Académique Documents

Professionnel Documents

Culture Documents

Hvac

Transféré par

mohamed adelCopyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Hvac

Transféré par

mohamed adelDroits d'auteur :

Formats disponibles

B.O.

Q HVAC WORKS

PROJECT TITLE : ااالفندقااالساحلي- منتجع ااالجل لة

DATE : Feb., 2016

SECTION MECHANICAL HVAC WORKS

ITEM NO. UNIT QTY. UNIT PRICE

NO.

DESCRIPTION

General notes:

01 Supply installation and commissioning of a complete system of Air

condition system, ductwork, all piping, fittings and controls as herein

specified and shown on plans. Price for system shall include all required

equipment accessories, pipe sleeves & Escutcheons, Equipment

identification, tools & spare parts, protective painting of all systems ...etc.

02 Specification, drawings, and bill of quantities are complimentary and are

to be taken together for complete interpretations of the work.

03 In case of conflict between contract document, please refer to the

engineer for clarification.

04 Quantities, include in this bill of quantities is for guidance, the contractor

shall check and verify all quantities.

05 The contractor should include in his offer all required materials needed

for optimum operation whatever or not mentioned in the bill of quantity.

06 Responsibility of contractor is to ensure that all works are in conformity

with international stated codes and local regulations.

07 The specification, the accompanying drawings and bill of quantities, are

intended to secure the provisions of all material, labor equipment, and

services necessary to install complete, tested, ready for operation and set

to work the fire fighting systems in accordance with the specifications

and drawings.

HVAC. WORKS Page 1 of 48 REV. 0

B.O.Q HVAC WORKS

PROJECT TITLE : ااالفندقااالساحلي- منتجع ااالجل لة

DATE : Feb., 2016

SECTION MECHANICAL HVAC WORKS

ITEM NO. UNIT QTY. UNIT PRICE

NO.

DESCRIPTION

To Collection LE

01 WATER- COOLED ABSORBTION CHILLERS

Supply,Installation, connection, start up, testing and balancing and

commissioning of direct fired absorbition chiller with a gas burner,

105°F as specified:- unit shall be c/w solution pumps, heat exchangers,

purge system, variable speed vacuam pump,automatic

decrystallization,complete with factory insulation for cold and hot

clading, include to supply all piping connections, pipe installation,

balancing valves, temperature /pressure ondicators, flow switches, batter

fly valve control panel (IP-55) with all safety and operating controls,

initial refrigerant solution charges, vibration absorbers, steel platform,

foundation ….etc. as herein specified and according to P.T.S & P.D.

Note:- chiller shall be c/w all interfaces and accessories requied for

connection to BMS (In case of using BMS system)

01.1 ENTERING /LEAVING CH.W.TEMP: 54/43 F

CH.W.RATE OF FLOW 1920 GPM

- COOLING CAPACITY 800 T.R WITH COP 1.35 No. 3 2,500,000

01.2 - Exh. chimany with insoulation 3 mm thickness and cap- 8m length No. 3 20,000

02 COOLING TOWERS

Supply, Install, connect, testing and commissioning of low noise cooling

tower ,induced flow cooling tower.unit casing cold and distribution

basins shall be made of anti-corrosion material (Hot deep galvanized). the

frame other steel section shall be hotdipped galvanized steel.the fan shall

be low noise variable speed type.motor shall be with IP55,unit shall be

c/w all controls,pvc fill ,water distribution system, eliminators,

accessories and in general all work,parts,devices and attachments

required for safe and proper operation of the unit as herein specified as

shown on plants include to supply shut-off valves, balancing valves,

butter fly valves neoprene connectors, thermometers temperature,

pressure gauge, flow switches, drainage valve, vent cock over flow, make

up, bleed valves, piping and connection including flanges, bolts, nuts,

gaskets, coupling, paint or surface treatment, supporting base frame, as

well as any sound isolation to reach good performance level, co-

ordination with other disciplines to get full harmony in operation and safe

installations, testing, balancing and start up. include to supply and install

steel structure base and frame see schedule, details and flow diagram

drawings

Note : Final capacity of cooling tower shall be determinated by chiller

supplier without addtional cost. Isolation and supporting against seismic

of above mentioned cooling towers as per specification (15547), relevant

and corresponding drawings - AMCA & cirtified CTI-ST-201 (Baltimor,

evapco or approved equal).

02.1 C.T-1&2&3 rate flow rate 3600 gpm

Entering and leaving water temperature 95/85F

Ambient air DB AND WB temperature 110/80 F No. 3 1,000,000

HVAC. WORKS Page 2 of 48 REV. 0

B.O.Q HVAC WORKS

PROJECT TITLE : ااالفندقااالساحلي- منتجع ااالجل لة

DATE : Feb., 2016

SECTION MECHANICAL HVAC WORKS

ITEM NO. UNIT QTY. UNIT PRICE

NO.

DESCRIPTION

02.2 (Baltimor, evapco or approved equal) fitlration system (sand filter with

fttration pump 360gpm No. 3 33,000

To Collection LE

03 CHILLED WATER PUMP

supply,install, connection, testing, balancing and commissioning of

chilled Vertical inline type water pumps, with aoutomatic water blance

according to the schedules and specifications including all accessories,

components, coupling guard, include to supply steel base and frame,

shut-off valves Balancing valve, check valve, drainage valve, vent valve,

strainer, neoprene connectors, earthing ,piping required to be connected

with the system including fittings, flange, bolts, nuts, gaskets, supports,

painting, thermometers temperature, pressure gauge, thermal insulation

for pump complete with aluminum cladding, tags, labels flow indicators

and color codes.capacity must be matching and compatible with above

chiller, Isolation and supporting against seismic and all other accessories

as shown per drawings and specifications (Armstrong or approved equal).

03.1 Constant speed primary pumps - 1920GPM with at static head of 85FT.

(One Stand By). No. 4 300,000

03.2 Variable speed secondary pumps -2880GPMat static head of 120FT.

(One Stand By). No. 3 350,000

04 CONDENSER WATER PUMP

Supply,Installation, connection, testing, balancing and commissioning of

condenser water pumps vertical inline type, according to the schedules

and specifications including all accessories, components, coupling guard,

include to supply steel base and frame, shut-off valves Balancing valve,

check valve, drainage valve, vent valve, strainer, neoprene connectors,

earthing ,piping required to be connected with the system including

fittings, flange, bolts, nuts, gaskets, supports, painting, thermometers

temperature, pressure gauge, thermal insulation for pump complete with

aluminum cladding, tags, labels flow indicators and color

codes.contractor to be check of pump capacities to mach with the

capacity of above cooling tower, Isolation and supporting and all other

accessories as shown per drawings and specifications.

04.1 constant speed pumps -3600GPM at static head of 85FT. (One Stand By)

(Armstrong or approved equal). No. 4 350,000

05 EXPANSION TANKS

HVAC. WORKS Page 3 of 48 REV. 0

B.O.Q HVAC WORKS

PROJECT TITLE : ااالفندقااالساحلي- منتجع ااالجل لة

DATE : Feb., 2016

SECTION MECHANICAL HVAC WORKS

ITEM NO. UNIT QTY. UNIT PRICE

NO.

DESCRIPTION

Supply and Install of closed type expansion tank according to the

schedule and specifications including accessories, components, steel

base, frame, water shut-off valves, vent valves, drain valves, level

indicator, cortroler valves, thermometers temperature and pressure

solenoid valve, piping required to be connected with the system include,

fittings, flanges, bolts, nuts, gaskets, supports and painting, rubber pads

for sound, thermal insulation of the tank complete with cladding, tags,

labels flow indicators and color finishing, startup and commissioning of

the unit. Isolation and all other accessories as shown per drawings and

specifications.

05.1 - Chilled water system 1000 Liter (Taco or approved equal) No. 1 60,000

To Collection

06 WATER TREATMENT

Supply and install water treatment system and provision of flushing and

chemical cleaning with tools and options as feeding, dosing

pumps.component, devices, consumable materials, chemicals to cover

one year operation, shut-off valves, drainage valves, vent valves,

chemical tanks, hoses, pumps and control panel with earthing, piping

required to be connected to the system include fittings and supporting,

painting, insulation and cladding, testing, balancing, start-up and

commissioning of the system as per specifications and drawings.

06.1 Chilled Water Network

- Dosing system shall be automatic type c/w dozing pumps and controls

for automatic operation Sys. 1 80,000

06.2 Condenser Water Network

- Dosing system shall be automatic type c/w dozing pumps and controls

for automatic operation

- Operation hours :18 [hr/day]

- Max circulating rate:10800[GPM]

- Make up flow rate:[Evaporating +Bleeding +window losses/tower]: 80

gpm approx Sys. 1 60,000

15997 07 Cleaning and Flushing

System Cleaning and Flushing include supply of chemicals and provision

of Systems Cleaning and Flushing include supply of chemicals and

provision of cleaning equipment, System Cleaning and Flushing based

on building chilled water network and capacity of chiller.

07.1 - COOLING CAPACITY 3x800 T.R Sys. 1 75,000

08 AIR SEPERATOR (Flashing Type)

Supplying, installing, and commisioning of an air seperator and a make

up water assembly c/w alla connections, isolation valves, check valves,

flow meters, presure regulating valves, relief valves, pressure gagues,

strainers, piping, mounting frame....ets, as herein specified and according

to P.T.S & P.D.

08.1 - dia 16" (Taco or approved equal) No. 1 135,000

HVAC. WORKS Page 4 of 48 REV. 0

B.O.Q HVAC WORKS

PROJECT TITLE : ااالفندقااالساحلي- منتجع ااالجل لة

DATE : Feb., 2016

SECTION MECHANICAL HVAC WORKS

ITEM NO. UNIT QTY. UNIT PRICE

NO.

