Académique Documents

Professionnel Documents

Culture Documents

Vesda Sped PDF

Transféré par

we2020 évaluation0% ont trouvé ce document utile (0 vote)

87 vues11 pagesTitre original

Vesda Sped.pdf

Copyright

© © All Rights Reserved

Formats disponibles

PDF ou lisez en ligne sur Scribd

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

© All Rights Reserved

Formats disponibles

Téléchargez comme PDF ou lisez en ligne sur Scribd

0 évaluation0% ont trouvé ce document utile (0 vote)

87 vues11 pagesVesda Sped PDF

Transféré par

we202Droits d'auteur :

© All Rights Reserved

Formats disponibles

Téléchargez comme PDF ou lisez en ligne sur Scribd

Vous êtes sur la page 1sur 11

COMPANY

CONTRACTOR

DOCUMENT TITLE :

DOCUMENT NO.

ConocoPhillips

NORTH BELUT PROJECT

ENGINEERING AND TECHNICAL SUPPORT SERVICES (ETSS) CONTRACT

CONTRACT NO : CS70-12397

PTTI PROJECT NO. : 7010

Technip

CONOCOPHILLIPS INDONESIA INC. LTD. (COPI)

P.T. TECHNIP INDONESIA (PTTI)

84508-3170-4L-001

SPECIFICATION FOR VESDA SYSTEM

No unauthorized copying is allowed

JORIGINATOR]_ CHECKER ‘APPROVED

REV| DATE | PURPOSE TT PTT COPI

NAME NAME NAME [NAME | DATE

: Siva R./

D | 19 Octos Inc | Dwis Martine | YP.Chow

iva R. /

D1 | 16 Novo6 IFC (Bows Ptontin C. y Cbiay,

¥

ConocoPhillips

Technip

NORTH BELUT PROJECT - ETSS

‘SPECIFICATION FOR VESDA SYSTEM

Doc.No.: 84508-3170-41-001

Revision : Dt

Page: 2oftt

Dt 91

Factory Acceptance Test reqi

as per IDC comments received.

onan,

ConocoPhillips NORTH BELUT PROJECT -ETSS | poc.no: 9¢808.217041-001

Technip SPECIFICATION FOR VESDA SYSTEM | Revision : 01

Page: 3oftt

a a)

en

41.

TABLE OF CONTENTS

ABBREVIATIONS.

DEFINITIONS.

REFERENCE SPECIFICATIONS, STANDARDS AND CODES

AVAILABILITY / RELIABILITY...

‘SITE CONDITIONS AND UTILITIES AVAILABLE.

AREA CLASSIFICATION ...

TECHNICAL REQUIREMENT ...

INSPECTION & TESTING...

PREPARATION FOR SHIPMENT.

WEIGHT CONTROL

a

ConocoPhillips NORTH BELUT PROJECT-ETSS | poc.No- 84608-3170-4-001

panel 5 Revision

Technip SPECIFICATION FOR VESDA SYSTEM | Rosen: 01

1. SCOPE

This specification defines the minimum requirements for the supply of Very Early Smoke

Detection Apparatus (VESDA) system for the ConocoPhillips North Belut Field

Development Project. Supplier shall be responsible for procuring or manufacturing,

inspecting, testing, documentation, certification and packing of VESDA system and

accessories in accordance with this specification and referenced documents,

The system shall be designed to provide early detection of smoke, before flames are

visible. The signal to Fire and Gas system upon detection of confirmed smoke shall be

provided, The annunciation shall be initiated by the F&G System.

5 Nos VESDA systems shalll be provided, one each for Electrical Equipment Building (level

1), Electrical Equipment Building (level 2), MCR & MER building, Telecom Equipment

Room, and LQ Electrical Switchgear Room. Each system shall include all instruments, field

interfaces / cabling / piping / tubing / fittings / sampling points, etc installed up to VESDA.

panel.

‘The Supplier scope of supply includes as minimum :

- Detection system, including the panel / enclosure, detection chamber, main

processor board, flow sensor, termination card, aspirator, air filter cartridge, air

exhaust port and interface terminals to F&G system

- Air sampling pipe network including accessories to transport air to the detection

system.

- Sampling point fittings, capillary tube, connectors and accessories.

= Programmer terminal including all associated software for system configuration.

- Calculation / air sampling pipe modeling,

- Factory Acceptance Test (FAT) and Site Acceptance Test (SAT).

- Packing.

- Documentation.

- Site Services,

= Special tools required for the system installation / configuration / maintenance.

