Académique Documents

Professionnel Documents

Culture Documents

Wind Analysis Results

Transféré par

Brahim HammamiCopyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Wind Analysis Results

Transféré par

Brahim HammamiDroits d'auteur :

Formats disponibles

Wind Analysis Results

User Entered Importance Factor is 1.000

Gust Factor (Gh, Gbar) Static 1.386

Shape Factor (Cf) for the Vessel is 0.523

User Entered Basic Wind Speed 112.7 Km/hr

Exposure Category C

Table Lookup Value Alpha from Table C6 7.0000

Table Lookup Value Zg from Table C6 900.0000

Table Lookup Value Do from Table C6 0.0050

Wind Load Results per ASCE-7 93:

Sample Calculation for the First Element:

Rougness Factor = 1.0

Values [cf1] and [cf2]

Because RoughFact = 1 and DQZ > 2.5 and H/D < 7.0

Interpolating to find the final cf:

Because H / D < 7.0

CF = CF1 + (CF2-CF1)*( H/D - 1) / (7 - 1)

= 0.5 + ( 0.6- 0.5)*( 2.409 - 1)/(7 - 1)

= 0.523

Value of Alpha, Zg is taken from Table C6-2 [Alpha, Zg]

For Exposure Category C:

Alpha = 7.0, Zg = 274320. mm.

Height of Interest for First Element [z]

= Centroid Hgt + Base Height

= 172.138 + 0.0 = 172.138 mm.

but: z = Max(4572.0, 172.138) = 4572.0 mm.

Note: Because z < 15 feet, use 15 feet to compute kz.

Velocity Pressure Coefficient [kZ]:

= 2.58( z/zg )^(2/Alpha) : z is Elevation of First Element

= 2.58( 4572.0/900 )^(2/7.0)

= 0.801

Determine if Static or Dynamic Gust Factor Applies

Height to Diameter ratio :

= Maximum Height(length)^2 / Sum of Area of the Elements

= 2353.7(^2)/22995.992

= 2.409

Vibration Frequency = 59.014 Hz

Because H/D < 5 And Frequency > 1.0: Static Analysis Implemented

The following two calculations allow for any user units

Compute [tz]

= 2.35 * Sqrt(DO / VesselHtg/30(feet)^(1/Alpha)

= 2.35 * Sqrt( 0.005/2353.7)^(1/9144.0)

= 0.202

Compute [Gh]

= 0.65 + 3.65 * tz

= 0.65 + 3.65 * 0.202 = 1.386

Wind Pressure - (performed in Imperial Units) [qz]

Importance Factor: I = 1.0

Wind Speed = 112.651 Km/hr Converts to 70.0 mph

qz = 0.00256 * kZ * (I * Vr)²

= 0.00256 * 0.801*(1.0 * 70.0)² = 10.046 psf

Converts to: 49.052 Kgs/m²

Force on the First Element [Fz]

= qz * Gh * CF * Wind Area

= 49.052 * 1.386 * 0.523 * 2985.588

= 10.628 Kgf

Element z GH Area qz Force

mm. cm² Kgs/m² Kgf

------------------------------------------------------------------------

1 172.1 1.386 2985.6 49.1 10.6

2 1298.7 1.386 24000.0 49.1 85.4

3 2429.5 1.386 2985.6 49.1 10.6

Wind Vibration Calculations

This evaluation is based on work by Kanti Mahajan and Ed Zorilla

Nomenclature

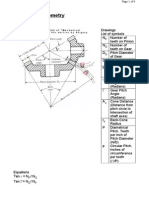

Cf - Correction factor for natural frequency

D - Average internal diameter of vessel mm.

Df - Damping Factor < 0.75 Unstable, > 0.95 Stable

Dr - Average internal diameter of top half of vessel mm.

f - Natural frequency of vibration (Hertz)

f1 - Natural frequency of bare vessel based on a unit value of

(D/L²)(10^(4))

L - Total height of structure mm.

Lc - Total length of conical section(s) of vessel mm.

tb - Uncorroded plate thickness at bottom of vessel mm.

V30 - Design Wind Speed provided by user Km/hr

Vc - Critical wind velocity Km/hr

Vw - Maximum wind speed at top of structure Km/hr

W - Total corroded weight of structure Kgf

Ws - Cor. vessel weight excl. weight of parts which do not effect stiff.

Kgf

Z - Maximum amplitude of vibration at top of vessel mm.