DESCRIPTION

09 AIR HANDLING UNIT

Supplying, Installing, and commissioning of double skin (5 cm-

insulation,internal and external sheet 0.7mm) Air Handling Units 450-550

f.p.m coile velocity according to specification, schedules and drawings,

c/w fresh air intake louver, supply plenum, mixing box, 1'' aluminum foil

pre filter, bag filter, chilled water cooling coil (copper tube aluminum fin

with zinc coated), DIDW high efficiency air foil or backward curved

supply fan, [C/W window + lamp], PVC drain piping connection to the

nearest drain point, base, hookup valves for the cooling coil,two way

control valve, balance valves, strainer, gate valves, flexable connection,

vent, thermostats pressure gauge, fans, ,.. etc., and all necessary

accessories as per standard specification.

Note:- Final static pressure to be submitted by contractor for approval

wihout variation order or extra cost.

To Collection

09.1 - AHU-B-01 15000 CFM 68 T.R with 2.5 inwg No. 1 135,000

09.2 - AHU-B-02 15500 CFM 70 T.R with 2.5 inwg No. 1 135,000

09.3 - AHU-B-03 16000 CFM 72 T.R with 2.5 inwg No. 1 135,000

09.4 - AHU-B-04 16000 CFM 72 T.R with 2.5 inwg No. 1 135,000

09.5 - AHU-B-05 16100 CFM 72.5 .5T.R with 2.5 inwg No. 2 135,000

09.6 - AHU-B-06 16800 CFM 76 T.R with 2.5 inwg No. 1 160,000

09.7 - AHU-B-07 21000 CFM 95 T.R with 2.5 inwg No. 1 160,000

09.8 - AHU-B-08 22300 CFM 79.5 T.R with 2.5 inwg No. 1 160,000

09.9 - AHU-B-09 23100 CFM 105 T.R with 2.5 inwg No. 1 180,000

09.10 - AHU-B-10 30000 CFM 120 T.R with 2.5 inwg No. 1 170,000

09.11 - AHU-B-11 24500 CFM 115 T.R with 2.5 inwg No. 1 190,000

09.12 - AHU-B-12 25430 CFM 115 T.R with 2.5 inwg (Variable Speed).

No. 1 170,000

09.13 - AHU-B-13 25850 CFM 105 T.R with 2.5 inwg No. 1 180,000

09.14 - AHU-B-14 29800 CFM 107 T.R with 2.5 inwg No. 1 170,000

09.15 - AHU-G-01 22900 CFM 82 T.R with 2.5 inwg No. 1 180,000

09.16 - AHU-G-02 31800 CFM 113.5 T.R with 3 inwg No. 1 180,000

09.17 - AHU-G-03 16000 CFM 60 T.R with 2 inwg (Variable Speed).

No. 1 125,000

09.18 - AHU-R-01 9000 CFM 40 T.R with 2 inwg No. 1 125,000

09.19 - AHU-R-02 9200 CFM 42 T.R with 2 inwg No. 1 125,000

09.20 - AHU-R-03 18250 CFM 65 T.R with 3 inwg No. 1 15,000

09.21 - AHU-R-04 22800 CFM 81.5 T.R with 3 inwg No. 1 180,000

09.22 - AHU-R-04 32000 CFM 114.5 T.R with 3 inwg No. 2 180,000

09.23 - FAHU-B-01 1300 CFM 6.5 T.R with 1.5 inwg No. 1 65,000

09.24 - FAHU-B-02 19750 CFM 152 T.R with 2 inwg No. 1 150,000

09.25 - FAHU-G-01 6000 CFM 46 T.R with 1.25 inwg No. 1 95,000

09.26 - FAHU-G-02 20000 CFM 70 T.R with 2 inwg No. 1 160,000

09.27 - FAHU-R-01 6600 CFM 51 T.R with 3 inwg No. 1 190,000

09.28 - FAHU-R-02 7475 CFM 37.5 T.R with 3 inwg No. 1 95,000

09.29 - FAHU-R-03 9175 CFM 46 T.R with 3 inwg No. 1 125,000

10 V.A.V UNITS

HVAC. WORKS Page 5 of 48 REV. 0

B.O.Q HVAC WORKS

PROJECT TITLE : ااالفندقااالساحلي- منتجع ااالجل لة

DATE : Feb., 2016

SECTION MECHANICAL HVAC WORKS

ITEM NO. UNIT QTY. UNIT PRICE

NO.

DESCRIPTION

Supply and install of standardfan variable air volume concealed complete

with all standard, accessories as shown on drawings, schedules and

specifications and motorized volume control damper) factory assmebly

complete with,temperature controller, flexible connection, sealers for

sound and leakage and isolation screens Item including testing,

balancing, startup and - commissioning of the units.and fitted to

ductwork and built into structure including insulation to match

surrounding ductwork as described in the specification and refer details

on drawing.

10.1 - V.A.V-01 From ( 1200 To2395 ) CFM,0.5kW- 2kw electric heats No. 2 9,500

10.2 - V.A.V-02 From ( 2395 To3400 ) CFM,0.5kW- 4kw electric heats No. 2 13,000

10.3 - V.A.V-03 From ( 2395 To3400 ) CFM,0.5kW- 4kw electric heats No. 3 13,000

10.4 - V.A.V-04 From ( 2395 To3400 ) CFM,0.5kW- 4kw electric heats No. 7 13,000

10.5 - V.A.V-05 From (3400 To4300 ) CFM,1kW- 6kw electric heats No. 2 14,000

10.6 - V.A.V-05 From (3400 To4300 ) CFM,1kW- 6kw electric heats No. 1 14,000

To Collection

11 FANS

Supplying, installing & commissioning of Exhaust fans;wall mounted

type,epoxy coated impeller and housingc/w electric motors class f IP55,

casing, gravity shutter, and bird screen at discharge side, hangers,

supports, canvass duct connections, electrical power and control cables

connection, and all necessary accessories as per the specifications,

drawings, and as herein specified:

11.1 CENTRIFUGAL EXHAUST FAN

- EXH.F-R-02, 450 CFM, 0.9 IN.W No. 1 6,500

- EXH.F-R-03, 1700 CFM, 1.75 IN.W No. 1 8,500

- EXH.F-R-04, 2725 CFM, 1.75 IN.W No. 1 10,200

- EXH.F-R-05, 2850 CFM, 1.75 IN.W No. 1 10,200

- EXH.F-R-06, 5350 CFM, 2.0 IN.W No. 1 15,500

- EXH.F-R-07, 6150 CFM, 2.0 IN.W No. 1 15,500

- EXH.F-B-01, 4000 CFM, 1.5 IN.W No. 1 12,500

- EXH.F-B-02, 10800 CFM, 2.5 IN.W No. 1 25,000

- EXH.F-B-03, 8000 CFM, 1.5 IN.W No. 1 25,000

- EXH.F-B-04, 4000 CFM, 0.5 IN.W No. 1 12,500

11.2 Parking Fan Type

Supplying, installing & commissioning of Exhaust and smoke extraction

fans; CENTRIFUGAL INLINE,epoxy coated impeller and housing,

smoke rated 300C for 2hr c/w electric motors class f IP55, casing, gravity

shutter, and bird screen at discharge side, hangers, supports, canvass duct

connections, electrical power and control cables connection, and all

necessary accessories as per the specifications, drawings, and as herein

specified (Max noise level 75 DB)

- EXH.F-B-04 (24000 /40320 CFM) with 3in.wg [2-speed] No. 2 95,000

- EXH.F-B-05 (27000 /45000 CFM) with 3in.wg [2-speed] No. 3 95,000

- EXH.F-B-06 (29000 /45000 CFM) with 3in.wg [2-speed] No. 1 95,000

HVAC. WORKS Page 6 of 48 REV. 0

B.O.Q HVAC WORKS

PROJECT TITLE : ااالفندقااالساحلي- منتجع ااالجل لة

DATE : Feb., 2016

SECTION MECHANICAL HVAC WORKS

ITEM NO. UNIT QTY. UNIT PRICE

NO.

DESCRIPTION

11.3 Smoke Fan

Supplying, installing & commissioning of smoke extraction fans;

centrifugal type,epoxy coated impeller and housing, smoke rated 300C

for 2hr c/w electric motors class f IP55, casing, gravity shutter, and bird

screen at discharge side, hangers, supports, canvass duct connections,

electrical power and control cables connection, and all necessary

accessories as per the specifications, drawings, and as herein specified:

- SM.F-B-01, 10000 CFM with 2 inwg No. 1 85,000

- SM.F-R-01, 3500 CFM with 2.5 inwg No. 2 40,000

- SM.F-R-02, 10000 CFM with 2.5 inwg No. 2 85,000

- SM.F-R-03, 24500/27000 CFM with 2.5 inwg (Two Speed) No. 2 95,000

- SM.F-R-04, 32000/40000 CFM with 2.5 inwg (Two Speed) No. 4 110,000

To Collection

11.4 Pressurization Fan (FAN SECTION WITH PREFILTER) Inter lock

with pressure relif damper

Note:- Final static pressure to be submitted by contractor for approval

without variation order or extra cost.

- PR.F-01, 4800 CFM with 2.5 inwg No. 6 12,800

- PR.F-02, 5250 CFM with 3 inwg No. 2 18,000

11.5 KITCHEN EXHAUST FAN

kitchen exhaust 1450 RPM, belt driven, tube centrifugal, black steel,

epoxy coated impeller and housing,suitable for air stream up to 130C c/w

electric motors class f IP55, casing, gravity shutter, and bird screen at

discharge side, hangers, supports, canvass duct connections, electrical

power and control cables connection, and all necessary accessories as per

the specifications, drawings, and as herein specified:

Note (A):- final capacity according to kit. furniture" (firrary manf. or

approved equal).

Note (B):- Final static pressure to be submitted by contractor for

approval without variation order or extra cost.

