Académique Documents

Professionnel Documents

Culture Documents

Automatic Flow-Limiting Valve: Installation, Operation and Service Instructions

Transféré par

Anonymous 7xHNgoKE6eTitre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Automatic Flow-Limiting Valve: Installation, Operation and Service Instructions

Transféré par

Anonymous 7xHNgoKE6eDroits d'auteur :

Formats disponibles

Bell & Gossett ®

INSTRUCTION MANUAL

V58044

WARNING LABEL PART NO. V56873

INSTALLED IN THIS LOCATION (UNDER

BELL & GOSSETT). IF MISSING IT MUST

BE REPLACED.

Automatic Flow-Limiting Valve

Installation, Operation and Service Instructions

INSTALLER: PLEASE LEAVE THIS MANUAL FOR THE OWNER’S USE.

b) Install the unit so that the flow arrow on the body

SAFETY housing points in the direction of flow.

c) Supports both sides of the unit with wrenches during

INSTRUCTION installation to prevent putting stress on the joint

This safety alert symbol will be used in this manual to draw joining the two sections.

attention to safety related instructions. When used, the safety

alert symbol means ATTENTION! BECOME ALERT! YOUR

SAFETY IS INVOLVED! FAILURE TO FOLLOW THESE IN- CAUTION: The generous use of pipe joint com-

STRUCTIONS MAY RESULT IN A SAFETY HAZARD. pound when installing the AFLV will foul the valve

operating mechanism preventing it from functioning

DESCRIPTION properly. Pipe joint compound must be conservatively

applied to male threads only. Failure to follow this

The Bell & Gossett Automatic Flow Limiting Valves (AFLV) are instruction can result in moderate personal injury and/or

designed to automatically control the flow in piping system to property damage.

selected preset limit. As pressure differential increases, a

cartridge inside the valve body reduces the flow area to

accurately maintain the pre-selected flow rate. CAUTION: The use of Teflon®** impregnated pipe

compound and Teflon tape on pipe threads pro-

Operational Limits vides lubricity, which can lead to overtightening and

breakage. Do not overtighten. Failure to follow this

Maximum Operating Temperature: 250ºF (121ºC)*

instruction can result in moderate personal injury and/or

Maximum Operating Pressure: 300 psig (2069 kPa)*

property damage.

Differential Pressure Flow Control

2 to 60 psig (14 to 414 kPa) nominal

2. For installing Sweat Connections:

INSTALLATION INSTRUCTIONS

a) Clean tube ends and valve connections thoroughly

1. For installing NPT Connections: according to good piping practices with a fine grade

a) Install the AFLV in the piping system/circuit where it is emery cloth or fine grit sandpaper.

desired to maintain the flow at a preselected value.

Apply pipe joint compound sparingly to the male pipe

threads only.

Bell & Gossett®

* Refer to chart A for solder joints for limitations.

** Teflon is a registered trademark of E.I. DuPont de Nemours and Company.

b) For soldering, use 95-5 (Tin-Antimony) solder and a HOW TO USE AUTOMATIC FLOW-LIMITING

good grade of flux. VALVE PRESSURE TAPS TO DETERMINE

c) Use a torch with a sharp pointed flame. PROPER FUNCTIONING OF VALVE.

d) When sweating the joints, first adjusting the

Automatic Flow-Limiting Valve in the full open 1. Using Bell & Gossett Model RP-250 readout probes,

position, then wrap the valve with a cool wet rag and attach a Bell & Gossett differential pressure readout kit to

then direct the flame with care to avoid subjecting the readout valves on the Automatic Flow-Limiting Valve.

AFLV to excessive heat. Allow the valve to cool before

touching or operating. WARNING: Hot water leakage can occur from

e) Check the soldered connection for leaks. readout valve during probe insertion and during

hookup of readout kit. Follow the instruction manual

WARNING: Use of improper procedures to sweat supplied with readout probes and readout kits for safe

valve model with union connection into system use. Failure to follow this instruction could result in

can damage valve. Before installing sweat union serious personal injury and/or property damage.

connection to valve, remove the union nut and O-ring

from the valve body, the union tailpiece with nut must be 2. Read the differential pressure across the Automatic Flow-

sweated (soldered) into place. Failure to follow this Limiting Valve. This can be compared to system pump

instruction could result in property damage and/or head to determine valve function, and system flow

moderate personal injury. blockage.