- Supply of consumable materials for system installation,

- Supply of commissioning spare parts.

- System installation.

The Supplier shall clearly identify any deviation to this specification, and the reference

codes, standards, and COPI specifications, and list them, with reference to the document

clause, in the quotation. In absence of any specific mentioning of the deviations, it shall be

assumed that the Supplier shall fully comply with all the specifications and codes

referenced herein.

Itis not the intent to specify herein all details of the design and construction. The Supplier

shall be responsible to ensure that supplied systems are in compliance with all engineering

codes standards and government regulations applicable to specified service and performs.

under conditions and standards. The work to be done by the Supplier shall include all

design development, analysis, and testing necessary to deliver products in compliance with

these requirements.

Sufficient descriptive information shall be furnished with the Supplier's Tender to enable

equipment size, weight, performance, quality, capacity, and specification adherence to be

determined.

ConocoPhi ips

Technip

NORTH BELUT PROJECT - ETSS ‘Doc. No: 84808-3170-41.001

‘SPECIFICATION FOR VESDA SYSTEM | Revision: Dt

Page: Softt

2. ABBREVIATIONS

MTBF

MTTR

ESD

Fes

VESDA

FIFO

FAT

SAT

3. DEFINITIONS

Company

Contractor

Supplier

Mean Time Between Failures

Mean Time To Repair

Emergency Shutdown

Fire & Gas System

Very Early Smoke Detection Apparatus

First Input First Output

Factory Acceptance Test

Site Acceptance Test

ConocoPhillips Indonesia (COPI).

An entity performing works under the project's main contract with

company.

The package equipment manufacturer or fabricator providing any

part of contractor supply.

4. REFERENCE SPECIFICATIONS, STANDARDS AND CODES

4.1 COMPANY SPECIFICATIONS

Applicable documents are listed below

44.4 General

84501-9200-91-005 General Requirements for Purchased Equipment.

84508-9700-SL-007 North Belut Site Conditions, Climate & Utility

Specification.

84501-9200-9T-001 Supplier Data Requirements Master Listing.

84501-9200-9L-002 Final Documentation.

4.1.2 Instrument Specifications / Drawings

84508-9787-4L-016 Packaged Equipment Instrumentation.

84501-9287-41-009 Instrument installation.

84501-9287-41-010 Instrument Piping.

84501-9287-41-056 Instrument Wiring, Shielding, & Grounding.

84508-3180-42-001 North Belut CPP Instrument Equipment Layout Main

Equipment Room.

84508-3180-42-002 North Belut CPP Instrument Equipment Layout Main

Control Room.

84508-3186-42-001 North Belut CPP LQ Module Equipment Layout

Telecommunication Equipment Room Floor

84508-3180-36-001 North Belut CPP Electrical Equipment Layout

Electrical Equipment Building Level - 1.

84508-3180-36-002 North Belut CPP Electrical Equipment Layout

Electrical Equipment Building Level - 2.

84508-3180-36-003 North Belut CPP LQ Electrical Switchroom Layout.

84508-3192-65-101 North Belut CPP Platform Architectural Control

Building Floor Plan.

Lr

ConocoPhillips NORTH BELUT PROJECT - ETSS DocNo. 84508-3170-41-001

Technip SPECIFICATION FOR VESDA SYSTEM | Revlon: Dt

4.2 CODES AND STANDARDS

In addition to the Company Specifications, the latest editions of the following Codes and

Standards are referenced and are considered a part of this Specification.

IEC 60079 Electrical Apparatus for Explosive Gas Atmospheres

IEC 60529 Classification of Degrees of Protection Provided by Enclosure

5. AVAILABILITY / RELIABILITY

‘The Supplier shall demonstrate the overall availability and reliability of the complete

units. The unit design life shall be 25 years.

‘The Supplier shall be required to meet an agreed specific minimum availability figure,

either to enable a particular machine configuration to be practicable or for operating

feasons. In addition, the Supplier shall furnish their best estimates of Mean Time

Between Failures (MBTF) and Mean Time To Repair (MTTR) for the equipment

concemed.

In making assessments of the availability and reliability, the Supplier will need to

estimate maintenance and repair times. For the purposes of making such estimates, the

Supplier may assume that the spares holding is in accordance with their submitted

recommendations unless otherwise stated. The Supplier may also neglect any delay

caused by factors not directly related to the unit in question, unless a basis for

estimating such delays is provided by the Principal. In case of failure modes, which

make a significant contribution to the overall unavailability, the Supplier may be required

to demonstrate that their assumed repair times can be achieved.

