Académique Documents

Professionnel Documents

Culture Documents

Aeratedautoclavedconcrete 140329093526 Phpapp01

Transféré par

Omar Daghistani0 évaluation0% ont trouvé ce document utile (0 vote)

39 vues19 pagesaeratedautoclavedconcrete

Titre original

aeratedautoclavedconcrete-140329093526-phpapp01

Copyright

© © All Rights Reserved

Formats disponibles

PDF, TXT ou lisez en ligne sur Scribd

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentaeratedautoclavedconcrete

Droits d'auteur :

© All Rights Reserved

Formats disponibles

Téléchargez comme PDF, TXT ou lisez en ligne sur Scribd

0 évaluation0% ont trouvé ce document utile (0 vote)

39 vues19 pagesAeratedautoclavedconcrete 140329093526 Phpapp01

Transféré par

Omar Daghistaniaeratedautoclavedconcrete

Droits d'auteur :

© All Rights Reserved

Formats disponibles

Téléchargez comme PDF, TXT ou lisez en ligne sur Scribd

Vous êtes sur la page 1sur 19

Noaina Hassan Khan---Tanzeel Ahmed--- Reema Khan

Nadia Ali --- Atia Khursheed

Autoclaved aerated concrete (“AAC”), is one of the many

building products being touted as “green” or

“environmentally friendly.”

Developed in Sweden in the 1920s in response to

increasing demands on timber supplies, AAC is a

lightweight manufactured building stone.

. Comprised of all natural raw materials, AAC is used in a

wide range of commercial, industrial, and residential

applications.

AAC now accounts for over 40% of all construction in the

United Kingdom and more than 60% of construction in

Germany.

AAC is a precast product manufactured by combining silica (either in

the form of sand, or recycled fly ash), cement, lime, water, and an

expansion agent - aluminium powder, and pouring it into a mould.

In structurally reinforced AAC products like lintels or roof panels,

steel rebar or mesh is also placed in the mould.

Once added to the concrete, the aluminium powder reacts with the

silica, resulting in the formation of millions of microscopic hydrogen

bubbles. The hydrogen bubbles cause the concrete to expand to

roughly five times its original volume.

The hydrogen subsequently evaporates, leaving a highly closed-cell

aerated concrete, then cut into which are further steam and

pressure cured in an autoclave.

AAC products consist of load bearing, non-load

bearing and cladding applications.

Complete load bearing applications, however, are

limited to low-rise construction.

Cladding and large panels are available to take

advantage of AAC’s insulative, fire proofing, and

other benefits on mid- and high-rise projects.

The large wall, floor, and roof panels, measuring up

to 20 feet long, 2 feet wide, and in various

thicknesses, are also used in load-bearing capacities

and are common in commercial and industrial

applications.

The remainder of the AAC system consists of blocks,

also called “units” which are stacked using thin-set

mortar, as opposed to the traditional cement-based

mortar.

The blocks are available in a variety of sizes and types.

STANDARD BLOCKS - typically measuring 24 inches long, 8 inches

high, and in thicknesses between 6 (non-load-bearing) and 12

inches

CORED BLOCKS – also known as O-blocks, which are used

adjacent to corners and openings and have a centred, 4 inch

vertical core at one end of the block to form a continuous

vertical core through the wall that is then filled with rebar

and concrete.

JUMBO BLOCKS - which reduce construction time.

U-BLOCKS- which have a channel running the length of

the block that once filled with concrete, provides

structural support as headers and on the top course of

each floor (the “bond beam”). AAC lintels with

integrated structural support are also manufactured

and are an alternative to using the U-block system for

headers.

AAC reduces additional material use and minimizes waste and pollution.

AAC is approximately 80% air, the finished product is up to 5 times the volume of the

raw material consumed in its production.

AAC production raw materials are generally locally sourced and may consist of

recycled materials.

AAC consumes approximately 50%-20% less energy than that needed to produce

CMUs.

The manufacturing process, produces no waste or pollution and the final product is

completely recyclable.