SERVICE INSTRUCTIONS

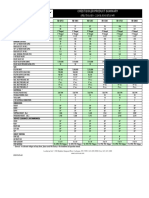

Chart A

(SOLDER TYPE LIMITS PER ASTM STD. B16.22-1989) Should the Automatic Flow-Limiting Valve require cleaning or

changing the orifice, follow the following instructions.

TYPE OF MAXIMUM LIMITATIONS

SOLDER PRESSURE PSIG TEMPERATURE ºF WARNING: System fluid under pressure and/or at

95-5 300 175 high temperature can be very hazardous. Before

TIN- 250 200 servicing, reduce system pressure to zero or isolate the

ANTIMONY 175 250 pressure reducing from the system. Leave drain valve

open. Allow system to cool below 100ºF (38ºC). Failure to

follow these instructions could result in serious personal

CAUTION: Heat associated with the use of silver

injury or death and property damage.

solder may damage an Automatic Flow-Limiting

valve and void the product warranty. Do not use silver 1. Loosen and remove the bonnet (cap) from the valve body.

solder. Failure to follow these instructions could result in 2. Pull the cartridge assembly from the valve body for

property damage and/or moderate personal injury. cleaning or change the new flow cartridge. Checking the

cartridge by pushing the orifice washer in to the cartridge

OPERATING INSTRUCTIONS housing for several times to make sure spring is

functional.

Operation of the Automatic Flow-Limiting Valve is fully 3. If you design to changing the orifice washer (for more or

automatic and does not require any adjustment. It auto- less flow rate). With a screwdriver, remove the clip ring

matically maintains the selected flow over the designed from inside the cartridge housing. Pull the orifice washer

differential pressure range. out and replace with the new orifice that you have

preferred.

CAUTION: Hot uninsulated surfaces can cause 4. Reinstall, or replace the clip ring in the cartridge housing

burns to the skin. Do not touch hot surfaces. groove and reassemble the bonnet with the O-ring.

Failure to follow these instructions could result in

moderate personal injury. WARNING: Corrosion or leakages are indications

that the Automatic Flow Control Valve may be

Before the system start up, remove cartridge from the valve. about to cause serious damage from leakage or rupture.

Flush the hydronic system and then reassemble cartridge into It must be periodically inspected and if noted, it must be

the valve and make sure cap is tightened properly. Start the replaced. Failure to follow these instructions could result

system and check for the AFLV leak. in serious personal injury or death and property damage.

CAUTION: Hot uninsulated surfaces can cause

burns to the skin. Do not touch hot surfaces.

Failure to follow these instructions could result in

moderate personal injury.

Bell & Gossett USA

Bell & Gossett

INTL.

Bell & Gossett / Export Dept.

CANADA

Fluid Products Canada

8200 N. Austin Avenue 8200 N. Austin Avenue 55 Royal Road

Morton Grove, IL 60053 Morton Grove, IL 60053 Guelph, Ontario,

Phone: (847) 966-3700 Phone: (847) 966-3700 N1H 1T1, Canada

© COPYRIGHT 2004 BY ITT INDUSTRIES, INC. Facsimile: (847) 966-9052 Facsimile: (847) 966-8366 Phone: (519) 821-1900

PRINTED IN U.S.A. 6-04 http://www.bellgossett.com http://www.bellgossett.com

Vous aimerez peut-être aussi

- Installation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitD'EverandInstallation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitPas encore d'évaluation

- Bell & Gossett: Circuit Setter Balance Valves 4" Thru 12" SizesDocument4 pagesBell & Gossett: Circuit Setter Balance Valves 4" Thru 12" SizessamPas encore d'évaluation

- Circuit Setter Bell & GrossetDocument6 pagesCircuit Setter Bell & GrossetKevinCostasCaceresPas encore d'évaluation

- Circuit Center ValvulaDocument4 pagesCircuit Center ValvulaLuis Carlos PardoPas encore d'évaluation

- Apollo Top Entry Ball Valves Installation, Operation, & Maintenance ManualDocument9 pagesApollo Top Entry Ball Valves Installation, Operation, & Maintenance ManualErcan YilmazPas encore d'évaluation

