Académique Documents

Professionnel Documents

Culture Documents

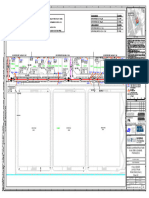

ITER - D - 3NSABX V 2.2: Piping and Instrumentation Diagram Standard Symbols and Nomenclature For CCWS, CHWS and HRS

Transféré par

Rakesh RanjanDescription originale:

Titre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

ITER - D - 3NSABX V 2.2: Piping and Instrumentation Diagram Standard Symbols and Nomenclature For CCWS, CHWS and HRS

Transféré par

Rakesh RanjanDroits d'auteur :

Formats disponibles

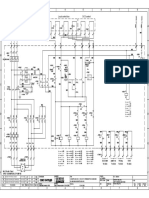

1 2 3 4 5 6 7 8

REVISION HISTORY NOTES:

INDEX DATE DESIGNER DESCRIPTION

Symbols Legend :

2.0 25/05/2015 ARJUN FOR FINAL DESIGN REVIEW (FDR) ITER_D_3NSABX v 2.2: Piping and instrumentation diagram standard symbols and

A A

2.1 15/10/2015 ARJUN ITER-INDIA AND IDM COMMENTS INCORPORATED nomenclature for CCWS, CHWS and HRS

This Document is the Property of L&T Construction and cannot be reproduced or communicated without its authorization.

TITLE BLOCK UPDATED (https://user.iter.org/?uid=3NSABX)

2.2 12/05/2016 ARJUN IDM COMMENTS INCORPORATED

B B

C C

D D

DRAWING NO. : ITER-26CC2C-PID-001

NUCLEAR OPERATOR: IO VALIDATION REQUIRED: VALIDATION FORM: FORM SIGNATORY: DATE OF SIGNATURE:

ITER Org. YES Steve Ployhar

RESPONSIBLE DA: DA VALIDATION REQUIRED: VALIDATION FORM: FORM SIGNATORY: DATE OF SIGNATURE:

IN_DA YES Dinesh Gupta

E DESIGN AGENCY: CREATED BY: TECHNICAL REFERENCE: APPROVER DATE:

E

L&T Construction Arjun Vijeesh D.Menon 12/05/2016

Uncontrolled Once Printed

DIAGRAM TITLE:

PIPING AND INSTRUMENTATION DIAGRAM

COMPONENT COOLING WATER SYSTEM-2C

PBS TITLE:

CCWS-2C

DOCUMENT TYPE: SAFETY CLASS: QUALITY DATE OF ISSUE: DESIGN AGENCY DOCUMENT Sheet Size:

F CLASS: STATUS:

F

PID Non-SIC QC2 12/05/2016 Approved A3

PBS NODE: IO REFERENCE: EXTERNAL REFERENCE: VERSION: Sheet N°:

26CC2C 9K6D7W O13188MCWCWPI1156 2.2 1/3

1 2 3 4 5 6 7 8

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24

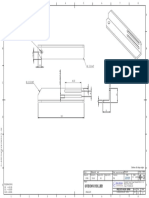

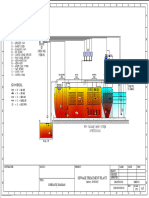

NOTES-

1.THE LEVEL SHOWN ON THE A

A

PRESSURIZER ARE FROM BOTTOM TANGENT

LINE. REFER DOCUMENT PRESSURIZER

2.1

CALCULATION FOR CCWS & CHWS

(ITER_D_QCEY7Q) FOR DETAILS.

2. FOR MOTOR OPERATED VALVE, TYPICAL

DETAIL OF THE LOCAL/REMOTE OPERATION IS

AS SHOWN BELOW.

38 WHERE

B Reactive Power Control Bldg L: LOCAL B

S: STOP

R: REMOTE

4. LCP DETAILS OF PUMP IS AS SHOWN BELOW

C C

3. (LOCAL/STOP/REMOTE)