Dl - Logarithmic decrement ( taken as 0.03 for Welded Structures )

Vp - Vib. Chance, <= 0.320E-06 (High); 0.320E-06 < 0.400E-06 (Probable)

P30 - wind pressure 30 feet above the base

Check other Conditions and Basic Assumptions:

#1 - Total Cone Length / Total Length < 0.5

0.0/2101.6 = 0.0

#2 - ( D / L² ) * 10^(4) < 8.0 (English Units)

- ( 3.28/6.9² ) * 10^(4) = 690.104 [Geometry Violation]

Compute the vibration possibility. If Vp > 0.400E-06 no chance. [Vp]:

= W / ( L * Dr²)

= 261/( 2101.6 * 992.41² )

= 0.12616E-06

Compute the damping factor Df which is a measure of instability [Df]:

= W * Dl/ ( L * Dr² )

= 261 * 0.03/( 2101.6 * 992.41² )

= 0.236

Compute the critical wind velocity [Vc]:

= 3.4 * f * Dr

= 3.4 * 59.014 * 3.256

= 653.299 mile/hr [1051.354 Km/hr]

Compute the velocity at the top of the tower [Vw]:

= V30 * ( L / ( 30 + BaseHeight ))^(0.143)

= 112.65 * ( 2101.6/( 30 + 0.0 ))^0.143

= 91.289 Km/hr

Compute the maximum gust velocity using the gust response factor Gh [Vg]:

= Vw * Gh

= 91.289 * 1.386

= 126.552 Km/hr

Since Vc is greater than Vg the dynamic deflection Z, does not

need to be computed.

The Natural Frequency for the Vessel (Ope...) is 59.0143 Hz.

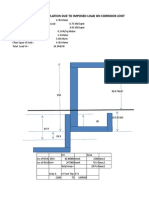

Wind Load Calculation:

| | Wind | Wind | Wind | Wind | Element |

From| To | Height | Diameter | Area | Pressure | Wind Load |

| | mm. | mm. | cm² | Kgs/m² | Kgf |

---------------------------------------------------------------------------

10| 20| 172.138 | 1200 | 2985.59 | 49.0518 | 10.6277 |

20| 30| 1298.7 | 1200 | 24000 | 49.0518 | 85.4323 |

30| 40| 2429.46 | 1200 | 2985.59 | 49.0518 | 10.6277 |

---------------------------------------------------------------------------

Earthquake Analysis Results

The UBC Zone Factor for the Vessel is ............. 0.0000

The Importance Factor as Specified by the User is . 1.000

The UBC Frequency and Soil Factor (C) is ......... 2.750

The UBC Force Factor as Specified by the User is .. 3.000

The UBC Total Weight (W) for the Vessel is ........ 295.7 Kgf

The UBC Total Shear (V) for the Vessel is ......... 0.0 Kgf

The UBC Top Shear (Ft) for the Vessel is .......... 0.0 Kgf

The Natural Frequency for the Vessel (Ope...) is 59.0143 Hz.

Earthquake Load Calculation:

| | Earthquake | Earthquake | Element | Element |

From| To | Height | Weight | Ope Load | Emp Load |

| | mm. | Kgf | Kgf | Kgf |

--------------------------------------------------------------

10|Legs| 50.8001 | ... | ... | ... |

Legs| 20| 50.8001 | 43.8973 | ... | ... |

20| 30| 1050.8 | 207.885 | ... | ... |

30| 40| 2076.2 | 43.9251 | ... | ... |

--------------------------------------------------------------

Top Load 2709.50 0 0

The following table is for the Operating Case.

Wind/Earthquake Shear, Bending:

| | Distance to| Cumulative |Earthquake | Wind | Earthquake |

From| To | Support| Wind Shear | Shear | Bending | Bending |

| | mm. | Kgf | Kgf | Kg-m. | Kg-m. |

---------------------------------------------------------------------------

10|Legs| ... | ... | ... | ... | ... |

Legs| 20| 25.4 | 106.688 | ... | 113.229 | ... |

20| 30| 1050.8 | 96.06 | ... | 108.08 | ... |

30| 40| 2181.56 | 10.6277 | ... | 1.38973 | ... |

---------------------------------------------------------------------------

Note:

The Wind Shears/Moments and the Earthquake Shears/Moments calculated

and printed in the Wind/Earthquake Shear and Bending report have

been factored by the input Scalar/Load reductions factors of;

Wind: 1.000; Earthquake: 1.000.

