Académique Documents

Professionnel Documents

Culture Documents

231D4055 - C - Off Base Piping GA - MEA Markup - For Safety

Transféré par

asfaruk2556Titre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

231D4055 - C - Off Base Piping GA - MEA Markup - For Safety

Transféré par

asfaruk2556Droits d'auteur :

Formats disponibles

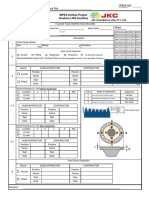

DWG Number UTILE

FORMAT 231D4055 :{801

Rev Cx 554}

Released 12/17/2014 Page 2 of 15

/

8 7 6 5 4 3 2

REVISIONS

Drawn

REV DESCRIPTION DATE Checked

N Approved

A

! ELI!

\ / +

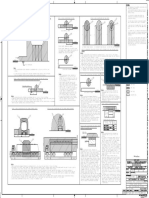

===ft===r GENERAL TOP VIEW GT2_ C BLEED LINE UPDATED 14/11/14 LOINTIER

cr

o

< 377 ==SjH== —i----- A— jT i— ' ' !i!

r ,

~i—

i

: r r n—EX

fW GALAS

Q_

\

i

i

i

FI

I x-v I I

i

I

ii

LJ

HRSG LER

l---- 1

i

I

i

-1 VANDEPOELE

o°

78 COMPRESSOR WASHING

I SKID 280 t 8rt

L®±tbj

I

i ! i lift©

u

i

i

I

i

Li r \ir\T \T\"\

i iri r i

trl ippBId

I ! rhv

I

I

i

i i

i

I

:

~i

i

I r"

I 0 I

MIL I L___I I I <

D i

I

I

T

i

o i

I

I I

I1

I

i

1 I //

“1 /

/

/

D

I ! I 7^~hvT?n PVTV' I i

i i i i/

I I I l i EQP. DESIGNATION

I

270° 90° i i —n bun i___ i

i /

r

l rTT»

I I i I

I

I

18 Li == ==

1 !/

I // N0TA: 1 GT MAINTENANCE AREA

L_ L -JP-L4 i

r I

_ L La i f rH| I / 2 GT AND GENERATOR ROTOR DISMANTLING AREA

8N rt! ___i_____ i____

ntl ■L

ri i

ifi __ 1 _L — I i

I__l___

I

'hip__ THE DIMENSIONS SHOWN ON THIS DRAWING ARE THEORICALS

AND MUST BE CHECKED ON SITE ACCORDING TO

100 GAS TURBINE

78

23 u___ La ~7

THE LAYOUT OF EQUIPMENTS BEFORE FABRICATION 1605 GT ACOUSTICAL ENCLOSURE

73 i\ /

/ * /!-'

i\ / f' hrmTHTi COORDINATES REFERENCES : 1 658 GAS MODULE ENCLOSURE

i\ HRSG MAIN

I STACK

/ i x

1 80° H I---------t--- 1 \ \

/

/ \

ri rrn rri i THE REFERENCE LEVEL (RL ) CORRESPONDS TO THE TOP 240 LOW PRESSURE C02 STORAGE

I \

\ /S I A / jl---- 1 A- > I I I I I I I I I I OF THE TURBINE PEDESTAL EMBEDDED SUBSOLES PLATES266 GENERATOR ACOUSTICAL ENCLOSURE

I /

r

4

hi I \ i 1

(GE RL = 7900 AHD)

/ \ \

iPSii 280 COMPRESSOR WASHING SKID (2 FOR 5 GT)

-i-i— \ i nt 13 1

\ « I 1y 1 NORTH/SOUTH: EXHAUST PLENUM AXIS 422 EXHAUST EMPTY DUCT

BLOWDOWN

\ TANK \ EAST/WEST: GAS TURBINE AXIS

\ I I 510 TEWAC GENERATOR

mv

Jj

28° i i—s i

! lK

I

tl

JT

I

---- -Id!

