Académique Documents

Professionnel Documents

Culture Documents

Sikadur 741

Transféré par

widayat81Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Sikadur 741

Transféré par

widayat81Droits d'auteur :

Formats disponibles

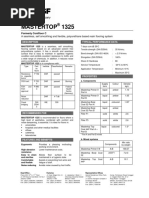

Technical Data Sheet

Edition 1, 2003

Identification no.

02 04 02 03 001 0 000047

Version no. 0010

Sikadur®-741

Sikadur -741

®

Epoxy Resin Patching Mortar

Description A solvent-free, thixotropic, 3-component thixotropic patching mortar based on

a combination epoxy resin and selected quarts aggregates. An easy

Construction

to use multi purpose repair and adhesive mortar.

Uses As adhesive mortar on concrete, stone, plasterwork, steel, wood and asbestos

cement.

For vertical and overhead filling of cavities.

As repair mortar for damaged concrete edges.

As abrasion resistant and impact resisteant wearing course.

For structural bonding of wide joints.

Advantages High mechanical strength.

Abrasion and impact resistant.

Good adhesion to concrete.

Shrinkage-free hardening.

Suitable for both, dry and damp surface.

Curing is not affected by high humidity.

Coverage 2 kg/cm2 per mm thickness

Instruction for Use

Surface Preparation Surface must be clean and sound. It may be dry or damp, but free of standing

water. Remove dust, laitance, grease, curing compounds, impregnation, waxes,

foreign particles, disintegrated materials.

Preparation work

Concrete - Sandblast or use other approved mechanical methods.

Steel - Sandblast to white metal finish.

Priming Sikadur 731 or 732 for damp, highly porous or metallic substrates for vertical and

overhead substrates.

Sikadur 752 for dense substrate.

Apply “wet on wet”

It is possible to apply Sikadur 741 without primer, however, best result are obtained

if the correct primer is used.

Mixing Pre-mix each component. Proportion 2 part Component A to 1 part Component

B into a clean pail.

Mix thoroughly for at least 2 minutes with a paddle on low - speed (400-600 rpm)

drill until the blend is uniform.

Proportion 3 part component C by weight or 3.5 part by volume. Then add the

proportion of component C and continue to mix until homogeneous mortar is

achieved.

Application Spread directly the mixed Sikadur 741 to the prepared substrate by spatula or

trowel. Strike off, level and finish with a steel float.

Limitations Maximum thickness per layer : 5 cm. Minimum thickness = 3-mm.

Minimum age of concrete must be 28 days prior to application.

1 Sikadur® -741 1/2

Technical Data

Colour Concrete Grey

Mix Ratio Comp. A : B : C = 2 : 1 : 3 by weight

Comp. A : B : C = 2 : 1 : 3.5 by volume

Mix Density 2.00 kg/l

o

Pot Life 30 C 40 minutes

Flexural Strength

2

(ASTM D-790) 28 days 310 kg/cm

Bond Strength

2

To concrete, 28 days >20 kg/cm

(concrete failure, over mechanically prepared concrete surface grade K400)

2

To steel, 28 days >90 kg/cm (steel surface blast cleaning to SA 2 ½)

Compressive Strength

(ASTM D-695)

Construction

7 days 670 kg/cm2

28 days 690 kg/cm2

-6 o

Coefficient of thermal 26 x 10 per C

expansion

(-20OC to +40O C)

Shelf Life 1 year when unopened

Storage Dry, cool, shaded place

Packaging 10 Kg set

Handling Precaution Avoid contact with skin and eyes

Wear protective gloves and eye protection during work

If skin contact occurs, wash skin thoroughly

If in eyes, hold eyes open, flood with warm water and seek medical attention

without delay

Legal Notes The information and in particular the recommendations relating to the application and end-use of Sika

products are given in good faith based on Sika’s current knowledge and experience of the product when

properly stored, handled and applied under normal conditions. In practice, the differences in materials,

substrates and actual site conditions are such that no warranty in respect of merchantability or fitness for a

particular purpose, nor any liability arising out of any legal relationship whatsoever, can be inferred either

from this information, or from any written recommendations, or from any other advice offered. The

proprietary rights of third parties must be observed. All orders are accepted subject to our current terms of

sales and delivery. Users should always refer to the most recent issue of the technical Data Sheet for the

product concerned, copies of which will be supplied on request.