Note:

Review the Vessel Design Summary for the cumulative shear force

and bending moment on the support.

Wind Deflection Calculations:

The following table is for the Operating Case.

Wind Deflection:

| | Cumulative | Centroid | Elem. End | Elem. Ang. |

From| To | Wind Shear | Deflection | Deflection | Rotation |

| | Kgf | mm. | mm. | |

---------------------------------------------------------------------

10|Legs| ... | 0.0066457 | 0.0066457 | 0.00003 |

Legs| 20| 106.688 | 0.0066469 | 0.0066506 | 0.00003 |

20| 30| 96.06 | 0.0081748 | 0.010936 | 0.00003 |

30| 40| 10.6277 | 0.011009 | 0.011083 | 0.00003 |

---------------------------------------------------------------------

Critical Wind Velocity for Tower Vibration:

| | 1st Crit. | 2nd Crit. |

From| To | Wind Speed | Wind Speed |

| | Km/hr | Km/hr |

-------------------------------------

10| 20| 1271.27 | 7945.47 |

20| 30| 1271.27 | 7945.47 |

30| 40| 1271.27 | 7945.47 |

-------------------------------------

Allowable deflection at the Tower Top (Ope)( 6.000"/100ft. Criteria)

Allowable deflection : 10.508 Actual Deflection : 0.011 mm.

Stress Combination Load Cases for Vertical Vessels:

Load Case Definition Key

IP = Longitudinal Stress due to Internal Pressure

EP = Longitudinal Stress due to External Pressure

HP = Longitudinal Stress due to Hydrotest Pressure

NP = No Pressure

EW = Longitudinal Stress due to Weight (No Liquid)

OW = Longitudinal Stress due to Weight (Operating)

HW = Longitudinal Stress due to Weight (Hydrotest)

WI = Bending Stress due to Wind Moment (Operating)

EQ = Bending Stress due to Earthquake Moment (Operating)

EE = Bending Stress due to Earthquake Moment (Empty)

HI = Bending Stress due to Wind Moment (Hydrotest)

HE = Bending Stress due to Earthquake Moment (Hydrotest)

WE = Bending Stress due to Wind Moment (Empty) (no CA)

WF = Bending Stress due to Wind Moment (Filled) (no CA)

CW = Longitudinal Stress due to Weight (Empty) (no CA)

VO = Bending Stress due to Vortex Shedding Loads ( Ope )

VE = Bending Stress due to Vortex Shedding Loads ( Emp )

VF = Bending Stress due to Vortex Shedding Loads ( Test No CA. )

FW = Axial Stress due to Vertical Forces for the Wind Case

FS = Axial Stress due to Vertical Forces for the Seismic Case

BW = Bending Stress due to Lat. Forces for the Wind Case, Corroded

BS = Bending Stress due to Lat. Forces for the Seismic Case, Corroded

BN = Bending Stress due to Lat. Forces for the Wind Case, UnCorroded

BU = Bending Stress due to Lat. Forces for the Seismic Case, UnCorroded

General Notes:

Case types HI and HE are in the Un-Corroded condition.

Case types WE, WF, and CW are in the Un-Corroded condition.

A blank stress and stress ratio indicates that the corresponding

stress comprising those components that did not contribute to that

type of stress.

An asterisk (*) in the final column denotes overstress.

Analysis of Load Case 1 : NP+EW+WI+FW+BW

From Tensile All. Tens. Comp. All. Comp. Tens. Comp.

Node Stress Stress Stress Stress Ratio Ratio

10 0.00 90.93 0.00 99.44 0.0000 0.0000

10 0.13 90.93 -0.64 99.44 0.0015 0.0064

20 0.15 90.93 -0.57 100.45 0.0017 0.0056

30 90.93 -0.04 99.44 0.0004

Analysis of Load Case 2 : NP+EW+EE+FS+BS

From Tensile All. Tens. Comp. All. Comp. Tens. Comp.

Node Stress Stress Stress Stress Ratio Ratio

10 0.00 90.93 0.00 99.44 0.0000 0.0000

10 90.93 -0.25 99.44 0.0025

20 90.93 -0.21 100.45 0.0021

30 90.93 -0.04 99.44 0.0004

Analysis of Load Case 3 : NP+OW+WI+FW+BW

From Tensile All. Tens. Comp. All. Comp. Tens. Comp.

