Académique Documents

Professionnel Documents

Culture Documents

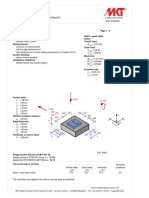

37c Floor Joists No Notch - PNG

Transféré par

Parthiban ArivazhaganTitre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

37c Floor Joists No Notch - PNG

Transféré par

Parthiban ArivazhaganDroits d'auteur :

Formats disponibles

xc

g Proj: Admin

Ref :

Tel:d Date: 24/08/17

--------------------------------------------------------------------------------------------------------------------------------------------------------------------

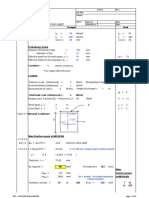

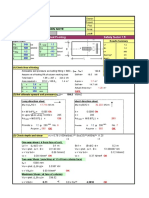

Joist section design

Calculations for timber joists are in accordance with BS5268:Pt 2:1996

Joist size - 300 wide x 300 deep

Timber type - Sawn Softwood as Table NA.2 of BS EN 336

Span of joist =2m

Span type - Simple

End bearing - left hand end X = 0 mm

Y = 50 mm

- right hand end X = 0 mm

Y = 50 mm

End notches - left hand end - none specified

- right hand end - none specified

Joist centres = 450 mm

Strength class from Table 7 (service classes 1 & 2) - C16

Service class - 2 (Covered and heated or unheated)

Maximum design moment = 25 kNm/m

Design shear force at left hand support = 35 kN/m

Design shear force at right hand support = 65 kN/m

Load Description Type A B C Gk Qk

3 Poin 1.0 0.5 10.0 10.0

UDL 0 2.0 10.0 10.0

Grade stresses - from Table 7

Bending parallel to grain = 5.3 N/mm2

Shear parallel to grain = 0.6 N/mm2

Compression perpendicular to grain = 2.2 N/mm2

(wane prohibited at bearing areas)

Modification factors

For service class 2 - moment K =1

2

- shear K =1

2

- bearing K =1

2

- Youngs mod. K =1

2

- Shear mod. K =1

2

For load duration - long K =1

3

For end bearing - left end K =1

4

- right end K =1

4

For no end notch - left end K =1

5

For no end notch - right end K =1

5

For depth between 72 and 300mm K = (300/h)0.11

7

= (300/300)0.11

= 1.00

For load sharing system K = 1.1

8

Bending Design

The allowable bending stress is

= *K *K *K *K

bpall bp 2 3 7 8

= 5.3*1*1*1*1.1

= 5.83 N/mm2

The moment per metre width of floor is 25 kNm/m. Hence, the moment per joist is

M = M*j /1000

j cc

= 25*450/1000

= 11.25 kNm

giving the required section modulus per joist as

z = M *106/

reqd j bpall

= 11.25*106/5.83

= 1929674 mm3

The section modulus of the joist chosen is 4500000 mm^3.

Shear Design

Left hand support

The allowable shear stress is

= *K *K *K *K

cpaall cpa 2 3 5 8

= 0.6*1*1*1*1.1

= 0.66 N/mm2

The shear per metre width of floor is 35 kN/m. Hence, the shear per joist is

R = R *j /1000

lj l cc

= 35*450/1000

= 15.75 kN

giving the required cross sectional area per joist as

A = 3*R *103/(2* )

lreqd lj cpaall

=3*15.75*103/(2*0.66)

= 35795 mm2

The cross sectional area of the joist chosen is

A = b*h

lprov

= 300*300

= 90000 mm2

Right hand support

The allowable shear stress is

= *K *K *K *K

cpaall cpa 2 3 5 8

= 0.6*1*1*1*1.1

= 0.66 N/mm2

The shear per metre width of floor is 65 kNm/m. Hence, the shear per joist is

R = R *j /1000

rj r cc

= 65*450/1000

= 29.25 kN

giving the required cross sectional area per joist as

A = 3*R *103/(2* )

rreqd rj cpaall

=3*29.25*103/(2*0.66)