- MN 03006Document2 pagesMN 03006hyarub9Pas encore d'évaluation

- Series "RVT" Relief Valves: Installation and Maintenance InstructionsDocument4 pagesSeries "RVT" Relief Valves: Installation and Maintenance InstructionsFernando Cesar PérezPas encore d'évaluation

- 1-8113 GBDocument8 pages1-8113 GBSaipp SrlPas encore d'évaluation

- IBHCVDocument71 pagesIBHCVdvmahiidaPas encore d'évaluation

- Automatic Air VentDocument2 pagesAutomatic Air VentmahmudazakirPas encore d'évaluation

- Steam Generator Steam Generator: Quality of LifeDocument29 pagesSteam Generator Steam Generator: Quality of LifeMiguel DexsPas encore d'évaluation

- CVS EZ Instruction ManualDocument28 pagesCVS EZ Instruction ManualJohn Harry RamirezPas encore d'évaluation

- CVS Series 50 Chemical Injection Pump ManualDocument12 pagesCVS Series 50 Chemical Injection Pump Manualiqmpslab0% (1)

- Circuit Setter Plus Model MC: Instruction ManualDocument4 pagesCircuit Setter Plus Model MC: Instruction Manualmacanipharoldf6220Pas encore d'évaluation

- Valtek MK1 IOMDocument12 pagesValtek MK1 IOMJuan HernandezPas encore d'évaluation

- General: IL Gas Vent Is Fi Re Rated To The Stability and Integrity Requirement BS 476 Part 20 For 90 MinutesDocument4 pagesGeneral: IL Gas Vent Is Fi Re Rated To The Stability and Integrity Requirement BS 476 Part 20 For 90 MinutesneilPas encore d'évaluation

- USA Bell & Gossett 116506 - D120 (68GAL)Document6 pagesUSA Bell & Gossett 116506 - D120 (68GAL)1092 hanna (primary soul)Pas encore d'évaluation

- Manual de Instalación de Válvula de BolaDocument4 pagesManual de Instalación de Válvula de BolaCesar GonzalesPas encore d'évaluation

- Circuit Setter ManualDocument4 pagesCircuit Setter ManualAnonymous 7xHNgoKE6ePas encore d'évaluation

- 101 ADocument8 pages101 AscrewzuckenbergerPas encore d'évaluation

- Dia-Flo & Pure-Flo Diaphragm Valves Instruction Manual With Dia-Flo ActuatorDocument16 pagesDia-Flo & Pure-Flo Diaphragm Valves Instruction Manual With Dia-Flo Actuatorabdul rehmanPas encore d'évaluation

- Freno Auxiliar Electrico HurstDocument7 pagesFreno Auxiliar Electrico HurstSam MarmorPas encore d'évaluation

- Please Read These Instructions Carefully: GRW/GRL Installation & Operation ManualDocument8 pagesPlease Read These Instructions Carefully: GRW/GRL Installation & Operation ManualCn RomaPas encore d'évaluation

- 400 Series Instructions 051118 WebDocument4 pages400 Series Instructions 051118 Webzidan080606Pas encore d'évaluation

- Check Valve: Product Bulletin 50-13 CDocument2 pagesCheck Valve: Product Bulletin 50-13 CHuong QuangPas encore d'évaluation

- Argo Ae2mi40ah - B PDFDocument102 pagesArgo Ae2mi40ah - B PDFNIkica BukaricaPas encore d'évaluation

- RP Is 009 009 FS+2214Document8 pagesRP Is 009 009 FS+2214Prabath KPas encore d'évaluation

- Manual Bomba PeristalticaDocument30 pagesManual Bomba PeristalticaEmanuell SantosPas encore d'évaluation

- Omi PB 02 0 Eng Plug ValveDocument4 pagesOmi PB 02 0 Eng Plug Valveakhilsyam21Pas encore d'évaluation

- Circuit SetterDocument4 pagesCircuit SetterHVACRNIC2005Pas encore d'évaluation

- Operating and Maintenance Instructions: Keystone Figure 79 Pneumatic ActuatorDocument13 pagesOperating and Maintenance Instructions: Keystone Figure 79 Pneumatic ActuatorjorgePas encore d'évaluation