Node Stress Stress Stress Stress Ratio Ratio

10 0.00 90.93 0.00 99.44 0.0000 0.0000

10 0.13 90.93 -0.64 99.44 0.0015 0.0064

20 0.15 90.93 -0.57 100.45 0.0017 0.0056

30 90.93 -0.04 99.44 0.0004

Analysis of Load Case 4 : NP+OW+EQ+FS+BS

From Tensile All. Tens. Comp. All. Comp. Tens. Comp.

Node Stress Stress Stress Stress Ratio Ratio

10 0.00 90.93 0.00 99.44 0.0000 0.0000

10 90.93 -0.25 99.44 0.0025

20 90.93 -0.21 100.45 0.0021

30 90.93 -0.04 99.44 0.0004

Analysis of Load Case 5 : NP+HW+HI

From Tensile All. Tens. Comp. All. Comp. Tens. Comp.

Node Stress Stress Stress Stress Ratio Ratio

10 0.00 118.21 0.00 104.14 0.0000 0.0000

10 0.00 118.21 0.00 104.14 0.0000 0.0000

20 0.00 118.21 0.00 104.99 0.0000 0.0000

30 0.00 118.21 0.00 104.14 0.0000 0.0000

Analysis of Load Case 6 : NP+HW+HE

From Tensile All. Tens. Comp. All. Comp. Tens. Comp.

Node Stress Stress Stress Stress Ratio Ratio

10 0.00 118.21 0.00 104.14 0.0000 0.0000

10 0.00 118.21 0.00 104.14 0.0000 0.0000

20 0.00 118.21 0.00 104.99 0.0000 0.0000

30 0.00 118.21 0.00 104.14 0.0000 0.0000

Analysis of Load Case 7 : IP+OW+WI+FW+BW

From Tensile All. Tens. Comp. All. Comp. Tens. Comp.

Node Stress Stress Stress Stress Ratio Ratio

10 133.74 90.93 99.44 1.4708 *

10 133.88 90.93 99.44 1.4723 *

20 130.34 90.93 100.45 1.4334 *

30 133.71 90.93 99.44 1.4705 *

Analysis of Load Case 8 : IP+OW+EQ+FS+BS

From Tensile All. Tens. Comp. All. Comp. Tens. Comp.

Node Stress Stress Stress Stress Ratio Ratio

10 133.74 90.93 99.44 1.4708 *

10 133.49 90.93 99.44 1.4681 *

20 129.98 90.93 100.45 1.4294 *

30 133.71 90.93 99.44 1.4704 *

Analysis of Load Case 9 : EP+OW+WI+FW+BW

From Tensile All. Tens. Comp. All. Comp. Tens. Comp.

Node Stress Stress Stress Stress Ratio Ratio

10 0.00 90.93 0.00 99.44 0.0000 0.0000

10 0.13 90.93 -0.64 99.44 0.0015 0.0064

20 0.15 90.93 -0.57 100.45 0.0017 0.0056

30 90.93 -0.04 99.44 0.0004

Analysis of Load Case 10 : EP+OW+EQ+FS+BS

From Tensile All. Tens. Comp. All. Comp. Tens. Comp.

Node Stress Stress Stress Stress Ratio Ratio

10 0.00 90.93 0.00 99.44 0.0000 0.0000

10 90.93 -0.25 99.44 0.0025

20 90.93 -0.21 100.45 0.0021

30 90.93 -0.04 99.44 0.0004

Analysis of Load Case 11 : HP+HW+HI

From Tensile All. Tens. Comp. All. Comp. Tens. Comp.

Node Stress Stress Stress Stress Ratio Ratio

10 0.00 118.21 0.00 104.14 0.0000 0.0000

10 0.00 118.21 0.00 104.14 0.0000 0.0000

20 0.00 118.21 0.00 104.99 0.0000 0.0000

30 0.00 118.21 0.00 104.14 0.0000 0.0000

Analysis of Load Case 12 : HP+HW+HE

From Tensile All. Tens. Comp. All. Comp. Tens. Comp.

Node Stress Stress Stress Stress Ratio Ratio

10 0.00 118.21 0.00 104.14 0.0000 0.0000

10 0.00 118.21 0.00 104.14 0.0000 0.0000

20 0.00 118.21 0.00 104.99 0.0000 0.0000

30 0.00 118.21 0.00 104.14 0.0000 0.0000

Analysis of Load Case 13 : IP+WE+EW

From Tensile All. Tens. Comp. All. Comp. Tens. Comp.