Due to its light weight and dimensional accuracy, AAC can be

assembled with minimal waste and a reduced need for additional

equipment.

The product is virtually maintenance free, eliminating the need for

repair materials, pesticides, and chemical treatments, while also

lowering operating costs

AAC Has High Thermal Efficiency

AAC structures result in solid wall construction with integrated

insulation, preventing thermal bridging, creating an airtight

building envelope, minimizing uncontrolled air changes.

AAC benefits from low thermal conductivity value.

AAC Reduces Noise Pollution and Improves

Indoor Air Quality

Its millions of independent air cells dampen sound

transmission.

Because AAC construction has very low air

infiltration and is mold resistant, indoor air quality

of AAC structures is improved.

AAC Structures Are Well-Suited to Withstand Fires, Earthquakes, and

Other Natural Disasters

It receives a 4 hr. UL fire rating and has a melting point of over 2900° F.

AAC is also termite and mold resistant, and nearly fireproof.

AAC Structures Are Price Competitive

AAC buildings constructed near a supplier’s manufacturing

facilities cost approx. the same as traditional materials.

AAC’s light weight helps lower shipping costs.

The higher initial cost must be balanced against savings due to

lower operating and maintenance costs, the structure’s longer

lifespan.

Easily workable

Less time consuming due to large size of blocks.

Light weight also makes it easy to handle.

Scarcity of Manufacturing Plants.

Projects far from manufacturing facilities will suffer

from higher initial costs.

Familiarity with Product

Few contractors are a currently familiar with the product, and trained

masons must adjust to using thin-set mortar as opposed to traditional

cement-based mortar, which requires less precision in its application.

General considerations

AAC masonry components(block units) can be used to build

load bearing or non load bearing walls.

O-block units used to build pilasters.

U-block units used to build bond beams and lintels.

Control joints on AAC reinforced walls must be placed at

maximum 16 ft. o.c.

Installation Guide

Check foundation.

Receiving and distribution of AAC

wall units.

Installation requirements.

Tools

Equipment

Other materials

Installing O-block for pilasters in first

course.

Laying the first course (levelling course).

Lay the first course over a semi-dry cement

mortar levelling bed- ½” to 2” thick.

Corner blocks are laid first and the first

course should be completed before second Anchoring vertical

course installation. reinforcement to foundation

Once corner blocks are placed apply thin bed

mortar, to the vertical joints for other blocks.

Thin bed mortar 1/16” inch to 1/8”

Cutting blocks (adjustments and chases)

A hand saw or band saw to cut the blocks to specific lengths.

Placing control joints in first course

These are vertical joints taken through the full wall thickness, and from

bottom to top.

3/8” to ½” thick.

Maximum spacing between control joints should be 15 ft.

Laying the subsequent courses

For subsequent courses use only thin bed mortaring on all joints between

AAC blocks.

Minimum overlapping of vertical joints between layers should be 4”.

Metal strip ties should be placed every two courses at – 1) connection of

secondary walls to main walls – 2) connection of walls to concrete

columns.

Control joints in subsequent layers.

V-shaped metal strips should be set at every two courses

unless there are two pilasters on both sides of control joints

and less than 2” from the joint.

Once the wall is built fill the gap using backer rod and seal

with caulking.

Fill up pilasters by pouring concrete.

Building on site lintels using U-blocks.

Install temporary supports before putting U-blocks in place apply

thin bed mortar to the vertical joints.

Once U-block are set, place rebars according to construction

drawings and with concrete.

Installing U-blocks to build bond beams.

Lay U-block course applying thin bed mortar on all joints.

At each pilaster location, drill a hole in the bottom side so the

vertical bars can be attached in the bond beam.

Before pouring concrete place rebar and anchor bolts according to

construction drawings.

Utilities installation after the walls are built:

For electrical conduits and piping installation, a chase is cut using

an electrical router or a chasing tool.

When required depth of chase is bigger than maximum depth

recommended, additional O-blocks are used to lodge the pipes or

interrupt wall continuity. Bond beam and pilaster

After installation, the chase are filled with repair mortar or cement connection

sand mortar.