- Network Blu-Ray Disc / DVD Home Theater System: Service ManualDocument151 pagesNetwork Blu-Ray Disc / DVD Home Theater System: Service ManualAlexPas encore d'évaluation

- 3D Blu-Ray / DVD Home Theater System: Service ManualDocument151 pages3D Blu-Ray / DVD Home Theater System: Service Manualferdy srghPas encore d'évaluation

- Sanyo Inverter Sap KRV 186-246 Eh Tech Data Om & ServiceDocument117 pagesSanyo Inverter Sap KRV 186-246 Eh Tech Data Om & ServiceambraPas encore d'évaluation

- LG Home TheaterDocument121 pagesLG Home TheaterhermiePas encore d'évaluation

- HB806TM PDFDocument121 pagesHB806TM PDFhermie100% (1)

- 08-INSTALLATION - (A) Ball ValvesDocument4 pages08-INSTALLATION - (A) Ball ValvesModassir ZaheenPas encore d'évaluation

- Fairchild Model m10bp Precision Back Pressure Regulator 2007 ManualDocument2 pagesFairchild Model m10bp Precision Back Pressure Regulator 2007 Manualshahrol effendy rodziPas encore d'évaluation

- Swing-Flex Check Valve: Operation, Maintenance and Installation ManualDocument8 pagesSwing-Flex Check Valve: Operation, Maintenance and Installation ManualAhmed ShawkyPas encore d'évaluation

- Press SW IndfossDocument2 pagesPress SW IndfossSting DâuPas encore d'évaluation

- 2 TTB 3Document8 pages2 TTB 3mikecom21Pas encore d'évaluation

- 2-Inch LW Plug Valve BroDocument12 pages2-Inch LW Plug Valve BroJavier Araque100% (1)

- Safet Old Style Sh5023p Rev.2 Is Sh5023 75Document6 pagesSafet Old Style Sh5023p Rev.2 Is Sh5023 75Adam SlatteryPas encore d'évaluation

- O&S Instructions - Reducing ValvesDocument1 pageO&S Instructions - Reducing ValvesTifano KhristiyantoPas encore d'évaluation

- Valvula de Gas HoneyWell VS820 - VS821Document16 pagesValvula de Gas HoneyWell VS820 - VS821John Carmona100% (1)

- 50B-4KG1/2050B-4KG1: Pressure Relief ValveDocument2 pages50B-4KG1/2050B-4KG1: Pressure Relief ValveEduardo CastilloPas encore d'évaluation

- Manual Guides Keystone Figure 79 Pneumatic Actuator Keystone en en 2718292Document13 pagesManual Guides Keystone Figure 79 Pneumatic Actuator Keystone en en 2718292vjPas encore d'évaluation

- Submersible Sewage Ejector Pump: Safety InformationDocument8 pagesSubmersible Sewage Ejector Pump: Safety Informationallen_worstPas encore d'évaluation

- Hotstart - Model OLA or OLE - Oil Circulating Heating System Hazardous LocationDocument16 pagesHotstart - Model OLA or OLE - Oil Circulating Heating System Hazardous Locationdiego106Pas encore d'évaluation

- Altronic GSVDocument8 pagesAltronic GSVhamadaPas encore d'évaluation

- SKF TMJL 50: Instructions For UseDocument136 pagesSKF TMJL 50: Instructions For UsePomaPas encore d'évaluation

- Manual de Uso SOPLADOR NEUMATICODocument16 pagesManual de Uso SOPLADOR NEUMATICOannie 13Pas encore d'évaluation

- Installer's Guide: Condensing UnitsDocument8 pagesInstaller's Guide: Condensing UnitsOmar PiñaPas encore d'évaluation

- 08 6.H Pressure VesselDocument32 pages08 6.H Pressure VesselstargaxxxxPas encore d'évaluation

- Mbfu120w InstallDocument4 pagesMbfu120w InstallMr NaikerPas encore d'évaluation

- LG LHB645Document113 pagesLG LHB645boroda2410100% (1)

- Codeline - 80E Series: 8 Inch End Entry Membrane Housing For Ro ApplicationsDocument29 pagesCodeline - 80E Series: 8 Inch End Entry Membrane Housing For Ro ApplicationsCecilia Guerra AburtoPas encore d'évaluation