LV J I 543 GENERATOR NEUTRAL ACCESSORY COMPARTMENT (GNAC)

I

1

I F. =h 543a GENERATOR LINE ACCESSORY COMPARTMENT (GLAC)

IP \

ill! i

--------- j y

rx tttlr-r I ‘v' MAINTENANCE AREA

;i

/ I X

tyj*l ^ i I \

LL._..__^ 81 1 FIN FAN COOLERS (DP )

VAPORISER

V SKID

--- 1---

I \

A- _Lj di__a

1

(9=3

P-3 'i

'i :i

I:

I

811b ATMOSPHERIC EXPANSION TANK

I f==i ilI 0639 FUEL GAS FLOWMETER

i

I

I

I I

l

f 1

SUPPLY BY GE

NOT SUPPLY BY GE

0991 DRY LOW NOX GAS MODULE (DLN)

I 2G0 FUEL GAS COALESCING FILTERS (2X100%)

!»+-! HRSG DRUM

I , . -urn hi u._ \ 2G0a FUEL GAS HEATER FOR START UP

J \

h

I WlI-I-J Iff! \ 2G0b FUEL GAS HEATER ELECTRICAL PANEL FOR START UP

r \

DUCT BURNER SKID

I I i== I \ 811 FIN FAN COOLERS ITEM NUMBER G028 FUEL GAS WOBBE METTER

lL J ■

I \ G064 FUEL GAS SAFETY SHUT OFF VALVE (SSOV)

I I I--- \

I I

fcr| j is l

I I \

\

\

2F6 GT UNIT WALKWAYS ( BY OTHERS )

H----r—-t- I

i

i i'

i l

H id! jt

\

\

\ LINE NUMBER LABEL

2J0

A040

GT AIR PROCESSING UNIT

SELF CLEANING AIR FILTER WITH INSECT SCREEN

■J

! In \

1 iF TTI I \ A041 AIR INLET DUCT WITH SILENCER

I III I x\

I I I A030 EXHAUST PRESSURE CONTROL PANEL

UII

I I Ji i'Tl' X

c 1 T

I

I

i

-4

II H

1

i

1

t

/

/

/

/

/ PIPING SUPPORT LABEL A053

A132

A980

EXHAUST FRAME BLOWERS PIPES

EXHAUST FRAME BLOWERS ENCLOSURES

AIR INLET SUPPORT STRUCTURE (DP)

c

l__3

III

I! I

I ri i«i I

I

i /

/

/

B10 PACKAGED ELECTRONIC & ELECTRICAL CONTROL CABINET

(PEECC )

GT ACOUSTICAL iii i

I

!

/

/

F10 GT HALL SCHELTER NOT SHOWN(BY OTHERS)

I I L-. I I- 1 MECHANICAL INTERFACE CONNECTIONS LABEL

ENCLOSURE /

V

\ ii I

H! i

I

i

I

EXHAUST EMPTY

— F1 01

F1 0 j

INTERMEDIATE WASHING WATER RECOVERY CONCRETE PIT (BY OTHERS)

LUBE OIL SECONDARY CONTAINMENT CONCRETE PIT (BY OTHERS)

X i

I DUCT I d si I F1 0 I PIPING TRENCHES AND SUPPORTS PEDESTALS (BY OTHERS)

II I

c

INTERMEDIATE

WASHING WATER

Tl IT-Slili

mu 1

III: H-|

II! !

|i I

I

1

1

Uti-__f*

Mil

-i-

!h+!-

LVJ m r

l REFERENCE POINT F1 On OIL AND WATER NETWORKS

(DP): DESIGN IS PRELIMINARY AND SUBJECT TO CHANGE

Il I I

RECOVERY TRANSFORMER I

I I II I

- I

CONCRETE PIT 1 II I

—1 1 u

1 i 1 i

1 0 7.5 15

1 ( 1 i

h 1 1 1 1

PEECC

1 1 1 1

i 1 _i=l i 1 Bio (PACKAGED ELECTRONIC &

GLAC ------- 1—I------:

Oil i|

I I I E I SCALE IN METERS

J. (GENERATOR

L

I---- 1 ELECTRICAL CONTROL CABINET)

l I I

LINE ACCESSORY l I

I I

COMPARTMENT) I

|l

EXHAUST

i I i

PRESSURE PIPING

I I I

I I CONTROL

I PANEL

L TRENCHES H

I______ L

\

-fc-V-t-V-i

GT UNIT i

I I

WALKWAYS

d----------- 1---------f-

E

17- GAS TURBINE

I

-| h

11

-llT-y ZONE 2 I'Jii

■

I 1 1 240 LOW PRESSURE CO2 STORAGE

I \ / I

X/I \

543a F10I 100 I

/

/

/

\

l

11

C (D-6 SHEET 07/15)

1 1

-

I

I

X

\

1 j.

l\l

Ld (XI ~ -74

ZONE 3 1 BYPASS /

CL O STACK

I LUBE OIL SECONDARY

\ / 2F6 A030

1 F10J

(D-6 SHEET 13/15)

II 1605 422 /X

1— 1/7

< F1 0 I l m A

I

CONTAINMENT CONCRETE PIT

II X /

B I

I

r r^v

1

\___ l._J___X

If

1

I- 4-— x

\ x

1/7 —•

3 X —

<<

I

I

3

i

1

/

/

/i

T B

on

I ;\

/ rrr\i/l 8.

mi

£E

LU

f—

OIL AND WATER

NETWORKS

1 it ' ll tti—r

p=r. I m

fl

s

3

£

±

IaL

10?