= 66477 mm2

The cross sectional area of the joist chosen is

A = b*h

rprov

= 300*300

= 90000 mm2

Bearing Design

Left hand support

The allowable bearing stress is

= *K *K *K *K

cpeall cpe 2 3 4 8

= 2.2*1*1*1*1.1

= 2.42 N/mm2

The shear per joist is 15.75 kN, giving the required bearing area as

A = R *103/

blreqd lj cpeall

= 15.75*103/2.42

= 6508 mm2

The bearing area of the joist chosen is

A = b*Y

blprov l

= 300*50

= 15000 mm2

Right hand support

The allowable bearing stress is

= *K *K *K *K

cpeall cpe 2 3 4 8

= 2.2*1*1*1*1.1

= 2.42 N/mm2

The shear per joist is 29.25 kN, giving the required bearing area as

A = R *103/

brreqd rj cpeall

= 29.25*103/2.42

= 12087 mm2

The bearing area of the joist chosen is

A = b*Y

brprov r

= 300*50

= 15000 mm2

Deflection check

The deflection calculated includes for shear deflection and is based on the following

- For a loadsharing system

- Youngs modulus - E = 8800 N/mm2

- Shear modulus - G = 550 N/mm2

- Shape factor - F = 1.2 (for rectangular sections)

and section properties of

- Area - A = 900 cm2

- Mom. of inertia - I = 67500 cm4

The maximum calculated deflection is 1 mm, which does not exceed the allowable deflection, determined from the span ratio (

0.003 x span ), of 6 mm.

Vous aimerez peut-être aussi

- Pile Foundation SpecificationDocument35 pagesPile Foundation SpecificationlearnafrenPas encore d'évaluation

- RCC Footing DesignDocument21 pagesRCC Footing Designnitin chaudharyPas encore d'évaluation

- Compressive Strength Beam DesignDocument70 pagesCompressive Strength Beam DesignDjuned0% (1)

- BS EN 14490-2010 Execution of Special Geotechnical Works - Soil NailingDocument72 pagesBS EN 14490-2010 Execution of Special Geotechnical Works - Soil Nailingjadrichem50% (2)

- 2.45M High Rubble Wall: Mila Feb-22Document4 pages2.45M High Rubble Wall: Mila Feb-22Nezza AriffPas encore d'évaluation

- Base PlateDocument13 pagesBase PlateNaga Manikanta TatikondaPas encore d'évaluation

- AiscDocument13 pagesAiscsteven bianesPas encore d'évaluation

- Design Spreadsheet Gusset Plate Connection For TrussDocument4 pagesDesign Spreadsheet Gusset Plate Connection For TrussMatumbi Naito100% (1)

- BS 8110 Data Given: Calculation SheetDocument10 pagesBS 8110 Data Given: Calculation SheetLee See VoonPas encore d'évaluation

- 21a-Gutter-Downpipe Sizing Double Pitch Roof-TrapezoidalDocument3 pages21a-Gutter-Downpipe Sizing Double Pitch Roof-TrapezoidalParthiban ArivazhaganPas encore d'évaluation

- StaircaseDocument2 pagesStaircaseMAGED MOHMMED AHMED QASEMPas encore d'évaluation

- Design of tension member calculationDocument1 pageDesign of tension member calculationchaPas encore d'évaluation

- Software Verification: AISC-360-05 Example 001Document8 pagesSoftware Verification: AISC-360-05 Example 001Zakir KhanPas encore d'évaluation

- Gantry Grider FinalDocument8 pagesGantry Grider Finalasvenk309Pas encore d'évaluation

- Slab DesignDocument38 pagesSlab Designmathewsujith31Pas encore d'évaluation

- Design of Base Plate and Anchor BoltDocument7 pagesDesign of Base Plate and Anchor BoltsavsagarPas encore d'évaluation

- Slab For Lift ProjectDocument2 pagesSlab For Lift ProjectAnonymous ptLRLiNNPas encore d'évaluation