- Actuador Valtek PDFDocument8 pagesActuador Valtek PDFEduardo Landa GonzalezPas encore d'évaluation

- LG bh7220bwDocument137 pagesLG bh7220bwCristiano BragaPas encore d'évaluation

- Am, Ap & Al Series Pumps Owners Manual: Safety InstructionsDocument10 pagesAm, Ap & Al Series Pumps Owners Manual: Safety InstructionsQC RegianPas encore d'évaluation

- Domestic Pump: Series CM Boiler Feed UnitsDocument4 pagesDomestic Pump: Series CM Boiler Feed UnitsAnonymous 7xHNgoKE6ePas encore d'évaluation

- Series 60 Inline Pump With Electronically Commutated Motor (ECM)Document3 pagesSeries 60 Inline Pump With Electronically Commutated Motor (ECM)Anonymous 7xHNgoKE6ePas encore d'évaluation

- Airtrol IOM 599 PDFDocument6 pagesAirtrol IOM 599 PDFAnonymous 7xHNgoKE6ePas encore d'évaluation

- Bell & Gossett: Submittal B-341BDocument2 pagesBell & Gossett: Submittal B-341BAnonymous 7xHNgoKE6ePas encore d'évaluation

- Modbus Communication Instructions: Models: 1.0 - 1.3 - 1.5Document24 pagesModbus Communication Instructions: Models: 1.0 - 1.3 - 1.5Anonymous 7xHNgoKE6ePas encore d'évaluation

- Crest Boiler Product Summary: (FB) 750,000 - 2,000,000 BTU/HRDocument1 pageCrest Boiler Product Summary: (FB) 750,000 - 2,000,000 BTU/HRAnonymous 7xHNgoKE6ePas encore d'évaluation

- AWX2-I-O Rev G - High Altitude PDFDocument68 pagesAWX2-I-O Rev G - High Altitude PDFAnonymous 7xHNgoKE6ePas encore d'évaluation

- B-313 Series E-1510 Technical Brochure PDFDocument8 pagesB-313 Series E-1510 Technical Brochure PDFAnonymous 7xHNgoKE6ePas encore d'évaluation

- Condensing Commercial Gas Water HeatersDocument4 pagesCondensing Commercial Gas Water HeatersAnonymous 7xHNgoKE6ePas encore d'évaluation

- Alstrom Series ASTEG Steam Generator BrochureDocument2 pagesAlstrom Series ASTEG Steam Generator BrochureAnonymous 7xHNgoKE6ePas encore d'évaluation

- Check-Trol: Isolation Flow Control FlangeDocument2 pagesCheck-Trol: Isolation Flow Control FlangeAnonymous 7xHNgoKE6ePas encore d'évaluation

- Usg Iom PDFDocument56 pagesUsg Iom PDFAnonymous 7xHNgoKE6ePas encore d'évaluation

- FTXL Boiler Product Summary: 399,999-850,000 BTU/HRDocument1 pageFTXL Boiler Product Summary: 399,999-850,000 BTU/HRAnonymous 7xHNgoKE6ePas encore d'évaluation

- B-312 Series E-1532 Technical BrochureDocument4 pagesB-312 Series E-1532 Technical BrochureAnonymous 7xHNgoKE6ePas encore d'évaluation

- High Efficiency Commercial BoilersDocument4 pagesHigh Efficiency Commercial BoilersAnonymous 7xHNgoKE6ePas encore d'évaluation

- 751-2001-FBII-I-O - Rev T - 100208043 - 2000004587 (6 INCH VENT) PDFDocument68 pages751-2001-FBII-I-O - Rev T - 100208043 - 2000004587 (6 INCH VENT) PDFAnonymous 7xHNgoKE6ePas encore d'évaluation

- HoffmanDocument12 pagesHoffmanAnonymous 7xHNgoKE6ePas encore d'évaluation

- HoffmanDocument4 pagesHoffmanAnonymous 7xHNgoKE6ePas encore d'évaluation

- HoffmanDocument148 pagesHoffmanAnonymous 7xHNgoKE6ePas encore d'évaluation

- HoffmanDocument2 pagesHoffmanAnonymous 7xHNgoKE6ePas encore d'évaluation

- Glascow Coma ScaleDocument10 pagesGlascow Coma ScaleJSeasharkPas encore d'évaluation

