23: AC Circuits, Power, and ResonanceDocument8 pagesMP EM Ass 23: AC Circuits, Power, and ResonanceBlueAstro100% (2)

- 2013 Revision Document Electric CircuitsDocument11 pages2013 Revision Document Electric Circuitsrowan chibiPas encore d'évaluation

- EEE 34 Lab 2Document5 pagesEEE 34 Lab 2darkfireballessencePas encore d'évaluation

- Resonance Problem SheetDocument18 pagesResonance Problem SheetJayanthiKathiresanPas encore d'évaluation

- Chapter 5 - Intro Capacitors - Inductors - Part IDocument52 pagesChapter 5 - Intro Capacitors - Inductors - Part ISHARENIYA A/P PRAKASH STUDENTPas encore d'évaluation

- SML LoopDocument4 pagesSML Loopriju_rahmanPas encore d'évaluation

- XII - I PreBoard - PHYSICSDocument12 pagesXII - I PreBoard - PHYSICSBhawesh Kumar SoniPas encore d'évaluation

- Lesson 2 4Document27 pagesLesson 2 4api-235028688Pas encore d'évaluation

- PescoDocument6 pagesPescomuhammadaliPas encore d'évaluation

- Comsats University Islamabad Applied Physics Lab FinalDocument42 pagesComsats University Islamabad Applied Physics Lab FinalmalkPas encore d'évaluation

- Ohms Law ProblemsDocument10 pagesOhms Law Problemsjoel dugeniaPas encore d'évaluation

- Midterm - With SolutionDocument5 pagesMidterm - With Solutionchienthan12345Pas encore d'évaluation

- Electrostatics Is The Branch of Physics That Deals With The Phenomena and Properties of Stationary or SlowDocument6 pagesElectrostatics Is The Branch of Physics That Deals With The Phenomena and Properties of Stationary or SlowfunandruinsPas encore d'évaluation

- Q1.An Electrical Circuit Is Shown in The Figure Below.: ST Thomas More Catholic SchoolDocument54 pagesQ1.An Electrical Circuit Is Shown in The Figure Below.: ST Thomas More Catholic SchooljsPas encore d'évaluation

- Find Burnt ResistorDocument0 pageFind Burnt Resistorsanlugo67% (3)

- Pads and Attenuators Lab 3Document6 pagesPads and Attenuators Lab 3Michael K GooneratnePas encore d'évaluation

- Physics 152 Lab ManualDocument80 pagesPhysics 152 Lab ManualtomtarrPas encore d'évaluation

- Cts MMV NSQFDocument77 pagesCts MMV NSQFShiva Sankar Behara100% (1)