- EXH.F-K-R-01, 1300 CFM, 2 IN.W No. 1 8,200

- EXH.F-K-R-02, 1350 CFM, 2 IN.W No. 1 8,200

- EXH.F-K-R-03, 1500 CFM, 2 IN.W No. 2 8,500

- EXH.F-K-R-04, 1700 CFM, 2 IN.W No. 1 8,500

- EXH.F-K-R-05, 1800 CFM, 2 IN.W No. 1 12,500

- EXH.F-K-R-06, 4000 CFM, 2 IN.W No. 1 22,000

- EXH.F-K-R-07, 5400 CFM, 2 IN.W No. 1 22,000

- EXH.F-K-R-08, 8000 CFM, 2 IN.W No. 1 28,000

- EXH.F-K-R-09, 9150 CFM, 2 IN.W No. 1 28,000

- EXH.F-K-R-10, 15000 CFM, 2.5 IN.W No. 1 30,000

- EXH.F-K-R-11, 4000 CFM, 2 IN.W No. 1 12,500

HVAC. WORKS Page 7 of 48 REV. 0

B.O.Q HVAC WORKS

PROJECT TITLE : ااالفندقااالساحلي- منتجع ااالجل لة

DATE : Feb., 2016

SECTION MECHANICAL HVAC WORKS

ITEM NO. UNIT QTY. UNIT PRICE

NO.

DESCRIPTION

- EXH.F-K-R-05A, 3000 CFM, 2 IN.W No. 2 12,500

- EXH.F-K-R-12, 3500 CFM, 2 IN.W No. 1 12,500

- EXH.F-K-R-13, 6000 CFM, 2 IN.W No. 1 25,000

- EXH.F-K-B1, 1300 CFM, 1 IN.W (In Line Centrifical) No. 1 8,200

11.6 WALL MOUNTED EXHAUST FAN

- W.M-01, 950 CFM, 0.15 IN.W No. 24 2,200

- W.M-02, 1450 CFM, 0.15 IN.W No. 2 3,200

- W.M-S-01, 200 CFM, 0.1 IN.W No. 2 1,200

- W.M-S-02, 300 CFM, 0.1 IN.W No. 1 1,200

- W.M-S-03, 1500 CFM, 0.17 IN.W No. 4 3,800

- W.M-S-04, 2000 CFM, 0.2 IN.W No. 2 4,200

- W.M-S-05, 3000 CFM, 0.25 IN.W No. 3 5,400

- W.M-S-06, 4000 CFM, 0.3 IN.W No. 1 6,800

- W.M-S-07, 5000 CFM, 0.4 IN.W No. 3 9,600

To Collection

11.7 FREASH AIR FAN

Supplying, installing & commissioning of FRESH AIR fan FAN

SECTION type c/w PREFILTER c/w electric motors class f IP55, casing,

gravity shutter, and bird screen at discharge side, hangers, supports, self

closing flaps canvass duct connections, electrical power and control

cables connection, and all necessary accessories as per the specifications,

drawings, and as herein specified:

Note:- Final static pressure to be submitted by contractor for approval

without variation order or extra cost.

- F.A.F-G-01, 9600 CFM, 1 IN.W No. 1 22,000

- F.A.F-K-R-01, 2000 CFM, 2 IN.W No. 1 14,000

- F.A.F-K-R-02, 3000 CFM, 2 IN.W No. 1 16,000

- F.A.F-K-R-03, 3000 CFM, 1 IN.W No. 1 16,000

12 FAN COIL UNIT

Supply and install, connecting, testing and commissioning of fan coil

units (FCUs) according to the schedules and specifications including

accessories, component, complete with coils, fan, filter, water shut-off

valves, double regulating valves, 3way modulating valves, vent valves,

strainer, dielectric connection, hard copper seamless piping with fitting

required to be connected with the system include, fittings, bolts, nuts,

gaskets, supports, paint, digital thermometers temperature, rubber pads,

electric heater, thermal insulation of the pipes complete with tags,

cladding, labels flow indicator and color code finishing. according to

detail drawing and schedule drawings. [CARRIER BRAND]

12.1 - FCU-02 600 CFM, 1.5TR with 0.15IN.W - 1.5 kw electric Heater No. 1 7,500

12.2 - FCU-03 800 CFM, 2TR with 0.15IN.W - 2 kw electric Heater No. 12 9,500

12.3 - FCU-04 1000 CFM, 2.5TR with 0.15IN.W - 2.5kw electric Heater No. 306 12,000

HVAC. WORKS Page 8 of 48 REV. 0

B.O.Q HVAC WORKS

PROJECT TITLE : ااالفندقااالساحلي- منتجع ااالجل لة

DATE : Feb., 2016

SECTION MECHANICAL HVAC WORKS

ITEM NO. UNIT QTY. UNIT PRICE

NO.

DESCRIPTION

12.4 - FCU- 05 1200 CFM, 3TR with 0.15IN.W - 3kw electric Heater No. 42 14,000

13 DX SPLIT UNITS

Supplying, installing & commissioning of HIGH WALLsplit air

conditioning unit, c/w, Refrigerant pipes, hermatic compressor, condenser

coil, condenser fan and motor, expansion device, charging valves and

controls, evaporator unit, remote control switch, overloads, controls,

wirring contactors, refrigerant charge, supports, and all necessary

accessories as per specifications and drawings, with the following

specifications:-

13.1 - SP.U-36 36000 BTU/HR No. 2 14,500

13.2 - SP.U-18 18500 BTU/HR No. 1 9,800

13.3 - SP.U-24 24000 BTU/HR No. 2 12,500

To Collection

14 PIPE AND FITTINGS

Supply and install of black seamless steel pipes according to

specifications and as shown on drawings complete with pipes, fittings,

specialties, tags, connections, flanges, bolts, nuts, gaskets, sealers,

coupling and expansion joint, supports, hangers including rods, anchors,

beams, rollers, saddle and surface cleaning, treatment, painting of flow

indicators with color code finishing, cutting, normalizing bending as well

as rubber pads for sound isolation, testing, balancing and start-up to the

connections with other units.

14.1 - 0.75" Diam. M 400 150

14.2 - 1" Diam. M 5120 190

14.3 - 1 1/4" Diam. M 1200 220

14.4 - 1 1/2" Diam. M 320 250

14.5 - 2" Diam. M 480 280

14.6 - 2 1/2" Diam. M 688 320

14.7 - 3" Diam. M 352 450

14.8 - 4" Diam. M 800 650

14.9 - 6" Diam. M 864 850

14.10 - 8" Diam. M 160 1,100

14.11 - 10" Diam. M 240 2,500

14.12 - 12" Diam. M 80 2,800

14.13 - 14" Diam. M 152 3,200

14.14 - 16" Diam. M 176 3,500

14.15 - 20" Diam. M 60 4,500

15 DRAINAGE

HVAC. WORKS Page 9 of 48 REV. 0

B.O.Q HVAC WORKS

PROJECT TITLE : ااالفندقااالساحلي- منتجع ااالجل لة

DATE : Feb., 2016

SECTION MECHANICAL HVAC WORKS

ITEM NO. UNIT QTY. UNIT PRICE

NO.

DESCRIPTION

Supplying, Installing, and commisioning of drainage piping for the

HVAC equipments from each equipment to the nearest drain point,

manufactured from waven pipe, c\w fittings, hangers, supports, and all

necessary accessories for proper installation and operation as per

drawings and specifications confirming the requirements of ASHRAE.

15.1 - 1" Diam. M. 1440 65

15.2 - 2" Diam. M. 480 75

16 CHILLED WATER NETWORK VALVES 0

Supplying , installing and commission of all required valves for the

chilled water piping network, gate valves and balancing valves as per the

specifications and the drawings. 0

16.1 GATE VALVES 0

- 1 1/25" Diam. No. 232 800

- 1 1/2" Diam. No. 40 2,000

- 2" Diam. No. 40 2,500

- 2 1/2" Diam. No. 10 3,000

- 3" Diam. No. 56 3,500

- 4" Diam. No. 14 4,500

- 6" Diam. No. 4 6,500

- 8" Diam. No. 4 8,500

- 10" Diam. No. 4 9,000

- 12" Diam. No. 4 10,800

To Collection

16.2 BALANCE VALVES 0

- 1 1/25" Diam. No. 20 2,500

- 1 1/2" Diam. No. 20 3,100

- 2" Diam. No. 10 4,500

- 2 1/2" Diam. No. 25 5,500

- 3" Diam. No. 10 8,000

- 4" Diam. No. 6 8,500

- 6" Diam. No. 4 9,800

- 8" Diam. No. 2 11,500

- 10" Diam. No. 2 13,500

- 12" Diam. No. 1 18,500

16.3 DRAIN VALVES 0

- 1" Diam. No. 90 550

- 2" Diam. No. 10 850

16.4 AUTOMATIC AIR VENT 0

- 1" Diam. No. 90 750

- 2" Diam. No. 10 1,200

17 DUCT WORK

HVAC. WORKS Page 10 of 48 REV. 0

B.O.Q HVAC WORKS

PROJECT TITLE : ااالفندقااالساحلي- منتجع ااالجل لة

DATE : Feb., 2016

SECTION MECHANICAL HVAC WORKS

ITEM NO. UNIT QTY. UNIT PRICE

NO.

DESCRIPTION

Supply, installation connecting, testing and commissioning of

galvanized or black steel or aluminum, or stainless steel materials

fabricated, according to the specifications and drawings including

all accessories, complete with-but not limited to: delivers, stored in

good conditions, flexible connection, splitter linear diffuser boxes,

inspection doors, support, hangers, rods, anchors nuts, bolts,

riveting and sealers, sleeves, tags, charts labels, color code

finishing, flow indicator, earthing, see detail drawings.

17.1 - Galvanized Duct. Ton 220 28,000

17.2 - Black Steel Duct Ton 12 26,000

17.3 - Stainless Steel Duct Ton 3 55,000

18 Fire Dampers and volume damper

Supply, installation, connection, testing and commissioning of fire

dampers complete with all accessoreis as shown on drawings and

specifications.

18.1 - 1 square inch IN2 62000 10

19 Volume damper

Supply, install, conntection, testing and commissioning of

additional separation manual volume dampers and blind capping

flange, complete with all accessories as shown on drawing and

specifications to manage operation of stages.

19.1 - 1 square inch IN2 76000 8

To Collection

20 Motarized smoke damper

Supply, install, conntection, testing and commissioning of

additional separation motarized smoke dampers and blind capping

flange, complete with all accessories as shown on drawing and

specifications to manage operation of stages.