Node Stress Stress Stress Stress Ratio Ratio

10 133.74 90.93 99.44 1.4708 *

10 133.49 90.93 99.44 1.4681 *

20 129.98 90.93 100.45 1.4294 *

30 133.71 90.93 99.44 1.4704 *

Analysis of Load Case 14 : IP+WF+CW

From Tensile All. Tens. Comp. All. Comp. Tens. Comp.

Node Stress Stress Stress Stress Ratio Ratio

10 133.74 90.93 99.44 1.4708 *

10 133.52 90.93 99.44 1.4684 *

20 130.00 90.93 100.45 1.4297 *

30 133.71 90.93 99.44 1.4705 *

Analysis of Load Case 15 : IP+VO+OW

From Tensile All. Tens. Comp. All. Comp. Tens. Comp.

Node Stress Stress Stress Stress Ratio Ratio

10 133.74 90.93 99.44 1.4708 *

10 133.49 90.93 99.44 1.4681 *

20 129.98 90.93 100.45 1.4294 *

30 133.71 90.93 99.44 1.4704 *

Analysis of Load Case 16 : IP+VE+EW

From Tensile All. Tens. Comp. All. Comp. Tens. Comp.

Node Stress Stress Stress Stress Ratio Ratio

10 133.74 90.93 99.44 1.4708 *

10 133.49 90.93 99.44 1.4681 *

20 129.98 90.93 100.45 1.4294 *

30 133.71 90.93 99.44 1.4704 *

Analysis of Load Case 17 : NP+VO+OW

From Tensile All. Tens. Comp. All. Comp. Tens. Comp.

Node Stress Stress Stress Stress Ratio Ratio

10 0.00 90.93 0.00 99.44 0.0000 0.0000

10 90.93 -0.25 99.44 0.0025

20 90.93 -0.21 100.45 0.0021

30 90.93 -0.04 99.44 0.0004

Analysis of Load Case 18 : FS+BS+IP+OW

From Tensile All. Tens. Comp. All. Comp. Tens. Comp.

Node Stress Stress Stress Stress Ratio Ratio

10 133.74 90.93 99.44 1.4708 *

10 133.49 90.93 99.44 1.4681 *

20 129.98 90.93 100.45 1.4294 *

30 133.71 90.93 99.44 1.4704 *

Analysis of Load Case 19 : FS+BS+EP+OW

From Tensile All. Tens. Comp. All. Comp. Tens. Comp.

Node Stress Stress Stress Stress Ratio Ratio

10 0.00 90.93 0.00 99.44 0.0000 0.0000

10 90.93 -0.25 99.44 0.0025

20 90.93 -0.21 100.45 0.0021

30 90.93 -0.04 99.44 0.0004

Absolute Maximum of the all of the Stress Ratio's 1.4723 *

** Warning: One or more elements were Overstressed due to combined loads !

Governing Element: 1

Governing Load Case 7 : IP+OW+WI+FW+BW

Vous aimerez peut-être aussi

- Discrete Element Method to Model 3D Continuous MaterialsD'EverandDiscrete Element Method to Model 3D Continuous MaterialsPas encore d'évaluation

- TQ-0305-R00 - Calculo Estrutura PDFDocument4 pagesTQ-0305-R00 - Calculo Estrutura PDFPeterson MagroPas encore d'évaluation

- Offshore Mechanics: Structural and Fluid Dynamics for Recent ApplicationsD'EverandOffshore Mechanics: Structural and Fluid Dynamics for Recent ApplicationsPas encore d'évaluation

- Deflection Calculation Due To Imposed Load On Corridor JoistDocument14 pagesDeflection Calculation Due To Imposed Load On Corridor JoistranjitPas encore d'évaluation

- Quake Ubc 97Document6 pagesQuake Ubc 97samuelcharca8194Pas encore d'évaluation

- (Engineersdaily Com) IBC2000E11Document21 pages(Engineersdaily Com) IBC2000E11Nazar ShafiqPas encore d'évaluation

- Design-II, 2016 Bevel Gear Design ProcedureDocument1 pageDesign-II, 2016 Bevel Gear Design ProcedureenggsantuPas encore d'évaluation