26CC2C-CU-0001

ALL LOGICS ARE

APPLICABLE

PZPC 2.1

38-L1-02 USED ONLY DURING

Cooling Water Room 38-L1 MAINTENANCE

PLOF, PLSW &

2.2 PLPR Ground Floor Level NO LOGICS WILL

H

MDS VH VH BE APPLICABLE

MTI MTI

0001 H H VH

MZH MZL 0124 0123

MTI H

1313 1313

TO ATMOSPHERE TO ATMOSPHERE 0125

VG-0022

D (REF. NOTE-11) (REF. NOTE-11) D

VG-0025

MDS MPG

VH 2.1

DN025-A1N-X-WD

X2 X2

MPI H 0001 0057

0057 L MZH MZL X2

MTE MTE 4. DRAINS HAVE TO BE PROVIDED AT THE

DN025-A1N-X-NG

0123 0125

VL 1313 1313

2.2 2.2 2.2 LOWEST POINT & VENTS TO BE PROVIDED AT

VG-0074

VG-0075

VG-1315

MTE

2.1 TO ATMOSPHERE M HIGHEST POINTS.

ECC.REDUCER 0124 CON. REDUCER PI-0010

PI-0009

(REF. NOTE-11) VK-0003

300X200 150X300

VR-0001 DN025-A1N-X-WD

PI-0003 PI-0028 5. ALL EQUIPMENT AND VALVES TAG NOS

PI-0002 PI-0064 PI-0065 DN300-A1N-X-WD

DN025-A1N-X-WD

MP

DN080-A1N-X-NG DN200-A1N-X-WD DN150-A1N-X-WD SHALL BE PREFIXED WITH 26CC2C.

2.2

VG-1314

0057 VG-1313 FI-0001 PL-0001 VG-1317

DN050-A1N-X-NG

PI-0024

DN020-A1N-X-NG

VG-0078

DN300-A1N-X-WD X2

VG-0072

VC-1307

VR-0002 2.2 MTE X2 MGP MGP 6. SCOPE LEGEND

M

MPG

N2 SUPPLY 0001

PI-0050

MTE

2.1 0126 0001

VG-1305

0062 X2

E PBS 65.00. NG PBS CLIENT PBS / E

PI-1006

0127

VG-1356

M MVS

PI-1054

PI-0007

0001

DN025-A1N-X-WD 26CC2C INTERFACING

PI-0049 VH VH SCOPE SYSTEM SCOPE

TO INDUSTRIAL DRAIN

DN025-A1N-X-NG PI-0036 H MTI H MTI MVS

6500NG-VG VK-1305 0001

VC-1301 VG-1307 DN080-A1N-X-WD 0126 0127

TO INDUSTRIAL DRAIN

MQ IN-DA DESIGN IN-DA DESIGN AND

2.1 PROCUREMENT

0079 ONLY SCOPE

VHWL

26CC2C-PL-0001 & 0002 (1W+1S) SCOPE

DN020-A1N-X-NG

26CC2C-CU-0002

2.1 HWL 2.2 FLOW:158.00 Kg/s (575 m³/hr)

VG-0033

DN025-A1N-X-WD

VG-0032

HEAD: 0.77MPa

DN025-A1N-X-WD

MFT

0079 26CC2C-PZ-0001

CLIENT PBS /

PI-1044

MZL

F PZ-0001 PRESSURIZER F

CAPACITY- 1 m 3 NWL 1318

PLOF, PLSW & INTERFACING PBS 26CC2C/

2.1 IN-DA SCOPE

PI-0011

MFE PLPR SYSTEM SCOPE

PI-0014

MAKE UP WATER M 0079

LWL

H

VH VH

MZH MDS

1318 0002 VH H

MTI

H

MTI PBS 41

H MTI 0129 0128

PI-1010 VLWL

DN020-A1N-X-WD

6500DW-VG

DN040-A1N-X-WD

VK-1304

0130

MPG VG-0054

THYRISTOR VALVE VG-0057

ABOVE GROUND ABOVE GROUND

MZL X2 PIPING PIPING

DN150-A1N-X-WD

DN150-A1N-X-WD

VG-1326 MDS X2 0058

PBS 65.00.DW 1318 X2

VG-1308 0002 MTE MTE

MZH

0129 0128

PI-1029

MTE

1318

2.2

VG-0076

VG-0077

VG-1320

0130 M B

CON. REDUCER

PI-0018

PI-0019

ECC.REDUCER

150X300 VK-0004 VG-1322

300X200

PI-1022

G PI-0066 PI-0067 DN300-A1N-X-WD G

VG-1318

DN200-A1N-X-WD DN150-A1N-X-WD BURIED PIPNG

VG-1319

VG-0079

FI-0002 CON. BURIED PIPNG

ML

PI-1019 PL-0002 X2 REDUCER

DN300-A1N-X-WD X2 PI-0021 200X150 CON.