20.1 - 1 square inch IN2 15500 15

21 Pressure reilf damper

Supply, install, conntection, testing and commissioning of pressure

reilf damper inter lock with pressure fan

21.1 - 36'' x 8'' No. 6 2,800

22 THERMAL INSULATION

Supply & Install thermal insulation of the chilled water pipes from fiber

glass high density not less than 64Kg/m3 with thickness 25mm in

conditioning area and 50mm in un-conditioning area with aluminum foil

and with supply and install cladding for exposed piping (roof, mech.

room and non reflecting ciling area) and all accessories as shown on

drawing and specification as following:-

22.1 - 0.75" Diam. M 400 75

HVAC. WORKS Page 11 of 48 REV. 0

B.O.Q HVAC WORKS

PROJECT TITLE : ااالفندقااالساحلي- منتجع ااالجل لة

DATE : Feb., 2016

SECTION MECHANICAL HVAC WORKS

ITEM NO. UNIT QTY. UNIT PRICE

NO.

DESCRIPTION

22.2 - 1" Diam. M 5120 75

22.3 - 1 1/4" Diam. M 1200 75

22.4 - 1 1/2" Diam. M 320 75

22.5 - 2" Diam. M 480 95

22.6 - 2 1/2" Diam. M 688 95

22.7 - 3" Diam. M 352 125

22.8 - 4" Diam. M 800 125

22.9 - 6" Diam. M 864 150

22.10 - 8" Diam. M 160 225

22.11 - 10" Diam. M 240 280

22.12 - 12" Diam. M 80 350

22.13 - 14" Diam. M 152 380

22.14 - 16" Diam. M 176 450

23 DUCT INSULATION

23.1 Supplying, Installing, and commisioning of thermal insulation for supply

and return air ducts manufactured from fiberglass with aluminum foil, 1''

thickness and 24 kg\m3 density for indoor ducts and 2'' thickness for

outdoor ducts,aluminum cladding for the outdoor ducts, 0.3mm thickness

c\w all necessary accessories for proper installation and operation as per

drawings and specifications confirming the requirements of ASHRAE &

SMACNA M2 20,000 75

23.2 Supply and install 25 mm thickness blanket arm flix duct insulation for

acoustic absorption inside first section of ducts connects to fan coil units

and air handling units, non combustible, faced with smoth tissue with

minimum thekness 6mm, including all required adhesive, sealing, metal

strips and any other accessories needed for proper installation and

fixation M2 4,500 65

To Collection

23.3 Supply, Installation, Connection, Testing and Commission of Black Steel

Duct thermal insulation from rockwall 10 cm complete with all

accessories as shown on drawings and specifications. M2 220 190

23.4 Supply, installation, connection, testing and commission of flexible duct

thermal insulation complete with cladding, vapor barrier and all

accessories as shown on drawings and specifications.

23.4.1 - dia 8" M 1600 220

23.4.2 - dia 10" M 2200 240

23.4.3 - dia 12" M 1200 260

23.5 Supply, installation, connection, testing and commission of 0.6mm

aluminum cladding for exposed duct and pipes at the roof, and all

accessories as shown on drawings and specifications. M2 3000 220

24 AIR DISTRIBUTION

HVAC. WORKS Page 12 of 48 REV. 0

B.O.Q HVAC WORKS

PROJECT TITLE : ااالفندقااالساحلي- منتجع ااالجل لة

DATE : Feb., 2016

SECTION MECHANICAL HVAC WORKS

ITEM NO. UNIT QTY. UNIT PRICE

NO.

DESCRIPTION

Supply, install, connection, balancing and commissioning of grilles, slots,

diffusers complete with-but not limited to straightners, dampers,

plenums, clamps, hangers support and paint and all other accessories as

per specifications and as shown on drawings.

24.1 Supply Grill

24.1.2 - 8"x6" No. 1 192

24.1.3 - 8"x8" No. 1 256

24.1.4 - 10"x6" No. 1 240

24.1.5 - 16"x6" No. 1 384

24.1.6 - 18"x10" No. 10 720

24.1.7 - 22"x6" No. 5 528

24.1.7 - 24"x12" No. 1 2,304

24.1.8 - 26"x14" No. 1 1,456

24.1.9 - 30"x8" No. 1 960

24.1.10 - 34"x12" No. 14 1,632

24.1.11 - 42"x14" No. 2 2,352

24.1.11 - 48"x20" No. 2 3,840

24.1.13 - 60"x20" No. 2 4,800

24.1.13 - 60"x14" No. 1 3,360

24.1.14 - 68"x20" No. 2 5,440

24.1.15 - 70"x32" No. 1 8,960

24.1.16 - 72"x14" No. 1 4,032

24.1.17 - One inch square (For any extra work option item) in2 1 4

24.2 Supply Register

24.1.2 - 8"x4" No. 4 192

24.1.3 - 8"x6" No. 8 288

24.1.4 - 10"x6" No. 8 360

24.1.5 - 18"x10" No. 13 1,080

24.1.6 - 22"x10" No. 1 1,320

24.1.7 - 24"x12" No. 3 1,728

24.1.8 - 28"x10" No. 1 1,680

To Collection

24.2.1 - 40"x6" No. 326 1,440

24.2.2 - 48"x6" No. 11 1,728

24.2.3 - One inch square (For any extra work option item) in2 1 6

24.3 SUPPLY CEILING DIFFUSER with face size 24''x24''

24.3.1 - 10"x10" No. 33 600

24.3.2 - 12"x12" No. 41 864

24.3.3 - 14"x14" No. 60 1,176

24.3.4 - 16"x16" No. 160 1,536

24.3.5 - 18"x18" No. 37 1,944

24.3.6 - 20"x20" No. 50 2,400

24.3.7 - 22"x22" No. 24 2,904

24.3.8 - 24"x24" No. 35 3,456

24.3.9 - One inch square (For any extra work option item) in2 1 6

HVAC. WORKS Page 13 of 48 REV. 0

B.O.Q HVAC WORKS

PROJECT TITLE : ااالفندقااالساحلي- منتجع ااالجل لة

DATE : Feb., 2016

SECTION MECHANICAL HVAC WORKS

ITEM NO. UNIT QTY. UNIT PRICE

NO.

DESCRIPTION

24.4 SUPPLY SLOT LINEAR DIFFUSER

24.4.1 Supply linear diffuser, 1.2 m long, 4 slot, 0.75" each slot width, with10"

inlet complete with plainum and volume damper, flex. Connection No. 4 1,200

24.4.2 Supply linear diffuser, 1.2 m long, 4 slot, 1" each slot width, with 10"

inlet complete with plainum and volume damper, flex. Connection No. 54 1,300

24.4.3 - Supply linear diffuser, 1.2 m long, 3 slot, 0.75" each slot width, with12"

inlet complete with plainum and volume damper, flex. Connection No. 8 1,100

24.4.4 - Supply linear diffuser, 1.2 m long, 4 slot, 0.75" each slot width, with12"

inlet complete with plainum and volume damper, flex. Connection No. 90 1,300

24.4.5 - Supply linear diffuser, 1.2 m long, 4 slot, 1" each slot width, with12"

inlet complete with plainum and volume damper, flex. Connection No. 393 1,400

24.5 Dummy Linear Grill

24.5.1 - Dummy Linear Grill M 80 600

24.6 RETURN GRILL

24.6.1 - 18"x6" No. 2 324

24.6.2 - 20"x14" No. 1 840

24.6.3 - 32"x14" No. 2 1,344

24.6.4 - 42"x14" No. 1 1,764

24.6.5 - 52"x14" No. 1 2,184

24.6.6 - One inch square (For any extra work option item) in2 1 3

24.7 Transfer Grill in2 1000 6

24.8 RETURN REGISTER

24.8.1 - 28"x10" No. 1 1,120

24.8.2 - 40"x6" No. 42 960

24.8.3 - 48"x6" No. 3 1,152

24.8.4 - 76"x14" No. 14 4,256

24.8.5 - One inch square (For any extra work option item) in2 1 4

To Collection

24.9 RETURN CEILING DIFFUSER with face size 24''x24''

24.9.1 - 12"x12" No. 2 864

24.9.2 - 14"x14" No. 3 1,176

24.9.3 - 16"x16" No. 14 1,536

24.9.4 - 18"x18" No. 273 1,944

24.9.5 - 20"x20" No. 33 2,400

24.9.6 - 24"x24" No. 50 3,456

24.9.7 - One inch square (For any extra work option item) in2 1 6

24.10 RETURN SLOT LINEAR DIFFUSER

HVAC. WORKS Page 14 of 48 REV. 0

B.O.Q HVAC WORKS

PROJECT TITLE : ااالفندقااالساحلي- منتجع ااالجل لة

DATE : Feb., 2016

SECTION MECHANICAL HVAC WORKS

ITEM NO. UNIT QTY. UNIT PRICE

NO.