Sub Distributor

PT. Sika Indonesia Branches Bandung, Tel : 022-5423855,5423857, Fax : 022-5423517

Jl. Raya Cibinong- Bekasi km. 20 Surabaya, Denpasar, Tel : 0361-235998 – 235973, Fax : 0361-237053

Limusnunggal- Cileungsi Tel : 031-8690202 Makassar, Tel : 0411- 859147 – 858527, Fax : 0411-858527

Fax : 031-8682123 Balikpapan, Tel : 0542-411258 Fax : 0542-412230

BOGOR 16820- Indonesia Medan, Pekanbaru, Tel : 0761-46993 – 47677, Fax : 0761-45112

Tel. +62 21 8230025 Tel : 061-7941200

Fax : 061-7940822

Duri/Dumai. Tel : 0765-595259 Fax : 0765-91135

Fax +62 21 8230025 Palembang, Tel : 0711-351523 Fax : 0711-369858

Batam,

www.sika.co. id Tel : 0778-424928, Palu, Tel : 0451-454855 – 422122, Fax : 0451-454855

e-mail: marketing@sika.co.id Fax : 0778-426913 Manado, Tel /Fax : (0431) 324069

2 Sikadur® -741 2/2

Vous aimerez peut-être aussi

- Casio Manual fx-9860GII - Soft - EN PDFDocument473 pagesCasio Manual fx-9860GII - Soft - EN PDFglazetmPas encore d'évaluation

- Casio Manual fx-9860GII - Soft - EN PDFDocument473 pagesCasio Manual fx-9860GII - Soft - EN PDFglazetmPas encore d'évaluation

- VSL Post Tensioning SolutionsDocument28 pagesVSL Post Tensioning SolutionsDea NurahmanPas encore d'évaluation

- Designing Members For Torsion PDFDocument35 pagesDesigning Members For Torsion PDFwidayat81Pas encore d'évaluation

- Lpile Users Manual PDFDocument231 pagesLpile Users Manual PDFRana HassanPas encore d'évaluation

- 1187Document2 pages1187widayat81Pas encore d'évaluation

- Lpile Technical ManualDocument217 pagesLpile Technical ManualLuoYun100% (6)

- Earthquake Analysis Using Seismic Coefficient MethodDocument4 pagesEarthquake Analysis Using Seismic Coefficient MethodV.m. RajanPas encore d'évaluation

- Lpile Users Manual PDFDocument231 pagesLpile Users Manual PDFRana HassanPas encore d'évaluation

- Soil Properties for LPILE & COM624P AnalysisDocument2 pagesSoil Properties for LPILE & COM624P Analysiswaleed4631100% (1)

- 13 SeismicDocument9 pages13 SeismicKumar AtrayPas encore d'évaluation

- Plates - Shells - ResultsDocument3 pagesPlates - Shells - Resultswidayat81Pas encore d'évaluation

- RCDesignerTutorial Draft1Document27 pagesRCDesignerTutorial Draft1Karthik Reddy ArekutiPas encore d'évaluation

- SPT Con Arcillas y LimosDocument4 pagesSPT Con Arcillas y LimosJose AlePas encore d'évaluation

- Initial Soil Springs Stiffness For Laterally Loaded Piles: AbstractsDocument6 pagesInitial Soil Springs Stiffness For Laterally Loaded Piles: Abstractswidayat81Pas encore d'évaluation

- RCDesignerTutorial Draft1Document27 pagesRCDesignerTutorial Draft1Karthik Reddy ArekutiPas encore d'évaluation

- 18 Chopra ArboledaDocument46 pages18 Chopra Arboledawidayat81Pas encore d'évaluation

- Gcgn5612 Iss 1Document39 pagesGcgn5612 Iss 1widayat81Pas encore d'évaluation

- Brosur Spun Pile Wika 2011Document2 pagesBrosur Spun Pile Wika 2011Angga Wahyudi Fajarianto80% (5)

- Priestley Calvi y KowalskyDocument733 pagesPriestley Calvi y KowalskySebastián Ojeda Uribe100% (1)

- 50 TS Irpan jembatan-OK PDFDocument12 pages50 TS Irpan jembatan-OK PDFAgustina ManurungPas encore d'évaluation

- TCG AutoCAD-IntelliCADCommands Handout PDFDocument9 pagesTCG AutoCAD-IntelliCADCommands Handout PDFPaco VillaseñorPas encore d'évaluation