7. ALL VENTS INSIDE BUILDING WILL BE FUNNEL

DN040-A1N-X-WD

0007 MVS MVS

MTE REDUCER

0002 DN025-A1N-X-WD

0131

0002 200X150 AND THE FUNNEL PIPE WILL BE CONNECTED

VG-0029

DN025-A1N-X-WD

X2

TO THE DRAIN POINT.

VG-0034

VH MTE MGP

DN025-A1N-X-WD

DN025-A1N-X-WD

MLI H 0132 0002

PI-1011

0007 L VH

VL MGP

TO INDUSTRIAL DRAIN

H MTI

VH 0002

PI-0051

0131 MTI

H

VG-1358

0132

PI-0015

PBS 41

PI-0012

LOCKED

2.1 OPEN

8. RESISTANCE TEMPERATURE DETECTOR

THYRISTOR VALVE (RTD s) ARE PROVIDED FOR EACH

H TO INDUSTRIAL DRAIN PZLC H

TO INDUSTRIAL DRAIN CIRCULATION PUMP MOTOR WINDING

VG-0055 VG-0058

VG-0081

PI-0026 PI-0027 TEMPERATURE MEASUREMENT: TWO PER

PI-0001 DN150-A1N-X-WD DN150-A1N-X-WD

DN025-A1N-X-WD PLPB PHASE ONE WILL BE WIRED TO MOTOR

PROTECTION RELAY & OTHER TO PLC.

TRENCH

VG-0082

TRENCH

9. ALL PIPING UPTO DN300 WHICH ARE

C2TC CFCM EXPOSED TO THE OUTSIDE ENVIRONMENT

2.2 PI-0063 MPG WILL BE HEAT TRACED. HEAT TRACING

VG-0035

MFI MFT MFE

DN025-A1N-X-WD 0001 SHALL BE SWITCHED ON WHEN THE PIPE LINE

VG-0027

DN025-A1N-X-WD

VG-0051 M

0078 0078 0078

DN025-A1N-X-WD

L TEMPERATURE IS LESS THAN 5°C. HEAT

FOR CONT. REFER DWG.NO.

I ITER_HRS_PID_002 PI-1026 TRACING WILL BE SWITCHED OFF WHEN I

DN200-A1N-X-WD H

(SHEET 2 OF 2) MFI PIPE LINE TEMPERATURE IS GREATER THAN

PI-0013

VG-0080 VC-1302 0075

L 8°C. REFER DOCUMENT THERMAL INSULATION

PI-0016

VG-0071 PI-0062 DI-1301 PBS 41

DN025-A1N-X-WD AND HEAT TRACING CALCULATION FOR

PI-0041

DN300-A1N-X-WD

DN025-A1N-X-WD THYRISTOR VALVE PIPING, VALVE AND PRESSURIZER

MFT

0075 VG-0056 VG-0059

(ITER_D_QQBRJD) FOR DETAILS.

PI-0023 PI-0029

VH

TO INDUSTRIAL DRAIN

MTI H TO INDUSTRIAL DRAIN DN150-A1N-X-WD DN150-A1N-X-WD

10. ALL DRAINS SHALL BE CONNECTED TO THE

PI-1017

0137 L H VG-1355 MFE

MPI MP

PRESSURE POINT VL MPG M 0075 PBS 61.00.ID

0061 0061

L

1 oo 2 (MAX) 0056 PZLC

VG-1351

FOR CONT. REF. TO 2.2 PI-0017 11. NITROGEN VENTING SHOULD BE ROUTED TO

MTI MTE

VG-1303

J ITER_26HR00_PID_002 MTG MTE MTE DN025-A1N-X-WD OUTSIDE OF THE BUILDING AT APPROPRIATE J

ECC. M 0136 0136

(SHEET 02 OF 02) 0090 0137 0138 VC-1303

PBS 26.CC.2C

REDUCER

VG-1301 TO INDUSTRIAL DRAIN

TO INDUSTRIAL DRAIN

VG-0036

HEIGHT FOR SAFE DISPOSAL.