DESCRIPTION

24.10.1 Return linear diffuser, 1.2 m long, 4 slot, 0.75" each slot width, with10"

inlet complete with plainum and volume damper, flex. Connection No. 4 900

24.10.2 Return linear diffuser, 1.2 m long, 4 slot, 1" each slot width, with 10"

inlet complete with plainum and volume damper, flex. Connection No. 25 950

24.10.3 - Return linear diffuser, 1.2 m long, 3 slot, 0.75" each slot width, with12"

inlet complete with plainum and volume damper, flex. Connection No. 6 850

24.10.4 - Return linear diffuser, 1.2 m long, 4 slot, 0.75" each slot width, with12"

inlet complete with plainum and volume damper, flex. Connection No. 70 1,100

24.10.5 - Return linear diffuser, 1.2 m long, 4 slot, 1" each slot width, with12"

inlet complete with plainum and volume damper, flex. Connection No. 211 1,200

24.10.6 - One inch square (For any extra work option item) in2 1 12

24.11 EXHAUST CEILING DIFFUSER with face size 24''x24'' 0

24.11.1 - 4"x4" No. 617 150

24.11.2 - 6"x6" No. 39 250

24.11.3 - 8"x8" No. 19 384

24.11.4 - 10"x10" No. 4 600

24.11.5 - 12"x12" No. 5 864

24.11.6 - 14"x14" No. 3 1,176

24.11.7 - 18"x18" No. 2 1,944

24.11.8 - 20"x20" No. 12 2,400

24.11.9 - 24"x24" No. 16 3,456

24.11.10 - One inch square (For any extra work option item) in2 1 6

24.12 EXHAUST REGISTER 0

24.12.1 - 76"x18" No. 4 8,208

24.12.2 - 76"x26" No. 8 11,856

24.12.3 - One inch square (For any extra work option item) in2 1 6

24.13 EXHAUST GRILLE 0

24.13.1 - 28"x8" No. 4 896

24.13.2 - 36"x12" No. 8 1,728

24.13.3 - One inch square (For any extra work option item) in2 1 4

24.14 Fresh Air LOUVER WITH SAND TRAP

24.14.1 - 40"x18" No. 1 7,200

24.14.2 - 50"x20" No. 1 10,000

To Collection

24.14.3 - 100"x40" No. 1 40,000

24.14.4 - 54"x30" No. 1 16,200

24.14.5 - 66"x30" No. 4 19,800

24.14.6 - 68"x30" No. 1 20,400

24.14.7 - 100"X78" No. 1 78,000

24.14.8 - 100"X60" No. 1 60,000

24.14.9 - 26"x10" No. 2 2,600

24.14.10 - One inch square (For any extra work option item) in2 1 10

HVAC. WORKS Page 15 of 48 REV. 0

B.O.Q HVAC WORKS

PROJECT TITLE : ااالفندقااالساحلي- منتجع ااالجل لة

DATE : Feb., 2016

SECTION MECHANICAL HVAC WORKS

ITEM NO. UNIT QTY. UNIT PRICE

NO.

DESCRIPTION

24.15 Exhaust Air LOUVER WITH SAND TRAP

24.15.1 - 36"x20" No. 1 5,760

24.15.2 - 86"x40" No. 2 27,520

24.15.3 - 96"x40" No. 2 30,720

24.15.4 - One inch square (For any extra work option item) in2 1 8

24.16 EXHAUST OPENING WITH WIRE MESH INTERLOCK WITH

THERMOSTAT 30"X12" No. 14 3,500

24.17 FRESH AIR INTAKE LOUVER 1.5MX1.5M WITH SAND TRAP

No. 6 8,500

24.18 EXHAUST OPENING WITH WIRE MESH 0 0

24.18.1 - 10"x12" No. 30 200

24.18.2 - 10"x14" No. 56 250

24.18.3 - 12"x20" No. 8 280

24.18.4 - 36"x12" No. 36 300

24.18.5 - 38"x12" No. 10 300

24.18.6 - 44"x12" No. 17 340

24.19 SMOKE OPENING WITH WIRE MESH 0 0

24.19.1 - 32"x18" No. 1 300

24.19.2 - 34"x18" No. 1 350

24.19.3 - 40"x22" No. 2 400

24.19.4 - 40"x24" No. 1 480

25 Air Curtain Type

Supplying, Installing, and commissioning Air Curtain c/w all necessary

accessories as per the specifications, drawings, and as herein specified:

25.1 - Air Curtain -01,0.9 M No. 21 2,200

26 TESTING & BALANCING

26.1 Total HVAC system testing, adjusting, and balancing, for both air and

water by a third part specialized in such works;having experienced

personnel;well equipped with the approperiate devices, including all

required instrumentations, leakage tests, devices, reports, as per the

standard specifications confirming the requirements of ASHRAE. L.S 1 150,000

To Collection

27 MOTOR CONTROL CENTERS:

HVAC. WORKS Page 16 of 48 REV. 0

B.O.Q HVAC WORKS

PROJECT TITLE : ااالفندقااالساحلي- منتجع ااالجل لة

DATE : Feb., 2016

SECTION MECHANICAL HVAC WORKS

ITEM NO. UNIT QTY. UNIT PRICE

NO.

DESCRIPTION

Supply and install motor control center with all standard components as

per specializations and electrical drawings complete with main panel

enclosure, cables from disconnect switches or power point as indicated

on HVAC and / or electrical drawings and considered the battery limit

between electrical discipline works and electrical for mechanical works.

cable between the motor control center and the units supplied from this

mcc including cable trays, flexible conduits control wiring, relays

contractors, over-load protection, phase sequence detectors including

lamps and alarms, volt, power, current meters and related inherent

systems and protective elements, earthling, interlocking and connection

with fire alarm item including testing, startup and -commissioning for the

power system.

27.1 - MCC-B-01 [ FAHU-B-01+A.H.U-B-02] No. 1 30,000

27.2 - MCC-B-02 [A.H.U-B-07, EXH.F-B-05] No. 1 30,000

27.3 - MCC-B-03 [A.H.U-B-13+A.H.U-B-04] No. 1 30,000

27.4 - MCC-B-04 [A.H.U-B-10+A.H.U-B-11] No. 1 30,000

27.5 - MCC-B-05 [A.H.U-B-05+A.H.U-B-01] No. 1 30,000

27.6 - MCC-B-06 [A.H.U-B-03+A.H.U-B-06] No. 1 30,000

27.7 - MCC-B-07 [A.H.U-B-08+A.H.U-B-09+A.H.U-B-05] No. 1 30,000

27.8 - MCC-B-08 [A.H.U-B-12+A.H.U-B-14+F.A.H.U-B-02+EXH.F-B-

02+EXH.F-B-03] No. 1 30,000

27.9 - MCC-G-01[A.H.U-G-01] No. 1 30,000

27.10 - MCC-G-02 [A.H.U-G-02+F.A.H.U-G-02+F.A.H.U-G-01+F.A.F-G-

01+EXH.F-K-G-01] No. 1 30,000

27.11 - MCC-R-01 [EXH.F-K-R-07+EXH.F-K-R-01+EXH.F-K-R-05+EXH.F-

R-01] No. 1 30,000

27.12 - MCC-R-02 [EXH.F-K-R-03+EXH.F-K-R-03+EXH.F-R-06+EXH.F-K-

R-05+EXH.F-R-09] No. 1 30,000

27.13 - MCC-R-03[EXH.F-K-R-04+EXH.F-K-R-10+F.A.H.U-R-02, A.H.U-R- No. 1

02, A.H.U-R-03, EXH.F-K-R-08] 30,000

27.14 - MCC-R-04[F.A.H.U-R-03 + F.A.H.U-R-01+ EXH.F-K-R-06+EXH.F-

K-R-01+A.H.U-R-04] No. 1 30,000

27.15 - MCC-R-05 [A.H.U-R-05] No. 1 30,000

27.16 - MCC-R-06 [EXH.F-R-05 + EXH.F-R-03 No. 1 30,000

27.17 - MCC-R-07[EXH.F-R-04+F.A.F-R-K-02] No. 1 30,000

27.18 - MCC-R-08[A.H.U-R-05+EXH.F-R-07] No. 1 30,000

27.19 - MCC-R-09[A.H.U-R-05] No. 1 30,000

27.20 - MCC-R-09[A.H.U-R-05] No. 1 30,000

27.21 - MCC-R-10[A.H.U-R-03+A.H.U-R-02+EXH.F-K-R-08+EXH.F-R-

02+EXH.F-K-R-11+FAF-K-R-03] No. 1 30,000

27.22 - EMCC-B-01[SM.F-B-01] No. 1 30,000

27.23 - EMCC-B-02[EXH.F-B-04+EXH.F-B-04] No. 1 30,000

27.24 - EMCC-B-03[EXH.F-B-05+EXH.F-B-05+EXH.F-B-01+W.M-01] No. 1 30,000

27.25 - EMCC-B-04[EXH.F-B-05+W.M-01] No. 1 30,000

27.26 - EMCC-R-01[PR.F-01+PR.F-02 +SM.F-R-03] No. 1 30,000

27.27 - EMCC-R-02[SM.F-R-01+PR.F-01 ] No. 1 30,000

27.28 - EMCC-R-03[SM.F-R-01+PR.F-01 ] No. 1 30,000

27.29 - EMCC-R-04[PR.F-01+PR.F-02 ] No. 1 30,000

To Collection

HVAC. WORKS Page 17 of 48 REV. 0

B.O.Q HVAC WORKS

PROJECT TITLE : ااالفندقااالساحلي- منتجع ااالجل لة

DATE : Feb., 2016

SECTION MECHANICAL HVAC WORKS

ITEM NO. UNIT QTY. UNIT PRICE

NO.

DESCRIPTION

27.30 - EMCC-R-05[PR.F-01+SM.F-R-02+SM.F-R-04 ] No. 1 30,000

27.31 - M.C.C-S-01[CH-01+CH-02+CH-03] No. 1 30,000

27.32 - M.C.C-S-02[COND.W.PUMPS] No. 2 30,000

27.33 - M.C.C-S-03[P.CH.W.P-01,02,03,04+S.CH.W.P-

01,02,03+C.T.W.01,02,03,04] No. 3 30,000

27.34 - EMCC-R-06[PR.F-01+SM.F-R-02+SM.F-R-04 ] No. 1 30,000

27.35 - EMCC-R-07[SM.F-R-03+SM.F-R-04 ] No. 1 30,000

27.36 - EMCC-R-08[SM.F-R-03+SM.F-R-04 ] No. 1 30,000

28 CONTOL AND MONITORING

28.1 Supply and install building automation system for as specified with all

needed accessories, thermostats, controls and as per schedule of BMS

points but not limited to BMS station located in control room, BMS

should be including chiller plant,

L.S L.S

28.2 Supply, install, program, configure, connection, test, commission and

startup of building and energy management system complete with all

required hardware and software as per detailed in the specifications,

including but not limited to:

L.S L.S

28.3 - Central Processing Unit (CPU). Complete with all its Hardware and

software, operating system,.... Etc. L.S L.S

28.4 - Visual Display Unit (VDU).Complete with all its power cable, data L.S L.S

cable,…etc. L.S L.S

28.5 - Printers.