S

I I

2J0 GT AIR PROCESSING UNIT

J J Lexuausl...

PLENUM 1 I I

IH ft ) I

FLANGE d_

1 ATMOSPHERIC EXPANSION TANK

LD

F1 On i

I

13

!

s t 81 1B

1

o

O I

cr> r-"

fl

i 1

ro 1

MLOAD X

l =tGENERATOR ■j----------- f

GEAR EXHAUST TURBINE ILciJtz:

AUXILIARY L-----

If LONGITUDINAL A040 SELF CLEANING AIR FILTER W/ INSECT

ROOM

t PLENUM ROOM ROOM

AXIS 1 ROOM r I SCREEN

■d-Jd-rr

I

I

1

I

1

1 !' -M~/ WJFBzfW 1

1 A041

SELF CLEANING AIR FILTER W/ INSECT

SCREEN

GT AND GENERATOR

1

ROTOR DISMANTLING AREA

1

2 t

IL

r

^4

1 Tr x I A A980 AIR INLET SUPPORT STRUCTURE

REFERENCE NBER :

\ W \A

T—T

•./ !

m

/V

\

\

/

/\ /\

REFERENCE I/

/ \ ECH. / SCALE DATE 14/11/14 14/11/14 14/11/14

GENERATOR ACOUSTICAL >* POINT

ZONE 1 \ FUEL GAS HEATER ELECTRICAL PANEL 1/150 NOM / NAME LOINTIER GALAS VANDEPOELE

266 \ 2G0b

ENCLOSURE (D-6 SHEET 04/15) \ FOR START UP FORMAT/SIZE VISA

g=l—p \

\

I \ A1 REDIGE / MADE VERIFIE / CHECKED APPROUVE/APPROVED

\

TEWAC GENERATOR 510 \ G064 FUEL GAS SAFETY SHUT OFF VALVE

\ \

X IL I

I i TITRE/TITLE

IZ \

J snr

n!

4- \

GENERATOR NEUTRAL

543 EXHAUST FRAME

I

4M :[]l T 1 1 \

\

G028 FUEL GAS WOBBE METRE

PIPING GENERAL

ACCESSORY BLOWERS PIPES

ARRANGEMENT DRAWING

O

A053

1 658

GAS MODULE

"

ENCLOSURE

r 1

A

F1 0 EXHAUST FRAME

BLOWERS

A1 32

0991 DRY LOW NOX JM *

2G0 FUEL GAS COALESCING FILTERS GENERAL PLAN VIEW GT2 A

GT MAINTENANCE AREA 1 i

ENCLOSURES

1 1 TR

GAS MODULE

n 2G0a FUEL GAS HEATER FOR START UP Ce documentt proprlete exclusive de REVISION

CO TW GE Energy Products France SNC

es+ strictement confidentiel.il ne peut GE Energy c

c etre conmunique. copie ou reproduit %

sans son autorisation ecrite prealable. INSTRUCTION DE

0639 FUEL GAS FLOWMETER MODIFICATION

This document» exclusive property of

Projection method \

GE Energy Products France SNC N° 231D4055

■

7i I /II is strictly confidential. It must not be

communicated, copied or reproduced

without our previous written consent.

Section Doc.

01

SHT. N

02/15 i__i__i__i__i

III IIIII

8

FORMAT A1:841x594 (ISO 5457-1990) 7 6 5 4 3 2 GE Proprietary Information - Class II (Internal) US EAR - NLR

Vous aimerez peut-être aussi

- The Yellow House: A Memoir (2019 National Book Award Winner)D'EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Évaluation : 4 sur 5 étoiles4/5 (98)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceD'EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceÉvaluation : 4 sur 5 étoiles4/5 (895)

- ACCY801 Subject Outline T1 2024 - OnlineDocument20 pagesACCY801 Subject Outline T1 2024 - Onlineasfaruk2556Pas encore d'évaluation

- 4037 PDFDocument10 pages4037 PDFasfaruk2556Pas encore d'évaluation

- Test Pack Register 170918Document78 pagesTest Pack Register 170918asfaruk2556Pas encore d'évaluation

- Flange Face Inspection Record CCPP R5Document1 pageFlange Face Inspection Record CCPP R5asfaruk2556100% (1)