250x300

PI-1032 TO INDUSTRIAL DRAIN

DN040-A1N-X-WD

DN040-A1N-X-WD 12. ALL THE INSULATIONS USED ARE ROCK

DN025-A1N-X-WD

VG-0026

PI-0006 WOOL AS PER ASTM C592

VG-1360

VG-1328

DN025-A1N-X-WD

VG-1310

PRESSURE POINT MFT MFI DN025-A1N-X-WD

VG-1331

0074 0074

CIMV

PLANT WORKING/TRIP SIGNAL, pH,

M

PI-1028

2.2

VG-1359

VG-1352

CONDUCTIVITY, TOTAL FLOW,

DN025-A1N-X-WD

FOR CONT. REF. TO

PI-1053

DIFFERENTIAL PRESSURE SIGNAL’S

ITER_26HR00_PID_002 FROM WPU PLC TO PCS

PI-1051

ECC. MFE

(SHEET 02 OF 02) REDUCER M 0074

300X250

PI-1052

VG-0053 VK-1303 MICRON

ELECTRO CARTRIDGE PI-1031

K DEIONISATION(EDI) FILTER(MCF) DN040-A1N-X-WD K

HX-0001 VG-1325

DN200-A1N-X-WD

VC-1306

26CC2C-HX-0001

SAMPLING 2.2 VH

DN300-A1N-X-WD

POINT 2.2 H MTI MTE

0133 0133

PI-1033

MICRON

ELECTRO CARTRIDGE

DEIONISATION(EDI) WCFC

PI-1025

FILTER(MCF)

MTG

DN040-A1N-X-WD

TO INDUSTRIAL DRAIN 26CC2C-SFU-0001 0087

2.1 2.2

WATER POLISHING UNIT

L (1W+1S) L

PI-0035

VG-1329

SUPPLY HEADER

FLOW RATE : 3.38 Kg/s (MAX) MPG

0059

2.2

TO INDUSTRIAL DRAIN

26CC2C-HX-0001 PRIMARY SIDE SECONDARY SIDE

MPI

PI-1038

SERVICE DM WATER HRS RAW WATER 0062

DN200-A1N-X-WD

TEMP. IN (°C ) 39.97 27 H H

MAI MAI MTI

0007 0008 0122

TEMP. OUT (°C ) 31 37.07 MP L

M 0062 M

FLOW (Kg/s) 158 140

VG-1357

Pressure drop

0.088 0.072 MAC MAP MTG MTE

(MPa) (max)

0007 0008 0086 0122 CON. REDUCER

CON. EXPANDER 300 X 200

200X300

RETURN HEADER

DN050-A1N-FP-WD

PI-1018

DN300-A1N-X-WD

VG-0070

VG-0073

VG-0021

BF-0001

BF-0002

2.2

AG

AG

PI-0056

BG

BG

N N

AG

TO BLDG 37 AND AREA 30

BG

PI-0004 PIPING ... 3

DN200-A1N-X-WD

B 4L

PI-0004

DN050-A1N-FP-WD

VG-0050

DN050-A1N-X-WD

FOR CONT. REFER TO :

ITER_26CC2C_PID_001

SHEET 03 OF 03

AG

PI-0022

PI-0057

O PI-0025 O

FROM BLDG 37 AND AREA 30

DN050-A1N-X-WD

BG

PI-0008 PI-0008

B 4M

DN200-A1N-X-WD PIPING ... 3

DRAIN PIT FOR CONT. REFER TO :

ITER_26CC2C_PID_001

VG-0037

2.1 SHEET 03 OF 03

VG-0041

P P

2.1

PROCESS CONNECTIONS FOR INSTRUMENTS LIST OF REFERENCE DRAWINGS:

SL.NO DESCRIPTION DOC. / DRG. NO IDM Ref. No.

Q Q

1 CCWS-2C PROCESS FLOW DIAGRAM ITER_26CC2C_PFD_001 ITER_D_4677LY DRAWING NO. : ITER-26CC2C-PID-001

Uncontrolled Once Printed

SHEET TITLE:

2 PIPING MATERIAL SPECIFICATION O13188-M-CW-CW-DC-1007

IDM REFERENCE

ITER_D_7GYNDL CCWS-2C DISTRIBUTION IN BUILDING 38

DIAGRAM TITLE:

3 CCWS-2C LOGIC NOTES O13188-I-CW-CW-LO-3217 ITER_D_PGDGUU

PIPING AND INSTRUMENTATION DIAGRAM

COMPONENT COOLING WATER SYSTEM-2C

4 CCWS-2C WATER POLISHING UNIT P&ID O13188-I-WT-CW-PI-1763 ITER_D_XXXXXX

PRESSURIZER CALCULATION FOR CCWS &

R 5 O13188-M-CW-CW-DC-1032 ITER_D_QCEY7Q PBS NODE: DOCUMENT TYPE: DATE OF ISSUE: DESGIN AGENCY DOCUMENT Sheet Size:

R

CHWS STATUS:

THERMAL INSULATION AND HEAT TRACING

26CC2C PID 12/05/2016 Approved A0

6 CALCULATION FOR PIPING, VALVE AND O13188-M-CW-CW-DC-1027 ITER_D_QQBRJD IO REFERENCE: EXTERNAL REFERENCE: VERSION: Sheet N°:

PRESSURIZER

9K6D7W O13188MCWCWPI1156 2.2 2/3

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24

Vous aimerez peut-être aussi

- Example Drawing GD&TDocument3 pagesExample Drawing GD&TEngineerPas encore d'évaluation

- Revision History: Cc2642 Ble+Can Auto-Addressing Public Release Ble+Can Auto-Addressing E2 Tida-020032 Changeme!Document4 pagesRevision History: Cc2642 Ble+Can Auto-Addressing Public Release Ble+Can Auto-Addressing E2 Tida-020032 Changeme!Dhashana MoorthyPas encore d'évaluation

- TIDRNE8Document4 pagesTIDRNE8rajareddy235Pas encore d'évaluation

- 522067-A-Main Buildig Elevation & Section R1 20.10.2023Document9 pages522067-A-Main Buildig Elevation & Section R1 20.10.2023monaliPas encore d'évaluation

- Modernizacion Refineria de Talara Petroperu, S.A.Document3 pagesModernizacion Refineria de Talara Petroperu, S.A.juancePas encore d'évaluation

- (E542-Part2 & 3-Plan) DN099-P02-QBC-SH-FS-1342 - 00Document1 page(E542-Part2 & 3-Plan) DN099-P02-QBC-SH-FS-1342 - 00ahmed yaqoobPas encore d'évaluation

- Application Configuration REC670-2Document15 pagesApplication Configuration REC670-2JADSON SOUZAPas encore d'évaluation

- Schematic Diagram of Relay & Tcms Panel T: REV Revised by Checked by Approved byDocument1 pageSchematic Diagram of Relay & Tcms Panel T: REV Revised by Checked by Approved byTaufiq HidayatPas encore d'évaluation

- Stock Aco Lbs and CB - PLN Disjaya: Panel Note QTY 150 SETDocument7 pagesStock Aco Lbs and CB - PLN Disjaya: Panel Note QTY 150 SETRioPas encore d'évaluation

- Revision History: 10kW Inverter Gate Driver Public Release TIDA-01606 - Gate Driver E4 TIDA-01606Document4 pagesRevision History: 10kW Inverter Gate Driver Public Release TIDA-01606 - Gate Driver E4 TIDA-01606hafizimtiazPas encore d'évaluation

- Revisions C: REVISED PER ECO-11-005150 RK HMR New Creo Drawing BV GBDocument1 pageRevisions C: REVISED PER ECO-11-005150 RK HMR New Creo Drawing BV GBhulanePas encore d'évaluation

- TanggaDocument1 pageTanggaKhairatul FitriPas encore d'évaluation

- 31 Es. CH.: Tappo 1 Destro X RadiatoreDocument1 page31 Es. CH.: Tappo 1 Destro X RadiatoreDani FernandezPas encore d'évaluation

- TIDRP15Document4 pagesTIDRP15hk220903Pas encore d'évaluation

- Tidrqm7 PDFDocument11 pagesTidrqm7 PDFzizouhichePas encore d'évaluation

- 1802.132kV Line PRTN and CTRL Panel - R2.0 PDFDocument56 pages1802.132kV Line PRTN and CTRL Panel - R2.0 PDFHarish PoondlaPas encore d'évaluation

- Biotech 5m3Document7 pagesBiotech 5m3Jhennery AgePas encore d'évaluation

- 13 - Organisational Structure 2020-03-03Document1 page13 - Organisational Structure 2020-03-03Sulakx KuruPas encore d'évaluation

- Revision History: High Efficiency and Cost Cometitive 3k5 PFC Public Release TIDA-00779 E1 TIDA-00779 TIDA-00779Document4 pagesRevision History: High Efficiency and Cost Cometitive 3k5 PFC Public Release TIDA-00779 E1 TIDA-00779 TIDA-00779g4okk8809100% (1)