6. SITE CONDITIONS AND UTILITIES AVAILABLE

For details of all utilities available on the project, climatic conditions etc., refer to 84508-

9700-9L-007, “North Belut Site Conditions Climate & Utility Specification’,

7. AREA CLASSIFICATION

All electrical and instrument equipment of the VESDA system shall be in un-classified

area in Electrical Equioment Building (level 1), Electrical Equipment Building (level 2),

MCR & MER building, Telecom Equipment Room, and LQ Electrical Switch Room, with

IP41 as minimum.

8. TECHNICAL REQUIREMENT

The Supplier shall only use components that have a proven reliability in an offshore

environment. The Supplier must ensure that a high integrity system is offered and that

all common mode failure points have been considered and eliminated where

practicable. MBTF for each and every component is required.

8.1 GENERAL,

5 Nos VESDA systems are to be provided. The dimension of the area to be protected by

each system is as per the drawings attached. The available space to install the system is

shown in the attached drawings.

Pee

ConocoPhillips NORTH BELUT PROJECT -ETSS | poco. axsn6.0170-4-001

Technip SPECIFICATION FOR VESDA SYSTEM | Revsion: Dt

VESDA system in Electrical Equipment Building — Level 1 (70 ZJP 054

in Switchgear Room & Transformer Room, the VESDA system (70 ZJP 054) shall perform

room sampling, in cabinet sampling (hofd), on cabinet sampling, and HVAC (return air path

protection).

VESDA system in Electrical Equipment Bullding — Level 2 (70 2UP 055)

in Switchgear Room & Transformer Room, the VESDA sysiom (70 ZJP 085) shall perform

room sampling, in cabinet sampling (hold) on cabinet sampling and HVAG (retum air path

protection).

VESDA system in MCR & MER Building (70 ZJP 051

in Main Control Room & Main Equipment Room, the VESDA system (70 ZJP 051) shall

perform for room sampling, in cabinet sampling (hold), on cabinet sampling, under floor

sampling, and HVAC (return air path protection).

VESDA system in Telecom Equipment Room (70 ZJP 052)

In Telecom Equipment Room, the VESDA system (70 ZJP 052) shall perform HVAC (return

air path protection) sampling, room sampling, under floor sampling, battery room sampling,

in cabinet sampling (hold), and on cabinet sampling.

VESDA system in LQ Electrical Switch Room (70 ZJP 053)

in LQ Electrical Switch Room, the VESDA system (70 ZJP 053) shall perform room

sampling, in cabinet sampling (hold), and HVAC (retum air path protection),

Vendor shalll provide the sampling arrangement details for all the above buildings along

with the bid for Purchaser's review and approval.

‘The detector shall have four (4) in-line sample pipe inlets and must contain a flow sensor

for each pipe inlet. It shall be possible to distinguish the fire from each above coverage

area.

The system shall consist of a highly sensitive LASER-based smoke detector, a high

efficiency aspirator, dual stage filter cartridges and air sampling pipe network. The system

shall continuously draw air into the pipe network through high efficiency aspirator. A sample

of this air is then passed through dual stage filter before entering the laser detection

chamber for smoke detection,

The air sampling pipe network to transport air to the detection system including numbers of

‘sampling points shall be studied by the Supplier based on each building drawings which are

Electrical Equipment Building (level 1), Electrical Equipment Building (level 2), MCR & MER

Building, Telecom Equipment Room, and LQ Electrical Switch Room. The supplier shall

provide the calculations from a computer-based modeling tool and detail proposed air

sampling pipe network during bid stage. Provision for future equipment sampling

connection shall be provided.

The system shall be able to measure very low to very high concentration of smoke. The

system shall have the sensitivity range of 0.005 ~ 0.2 obs/meter. The following facilities

shall be available at front face of the system :

- LED's status display (fre, alert, fault, action, system status, reset/isolate).

= Reset /isolate push button.

Bar graph displays.

Ar

ConocoPhillips NORTH BELUT PROJECT-ETSS —_| poco. 84508-3170-4..001

Technip SPEGIFICATION FOR VESDA SYSTEM | Revion: D1

The system shall have self diagnostic features which report any fault on the aspirator,

detector, power supply, filter and air sampling network by using configurable general fault

output relays.

‘The automatic system adjustment feature (to environment / air sampling network) shall be

available. As a minimum, the system shall allow programming of :

- Four (4) smoke threshold alarm levels.

- Time delays.