- Main Report Plot#1494, Street#50, Sector-M, Phase-VIII, Bahria Town RWPDocument11 pagesMain Report Plot#1494, Street#50, Sector-M, Phase-VIII, Bahria Town RWPMian Muhammad Jazib100% (1)

- Rectangular Steel Bar DesignDocument2 pagesRectangular Steel Bar DesignAmit Kumar PaulPas encore d'évaluation

- Hollow Pot Slabs DesignDocument4 pagesHollow Pot Slabs Designchris100% (4)

- Aisc LRFDDocument30 pagesAisc LRFDlapt75100% (1)

- Anchor Bolt Design, IS Code LSDDocument33 pagesAnchor Bolt Design, IS Code LSDamlan jyoti ChakravortyPas encore d'évaluation

- Design of Two-Way SlabDocument48 pagesDesign of Two-Way SlabAboobackar SidheeqPas encore d'évaluation

- Purlin Design PDFDocument3 pagesPurlin Design PDFUday Udmale100% (1)

- Crack Width Check BS5400 4Document6 pagesCrack Width Check BS5400 4Parthiban ArivazhaganPas encore d'évaluation

- Design of Base Plate C1 Size CheckDocument56 pagesDesign of Base Plate C1 Size CheckajPas encore d'évaluation

- Column DesignDocument98 pagesColumn DesignJessa OpenianoPas encore d'évaluation

- Element Location: Subject: Made by Design Code: Loading On Slab Value Units JamesDocument5 pagesElement Location: Subject: Made by Design Code: Loading On Slab Value Units JamesJames AswaPas encore d'évaluation

- Design of 75T Crane Girder for 10m SpanDocument29 pagesDesign of 75T Crane Girder for 10m Spananbukgi100% (2)

- Solution Manual for an Introduction to Equilibrium ThermodynamicsD'EverandSolution Manual for an Introduction to Equilibrium ThermodynamicsPas encore d'évaluation

- Appendix A1Document5 pagesAppendix A1Thomas Stephen100% (1)

- Design Concrete SheetDocument14 pagesDesign Concrete SheetIan Roderick JafferyPas encore d'évaluation

- BS8110 Column DesignDocument11 pagesBS8110 Column DesignchaPas encore d'évaluation

- Support of Deep Excavation in Soft Clay A Case History StudyDocument8 pagesSupport of Deep Excavation in Soft Clay A Case History StudyAlfredo A LopezPas encore d'évaluation

- Design and Detailing of Seismic Connections For Braced Frame StructuresDocument19 pagesDesign and Detailing of Seismic Connections For Braced Frame StructuresDavid SantiagoPas encore d'évaluation

- Manholes PolycreteDocument8 pagesManholes PolycreteLuzmin DelaCruzPas encore d'évaluation

- 39c Floor Joists Types01.PngDocument4 pages39c Floor Joists Types01.PngParthiban ArivazhaganPas encore d'évaluation

- Drawing & Design GantryDocument27 pagesDrawing & Design Gantrysita ram doraPas encore d'évaluation

- Project: Subject:: Design of SheathingDocument2 pagesProject: Subject:: Design of Sheathingbmurali19783190Pas encore d'évaluation

- Column Inter at Ion DiagramDocument7 pagesColumn Inter at Ion DiagramPremasiri KarunarathnaPas encore d'évaluation

- # 06) Design of Compression MembersDocument23 pages# 06) Design of Compression MembersSeif elsaeedPas encore d'évaluation

- Formulas DstsDocument16 pagesFormulas DstsGrey AsusPas encore d'évaluation

- S2 Slab Calculation PDFDocument1 pageS2 Slab Calculation PDFashishPas encore d'évaluation

- Conductor Cone Guide Design CalculationsDocument3 pagesConductor Cone Guide Design CalculationsThomas StephenPas encore d'évaluation

- Welding CheckingDocument1 pageWelding Checkingxlw955597Pas encore d'évaluation

- Shear Key Design UpdatedDocument4 pagesShear Key Design UpdatedNitin SakpalPas encore d'évaluation

- Loads:: Housing Layout-Sd-EastDocument2 pagesLoads:: Housing Layout-Sd-Eastpvrk_78Pas encore d'évaluation