- Bevel GearDocument17 pagesBevel Gearparesh09Pas encore d'évaluation

- 2015 - Finite Element Modelling of Debonding Failures in Steel Beams Flexurally Strengthened With CFRP Laminates - Teng Fernando Yu PDFDocument12 pages2015 - Finite Element Modelling of Debonding Failures in Steel Beams Flexurally Strengthened With CFRP Laminates - Teng Fernando Yu PDFvlad lupasteanuPas encore d'évaluation

- Example Problem 9.1 GivenDocument12 pagesExample Problem 9.1 GivengertjaniPas encore d'évaluation

- MESYS Shaft CalculationDocument28 pagesMESYS Shaft CalculationZoebairPas encore d'évaluation

- Pressure Vessel Inspection ReportDocument33 pagesPressure Vessel Inspection ReportJinlong SuPas encore d'évaluation

- Bolted Connections: 1.1 Range and Class of The Screw FastenersDocument8 pagesBolted Connections: 1.1 Range and Class of The Screw FastenersksPas encore d'évaluation

- Bevel ExplanationDocument4 pagesBevel ExplanationVarun VaidyaPas encore d'évaluation

- BMD SFDDocument3 pagesBMD SFDShrinath ShetPas encore d'évaluation

- Wind LoadDocument45 pagesWind LoadglaydellePas encore d'évaluation

- Assignment 5 - Y-Joint FatigueDocument5 pagesAssignment 5 - Y-Joint Fatiguenallay17050% (1)

- Subroutine For Cohesive ElementDocument41 pagesSubroutine For Cohesive ElementBhushanRaj100% (1)

- FT GT F GT D FT G D: AsteriskDocument22 pagesFT GT F GT D FT G D: Asterisk174A1 HindupriyaPas encore d'évaluation

- Calculation Note For Compressor Shelter - Rev ADocument54 pagesCalculation Note For Compressor Shelter - Rev AmaniaxpdfPas encore d'évaluation

- Gantry Crane Load r2Document12 pagesGantry Crane Load r2Bang OchimPas encore d'évaluation

- Types of Damping 1. Viscous DampingDocument6 pagesTypes of Damping 1. Viscous DampingZandro GagotePas encore d'évaluation

- Combined Footing: Project Barrack - Mamnoor Silparupa, Hyderabad Title Combined Footing - 2Document60 pagesCombined Footing: Project Barrack - Mamnoor Silparupa, Hyderabad Title Combined Footing - 2Karthik Kala KondaPas encore d'évaluation

- Chapter 8 Two-Dimensional Problem SolutionDocument51 pagesChapter 8 Two-Dimensional Problem SolutionJoseph Daguio JrPas encore d'évaluation

- Chapter 7 Two-Dimensional FormulationDocument18 pagesChapter 7 Two-Dimensional FormulationHk Lorilla QuongPas encore d'évaluation

- Heat ExchangersDocument30 pagesHeat ExchangersvpjagannaathPas encore d'évaluation

- Bond-Slip Model For Detailed Finite-Element AnalysisDocument10 pagesBond-Slip Model For Detailed Finite-Element AnalysisSilver rayleighPas encore d'évaluation

- Moment Baseplate Design Rev. 0Document3 pagesMoment Baseplate Design Rev. 0Bok MortegaPas encore d'évaluation

- Terminal Report ShredderDocument25 pagesTerminal Report ShredderEnriv YasiladPas encore d'évaluation

- Super Structure: Verticle Sei. Coeff. (Only For Stru. Built in Zone 4 & 5)Document3 pagesSuper Structure: Verticle Sei. Coeff. (Only For Stru. Built in Zone 4 & 5)Omar RubioPas encore d'évaluation

- Bolt Load Calculation StepsDocument2 pagesBolt Load Calculation StepsSrikanth ShankarPas encore d'évaluation

- Foundation Analysis: Calculation SheetDocument1 pageFoundation Analysis: Calculation Sheettaz_taz3Pas encore d'évaluation

- EQL and DesignDocument6 pagesEQL and Designsabareesan09Pas encore d'évaluation

- Fatigue Behavior of Materials Under Strain Cycling in Low and Intermediate Life Range PDFDocument58 pagesFatigue Behavior of Materials Under Strain Cycling in Low and Intermediate Life Range PDFLeonardo TerraPas encore d'évaluation

- Tips For FEA AnalysisDocument6 pagesTips For FEA Analysissagar1503Pas encore d'évaluation