- As 4037Document10 pagesAs 4037Syed Mahmud Habibur RahmanPas encore d'évaluation

- Scaffold & Paint Priorities Rev 1Document12 pagesScaffold & Paint Priorities Rev 1asfaruk2556Pas encore d'évaluation

- Test Pack Register 170918Document78 pagesTest Pack Register 170918asfaruk2556Pas encore d'évaluation

- Scaffold & Paint Priorities Rev 2Document30 pagesScaffold & Paint Priorities Rev 2asfaruk2556Pas encore d'évaluation

- Testpack Status ReportDocument383 pagesTestpack Status Reportasfaruk2556Pas encore d'évaluation

- Chartek Application TrainingDocument43 pagesChartek Application TrainingSerkan Akça100% (5)

- Loose Spool ScopingDocument12 pagesLoose Spool Scopingasfaruk2556Pas encore d'évaluation

- 2018Document16 pages2018asfaruk2556Pas encore d'évaluation

- Chartek Application TrainingDocument43 pagesChartek Application TrainingSerkan Akça100% (5)

- YourBeautifulYard PDFDocument45 pagesYourBeautifulYard PDFshafiuthaPas encore d'évaluation

- NDT Recieved DetailsDocument10 pagesNDT Recieved Detailsasfaruk2556Pas encore d'évaluation

- 2018Document16 pages2018asfaruk2556Pas encore d'évaluation

- GHGFHDocument4 pagesGHGFHasfaruk2556Pas encore d'évaluation

- Leave FormDocument1 pageLeave Formasfaruk2556Pas encore d'évaluation

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeD'EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeÉvaluation : 4 sur 5 étoiles4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingD'EverandThe Little Book of Hygge: Danish Secrets to Happy LivingÉvaluation : 3.5 sur 5 étoiles3.5/5 (400)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaD'EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaÉvaluation : 4.5 sur 5 étoiles4.5/5 (266)

- Shoe Dog: A Memoir by the Creator of NikeD'EverandShoe Dog: A Memoir by the Creator of NikeÉvaluation : 4.5 sur 5 étoiles4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureD'EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureÉvaluation : 4.5 sur 5 étoiles4.5/5 (474)

- Never Split the Difference: Negotiating As If Your Life Depended On ItD'EverandNever Split the Difference: Negotiating As If Your Life Depended On ItÉvaluation : 4.5 sur 5 étoiles4.5/5 (838)

- Grit: The Power of Passion and PerseveranceD'EverandGrit: The Power of Passion and PerseveranceÉvaluation : 4 sur 5 étoiles4/5 (588)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryD'EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryÉvaluation : 3.5 sur 5 étoiles3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerD'EverandThe Emperor of All Maladies: A Biography of CancerÉvaluation : 4.5 sur 5 étoiles4.5/5 (271)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyD'EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyÉvaluation : 3.5 sur 5 étoiles3.5/5 (2259)

- On Fire: The (Burning) Case for a Green New DealD'EverandOn Fire: The (Burning) Case for a Green New DealÉvaluation : 4 sur 5 étoiles4/5 (73)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersD'EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersÉvaluation : 4.5 sur 5 étoiles4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnD'EverandTeam of Rivals: The Political Genius of Abraham LincolnÉvaluation : 4.5 sur 5 étoiles4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaD'EverandThe Unwinding: An Inner History of the New AmericaÉvaluation : 4 sur 5 étoiles4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreD'EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreÉvaluation : 4 sur 5 étoiles4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)D'EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Évaluation : 4.5 sur 5 étoiles4.5/5 (121)

- Her Body and Other Parties: StoriesD'EverandHer Body and Other Parties: StoriesÉvaluation : 4 sur 5 étoiles4/5 (821)

- Pump User Instructions M SlurryDocument60 pagesPump User Instructions M SlurryAndhika Bani Gunawan0% (1)

- Ra-616190-001 (D-1) PDFDocument1 pageRa-616190-001 (D-1) PDFmuthuvelaaPas encore d'évaluation

- Parts C490BPGDocument30 pagesParts C490BPGניקולאי איןPas encore d'évaluation

- Bhel Jhansi ReportDocument73 pagesBhel Jhansi ReportTarun VermaPas encore d'évaluation

- 9184 - Airport Planning Manual Part 2 - Land Use and Environmental Control PDFDocument97 pages9184 - Airport Planning Manual Part 2 - Land Use and Environmental Control PDFDavid GrimaPas encore d'évaluation