- TIDRES7Document12 pagesTIDRES7moel539Pas encore d'évaluation

- Schematic Diagram of Relay & Tcms Panel T: REV Revised by Checked by Approved byDocument1 pageSchematic Diagram of Relay & Tcms Panel T: REV Revised by Checked by Approved byTaufiq HidayatPas encore d'évaluation

- Confidential For KS - DFB at 1024: Schematic DocumentDocument56 pagesConfidential For KS - DFB at 1024: Schematic Documentcompu centerPas encore d'évaluation

- Functional Block Diagram: Revision HistoryDocument4 pagesFunctional Block Diagram: Revision Historyanbarasuval84Pas encore d'évaluation

- Functional Block Diagram: Revision HistoryDocument4 pagesFunctional Block Diagram: Revision Historyanbarasuval84Pas encore d'évaluation

- H-Worm 12T WeldDocument1 pageH-Worm 12T Weldpanca_26Pas encore d'évaluation

- Client: Panel Reference: Riyadh Aletqan Co. Motor, CM2 Vent Bag Filter FanDocument7 pagesClient: Panel Reference: Riyadh Aletqan Co. Motor, CM2 Vent Bag Filter FanMostafaElrakhawyPas encore d'évaluation

- Panel Inverter 130Kw Pompa 3M1: Industrial WaterDocument5 pagesPanel Inverter 130Kw Pompa 3M1: Industrial WaterBasadi ZtmPas encore d'évaluation

- 전기도면Document89 pages전기도면Ferdinan HutagalungPas encore d'évaluation

- Architecture DrawingDocument3 pagesArchitecture DrawingDwiki SetiabudiPas encore d'évaluation

- Deck Crane Truck M-CT-390Document2 pagesDeck Crane Truck M-CT-390Susi AndraPas encore d'évaluation

- Typical Process FlowDocument1 pageTypical Process FlowWasis GreendotPas encore d'évaluation

- Pha4054902 02Document2 pagesPha4054902 02German BernalPas encore d'évaluation

- Pib22-073-Fagr - GRP04Document1 pagePib22-073-Fagr - GRP04fendri firstPas encore d'évaluation

- Panel Dol 7,5 KW-SLDDocument1 pagePanel Dol 7,5 KW-SLDabdul aziz alfiPas encore d'évaluation

- Schematic Diagram of Relay & Tcms Panel T: REV Revised by Checked by Approved byDocument1 pageSchematic Diagram of Relay & Tcms Panel T: REV Revised by Checked by Approved byTaufiq HidayatPas encore d'évaluation

- Application Configuration RED670-3Document18 pagesApplication Configuration RED670-3JADSON SOUZAPas encore d'évaluation

- Potong Alumunium 350 X 125Document1 pagePotong Alumunium 350 X 125ahmadfalahofficialPas encore d'évaluation

- SNLR 042Document8 pagesSNLR 042Daniel Gustavo Martinez MartinezPas encore d'évaluation

- Schematic Diagram of Relay & Tcms Panel T: REV Revised by Checked by Approved byDocument1 pageSchematic Diagram of Relay & Tcms Panel T: REV Revised by Checked by Approved byTaufiq HidayatPas encore d'évaluation

- Revision History: 480W, Industrial AC/DC Public Release TIDA-01494 E1 TIDA-01494 N/ADocument5 pagesRevision History: 480W, Industrial AC/DC Public Release TIDA-01494 E1 TIDA-01494 N/AhaiderPas encore d'évaluation

- O12166-REV - 03 (Busbar Protection)Document33 pagesO12166-REV - 03 (Busbar Protection)prati121Pas encore d'évaluation

- Z 4023285 30 102 1 30 - Rev2 - LBS2Document25 pagesZ 4023285 30 102 1 30 - Rev2 - LBS2Febrianto HermawanPas encore d'évaluation

- SCH - 501 1 01180 - A0 01Document11 pagesSCH - 501 1 01180 - A0 01imran khanPas encore d'évaluation

- Sc2013110201-Line Protection & Bcu Panel Bay Pudakpayung I-02lr01Document32 pagesSc2013110201-Line Protection & Bcu Panel Bay Pudakpayung I-02lr01Putra Mangku Ginanjar100% (1)

- 3FE82521AAAA Spooler SpecificationDocument3 pages3FE82521AAAA Spooler SpecificationKEVIN COLMOPas encore d'évaluation