- Modal Space - in Our Own Little World: by Pete AvitabileDocument2 pagesModal Space - in Our Own Little World: by Pete AvitabileVignesh SelvarajPas encore d'évaluation

- Slot Expansion CalculationDocument1 pageSlot Expansion CalculationSarfaraz KhanPas encore d'évaluation

- Solutions Manual C To Accompany Mechanical Vibration, First Edition by William J. Palm III University of Rhode IslandDocument62 pagesSolutions Manual C To Accompany Mechanical Vibration, First Edition by William J. Palm III University of Rhode Islandkeerthiv7Pas encore d'évaluation

- Example 04 (Thermal Stress) PDFDocument12 pagesExample 04 (Thermal Stress) PDFLuis HuayaneyPas encore d'évaluation

- V-340 OutDocument14 pagesV-340 OutSachin5586Pas encore d'évaluation

- 226 - Shaking Table Testing of A Steel Framce Structure...Document9 pages226 - Shaking Table Testing of A Steel Framce Structure...Ing Jaime Espinoza SkinfieldPas encore d'évaluation

- 4 - PFC To Hanging Plate ConnDocument13 pages4 - PFC To Hanging Plate Connabdul khaderPas encore d'évaluation

- AS4041 ASME B31 - 3 Pipe Wall ThicknessDocument1 pageAS4041 ASME B31 - 3 Pipe Wall ThicknessellePas encore d'évaluation

- WF Base Plate Design Based On AISC-ASD 9th Edition: Input Data & Design SummaryDocument2 pagesWF Base Plate Design Based On AISC-ASD 9th Edition: Input Data & Design SummaryShanoor ASPas encore d'évaluation

- Pt. Tripatra Engineering: Calculation SheetDocument6 pagesPt. Tripatra Engineering: Calculation SheetriandiPas encore d'évaluation

- Calculation of Horizontal Seismic Co-Efficient in Transverse DirectionDocument1 pageCalculation of Horizontal Seismic Co-Efficient in Transverse Directionbhavdip_shahPas encore d'évaluation

- Pin Base ModuleDocument16 pagesPin Base ModuleMd Ahsanul KabirPas encore d'évaluation

- Wind Speed Calculation As Per SP-1275Document7 pagesWind Speed Calculation As Per SP-1275Siva baalanPas encore d'évaluation

- LiftingLugStress Rev 1.5Document17 pagesLiftingLugStress Rev 1.5mohdshakir bahariPas encore d'évaluation

- Mathcad C 8220Document29 pagesMathcad C 8220Landon MitchellPas encore d'évaluation

- Machine Design Project ReportDocument11 pagesMachine Design Project ReportMuhammad Abdullah100% (1)

- 40 Seismic ASCE 7-02-05Document2 pages40 Seismic ASCE 7-02-05mohamedabdelalPas encore d'évaluation

- Vessel Side Shell Check CalculationsDocument5 pagesVessel Side Shell Check CalculationsShahir MeledathPas encore d'évaluation

- Fea Project ReportDocument58 pagesFea Project ReportAvnish DubeyPas encore d'évaluation

- Wind CalculatorDocument12 pagesWind Calculatorilyasmd7Pas encore d'évaluation

- Honbun-5030 05 PDFDocument14 pagesHonbun-5030 05 PDFAsif MuhammadPas encore d'évaluation

- ASME Horizontal Vessel AnalysisDocument16 pagesASME Horizontal Vessel AnalysisAsep Darojat100% (1)

- Siesmic LoadDocument2 pagesSiesmic Loadmohit.ojha2013Pas encore d'évaluation

- Wind Seismic Calculation DataDocument8 pagesWind Seismic Calculation Dataaknauriyal2013Pas encore d'évaluation

- So2 BlowerDocument1 647 pagesSo2 Blowersgupta_615796Pas encore d'évaluation

- Irjet V4i5568Document7 pagesIrjet V4i5568mahdiPas encore d'évaluation

- PV Elite 2011Document21 pagesPV Elite 2011chagar_harshPas encore d'évaluation

- Interactive Form U-1ADocument1 pageInteractive Form U-1ADimas AnugrahPas encore d'évaluation

- GuideToModifyIRBTDouble DELMIA-V5Track - 02 PDFDocument20 pagesGuideToModifyIRBTDouble DELMIA-V5Track - 02 PDFBrahim HammamiPas encore d'évaluation