Renders and finishes

Surface patching: rasp block joints and other areas where AAC

surface is out of plane.

Surface must be cleaned using a scrub brush and any loose or

damaged material be removed.

A rubber float is commonly used to smooth the wall surface.

Fiber glass mesh: This should be installed directly over one layer of

render in all control joints, around windows, doors and utility

locations.

Finishes:

AAC masonry walls can be finished with stucco , acrylic texture

coats, or a combination of both, also laminated stones, ceramic or

clay tiles, concrete pieces and ornamental products.

Anchoring to AAC:

Fasteners: Anchors used with AAC shall be made of plastic or nylon. Wood, fiber,

lead, metal or expansion anchors are not recommended.

Use power drills to make holes for fasteners. Percussion drilling or inverting the

rotation direction when drilling shall be avoided.

The anchor shall penetrate tightly to avoid rotation when placing the screw.

Hebel AAC nail: Galvanized nails are designed specifically to provide definitive

anchorage in the AAC, and are directly hammered into it.

Screws: minimum length of screw is defined by anchor length plus thickness of

the finish layer and the element to be fixed.

Vous aimerez peut-être aussi

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeD'EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeÉvaluation : 4 sur 5 étoiles4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingD'EverandThe Little Book of Hygge: Danish Secrets to Happy LivingÉvaluation : 3.5 sur 5 étoiles3.5/5 (399)

- 1 s2.0 S0306261911005058 MainDocument13 pages1 s2.0 S0306261911005058 MainOmar DaghistaniPas encore d'évaluation

- Are 522Document20 pagesAre 522Omar DaghistaniPas encore d'évaluation

- Project Management Professional HandbookDocument41 pagesProject Management Professional HandbookSara Lopez100% (1)

- Autoclaved Aerated Concrete Blocks (Acc Blocks)Document3 pagesAutoclaved Aerated Concrete Blocks (Acc Blocks)Omar DaghistaniPas encore d'évaluation

- I Am A DedicatedDocument1 pageI Am A DedicatedOmar DaghistaniPas encore d'évaluation

- AAC Blocks Revolutionize ConstructionDocument8 pagesAAC Blocks Revolutionize ConstructionOmar DaghistaniPas encore d'évaluation

- SustainabilityDocument21 pagesSustainabilityOmar DaghistaniPas encore d'évaluation

- Mid 514Document21 pagesMid 514Omar DaghistaniPas encore d'évaluation

- PMP in Mindmaps, 2018, Ahmed Alsenosy' BookDocument10 pagesPMP in Mindmaps, 2018, Ahmed Alsenosy' BookIbrahimSamir100% (9)

- Total Chapters PDFDocument437 pagesTotal Chapters PDFOmar DaghistaniPas encore d'évaluation

- Added values through safety, sustainability and educationDocument2 pagesAdded values through safety, sustainability and educationOmar DaghistaniPas encore d'évaluation

- Ricardo Vargas Simplified Pmbok Flow 6ed Color En-A3Document1 pageRicardo Vargas Simplified Pmbok Flow 6ed Color En-A3Hero Sa Mac100% (1)

- AAC Product InfoDocument5 pagesAAC Product InfoAmit Jagrith ChoudharyPas encore d'évaluation

- Autoclaved Aerated Concrete (AAC) Blocks Project - Brief ReportDocument12 pagesAutoclaved Aerated Concrete (AAC) Blocks Project - Brief ReportVishal Kansagra77% (31)

- 1200 Buildings Program BMS Seminar 1Document37 pages1200 Buildings Program BMS Seminar 1HayanJanakatPas encore d'évaluation

- Paul Kilminster Grade5 ThesisDocument13 pagesPaul Kilminster Grade5 ThesisOmar DaghistaniPas encore d'évaluation

- Icrc 31 C ProjectcostoverrunsandriskmanagementARCOM2002Document10 pagesIcrc 31 C ProjectcostoverrunsandriskmanagementARCOM2002realchicPas encore d'évaluation