- TailoringIntelliCAD PDFDocument162 pagesTailoringIntelliCAD PDFwidayat81Pas encore d'évaluation

- 28 Pavement DesignDocument37 pages28 Pavement Designsomesh2727Pas encore d'évaluation

- Numerical Modeling of Rock Slopes in Siwalik Hills Near Manali Region: A Case StudyDocument21 pagesNumerical Modeling of Rock Slopes in Siwalik Hills Near Manali Region: A Case Studywidayat81Pas encore d'évaluation

- 28 Pavement DesignDocument37 pages28 Pavement Designsomesh2727Pas encore d'évaluation

- Settlement of Piled FoundationsDocument24 pagesSettlement of Piled FoundationsWubetie MengistPas encore d'évaluation

- STEEL Designer ManualDocument27 pagesSTEEL Designer ManualDeveloperPas encore d'évaluation

- Simplified Method for Sequential Load Analysis of Tall BuildingsDocument11 pagesSimplified Method for Sequential Load Analysis of Tall Buildingswidayat81Pas encore d'évaluation

- NAVFAC-DM-7.2 Foundation & Earth Structure PDFDocument280 pagesNAVFAC-DM-7.2 Foundation & Earth Structure PDFFauzankalibata100% (1)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeD'EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeÉvaluation : 4 sur 5 étoiles4/5 (5783)

- The Yellow House: A Memoir (2019 National Book Award Winner)D'EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Évaluation : 4 sur 5 étoiles4/5 (98)

- Never Split the Difference: Negotiating As If Your Life Depended On ItD'EverandNever Split the Difference: Negotiating As If Your Life Depended On ItÉvaluation : 4.5 sur 5 étoiles4.5/5 (838)

- Shoe Dog: A Memoir by the Creator of NikeD'EverandShoe Dog: A Memoir by the Creator of NikeÉvaluation : 4.5 sur 5 étoiles4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerD'EverandThe Emperor of All Maladies: A Biography of CancerÉvaluation : 4.5 sur 5 étoiles4.5/5 (271)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceD'EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceÉvaluation : 4 sur 5 étoiles4/5 (890)

- The Little Book of Hygge: Danish Secrets to Happy LivingD'EverandThe Little Book of Hygge: Danish Secrets to Happy LivingÉvaluation : 3.5 sur 5 étoiles3.5/5 (399)

- Team of Rivals: The Political Genius of Abraham LincolnD'EverandTeam of Rivals: The Political Genius of Abraham LincolnÉvaluation : 4.5 sur 5 étoiles4.5/5 (234)

- Grit: The Power of Passion and PerseveranceD'EverandGrit: The Power of Passion and PerseveranceÉvaluation : 4 sur 5 étoiles4/5 (587)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaD'EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaÉvaluation : 4.5 sur 5 étoiles4.5/5 (265)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryD'EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryÉvaluation : 3.5 sur 5 étoiles3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealD'EverandOn Fire: The (Burning) Case for a Green New DealÉvaluation : 4 sur 5 étoiles4/5 (72)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureD'EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureÉvaluation : 4.5 sur 5 étoiles4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersD'EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersÉvaluation : 4.5 sur 5 étoiles4.5/5 (344)

- The Unwinding: An Inner History of the New AmericaD'EverandThe Unwinding: An Inner History of the New AmericaÉvaluation : 4 sur 5 étoiles4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyD'EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyÉvaluation : 3.5 sur 5 étoiles3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreD'EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreÉvaluation : 4 sur 5 étoiles4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)D'EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Évaluation : 4.5 sur 5 étoiles4.5/5 (119)

- Her Body and Other Parties: StoriesD'EverandHer Body and Other Parties: StoriesÉvaluation : 4 sur 5 étoiles4/5 (821)

- 2 Quality Standard in Construction - necCPSDocument102 pages2 Quality Standard in Construction - necCPSSuraj PantPas encore d'évaluation

- Steel Bridge PaintingDocument66 pagesSteel Bridge PaintingSon Kumar PatelPas encore d'évaluation

- T.o.1.55 (Zinc Rich Epoxy Primer)Document2 pagesT.o.1.55 (Zinc Rich Epoxy Primer)Sachin NambiarPas encore d'évaluation