- Connection Check: Cast in RebarsDocument2 pagesConnection Check: Cast in RebarsSiva JasePas encore d'évaluation

- Steel ColumnDocument4 pagesSteel ColumnsansamPas encore d'évaluation

- Lateral-Torsional Buckling: Bending About Its Major Axis, Failure May Occur by A Form of Buckling Which Involves Lateral Deflection and TwistingDocument27 pagesLateral-Torsional Buckling: Bending About Its Major Axis, Failure May Occur by A Form of Buckling Which Involves Lateral Deflection and TwistingMohammed HanafiPas encore d'évaluation

- Steel GateDocument12 pagesSteel GateSaravanan SPas encore d'évaluation

- Formula-1 truss design analysisDocument3 pagesFormula-1 truss design analysisSM WorldPas encore d'évaluation

- Pedestal DesignDocument11 pagesPedestal DesignNikhil TawadePas encore d'évaluation

- R.C. Slab Design Calculation Sheet for Two Way Slab S1Document1 pageR.C. Slab Design Calculation Sheet for Two Way Slab S1sallysel90Pas encore d'évaluation

- RC Two Way Slab Design ACI318 05 PDFDocument6 pagesRC Two Way Slab Design ACI318 05 PDFSafi Zabihullah SafiPas encore d'évaluation

- Bottom bracket anchor designDocument4 pagesBottom bracket anchor designMohammed AyeshPas encore d'évaluation

- Case NoDocument13 pagesCase NoGovendan GopalakrishnanPas encore d'évaluation

- C-End Bottom Bracket ReportDocument4 pagesC-End Bottom Bracket ReportMohammed AyeshPas encore d'évaluation

- VMH AnchorDocument4 pagesVMH Anchormohamed rafiPas encore d'évaluation

- Vessel Side Shell Check CalculationsDocument5 pagesVessel Side Shell Check CalculationsShahir MeledathPas encore d'évaluation

- BS5950-1990Document18 pagesBS5950-1990rkafinaPas encore d'évaluation

- Project Job No.: H H Dia ColDocument3 pagesProject Job No.: H H Dia ColAdam HussaryPas encore d'évaluation

- Fundamentals of Metal Forming ProcessesDocument87 pagesFundamentals of Metal Forming ProcessesBahrul HayatPas encore d'évaluation

- Rigid Pavement Design PDFDocument2 pagesRigid Pavement Design PDFRaju SainiPas encore d'évaluation

- Project: Architect: Footing No.Document4 pagesProject: Architect: Footing No.Maninder ChaudharyPas encore d'évaluation

- Check For Compression Welds Between Beam Flanges and End PlateDocument3 pagesCheck For Compression Welds Between Beam Flanges and End PlateKrish ChandPas encore d'évaluation

- 3 Pilecap Design-ACIDocument3 pages3 Pilecap Design-ACIShamim Ahsan ZuberyPas encore d'évaluation

- FootingsDocument5 pagesFootingsFaazPas encore d'évaluation

- B-Ket ReportDocument3 pagesB-Ket ReportMohammed AyeshPas encore d'évaluation

- Design of Two Way Slab (Continuous) : Given DataDocument3 pagesDesign of Two Way Slab (Continuous) : Given DataParwan Exceltech100% (1)

- Minimum Pressure Case Stress AnalysisDocument2 pagesMinimum Pressure Case Stress AnalysisParthiban ArivazhaganPas encore d'évaluation

- UI Reinforcement DetailsDocument3 pagesUI Reinforcement DetailsParthiban ArivazhaganPas encore d'évaluation

- Web Content - Monorail-R2Document2 pagesWeb Content - Monorail-R2Parthiban ArivazhaganPas encore d'évaluation

- 38a-Columns Axial Compression and Moments - PNGDocument3 pages38a-Columns Axial Compression and Moments - PNGParthiban ArivazhaganPas encore d'évaluation