28.6 - Network Cables to connect BEMS CPU to various DDC's around the

building. L.S L.S

28.7 - All Softwares sequences required to satisfy energy management

requirements, extending mechanical equipments life cycles, fire and

smoke sequences and all other sequences required and as detailed in the

specifications.

L.S L.S

28.8 - Configured Communications Softwares L.S L.S

28.9 - Protocols. L.S L.S

28.10 - Graphics L.S L.S

28.11 - Communication Cables. L.S L.S

28.12 - All other software and hardware that might be needed for the successful

Interface operation. L.S L.S

28.13 Supply, install, configure, connection, test, commission and startup of a

UPS system for the BEMS complete with all its accessories, cables,

cables trays, batteries,…etc. L.S L.S

28.14 Supply of startup and commissionong recommended spare parts L.S L.S

28.15 Supply of one year recommended spare parts. L.S L.S

28.16 Supply of recommended training for the operators, maintenance and

engineering stuff. L.S L.S

29 FIELD DEVICES AND DIRECT DIGITAL CONTRILLERS

29.1 Supply, install, test, commission of field devices and DDC points with all

required control cable to connect to MCCs and DDCs and according to

the specifications and schedule of mechanical / Electrical equipments and

as detailed.

L.S L.S

HVAC. WORKS Page 18 of 48 REV. 0

B.O.Q HVAC WORKS

PROJECT TITLE : ااالفندقااالساحلي- منتجع ااالجل لة

DATE : Feb., 2016

SECTION MECHANICAL HVAC WORKS

ITEM NO. UNIT QTY. UNIT PRICE

NO.

DESCRIPTION

To Collection

30 Outdoor Air Conditions

30.1 For more details about field devices and DDC points please refer to the

attached sample control diagram of input/output points sheet - outdoor air

conditions and the attached sample control diagram - outdoor air

conditions.

L.S L.S

31 Chilled Water System

31.1 For more details about Field Devices and DDC Points please refer to the

attached Sample Schedule of Input/Output Points Sheet - Chilled Water

System and the attached Sample Control Diagram - Chilled Water System

L.S L.S

32 Cooled Water System

32.1 For more details about Field Devices and DDC Points please refer to the

attached Sample Schedule of Input/Output Points Sheet - Cooled Water

System and the attached Sample Control Diagram - Cooled Water System

L.S L.S

33 Air Handling Unit - arrangement-A

33.1 For more details about field devices and DDC points please refer to the

attached sample control diagram of input/output points sheets - air

handling unit - arrangement-1 and the attached sample control diagram -

air handling unit - arrangement-A.

L.S L.S

34 Air Handling Unit - arrangement-B

34.1 For more details about field devices and DDC points please refer to the

attached sample control diagram of input/output points sheet - air

handling unit - arrangement-2 and the attached sample control diagram -

air handling unit - arrangement-B.

L.S L.S

35 Air Handling Unit - arrangement-C

35.1 For more details about field devices and DDC points please refer to the

attached sample control diagram of input/output points sheet - air

handling unit - arrangement-3 and the attached sample control diagram -

air handling unit - arrangement-C

L.S L.S

36 VAV Boxes

36.1 For more details about field devices and DDC points please refer to

the attached sample control diagram - VAV Boxes. L.S L.S

37 Fans

37.1 For more details about field devices and DDC points please refer to

the attached sample sample control diagram of input/output points

sheets fans, and the attached sample control diagram-fans. L.S L.S

38 Filters for Supply Fans

HVAC. WORKS Page 19 of 48 REV. 0

B.O.Q HVAC WORKS

PROJECT TITLE : ااالفندقااالساحلي- منتجع ااالجل لة

DATE : Feb., 2016

SECTION MECHANICAL HVAC WORKS

ITEM NO. UNIT QTY. UNIT PRICE

NO.

DESCRIPTION

38.1 For more details about field devices and DDC points please refer to

the attached sample sample control diagram of input/output points

sheets fans, and the attached sample control diagram-fans. L.S L.S

To Collection

39 CO-Detectors

For more details about field devices and DDC points please refer to

the attached sample sample control diagram of input/output points

sheet - fans. L.S L.S

40 Temperature Sensors

40.1 For more details about field devices and DDC points please refer to

the attached sample control diagram of input/output points sheet -

fans. L.S L.S

41 Electric

41.1 - Medium Voltage Switchgear - (MVSG) L.S L.S

41.2 - Transformers. L.S L.S

41.3 - Main Low Voltage Switchboard - (MDB) L.S L.S

41.4 - Emergency Generator L.S L.S

41.5 - ATS L.S L.S

41.6 - Elevators L.S L.S

41.7 - UPS L.S L.S

41.8 - Fire Alarm Panel L.S L.S

41.9 - Light Current System L.S L.S

41.10 - Emergency Generator Feul System L.S L.S

41.11 For more details about field devices and DDC points please refer to

the attached sample schedule of input/output points sheets -

electrical services. L.S L.S

42 Expansion Tank

42.1 For more details about field devices and DDC points please refer to

the attached sample schedule of input/output points sheet -

expansion tank, and the attached sample control diagram -

expansion tank.

L.S L.S

43 Plumbing & Fire Fighting & Irrigation

43.1 - Boiler Plant L.S L.S

43.2 - Irrigation System L.S L.S

43.3 - All Plumbing Pumps L.S L.S

43.4 - Flow Meters L.S L.S

44 SYSTEM CLEAINING AND FLUSHING

44.1 System cleaning and flushing include supply of chemicals and

provision of system cleaning and flushing include supply of

chemicals and provision of cleaning equipment. L.S 1 85,000

45 INSTRUMENTATION

HVAC. WORKS Page 20 of 48 REV. 0

B.O.Q HVAC WORKS

PROJECT TITLE : ااالفندقااالساحلي- منتجع ااالجل لة

DATE : Feb., 2016

SECTION MECHANICAL HVAC WORKS

ITEM NO. UNIT QTY. UNIT PRICE

NO.

DESCRIPTION

45.1 Supply, installation and commission of Instrumentation as shown

on drawings and specifications. L.S 1 18,000

To Collection

46 AIR INTAKE AND RELIEF VENTS

46.1 Supply, installation, connection, balancing and commission of

louvers and relief vents from painted aluminum section complete

with all accessories as shown on drawings and specifications. L.S 1 80,000

47 Painting to pipework

47.1 Painting to exposed piping as specification L.S 1 90,000

HVAC. WORKS Page 21 of 48 REV. 0

B.O.Q HVAC WORKS

PROJECT TITLE : ااالفندقااالساحلي- منتجع ااالجل لة

DATE : Feb., 2016

SECTION MECHANICAL HVAC WORKS

ITEM NO. UNIT QTY. UNIT PRICE

NO.

DESCRIPTION

To Collection

TO SUMMARY

HVAC. WORKS

الفندق الساحلي- منتجع الجللة

Page No. 01

Page No. 02

Page No. 03

Page No. 04

Page No. 05

Page No. 06

Page No. 07

Page No. 08

Page No. 09

Page No. 10

Page No. 11

Page No. 12

Page No. 13

Page No. 14

Page No. 15

Page No. 16

Page No. 17

HVAC. WORKS Page 22 of 48 REV. 0

B.O.Q HVAC WORKS

PROJECT TITLE : ااالفندقااالساحلي- منتجع ااالجل لة

DATE : Feb., 2016

SECTION MECHANICAL HVAC WORKS

ITEM NO. UNIT QTY. UNIT PRICE

NO.