- Thi Công Chống Thấm Chop MBS Marina-Bay-SandsDocument5 pagesThi Công Chống Thấm Chop MBS Marina-Bay-SandsTrần KhươngPas encore d'évaluation

- C510WNDocument2 pagesC510WNEdgarDavidDiazCamposPas encore d'évaluation

- Masterseal Traffic 1330 TdsDocument3 pagesMasterseal Traffic 1330 TdsSolomon AhimbisibwePas encore d'évaluation

- Katalog MetalindoDocument20 pagesKatalog MetalindoGusti EgorPas encore d'évaluation

- Interbond 2340UPC Application Guidelines Rev 03 180321Document6 pagesInterbond 2340UPC Application Guidelines Rev 03 180321Kingsman 86Pas encore d'évaluation

- Fenomastic Hygiene Emulsion SilkDocument4 pagesFenomastic Hygiene Emulsion Silkمحمد عزتPas encore d'évaluation

- Carbothane 134 HG PDSDocument5 pagesCarbothane 134 HG PDSsanthoshkumarplPas encore d'évaluation

- Tds Dekso-5 En-729634Document3 pagesTds Dekso-5 En-729634LPas encore d'évaluation

- Basf Masterseal NP 474 TdsDocument3 pagesBasf Masterseal NP 474 TdsAdnan ČehajićPas encore d'évaluation

- Silicone Sealants Manual: Perfect Joints Made EasyDocument24 pagesSilicone Sealants Manual: Perfect Joints Made EasySanthosh PaulPas encore d'évaluation

- Jotabar ZEP Technical Data SheetDocument3 pagesJotabar ZEP Technical Data SheetthirdPas encore d'évaluation

- Blasting and Painting Procedure PDFDocument9 pagesBlasting and Painting Procedure PDFharry50% (2)

- Oathmark Skeletons From ScratchDocument54 pagesOathmark Skeletons From ScratchjpPas encore d'évaluation

- Aquaarm Wpu 1K (E) Aquaarm Wpu 1K (E) Aquaarm Wpu 1K (E)Document3 pagesAquaarm Wpu 1K (E) Aquaarm Wpu 1K (E) Aquaarm Wpu 1K (E)PANDU RANGARAO A N VPas encore d'évaluation

- Berger: Product SpecificationsDocument2 pagesBerger: Product SpecificationsAabhas UpadhyayaPas encore d'évaluation

- Use of Adhesive and Primers in Shoe ManufacturingDocument24 pagesUse of Adhesive and Primers in Shoe ManufacturingVijay ChandanPas encore d'évaluation

- PTS Painting and Linings2019Document64 pagesPTS Painting and Linings2019MOHAMAD NIZAMUDIN100% (7)

- 7420 0005 250 Esp 005 - 0 Specification For PaintingDocument23 pages7420 0005 250 Esp 005 - 0 Specification For PaintingJorge Isaac Lara RamosPas encore d'évaluation

- Structured Method Statement For Concrete Repair - 6Document14 pagesStructured Method Statement For Concrete Repair - 6m.umarPas encore d'évaluation

- I1912-AI-OPR-MST-0066-00 CMS For Acrylic Emulsion Paint WorksDocument15 pagesI1912-AI-OPR-MST-0066-00 CMS For Acrylic Emulsion Paint WorksAiplshubh ChavanPas encore d'évaluation

- BLD 205-Workshop Practice IIIDocument139 pagesBLD 205-Workshop Practice IIIVietHungCao83% (18)

- Fosroc CatalogueDocument298 pagesFosroc CatalogueGeorge Tsiamtsouris75% (4)

- F 2 Pentathane 4510Document3 pagesF 2 Pentathane 4510Gunjan GaganPas encore d'évaluation

- Pds CPD Sikadur22LM UsDocument2 pagesPds CPD Sikadur22LM Uspandavision76Pas encore d'évaluation

- 10.3290@j.jad.a43994 (1) .pdf-1Document28 pages10.3290@j.jad.a43994 (1) .pdf-1FFDF0% (1)

- Mastertop 1325Document3 pagesMastertop 1325Doby YuniardiPas encore d'évaluation

- MKS 112 GEN AZ7 SP 01 A Specification For PaintingDocument31 pagesMKS 112 GEN AZ7 SP 01 A Specification For PaintingĐiệnBiênNhâm100% (2)