- Four (4) or more configurable relay outputs for faults, alert (pre-alarm), action and

fire signal output to F&G system,

The signal output to F&G System shall be voltage free contact (open to alarm).

The system shall have builtin event and smoke logging. It shall store smoke levels, alarm

conditions, operator actions and faults. The date and time of each event shall be recorded.

At least 15000 events stored in FIFO basis. intemal battery back-up shall be available for

‘event storage in purpose in case power supplies failed.

‘The system shall be powered from redundant 120 VAC UPS provided by Contractor. The

Supplier shall indicate the power consumption of the VESDA system in the bid, Heat

Dissipation Calculation shall also be provided by Supplier.

10% spare quantity shall be considered for the Bill of Material.

8.2 ENCLOSURE

The system shall be housed in a panel and shall be arranged in such way that air is drawn

from the fire risk and a sample passed through the Dual Stage Filter to Detector by the

Aspirator.

‘The cabinet shall be wall mounted type, and :

- 3mmsteel plate thickness IP 41 protection rating as minimum.

= Shatterproof glass window shall be available to view the system front face display.

~The keylock shall be provided.

Cable entries (redundant 120 VAC power supply and signal cables) and exhaust port shall

be provided. Hole for cable gland shalll be in ISO metric.

‘Top side opening for sample pipe inlet manifold shall be furnished.

8.3 AIR SAMPLING PIPE NETWORK

8.3.1 General

The air sampling pipe network calculation note shall be submitted for Contractor

approvals using Supplier computer based modeling tools. The calculation of proposed

air sampling pipe network design shall indicate the following :

= Smoke transport time.

- Balance between airflows amongst sampling pipes and holes.

Evidence for applicability of the modeling tool(s) shall be submitted with the bid.

Technip SPECIFICATION FOR VESDA SYSTEM | Revsion: D1,

The pipe network detail drawing, complete with bill of material shall be submitted for

Contractor approval. It is the Supplier responsibility to design the pipe network for

effective operation, maintenance and safety. It is essential to minimize transport time

of the air flow to the detector (less than 60 seconds) to ensure the earliest possible

detection.

8.3.2 Pipe, Fittings, Capillary Sampling and Accessories

‘The Supplier standard pipe and fittings material for this application shall be used, The

‘Supplier shall provide the detail of proposed material during bid stage. The following

consideration shall take into account on the pipe selection :

= Chemical and corrosion resistance,

- Toughness and durability (against heat exposure).

+ Easy to joint / install and maintenance.

= Low friction to minimize the air sampling transport time.

= Lightweight.

The capillary sampling shall be used when trunk tine is not the same horizontal or

vertical plane as the desired sampling point (ie. inside the electrical / instrument

cabinet). The flexible tubing that branches off from the trunk pipe to the sampling point

shall be used for this purpose. The sampling point fitting detail shall be submitted

during the bid stage. Adequate protection shall be considered along the capillary

routing.

‘The far end of each trunk or branch pipe shall be fitted with an end cap and drilled

with a hole appropriately sized to achieve the requirements as calculated by the

system design. All pipes shall be supported at not less than each 2 meters, or not

exceed the Supplier recommendation.

8.3.3 Programmer Terminal

The VESDA system shall be programmable / configurable through Programmer

Terminal. The Programmer Terminal shall be hand held type or mounted type Inside

the VESDA panel.

The following features shall be available in Programmer Terminal as minimum :

+ System configuration (detector / display, zone).

= System programming (latching / non latching relay operation, time delay,

aspirator speed control, etc).

~ Smoke threshold and detector sensitivity settings.

- System fault diagnostic.

- Viewing the status of any device in the system, configuration the detectors

alarm threshold settings to suit the current environment.

- Multi level password control to prevent an unauthorized modification,

- Programmable maintenance intervals.

- Download history and event log from the detection system.

Connection cables to the system shall be provided.

NORTH BELUT PROJECT - ETSS Doc:No.: 84508-3170-4L-001

Technip SPECIFICATION FOR VESDA SYSTEM | Revision: 01

NORTH BELUT PROJECT - ETSS oc.No.: 84508-8170-41-001

9. INSPECTION & TESTING

9.1 FACTORY ACCEPTANCE TEST (FAT)

The complete system shall be submitted to a complete operational shop test prior to

shipment. The Supplier shall notify Company, ten(40) 7 (seven) working days in

advance of system completion, in order that Contractor / Company's inspectors may be

present during the inspection and testing. The Supplier shall submit system functional

fest procedure for approval not less than six (6) weeks before the scheduled FAT date.