DESCRIPTION

Page No. 18

Page No. 19

Page No. 20

HVAC WORK

HVAC. WORKS Page 23 of 48 REV. 0

.O.Q HVAC WORKS

TOTAL

HVAC. WORKS Page 24 of 48 REV. 0

.O.Q HVAC WORKS

TOTAL

7,500,000

0

60,000

0

0

0

0

3,000,000

HVAC. WORKS Page 25 of 48 REV. 0

.O.Q HVAC WORKS

TOTAL

99,000

10,659,000

1,200,000

1,050,000

0

0

1,400,000

0

0

HVAC. WORKS Page 26 of 48 REV. 0

.O.Q HVAC WORKS

TOTAL

0

60,000

0

0

3,710,000

80,000

60,000

0

75,000

0

135,000

HVAC. WORKS Page 27 of 48 REV. 0

.O.Q HVAC WORKS

TOTAL

350,000

135,000

135,000

135,000

135,000

270,000

160,000

160,000

160,000

180,000

170,000

190,000

170,000

180,000

170,000

180,000

180,000

125,000

125,000

125,000

15,000

180,000

360,000

65,000

150,000

95,000

160,000

190,000

95,000

125,000

0

0

HVAC. WORKS Page 28 of 48 REV. 0

.O.Q HVAC WORKS

TOTAL

0

19,000

26,000

39,000

91,000

28,000

14,000

4,737,000

6,500

8,500

10,200

10,200

15,500

15,500

12,500

25,000

25,000

12,500

0

0

0

190,000

285,000

95,000

HVAC. WORKS Page 29 of 48 REV. 0

.O.Q HVAC WORKS

TOTAL

0

0

0

85,000

80,000

170,000

190,000

440,000

0

1,676,400

76,800

36,000

0

0

0

8,200

8,200

17,000

8,500

12,500

22,000

22,000

28,000

28,000

30,000

12,500

HVAC. WORKS Page 30 of 48 REV. 0

.O.Q HVAC WORKS

TOTAL

25,000

12,500

25,000

8,200

0

0

52,800

6,400

2,400

1,200

15,200

8,400

16,200

6,800

28,800

518,600

22,000

14,000

16,000

16,000

0

0

0

7,500

114,000

3,672,000

HVAC. WORKS Page 31 of 48 REV. 0

.O.Q HVAC WORKS

TOTAL

588,000

0

0

0

29,000

9,800

25,000

0

0

0

4,513,300

60,000

972,800

264,000

80,000

134,400

220,160

158,400

520,000

734,400

176,000

600,000

224,000

486,400

616,000

270,000

0

0

HVAC. WORKS Page 32 of 48 REV. 0

.O.Q HVAC WORKS

TOTAL

0

93,600

36,000

0

0

0

0

185,600

80,000

100,000

30,000

196,000

63,000

26,000

34,000

36,000

43,200

6,439,960

50,000

62,000

45,000

137,500

80,000

51,000

39,200

23,000

27,000

18,500

0

0

49,500

8,500

0

0

67,500

12,000

0

0

HVAC. WORKS Page 33 of 48 REV. 0

.O.Q HVAC WORKS

TOTAL

0

6,160,000

312,000

165,000

0

0

0

620,000

0

0

0

608,000

0

0

8,535,700

0

232,500

0

0

16,800

0

0

30,000

HVAC. WORKS Page 34 of 48 REV. 0

.O.Q HVAC WORKS

TOTAL

384,000

90,000

24,000

45,600

65,360

44,000

100,000

129,600

36,000

67,200

28,000

57,760

79,200

0

0

1,500,000

0

292,500

3,222,520

41,800

0

0

352,000

528,000

312,000

0

660,000

0

0

HVAC. WORKS Page 35 of 48 REV. 0

.O.Q HVAC WORKS

TOTAL

0

0

192

256

240

384

7,200

2,640

2,304

1,456

960

22,848

4,704

7,680

9,600

3,360

10,880

8,960

4,032

4

0

0

768

2,304

2,880

14,040

1,320

5,184

1,680

2,009,676

469,440

19,008

6

0

0

19,800

35,424

70,560

245,760

71,928

120,000

69,696

120,960

6

HVAC. WORKS Page 36 of 48 REV. 0

.O.Q HVAC WORKS

TOTAL

0

0

4,800

70,200

8,800

117,000

550,200

0

0

48,000

0

0

648

840

2,688

1,764

2,184

3

0

6,000

0

0

1,120

40,320

3,456

59,584

4

2,160,199

1,728

3,528

21,504

530,712

79,200

172,800

6

0

0

HVAC. WORKS Page 37 of 48 REV. 0

.O.Q HVAC WORKS

TOTAL

3,600

23,750

5,100

77,000

253,200

12

0

0

92,550

9,750

7,296

2,400

4,320

3,528

3,888

28,800

55,296

6

0

0

32,832

94,848

6

0

0

3,584

13,824

4

0

0

7,200

10,000

1,542,272

40,000

16,200

79,200

20,400

78,000

60,000

5,200

10

HVAC. WORKS Page 38 of 48 REV. 0

.O.Q HVAC WORKS

TOTAL

0

0

5,760

55,040

61,440

8

0

49,000

0

51,000

0

0

6,000

14,000

2,240

10,800

3,000

5,780

0

0

300

350

800

480

0

0

0

46,200

0

0

150,000

761,208

HVAC. WORKS Page 39 of 48 REV. 0

.O.Q HVAC WORKS

TOTAL

30,000

30,000

30,000

30,000

30,000

30,000

30,000

30,000

30,000

30,000

30,000

30,000

30,000

30,000

30,000

30,000

30,000

30,000

30,000

30,000

30,000

30,000

30,000

30,000

30,000

30,000

30,000

30,000

30,000

870,000

HVAC. WORKS Page 40 of 48 REV. 0

.O.Q HVAC WORKS

TOTAL

30,000

30,000

60,000

90,000

30,000

30,000

30,000

0

0

HVAC. WORKS Page 41 of 48 REV. 0

.O.Q HVAC WORKS

TOTAL

300,000

HVAC. WORKS Page 42 of 48 REV. 0

.O.Q HVAC WORKS

TOTAL

3,000,000

85,000

0

0

HVAC. WORKS Page 43 of 48 REV. 0

.O.Q HVAC WORKS

TOTAL

18,000

0

3,103,000

80,000

0

0

90,000

0

HVAC. WORKS Page 44 of 48 REV. 0

.O.Q HVAC WORKS

TOTAL

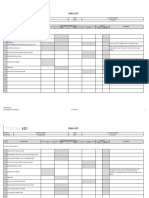

170,000

10,659,000

3,710,000

350,000

4,737,000

1,676,400

518,600

4,513,300

6,439,960

8,535,700

3,222,520

2,009,676

2,160,199

1,542,272

761,208

870,000

300,000

HVAC. WORKS Page 45 of 48 REV. 0

.O.Q HVAC WORKS

TOTAL

3,103,000

170,000

55,278,835

HVAC. WORKS Page 46 of 48 REV. 0

مكتب التصميمات الكهربائية والميكانيكية

مقايسة أعمال تكييف الهواء والتهوية

منتجع الجللة- لمشروع الفندق الساحلى

BY

ELECTRO-MECH. DESIGN GROUP

CAIRO, EGYPT

143 Corniche El Nil, Maadi Plaza Building, 4th Floor, Apartment # 404 - opposite to National People's Center- Maadi

Tele. : (+202) 25242308 - 25242309 / Fax. : (+202) 25242309

E mail: emghm@yahoo.com & emgkh@yahoo.com & emg.hany@gmail.com

Vous aimerez peut-être aussi

- North-South Railway InspectionDocument18 pagesNorth-South Railway InspectionResearcherPas encore d'évaluation

- Progress Matrix Table - Mep WorksDocument3 pagesProgress Matrix Table - Mep WorksAssem ElhajjPas encore d'évaluation

- Guide in Making Comment For O&M ManualDocument13 pagesGuide in Making Comment For O&M ManualjoechengshPas encore d'évaluation

- Indoor Air Quality Environmental & Comfort Level Testing For HVAC SystemDocument3 pagesIndoor Air Quality Environmental & Comfort Level Testing For HVAC Systemvin ss100% (1)

- MEP Sanitary Fixtures Installation ChecklistDocument36 pagesMEP Sanitary Fixtures Installation ChecklistankurPas encore d'évaluation

- Inspection Amp Test Plan Itp Hvac Installation New Pump Station Ps 56a and Force Main To SWTP 9 Jubail PDF FreeDocument28 pagesInspection Amp Test Plan Itp Hvac Installation New Pump Station Ps 56a and Force Main To SWTP 9 Jubail PDF Freeأبو محمدPas encore d'évaluation

- QCDFSS-6.7 - Fire Pumps - Arabic Version of Rev ADocument4 pagesQCDFSS-6.7 - Fire Pumps - Arabic Version of Rev AAnoirPas encore d'évaluation

- Material Approval ChecklistDocument2 pagesMaterial Approval ChecklistROYCE1983Pas encore d'évaluation

- AHU Commissioning Report DF016eDocument8 pagesAHU Commissioning Report DF016evishwas salunkhePas encore d'évaluation

- Method Stament For Street Pole LightDocument16 pagesMethod Stament For Street Pole Lightمقاول تكييف كهرباء وصحيPas encore d'évaluation

- MEP Services PDFDocument1 pageMEP Services PDFmpwasaPas encore d'évaluation

- Installation of Toilet Exhaust FansDocument51 pagesInstallation of Toilet Exhaust FansAnandu AshokanPas encore d'évaluation

- Material SubmittalDocument4 pagesMaterial SubmittalshoaibPas encore d'évaluation

- HVAC System: Exhaust FanDocument4 pagesHVAC System: Exhaust FanAnsari1918Pas encore d'évaluation

- ChecklistDocument10 pagesChecklistsa hePas encore d'évaluation

- AcmvDocument8 pagesAcmvHafiz AbdullahPas encore d'évaluation

- CV - Draftsman - Ahamed CV-1Document3 pagesCV - Draftsman - Ahamed CV-1Ziad EzzeddinePas encore d'évaluation

- Method of Statement For Precommissioning & Commissioning of Chiller Plant ManagerDocument3 pagesMethod of Statement For Precommissioning & Commissioning of Chiller Plant Managervin ssPas encore d'évaluation

- M & e MST - 036 Rev. 0Document3 pagesM & e MST - 036 Rev. 0Anonymous 3eHGEDbxPas encore d'évaluation

- 2011 03 15 Comm Plan Rev 01Document138 pages2011 03 15 Comm Plan Rev 01Jawad Kamal100% (1)

- HVAC LifeDocument8 pagesHVAC LifeNadeem QaisarPas encore d'évaluation

- Check List For Commissioning of Fm200 System: IR Ref. No.: Date: Ref. Documents: Discipline: Area/Location: ElementDocument1 pageCheck List For Commissioning of Fm200 System: IR Ref. No.: Date: Ref. Documents: Discipline: Area/Location: ElementUmair BaBerPas encore d'évaluation

- Fire Sprinkler Installation MethodDocument19 pagesFire Sprinkler Installation Methodمقاول تكييف كهرباء وصحيPas encore d'évaluation

- KKIA T5 Electrical Conduit InspectionDocument3 pagesKKIA T5 Electrical Conduit InspectionmsmkhanPas encore d'évaluation

- Maintain Critical HVAC Spare Parts InventoryDocument14 pagesMaintain Critical HVAC Spare Parts Inventoryrazi khanPas encore d'évaluation

- Testing and Commissioning of Emergency Light SystemDocument1 pageTesting and Commissioning of Emergency Light SystemUmair BaBerPas encore d'évaluation

- Shop Drawing Check List (Electrical)Document1 pageShop Drawing Check List (Electrical)Satya N.GPas encore d'évaluation

- Testing and Commissioning Catering EquipmentDocument27 pagesTesting and Commissioning Catering EquipmentTrần ChâuPas encore d'évaluation

- Install Electric Water HeaterDocument5 pagesInstall Electric Water HeaterGwenn AsprerPas encore d'évaluation

- Fire Alarm System Maintenance 2Document3 pagesFire Alarm System Maintenance 2renvPas encore d'évaluation

- Mechanical BOQ 150710Document56 pagesMechanical BOQ 150710Jaime Manalili Landingin100% (1)

- Material Submittal - Checklist PDFDocument1 pageMaterial Submittal - Checklist PDFDanish AhamadPas encore d'évaluation

- MEP Snag List TawarDocument13 pagesMEP Snag List Tawarmohammad100% (1)