- ThermoDocument25 pagesThermoJerryco AlviarPas encore d'évaluation

- IEEE 1547 - Explicacion PDFDocument11 pagesIEEE 1547 - Explicacion PDFAlejandro Gil RestrepoPas encore d'évaluation

- Vocational Training Report, Indian Oil Corporation Limited, Gujarat RefineryDocument43 pagesVocational Training Report, Indian Oil Corporation Limited, Gujarat Refineryjhashashank26883% (12)

- Tsurumi Cutter ImpellerDocument5 pagesTsurumi Cutter ImpellerJapril AgustinPas encore d'évaluation

- Green Tea ExtractDocument28 pagesGreen Tea ExtractNikhil TribhuwanPas encore d'évaluation

- JSW SteelDocument44 pagesJSW Steelauttyhubli100% (1)

- Testing Cellular Glass Insulation Block: Standard Test Methods ofDocument4 pagesTesting Cellular Glass Insulation Block: Standard Test Methods ofArun UdayabhanuPas encore d'évaluation

- 2007 Oprema Za Gole I Izolirane Nadzemne Elektromagnetske Mreze HR PDFDocument212 pages2007 Oprema Za Gole I Izolirane Nadzemne Elektromagnetske Mreze HR PDFTarik KrivokapaPas encore d'évaluation

- Heat Pump 1-1Document9 pagesHeat Pump 1-1sdio06Pas encore d'évaluation

- Test - Astm 1378 Rev2Document16 pagesTest - Astm 1378 Rev2Matthew KuttikadPas encore d'évaluation

- Carbon Aerogels For Electrochemical Applications - Journal of Non Crystalline Solids - Pekala - 1998Document7 pagesCarbon Aerogels For Electrochemical Applications - Journal of Non Crystalline Solids - Pekala - 1998Fadhlullah RamadhaniPas encore d'évaluation

- Product Data Sheet: Motor - M40 - Sepam Series 40Document2 pagesProduct Data Sheet: Motor - M40 - Sepam Series 40Akriti AgrawalPas encore d'évaluation

- Assignment#2, Potential, Capacitors, Magnetic Force and FieldDocument5 pagesAssignment#2, Potential, Capacitors, Magnetic Force and FieldBilal KhalidPas encore d'évaluation

- Scicent SQ U8 1-2 SetB Final eDocument7 pagesScicent SQ U8 1-2 SetB Final eApple LouPas encore d'évaluation

- Catalog - Regent RSV Ed 3Document14 pagesCatalog - Regent RSV Ed 3Nyu123456Pas encore d'évaluation

- Longman Exam Skills Proficiency Writing Teacher's BookDocument27 pagesLongman Exam Skills Proficiency Writing Teacher's Booktrancedrift100% (8)

- The Effect of Financial Development On Renewable Energy Consumption. A Panel Data ApproachDocument9 pagesThe Effect of Financial Development On Renewable Energy Consumption. A Panel Data ApproachArnawan Hasibuan, ST., MT Arnawan Hasibuan, ST., MTPas encore d'évaluation

- The Future of Advanced Aerial MobilityDocument54 pagesThe Future of Advanced Aerial MobilityShambhu Dewasi100% (2)

- TP30Document9 pagesTP30abelmonte_geotecniaPas encore d'évaluation

- Encorp Group ServicesDocument26 pagesEncorp Group ServicesVinay NowalPas encore d'évaluation

- Yihong Qiu, Yisheng Chen, Geoff G.Z. Zhang, Lawrence Yu, Rao v. Mantri (Eds.) - Developing Solid Oral Dosage Forms - Pharmaceutical Theory and Practice-Academic Press (2016) - 166-190Document25 pagesYihong Qiu, Yisheng Chen, Geoff G.Z. Zhang, Lawrence Yu, Rao v. Mantri (Eds.) - Developing Solid Oral Dosage Forms - Pharmaceutical Theory and Practice-Academic Press (2016) - 166-190unnik06Pas encore d'évaluation

- Ibc 2003Document10 pagesIbc 2003MIKHA2014Pas encore d'évaluation

- 70627-Fault Codes Identification StandardDocument26 pages70627-Fault Codes Identification StandardNovie Rizky71% (7)

- Fault Code 195 Coolant Level Sensor Circuit - Voltage Above Normal or Shorted To High SourceDocument13 pagesFault Code 195 Coolant Level Sensor Circuit - Voltage Above Normal or Shorted To High SourceAhmedmah100% (1)

- Science F3 C8-PPT-Part I Dynamo and GeneratorDocument36 pagesScience F3 C8-PPT-Part I Dynamo and GeneratorRebecca Choong Xin Hui100% (2)