- 21a-Gutter-Downpipe Sizing Double Pitch Roof-True Half RoundDocument2 pages21a-Gutter-Downpipe Sizing Double Pitch Roof-True Half RoundParthiban ArivazhaganPas encore d'évaluation

- 21a-Gutter-Downpipe Sizing Double Pitch Roof-True Half RoundDocument2 pages21a-Gutter-Downpipe Sizing Double Pitch Roof-True Half RoundParthiban ArivazhaganPas encore d'évaluation

- 22a-RSJ Runway Beam Check-Simply Supported-Hand OperatedDocument2 pages22a-RSJ Runway Beam Check-Simply Supported-Hand OperatedParthiban Arivazhagan100% (1)

- 45a-Columns Axial Force and Bending - PNGDocument5 pages45a-Columns Axial Force and Bending - PNGParthiban ArivazhaganPas encore d'évaluation

- 13a-Building Near Trees To NHBC STANDARDSDocument1 page13a-Building Near Trees To NHBC STANDARDSParthiban ArivazhaganPas encore d'évaluation

- 21a-Gutter-Downpipe Sizing Double Pitch Roof-True Half RoundDocument2 pages21a-Gutter-Downpipe Sizing Double Pitch Roof-True Half RoundParthiban ArivazhaganPas encore d'évaluation

- 45b-Floor Joits Type 01.PngDocument7 pages45b-Floor Joits Type 01.PngParthiban ArivazhaganPas encore d'évaluation

- 34e Trussed Beam - PNGDocument3 pages34e Trussed Beam - PNGParthiban ArivazhaganPas encore d'évaluation

- 34d-Rafter or Sloping Beam-Roller at Lower Lever - PNGDocument3 pages34d-Rafter or Sloping Beam-Roller at Lower Lever - PNGParthiban ArivazhaganPas encore d'évaluation

- 34e Trussed Beam - PNGDocument3 pages34e Trussed Beam - PNGParthiban ArivazhaganPas encore d'évaluation

- 35c Floor Joists Medium Type A Notch Both Wet - PNGDocument5 pages35c Floor Joists Medium Type A Notch Both Wet - PNGParthiban ArivazhaganPas encore d'évaluation

- 22a-RSJ Runway Beam Check-Simply Supported-Hand OperatedDocument2 pages22a-RSJ Runway Beam Check-Simply Supported-Hand OperatedParthiban Arivazhagan100% (1)

- 37b-Columns Axial Compression Only Type 02.PngDocument2 pages37b-Columns Axial Compression Only Type 02.PngParthiban ArivazhaganPas encore d'évaluation

- 37a-Colums Axial Compression and Moments Type 03.PngDocument4 pages37a-Colums Axial Compression and Moments Type 03.PngParthiban ArivazhaganPas encore d'évaluation

- 34d-Rafter or Sloping Beam-Roller at Lower Lever-With Depth and Width - PNGDocument3 pages34d-Rafter or Sloping Beam-Roller at Lower Lever-With Depth and Width - PNGParthiban ArivazhaganPas encore d'évaluation

- 30F-I Stability Check Bending Simply Supported Beams-On Bottom Flange - PNGDocument3 pages30F-I Stability Check Bending Simply Supported Beams-On Bottom Flange - PNGParthiban ArivazhaganPas encore d'évaluation

- 35c Floor Joists Long No Notch Dry - PNGDocument5 pages35c Floor Joists Long No Notch Dry - PNGParthiban ArivazhaganPas encore d'évaluation

- 39b-Columns Axial Compression Only - PNGDocument2 pages39b-Columns Axial Compression Only - PNGParthiban ArivazhaganPas encore d'évaluation

- 37b-Columns Axial Compression Only Type 03.PngDocument2 pages37b-Columns Axial Compression Only Type 03.PngParthiban ArivazhaganPas encore d'évaluation

- 38i-Ties Axial Tension and Moments - PNGDocument2 pages38i-Ties Axial Tension and Moments - PNGParthiban ArivazhaganPas encore d'évaluation

- 38j-Ties Axial Tension Only - PNGDocument2 pages38j-Ties Axial Tension Only - PNGParthiban ArivazhaganPas encore d'évaluation