All materials and fabrication shall be inspected before, during and after assembly to

assure correctness of design and workmanship. The Contractor / Company may inspect

at any stage prior to shipping.

Final inspection shall include all examinations stipulated in codes and specification but

Not limited to the following :

- Conformity with the approved drawings and system specification.

- Complete functional tests of the complete system (hardware / software) for the

proper operation and display. This shall include =

© Smoke transport time verification and response time simulation.

‘System recovery test after power outage.

‘System event recording,

System failure test.

‘System display.

Immunity to radio interference.

oo000

‘The Supplier shall provide the required equipment and consumable material during the

tests. The qualified engineer(s) to perform the system test shall be available until

satisfactory and complete test.

9.2 SITE ACCEPTANCE TEST (SAT)

The site installation supervision and testing of the VESDA system shall be carried out

by the Supplier. The test shall be conducted by the Supplier with the Contractor /

Company representatives’ presence. The test shall essentially be a repetition of most

the Factory Acceptance Test with a purpose of ensuring that the system has been

installed and functions properly. Integrated test with F&G system shall also be made.

9.3 FINAL DOCUMENTATION

Documentation shall be in accordance with “Final Documentation Specification Doc. No.

84501-9200-9L-002 Rev 5". The types and quantity of documents shall be as requested

document on Requisition’s attachment.

Operating and Maintenance Manual shall be written specifically for the particular

system.

‘Operating and Maintenance Manual shall include the following as a minimum :

Installation manual section shall contain all information necessary for site preparation,

powering, grounding, installation procedure, commissioning, start up, etc. All auxiliary

AN

Ohi,

ConocoPhillips NORTH BELUT PROJECT -ETSS | poco: a1s08-s170-41-001

Technip SPECIFICATION FOR VESDA SYSTEM | Revision: 01

equipment supplied shall be provided with manufacturer's installation, operating and

maintenance manual specific to the equipment.

Operating manual shall completely describe the theory, configuration and overall

operation of VESDA system.

Maintenance manual shall contain all necessary information to maintain VESDA

system. The manual shall have instructions for trouble shooting, routine maintenance,

preventive maintenance, assembly, and disassembly, etc.

The Supplier shall be responsible for producing an ‘as built’ set of documents reflecting

all modifications made during testing and commissioning. Operation and maintenance

manuals shall be provided in editable format to aid preparation of the Contractor /

Company documentation.

10. PREPARATION FOR SHIPMENT

Preparation for shipment shall be in accordance with the document “General

Requirements for Purchased Equipment, Doc. No. 84501-9200-9L-005".

411, WEIGHT CONTROL

The Supplier shall exercise an active weight control system throughout the proposal,

design, fabrication and assembly.

‘Supplier shall provide the location of the center of gravity of the supplied equipment.

‘Supplier shall provide ‘as built” weighing of all equipment being furnished with complete

description of what is included in each weight.

Vous aimerez peut-être aussi

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryD'EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryÉvaluation : 3.5 sur 5 étoiles3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)D'EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Évaluation : 4.5 sur 5 étoiles4.5/5 (121)

- Grit: The Power of Passion and PerseveranceD'EverandGrit: The Power of Passion and PerseveranceÉvaluation : 4 sur 5 étoiles4/5 (588)

- Never Split the Difference: Negotiating As If Your Life Depended On ItD'EverandNever Split the Difference: Negotiating As If Your Life Depended On ItÉvaluation : 4.5 sur 5 étoiles4.5/5 (838)

- The Little Book of Hygge: Danish Secrets to Happy LivingD'EverandThe Little Book of Hygge: Danish Secrets to Happy LivingÉvaluation : 3.5 sur 5 étoiles3.5/5 (400)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaD'EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaÉvaluation : 4.5 sur 5 étoiles4.5/5 (266)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeD'EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeÉvaluation : 4 sur 5 étoiles4/5 (5794)

- Her Body and Other Parties: StoriesD'EverandHer Body and Other Parties: StoriesÉvaluation : 4 sur 5 étoiles4/5 (821)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreD'EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreÉvaluation : 4 sur 5 étoiles4/5 (1090)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyD'EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyÉvaluation : 3.5 sur 5 étoiles3.5/5 (2259)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersD'EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersÉvaluation : 4.5 sur 5 étoiles4.5/5 (345)