- H.M.C. MOHIDEEN (Bsc. Eng.) : Personal InformationsDocument7 pagesH.M.C. MOHIDEEN (Bsc. Eng.) : Personal InformationsmohideenPas encore d'évaluation

- Gi DuctDocument8 pagesGi DuctCham Kok SoonPas encore d'évaluation

- Item No. Description QTY Unit Unit Price Labor MAT'L. CostDocument10 pagesItem No. Description QTY Unit Unit Price Labor MAT'L. Costكابتشينو كابتشينو100% (1)

- Grounding Installation Inspection and Test Plan ITPDocument2 pagesGrounding Installation Inspection and Test Plan ITPtristan guarinoPas encore d'évaluation

- Earthing and Bonding Method StatementDocument4 pagesEarthing and Bonding Method StatementMusthafa Shaik100% (1)

- 1 CHKLSTDocument5 pages1 CHKLSTsardarmkhanPas encore d'évaluation

- Checklist of Fcu-AhuDocument4 pagesChecklist of Fcu-AhuMoizuddin Khaja100% (1)

- HVAC Documents Summary as of 29 June 2020Document11 pagesHVAC Documents Summary as of 29 June 2020kokocdf100% (1)

- Ahu ItpDocument3 pagesAhu ItpMEELMAHDYPas encore d'évaluation

- Electrical Installation Flow ChartDocument1 pageElectrical Installation Flow ChartKing王Pas encore d'évaluation

- T&C Chilled Water BalancingDocument1 pageT&C Chilled Water BalancingAzwan SunlinePas encore d'évaluation

- MOS Insrtallation of VRFDocument22 pagesMOS Insrtallation of VRFsuban hari kumarPas encore d'évaluation

- Division 15 Mechanical IBS HVACDocument164 pagesDivision 15 Mechanical IBS HVACmasahinPas encore d'évaluation

- Project Atlantis Ductwork InspectionDocument2 pagesProject Atlantis Ductwork InspectionIbrahim Sirpi100% (1)

- Project: Contract Ref: Project No: Location: Drawing Ref: Rfi No: Descrption: VRF System Installation Inspection ChecklistDocument2 pagesProject: Contract Ref: Project No: Location: Drawing Ref: Rfi No: Descrption: VRF System Installation Inspection ChecklistWasim AhmedPas encore d'évaluation

- MST For Below Ground UPVC Drainage PipesDocument17 pagesMST For Below Ground UPVC Drainage Pipesمقاول تكييف كهرباء وصحيPas encore d'évaluation

- Plumbing Systems - CommissioningDocument4 pagesPlumbing Systems - CommissioningLouie MirandaPas encore d'évaluation

- Specification - Electrical & CommunicationDocument89 pagesSpecification - Electrical & Communicationkoduvayur2001100% (2)

- 15-1-2 - Hvac DuctworkDocument15 pages15-1-2 - Hvac Ductworkfarshan296015Pas encore d'évaluation

- Grundfos Chilled Water Pumps Testing & Commissioning Method StatementDocument10 pagesGrundfos Chilled Water Pumps Testing & Commissioning Method Statementshanu YahiyaPas encore d'évaluation

- Testing and Commissioning of HVACDocument247 pagesTesting and Commissioning of HVACAnand Naidoo100% (4)

- Boiler Equipment (1&2)Document7 pagesBoiler Equipment (1&2)mohamedmizoPas encore d'évaluation

- 安 装 使 用 说 明 书 Installation and Operation Manual: AQC Waste Heat BoilerDocument35 pages安 装 使 用 说 明 书 Installation and Operation Manual: AQC Waste Heat BoilerSitaram JhaPas encore d'évaluation

- Water Chilled Centrifugal UnitsDocument40 pagesWater Chilled Centrifugal UnitskdpmansiPas encore d'évaluation

- Fire Protection Water Mist SystemDocument18 pagesFire Protection Water Mist SystemAhmed MahmoudPas encore d'évaluation

- Ajmera - Treon - FF - R4 - 13-11-17 FinalDocument45 pagesAjmera - Treon - FF - R4 - 13-11-17 FinalNikita KadamPas encore d'évaluation

- Air Cooled Screw Liquid Free Cooling Chiller - YORK YVFA R134a 50Hz & 60HzDocument6 pagesAir Cooled Screw Liquid Free Cooling Chiller - YORK YVFA R134a 50Hz & 60Hzalf_haroPas encore d'évaluation

- CIBSE Pipe Sizing V2.2Document9 pagesCIBSE Pipe Sizing V2.2mohamed adelPas encore d'évaluation

- Pac Catalogue 2015 Uk PDFDocument16 pagesPac Catalogue 2015 Uk PDFmohamed adelPas encore d'évaluation

- Linear DiffuserDocument52 pagesLinear Diffusermohamed adelPas encore d'évaluation

- 3.3.4 Classifications For Fires. 3.3.4.1 Class A FiresDocument1 page3.3.4 Classifications For Fires. 3.3.4.1 Class A Firesmohamed adelPas encore d'évaluation

- Pac Catalogue 2015 Uk PDFDocument16 pagesPac Catalogue 2015 Uk PDFmohamed adelPas encore d'évaluation

- Linear DiffuserDocument52 pagesLinear Diffusermohamed adelPas encore d'évaluation

- 1-Bms DesignDocument6 pages1-Bms Designmohamed adelPas encore d'évaluation

- Manage Building Efficiently with BMS in ArabicDocument38 pagesManage Building Efficiently with BMS in Arabicياسين حسين100% (1)

- Clean RoomDocument23 pagesClean Roommohamed adelPas encore d'évaluation

- Clean RoomDocument23 pagesClean Roommohamed adelPas encore d'évaluation

- 398H271671 en Es FR Rev1Document28 pages398H271671 en Es FR Rev1Eozz JaorPas encore d'évaluation

- Energy Recovery Wheel Technical GuideDocument36 pagesEnergy Recovery Wheel Technical GuideDeepakkumarPas encore d'évaluation

- Building Automated SystemsDocument10 pagesBuilding Automated SystemsSharon LambertPas encore d'évaluation

- Aquaforce: Summary Performance Report For Ch-01Document1 pageAquaforce: Summary Performance Report For Ch-01Usman ShaikhPas encore d'évaluation

- Liebert CRV BR EN UK EMEA Rev.5 12 2018Document12 pagesLiebert CRV BR EN UK EMEA Rev.5 12 2018Florin NedeaPas encore d'évaluation

- Cooling Tower Chilling PlantsDocument8 pagesCooling Tower Chilling PlantsKamal Kumar AgrawalPas encore d'évaluation

- 2 Clivet - Screw and Scroll - Air Cooled ChillerDocument38 pages2 Clivet - Screw and Scroll - Air Cooled ChillerTony Nguyen0% (1)

- ChillerDocument22 pagesChilleredhjksdhPas encore d'évaluation

- كتالوج الشيلراتDocument54 pagesكتالوج الشيلراتFathy RakhaPas encore d'évaluation

- STULZ CyberAir 3PRO CW Brochure 2001 ENDocument20 pagesSTULZ CyberAir 3PRO CW Brochure 2001 ENIvan Rudolf De FretesPas encore d'évaluation

- Chapter 1. Hvac System Analysis and SelectionDocument20 pagesChapter 1. Hvac System Analysis and SelectionRolando Valdez GutierrezPas encore d'évaluation

- SOP Dept IndexDocument77 pagesSOP Dept Indexmohd naveeduddin musaPas encore d'évaluation

- Capston VVHPDocument37 pagesCapston VVHPsnj144Pas encore d'évaluation

- Yz Mod A With Optiview Control CenterDocument60 pagesYz Mod A With Optiview Control Centerxihua liuPas encore d'évaluation

- Iom1264 WWV 1217 Da HRDocument48 pagesIom1264 WWV 1217 Da HRHa CongPas encore d'évaluation

- H2O Buffer Tank IOMDocument8 pagesH2O Buffer Tank IOMNgọc Yến NguyễnPas encore d'évaluation

- Case Study of Shopping MallDocument30 pagesCase Study of Shopping Malldolar buha80% (10)

- SMARDT Catalogue Ta ClassDocument18 pagesSMARDT Catalogue Ta ClassAlhgasjsghjagjsdajlsd AsdalsdlkaksdPas encore d'évaluation

- MccmanualDocument22 pagesMccmanualJohan SmitPas encore d'évaluation

- R30ca0168ej0500 BaDocument36 pagesR30ca0168ej0500 BaJohn ThompsonPas encore d'évaluation

- Failure Analysis of Heat Exchngers: An Approach and Case StudiesDocument51 pagesFailure Analysis of Heat Exchngers: An Approach and Case Studiessathish69100% (5)

- Zia 6000-8000 9CND TechnicalManual 5DTCNP20 EN v1-0Document93 pagesZia 6000-8000 9CND TechnicalManual 5DTCNP20 EN v1-0convofixPas encore d'évaluation

- Catalogue - LG Air-Cooled Scroll Chiller - 220.380.460VDocument42 pagesCatalogue - LG Air-Cooled Scroll Chiller - 220.380.460VchristopherPas encore d'évaluation

- HVAC Design, Drafting, Construction & Estimation Per ASHRAE & SMACNADocument9 pagesHVAC Design, Drafting, Construction & Estimation Per ASHRAE & SMACNASafdar AlamPas encore d'évaluation

- York Pres IPLVDocument40 pagesYork Pres IPLVArclassePas encore d'évaluation

- Rating: 5 - 1 Vote: Related ArticlesDocument2 pagesRating: 5 - 1 Vote: Related ArticlesChadPas encore d'évaluation

- Sample Mechanical Basis of Design For UW - Chiller SystemsDocument4 pagesSample Mechanical Basis of Design For UW - Chiller SystemsdaveleyconsPas encore d'évaluation

- Water Cooled ChillersDocument62 pagesWater Cooled ChillersRenan Gonzalez100% (26)

- DAIKIN General Catalogue 2015 Part2Document198 pagesDAIKIN General Catalogue 2015 Part2Nemesis2103Pas encore d'évaluation