- 35b Columns Axial Compression Only Spaced Screws or Bolts Wet Load Sharing - PNGDocument3 pages35b Columns Axial Compression Only Spaced Screws or Bolts Wet Load Sharing - PNGParthiban ArivazhaganPas encore d'évaluation

- 35b Columns Axial Compression Only Single Nails Dry No Load Sharing - PNGDocument2 pages35b Columns Axial Compression Only Single Nails Dry No Load Sharing - PNGParthiban ArivazhaganPas encore d'évaluation

- Method of Consistent DeformationDocument8 pagesMethod of Consistent DeformationBeatrice CastilloPas encore d'évaluation

- Acceleration and Deceleration Lanes Improve Traffic FlowDocument1 pageAcceleration and Deceleration Lanes Improve Traffic FlowKasturi LetchumananPas encore d'évaluation

- 16 EC8-ReLUISDocument14 pages16 EC8-ReLUISJordan BojadzievPas encore d'évaluation

- 1st draft-BI-LDocument18 pages1st draft-BI-LMulugeta BezaPas encore d'évaluation

- Chaukhat: Bath BathDocument1 pageChaukhat: Bath BathSALONIKA AHUJAPas encore d'évaluation

- 2.4M Pedestal Mount: 4096-213 January 10, 2002 Assembly Instructions Revision BDocument3 pages2.4M Pedestal Mount: 4096-213 January 10, 2002 Assembly Instructions Revision BMemoPalacioPas encore d'évaluation

- Inspection Certificate 3.1+PED PN-EN 10204Document1 pageInspection Certificate 3.1+PED PN-EN 10204lwwwl2Pas encore d'évaluation

- Chapter Eight Check DamDocument30 pagesChapter Eight Check DamSurendra Maharjan100% (1)

- University of Zimbabwe B.Sc. (Engineering) Honours - Level IIDocument5 pagesUniversity of Zimbabwe B.Sc. (Engineering) Honours - Level IIkundayi shavaPas encore d'évaluation

- ETABS 2016 Concrete Frame Design: ETABS 2016 16.2.1 License # 18YKGXQNC843LKLDocument2 pagesETABS 2016 Concrete Frame Design: ETABS 2016 16.2.1 License # 18YKGXQNC843LKLSES DESIGNPas encore d'évaluation

- Design and Analysis of Rectangular Beams for FlexureDocument103 pagesDesign and Analysis of Rectangular Beams for FlexureLhee Ann GarboPas encore d'évaluation

- WEEK-1 AnswersDocument6 pagesWEEK-1 AnswersMichael MasisicPas encore d'évaluation

- Guideline For Quality Management of Concrete BDocument62 pagesGuideline For Quality Management of Concrete BRam KrishnaPas encore d'évaluation

- Boundary Layer Flow CharacteristicsDocument16 pagesBoundary Layer Flow CharacteristicsSatyanand ErankiPas encore d'évaluation

- 2020-04-15 - JMB - WWTP - Instrument ListDocument1 page2020-04-15 - JMB - WWTP - Instrument ListAzisPas encore d'évaluation

- As Tuguegarao Clubhouse BoqDocument55 pagesAs Tuguegarao Clubhouse BoqJake CortezPas encore d'évaluation

- Design Steel Concrete Composite StructuresDocument1 pageDesign Steel Concrete Composite StructuresDinuSkyPas encore d'évaluation

- Slab Manual CalculationDocument9 pagesSlab Manual CalculationArchana PoudelPas encore d'évaluation

- Double Integration Beam Deflection MethodDocument22 pagesDouble Integration Beam Deflection Methodacurvz2005Pas encore d'évaluation

- STAAD - Pro Report: Section PropertiesDocument2 pagesSTAAD - Pro Report: Section Propertiesdheeraj SureshPas encore d'évaluation

- Mokveld-Product Sheet Axial Control ValveDocument2 pagesMokveld-Product Sheet Axial Control Valveจตุพล กมลเลิศPas encore d'évaluation