- The Functional Anatomy of The Knee JointDocument12 pagesThe Functional Anatomy of The Knee JointFadzlee SoujiPas encore d'évaluation

- Abd Wall - Inguinal Reg. - Upnm7 - 210218Document38 pagesAbd Wall - Inguinal Reg. - Upnm7 - 210218Gx NavinPas encore d'évaluation

- Yoga Kaivalyadham ModuleDocument71 pagesYoga Kaivalyadham Modulearunsrl100% (1)

- PE 1 (Foundation of Physical Fitness) PDFDocument13 pagesPE 1 (Foundation of Physical Fitness) PDFKen Rubio67% (3)

- 70 Đề Thi Chứng Chỉ B Tiếng AnhDocument502 pages70 Đề Thi Chứng Chỉ B Tiếng AnhTran Thi Thanh Hien100% (1)

- Physical Therapy MalpracticeDocument3 pagesPhysical Therapy MalpracticeAbdul KhadeerPas encore d'évaluation

- Colonial Skirmish RulesDocument10 pagesColonial Skirmish RulesBrett Michael Chinchen100% (1)

- Jadepunk Tales Vigilance Committee Volume OneDocument36 pagesJadepunk Tales Vigilance Committee Volume OneDaniel Araujo100% (1)

- Luftwaffe Plot Against GoeringDocument204 pagesLuftwaffe Plot Against Goeringcheapgary100% (1)

- Hori Lal V State of Up PDFDocument4 pagesHori Lal V State of Up PDFSandeep Kumar VermaPas encore d'évaluation

- Lumbar Radioculopathy HomeworkDocument12 pagesLumbar Radioculopathy Homeworkbeta100% (1)

- Case Presentatio Insomnia 1Document49 pagesCase Presentatio Insomnia 1kiran mahal100% (1)

- 5N06HDDocument8 pages5N06HDahagen00Pas encore d'évaluation

- Santo Lin I 2020Document13 pagesSanto Lin I 2020Jose Tellez HuertaPas encore d'évaluation

- LiposuctionDocument14 pagesLiposuctionMaria BudnicPas encore d'évaluation

- Human Anatomy Physiology 8Th Edition Marieb Test Bank Full Chapter PDFDocument55 pagesHuman Anatomy Physiology 8Th Edition Marieb Test Bank Full Chapter PDFninhdermotc1u100% (9)

- Analzying Sensory Somatic Responces - System Reinforcemnt Worksheet1Document2 pagesAnalzying Sensory Somatic Responces - System Reinforcemnt Worksheet1Creative DestinyPas encore d'évaluation

- Seb D 017208Document970 pagesSeb D 017208Ravinder SinghPas encore d'évaluation

- Alata SaminaMCQsDocument132 pagesAlata SaminaMCQsmintahmeshackbenjaminPas encore d'évaluation

- Halo Savage WorldsDocument21 pagesHalo Savage Worldsscottwelchkin0% (1)

- 7 - Spinal Column and Spinal Cord Injuries TestDocument3 pages7 - Spinal Column and Spinal Cord Injuries Testkamilkasim262Pas encore d'évaluation

- Employee Benefits CGHSDocument3 pagesEmployee Benefits CGHSaruvindhuPas encore d'évaluation

- Marathon Strength TrainingDocument1 pageMarathon Strength TrainingAndrew O'BrienPas encore d'évaluation

- Health Assessment ChecklistDocument14 pagesHealth Assessment ChecklistLindy JanePas encore d'évaluation

- Post-Falls Assessment Form FCG FinalDocument2 pagesPost-Falls Assessment Form FCG Finalbernie hewsonPas encore d'évaluation

- Ergonomics NotesDocument15 pagesErgonomics NotesSarah Abdalla100% (1)

- Chapter 1 The Human Body Orientation Edited 55 SlidesDocument55 pagesChapter 1 The Human Body Orientation Edited 55 SlidesFonzy EstrellaPas encore d'évaluation

- Work Alert Form Ip 6a 1Document3 pagesWork Alert Form Ip 6a 1NKH Mega GasPas encore d'évaluation

- Pe ReviewerDocument10 pagesPe ReviewerLean Amara VillarPas encore d'évaluation