- Autoclave Aerated ConcreteDocument3 pagesAutoclave Aerated ConcreteFireSwarmPas encore d'évaluation

- Project Time Overruns in Saudi Arabian Con Struction IndustryDocument6 pagesProject Time Overruns in Saudi Arabian Con Struction IndustryDagPas encore d'évaluation

- FIST - Ling Zhi Jia 1Document24 pagesFIST - Ling Zhi Jia 1Omar DaghistaniPas encore d'évaluation

- Web IET I&CBE InsightDocument6 pagesWeb IET I&CBE InsightJeffrey TeoPas encore d'évaluation

- Global Construction Survey 2015Document36 pagesGlobal Construction Survey 2015SmehrunnisaPas encore d'évaluation

- Westside For Skinny Bastards by Joe DefrancoDocument22 pagesWestside For Skinny Bastards by Joe DefrancoJason Clusiault100% (14)

- 175 PMP Sample Questions PDFDocument109 pages175 PMP Sample Questions PDFKamlakar MohitePas encore d'évaluation

- What Is An Intelligent BuildingDocument6 pagesWhat Is An Intelligent BuildingOmar DaghistaniPas encore d'évaluation

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryD'EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryÉvaluation : 3.5 sur 5 étoiles3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceD'EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceÉvaluation : 4 sur 5 étoiles4/5 (894)

- The Yellow House: A Memoir (2019 National Book Award Winner)D'EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Évaluation : 4 sur 5 étoiles4/5 (98)

- Shoe Dog: A Memoir by the Creator of NikeD'EverandShoe Dog: A Memoir by the Creator of NikeÉvaluation : 4.5 sur 5 étoiles4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureD'EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureÉvaluation : 4.5 sur 5 étoiles4.5/5 (474)

- Never Split the Difference: Negotiating As If Your Life Depended On ItD'EverandNever Split the Difference: Negotiating As If Your Life Depended On ItÉvaluation : 4.5 sur 5 étoiles4.5/5 (838)

- Grit: The Power of Passion and PerseveranceD'EverandGrit: The Power of Passion and PerseveranceÉvaluation : 4 sur 5 étoiles4/5 (587)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaD'EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaÉvaluation : 4.5 sur 5 étoiles4.5/5 (265)

- The Emperor of All Maladies: A Biography of CancerD'EverandThe Emperor of All Maladies: A Biography of CancerÉvaluation : 4.5 sur 5 étoiles4.5/5 (271)

- On Fire: The (Burning) Case for a Green New DealD'EverandOn Fire: The (Burning) Case for a Green New DealÉvaluation : 4 sur 5 étoiles4/5 (73)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersD'EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersÉvaluation : 4.5 sur 5 étoiles4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnD'EverandTeam of Rivals: The Political Genius of Abraham LincolnÉvaluation : 4.5 sur 5 étoiles4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaD'EverandThe Unwinding: An Inner History of the New AmericaÉvaluation : 4 sur 5 étoiles4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyD'EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyÉvaluation : 3.5 sur 5 étoiles3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreD'EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreÉvaluation : 4 sur 5 étoiles4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)D'EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Évaluation : 4.5 sur 5 étoiles4.5/5 (119)

- Her Body and Other Parties: StoriesD'EverandHer Body and Other Parties: StoriesÉvaluation : 4 sur 5 étoiles4/5 (821)

- Rolls - Royce: M250 - C30 Series Operation and MaintenanceDocument16 pagesRolls - Royce: M250 - C30 Series Operation and MaintenanceDee Lowe0% (1)

- D427Document4 pagesD427Nouman KhalidPas encore d'évaluation

- Mercedes C Classe Owner ManualDocument406 pagesMercedes C Classe Owner ManualDan Șerbănescu100% (2)

- 08 RTU560 SCADA-Functions MonitorDir EDocument29 pages08 RTU560 SCADA-Functions MonitorDir EngocanhvyPas encore d'évaluation