- Shoe Dog: A Memoir by the Creator of NikeD'EverandShoe Dog: A Memoir by the Creator of NikeÉvaluation : 4.5 sur 5 étoiles4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerD'EverandThe Emperor of All Maladies: A Biography of CancerÉvaluation : 4.5 sur 5 étoiles4.5/5 (271)

- Team of Rivals: The Political Genius of Abraham LincolnD'EverandTeam of Rivals: The Political Genius of Abraham LincolnÉvaluation : 4.5 sur 5 étoiles4.5/5 (234)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceD'EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceÉvaluation : 4 sur 5 étoiles4/5 (895)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureD'EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureÉvaluation : 4.5 sur 5 étoiles4.5/5 (474)

- On Fire: The (Burning) Case for a Green New DealD'EverandOn Fire: The (Burning) Case for a Green New DealÉvaluation : 4 sur 5 étoiles4/5 (74)

- The Yellow House: A Memoir (2019 National Book Award Winner)D'EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Évaluation : 4 sur 5 étoiles4/5 (98)

- The Unwinding: An Inner History of the New AmericaD'EverandThe Unwinding: An Inner History of the New AmericaÉvaluation : 4 sur 5 étoiles4/5 (45)

- AnsiDocument10 pagesAnsiwe202Pas encore d'évaluation

- NPT Thread PDFDocument1 pageNPT Thread PDFAli BelhaylaPas encore d'évaluation

- Pipeline Operations and Maintenance ManualDocument72 pagesPipeline Operations and Maintenance Manualwe2020% (1)

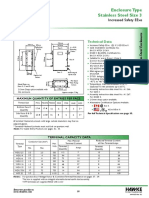

- Stainless Steel Size 3 Enclosure Type: Increased Safety EexeDocument1 pageStainless Steel Size 3 Enclosure Type: Increased Safety Eexewe202Pas encore d'évaluation

- Epc1 - Floating Production UnitDocument15 pagesEpc1 - Floating Production Unitwe202Pas encore d'évaluation

- Prepare For A New ERA: InternationalDocument4 pagesPrepare For A New ERA: Internationalwe202Pas encore d'évaluation

- Gex Sis Switchboard WireDocument2 pagesGex Sis Switchboard Wirewe202Pas encore d'évaluation

- 701 Cable Gland Type: Industrial General PurposeDocument1 page701 Cable Gland Type: Industrial General Purposewe202Pas encore d'évaluation

- 753 Cable Gland Type: Explosion ProofDocument1 page753 Cable Gland Type: Explosion Proofwe202Pas encore d'évaluation

- Stainless Steel Size 1 Enclosure Type: Increased Safety EexeDocument1 pageStainless Steel Size 1 Enclosure Type: Increased Safety Eexewe202Pas encore d'évaluation

- Type 501-453-Universal PDFDocument1 pageType 501-453-Universal PDFwe202Pas encore d'évaluation

- 501/421 Cable Gland Type: Flameproof and Increased SafetyDocument1 page501/421 Cable Gland Type: Flameproof and Increased Safetywe202Pas encore d'évaluation

- AXIS P72 Video Encoder Series: Full-Featured, Cost-Effective Video Encoders With H.264Document4 pagesAXIS P72 Video Encoder Series: Full-Featured, Cost-Effective Video Encoders With H.264we202Pas encore d'évaluation

- DFJ-AE3 Heat DetectorDocument1 pageDFJ-AE3 Heat Detectorwe202Pas encore d'évaluation

- 121 Cable Gland Type: Industrial General PurposeDocument1 page121 Cable Gland Type: Industrial General Purposewe202Pas encore d'évaluation

- Cross Link Process ComparisonDocument1 pageCross Link Process Comparisonwe202Pas encore d'évaluation

- Cable Solutions: Harsh EnvironmentDocument1 pageCable Solutions: Harsh Environmentwe202Pas encore d'évaluation

- Avery Hardoll DM Series BulkmeterDocument4 pagesAvery Hardoll DM Series Bulkmeterwe202Pas encore d'évaluation

- Mpa 1600 Paga VB 186677Document4 pagesMpa 1600 Paga VB 186677we202Pas encore d'évaluation

- Magnetic Float Switch For Vertical Installation Model FLS: (Models With Ex Approval: 60, AL-ADF)Document18 pagesMagnetic Float Switch For Vertical Installation Model FLS: (Models With Ex Approval: 60, AL-ADF)we202Pas encore d'évaluation

- IEC Pub 245-6 Rubber Insulated CablesDocument12 pagesIEC Pub 245-6 Rubber Insulated Cableswe202Pas encore d'évaluation