- GE ED: ToolboxDocument1 pageGE ED: ToolboxstefanPas encore d'évaluation

- I304V2 A Rev00 PDFDocument1 pageI304V2 A Rev00 PDFer_paramjeetgillPas encore d'évaluation

- Servo Micro SCH 20180404Document8 pagesServo Micro SCH 20180404vicPas encore d'évaluation

- STP 20MPDDocument5 pagesSTP 20MPDmuhamad taufikPas encore d'évaluation

- Calvin Dis 6050A247001-MB-AX1 SI 2011-08-02Document73 pagesCalvin Dis 6050A247001-MB-AX1 SI 2011-08-02Darwin HernandezPas encore d'évaluation

- JSFA M42x2Document1 pageJSFA M42x2Luong LePas encore d'évaluation

- Diagrama de Alimentación Electrica para Bombas de Pozo ProfundoDocument1 pageDiagrama de Alimentación Electrica para Bombas de Pozo ProfundoAmairani MartínezPas encore d'évaluation

- Calvin Dis 6050A247001-MB-X01 DB 2011-05-23Document72 pagesCalvin Dis 6050A247001-MB-X01 DB 2011-05-23刘攀杰Pas encore d'évaluation

- Truss T4 PDFDocument15 pagesTruss T4 PDFquocphong199Pas encore d'évaluation

- Oltc Schematic Diagram (5022)Document1 pageOltc Schematic Diagram (5022)Devi Prasad100% (1)

- Revision History: TIDA-01614 Public Release TIDA-01614 E2 01614 NADocument8 pagesRevision History: TIDA-01614 Public Release TIDA-01614 E2 01614 NAasokanenPas encore d'évaluation

- Grating Covers at EL.323 PDFDocument1 pageGrating Covers at EL.323 PDFma.shahePas encore d'évaluation

- Cubicle Pix GH PLTD Kairatu: Pt. Schneider IndonesiaDocument7 pagesCubicle Pix GH PLTD Kairatu: Pt. Schneider IndonesiaMUH ILHAM MARZUKIPas encore d'évaluation

- Revision History: USB Type-C With Data Public Release TIDA-00987 E1 N/A EVM - OrderableDocument4 pagesRevision History: USB Type-C With Data Public Release TIDA-00987 E1 N/A EVM - OrderableTrung Nguyen ChiPas encore d'évaluation

- Samsung M10 Remote Service ManualDocument2 pagesSamsung M10 Remote Service ManualRakesh RanjanPas encore d'évaluation

- How To Read P&IDDocument27 pagesHow To Read P&IDRakesh Ranjan100% (3)

- Quotation: PDF Created With Pdffactory Pro Trial VersionDocument11 pagesQuotation: PDF Created With Pdffactory Pro Trial VersionRakesh RanjanPas encore d'évaluation

- Pipe Videoscope Code Isv-Vp280: Resistance To Acid and Alkali Liquid (Consult Is Needed)Document1 pagePipe Videoscope Code Isv-Vp280: Resistance To Acid and Alkali Liquid (Consult Is Needed)Rakesh RanjanPas encore d'évaluation

- Welding NotesDocument5 pagesWelding NotesRakesh RanjanPas encore d'évaluation

- Para:304.2:Pressure Design of Components - BENDSDocument1 pagePara:304.2:Pressure Design of Components - BENDSRakesh RanjanPas encore d'évaluation

- Code Extract PDFDocument19 pagesCode Extract PDFRakesh RanjanPas encore d'évaluation

- General Science (Erexams - Com)Document42 pagesGeneral Science (Erexams - Com)Rakesh RanjanPas encore d'évaluation

- Indian Cabinet OK''s Participation in ITER ProjectDocument1 pageIndian Cabinet OK''s Participation in ITER ProjectRakesh RanjanPas encore d'évaluation

- Valve Sizing TablesDocument5 pagesValve Sizing TablesRakesh RanjanPas encore d'évaluation

- Particle FilterDocument16 pagesParticle Filterlevin696Pas encore d'évaluation

- Growth Performance of Papaya Plants As Influenced by Organic MulchesDocument9 pagesGrowth Performance of Papaya Plants As Influenced by Organic MulchesMa. Christine Lyn AustriaPas encore d'évaluation