- M.tech ThesisDocument59 pagesM.tech ThesisRama Krishna100% (1)

- Basic Petroleum Engineering Practices PDFDocument1 pageBasic Petroleum Engineering Practices PDFMrbughyoPas encore d'évaluation

- Caterpillar 914GDocument28 pagesCaterpillar 914GForomaquinas100% (3)

- BIM 3D To 7D Implementation - Hani Elsafadi - Pulse - LinkedInDocument4 pagesBIM 3D To 7D Implementation - Hani Elsafadi - Pulse - LinkedInNurul Nabila SahriPas encore d'évaluation

- Pre Concreting ChecklistDocument1 pagePre Concreting ChecklistFahmi ZahariPas encore d'évaluation

- Agepan EducationDocument100 pagesAgepan EducationsswinforPas encore d'évaluation

- Shivaji University, Kolhapur: Course Part Pattern CourseDocument4 pagesShivaji University, Kolhapur: Course Part Pattern CourseDatta PanchalPas encore d'évaluation

- Mod. REC1/EV Mod. REC1c/EV Mod. REC1a/EV: Continuous Reaction (CSTR) Pilot PlantDocument2 pagesMod. REC1/EV Mod. REC1c/EV Mod. REC1a/EV: Continuous Reaction (CSTR) Pilot Plantcgjp120391Pas encore d'évaluation

- Ena Solar Inverter GT-ManualDocument32 pagesEna Solar Inverter GT-ManualRob DuthiePas encore d'évaluation

- Water Management ManualDocument175 pagesWater Management Manualwinston100% (3)

- Manual On TransformersDocument595 pagesManual On TransformersRK K100% (3)

- Design Gates for Hydropower ProjectsDocument55 pagesDesign Gates for Hydropower ProjectsDangol RupeshPas encore d'évaluation

- Track TractorsDocument30 pagesTrack Tractorsmdnc1985Pas encore d'évaluation

- 15 Design For Safety HazanDocument12 pages15 Design For Safety Hazansauravsagar14Pas encore d'évaluation

- Hazel International Storage Tank Inspection Checklist: Tank No: SL - NO. List of Items Remarks FoundationDocument4 pagesHazel International Storage Tank Inspection Checklist: Tank No: SL - NO. List of Items Remarks Foundationantopaul2Pas encore d'évaluation

- Absorption ChillerDocument12 pagesAbsorption Chillerjylee@100% (1)

- Epson R200, R210 Visão ExplodidaDocument8 pagesEpson R200, R210 Visão ExplodidaKedinaldoPas encore d'évaluation

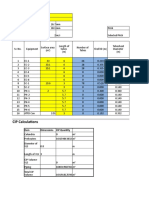

- Calculations For Heat Exchanger, CIP & ATFD (Master Copy)Document21 pagesCalculations For Heat Exchanger, CIP & ATFD (Master Copy)saurabhzalte100% (1)

- Apartment - Final Case - 40Document1 pageApartment - Final Case - 40alexanderPas encore d'évaluation

- BROCO Standard Line Series Electrical Fittings and Accessories Price ListDocument14 pagesBROCO Standard Line Series Electrical Fittings and Accessories Price ListKiyahPas encore d'évaluation

- Auditorium - WBDG Whole Building Design GuideDocument4 pagesAuditorium - WBDG Whole Building Design GuideArniel LaguardiaPas encore d'évaluation

- Calculating Overall Equipment EffectivenessDocument2 pagesCalculating Overall Equipment Effectivenessbhavesh_balasPas encore d'évaluation

- Machine DesignDocument14 pagesMachine Designraj gangwarPas encore d'évaluation

- 24 - FormworksDocument2 pages24 - FormworksRafee PiePas encore d'évaluation

- The Bottom Up Refining Revolution Part4 PDFDocument1 pageThe Bottom Up Refining Revolution Part4 PDFOscar ViverosPas encore d'évaluation

- Types of StairsDocument12 pagesTypes of Stairsfaris danial100% (1)