- BSTC Straube Driving Rain-FinalDocument12 pagesBSTC Straube Driving Rain-FinalJohn StraubePas encore d'évaluation

- Calculation Sheet WINDDocument5 pagesCalculation Sheet WINDMuraleedharanPas encore d'évaluation

- Air Pollution Meteorology: Zbigniew SorbjanDocument63 pagesAir Pollution Meteorology: Zbigniew Sorbjanibrahim syedPas encore d'évaluation

- Geography Study GuideDocument6 pagesGeography Study Guidecaptainnemo18Pas encore d'évaluation

- San Isidro Caluan LagunaDocument6 pagesSan Isidro Caluan LagunaDPWH R4A GEOTECHPas encore d'évaluation

- Atmospheric Physics NotesDocument146 pagesAtmospheric Physics NotesZiying FangPas encore d'évaluation

- FILCLAIR. SHELTER. Polydome - Shelter - BrochureDocument5 pagesFILCLAIR. SHELTER. Polydome - Shelter - BrochuretomasfebreroPas encore d'évaluation

- DRRR Module 3 Basic Concept of HazardDocument15 pagesDRRR Module 3 Basic Concept of HazardAbia Annieson A. Lorenzo100% (1)

- Planting System, Lecture 6Document4 pagesPlanting System, Lecture 6Abdullah Al Mamun100% (1)

- Science9 Q3 SLM12Document14 pagesScience9 Q3 SLM12mPas encore d'évaluation

- C Karnaugh PDFDocument4 pagesC Karnaugh PDFIlyas BahjaPas encore d'évaluation

- Inside Tropical Cyclones: Psws # 1Document18 pagesInside Tropical Cyclones: Psws # 1amorembonePas encore d'évaluation

- User Instruction Manual Adjust-A-Net Personnel Net SystemDocument8 pagesUser Instruction Manual Adjust-A-Net Personnel Net SystemTiago FernandesPas encore d'évaluation

- Orthogonal Chime Wind Sail by Lee HiteDocument2 pagesOrthogonal Chime Wind Sail by Lee HiteEvanWinslowPas encore d'évaluation

- Storm Damage ReportsDocument1 pageStorm Damage ReportsCurtis HeyenPas encore d'évaluation

- 050 MeteorologyDocument894 pages050 MeteorologykgyjuhiPas encore d'évaluation

- Land Sea BreezesDocument2 pagesLand Sea BreezesShemae ObniPas encore d'évaluation

- Chinese PoetryDocument125 pagesChinese PoetrywriterhariPas encore d'évaluation

- Results of The Electromagnetic InvestigationsDocument84 pagesResults of The Electromagnetic InvestigationsJohn WilliamsonPas encore d'évaluation

- DP1 - Wave Tidal Energy in UAE. Week 11 ModefiedDocument37 pagesDP1 - Wave Tidal Energy in UAE. Week 11 ModefiedMuhammad Raza RafiqPas encore d'évaluation

- SSSSWDocument8 pagesSSSSWRavi GajenthranPas encore d'évaluation

- Typhoon - WorksheetDocument2 pagesTyphoon - WorksheetNeilJohnYumul56% (9)

- Downsizing On The Water: Sailing & WindsurfingDocument1 pageDownsizing On The Water: Sailing & WindsurfingSF ghhgPas encore d'évaluation

- Physiography of Lakes and Reservoirs - Mixing Regimes and Water MovementDocument4 pagesPhysiography of Lakes and Reservoirs - Mixing Regimes and Water MovementSalemGoodsPas encore d'évaluation

- Bioclimatic Architecture: Housing and Sustainability: December 2014Document14 pagesBioclimatic Architecture: Housing and Sustainability: December 2014Vanshika DograPas encore d'évaluation

- Clouds E PDFDocument28 pagesClouds E PDFvgdlpc74Pas encore d'évaluation

- 1 GRCDocument10 pages1 GRCmsiddiq1Pas encore d'évaluation

- Erosion and Deposition 2015-2016 v3Document58 pagesErosion and Deposition 2015-2016 v3api-263382165Pas encore d'évaluation

- 1.1 Aviation and Electronics: A Symbiotic RelationshipDocument9 pages1.1 Aviation and Electronics: A Symbiotic RelationshipramchanderPas encore d'évaluation

- Beaufort ScaleDocument6 pagesBeaufort Scaleavi_cha5215Pas encore d'évaluation