- Determination of Iron in Water - SpectrophotometryDocument4 pagesDetermination of Iron in Water - Spectrophotometryhanif ahmadPas encore d'évaluation

- Serie10 ElecDocument75 pagesSerie10 Elecmealier severinePas encore d'évaluation

- Prishusingh Blogspot Com 2024 03 Digital-Marketing-Course HTMLDocument12 pagesPrishusingh Blogspot Com 2024 03 Digital-Marketing-Course HTMLsudharaj86038Pas encore d'évaluation

- Sow and Learning ObjectivesDocument14 pagesSow and Learning ObjectivesEhsan AzmanPas encore d'évaluation

- Steel Sections PDFDocument36 pagesSteel Sections PDFTonderai RuserePas encore d'évaluation

- Lesson 5 Flight of Projectile, Air Resistance Neglected: OverviewDocument7 pagesLesson 5 Flight of Projectile, Air Resistance Neglected: OverviewNadjer C. AdamPas encore d'évaluation

- Essay Writing TipsDocument4 pagesEssay Writing TipsSubhasish MitraPas encore d'évaluation

- Freeman Has Been A Partner in A Commercial Construction CompanyDocument1 pageFreeman Has Been A Partner in A Commercial Construction CompanyMuhammad ShahidPas encore d'évaluation

- R820T Datasheet-Non R-20111130 UnlockedDocument26 pagesR820T Datasheet-Non R-20111130 UnlockedKonstantinos GoniadisPas encore d'évaluation

- Tes - 29 October 2021 UserUploadNetDocument120 pagesTes - 29 October 2021 UserUploadNetTran Nhat QuangPas encore d'évaluation

- Financial Statements Ias 1Document34 pagesFinancial Statements Ias 1Khalid AzizPas encore d'évaluation

- Javascript PrefiDocument66 pagesJavascript Prefiguendelyn omegaPas encore d'évaluation

- Hex 33 X 80Document1 pageHex 33 X 80PurchasePas encore d'évaluation

- Assessment of Locomotive and Multi-Unit Fatigue Strength Considering The Results of Certifi Cation Tests in Ukraine and EU CountriesDocument8 pagesAssessment of Locomotive and Multi-Unit Fatigue Strength Considering The Results of Certifi Cation Tests in Ukraine and EU CountriesLeonardo Antônio Pereira100% (1)

- New DOCX DocumentDocument2 pagesNew DOCX DocumentPunjabi FootballPas encore d'évaluation

- Usp3 ComDocument5 pagesUsp3 ComMike MelgaPas encore d'évaluation

- Cure Jealousy WorksheetsDocument20 pagesCure Jealousy WorksheetsSelina CothrenPas encore d'évaluation

- ToobaKhawar 6733 VPL Lab Sat 12 3 All TasksDocument38 pagesToobaKhawar 6733 VPL Lab Sat 12 3 All TasksTooba KhawarPas encore d'évaluation

- Smartpilot s1 s1g Service ManualDocument30 pagesSmartpilot s1 s1g Service Manualmalte winbaldPas encore d'évaluation

- Principles of Public ExpenditureDocument1 pagePrinciples of Public ExpenditureNikhil Shenai100% (1)

- 4148-Article Text-14752-1-10-20211029Document7 pages4148-Article Text-14752-1-10-20211029Daffa AzkaPas encore d'évaluation

- Cultures of The West A History, Volume 1 To 1750 3rd PDFDocument720 pagesCultures of The West A History, Volume 1 To 1750 3rd PDFtonnyPas encore d'évaluation

- Box Transport MechanismDocument36 pagesBox Transport MechanismInzi Gardezi81% (16)

- Mindset For IELTS Level 1 Student's Book PDF English As A Second or Foreign Language International English Language TestinDocument1 pageMindset For IELTS Level 1 Student's Book PDF English As A Second or Foreign Language International English Language TestinhiPas encore d'évaluation

- Culture-Partners M&A EbookDocument12 pagesCulture-Partners M&A EbookapachemonoPas encore d'évaluation

- Tcs IntroDocument12 pagesTcs IntroRomi.Roy1820 MBAPas encore d'évaluation

- Chemical Recycling of Textile PolymersDocument8 pagesChemical Recycling of Textile PolymersVaishali RanePas encore d'évaluation

- Essentials of Repertorization Tiwari Link PageDocument11 pagesEssentials of Repertorization Tiwari Link PageBibin TSPas encore d'évaluation