Académique Documents

Professionnel Documents

Culture Documents

Practical Soil Mechanics at Muskingum IV-Knappen & Philippe

Transféré par

Anonymous GnfGTwCopyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Practical Soil Mechanics at Muskingum IV-Knappen & Philippe

Transféré par

Anonymous GnfGTwDroits d'auteur :

Formats disponibles

E n g i n e e r i n g N e w s - R ecoku , May 7, 1936

Practical Soil Mechanics at Muskingum— IV

By Theodore T. Knappen and Robert R. Philippe

C/fief, E n g in e e r in g D iv is io n , an d D irector, S o ils M e c h a n ic s La b o ra to ry ,

U. S . E n g in e e r Office, Zanesville. O hio

Selection and Control o f Embankment Materials

HE P R E V IO U S ART IC LES in an analysis of the cost of the laboratory

T this series ( E N R , March 26, p.

453; April 9, p. 532; April 23,

p. 595) have discussed: (1) the meth

work.

One of the most important items in

the design of earth dams is the selection

and use of embankment materials. Econ

ods of investigation and classification, in

omy dictates that all materials from

producing a picture of the problem in

required excavations should be used in

volved in the design of the Muskingum

the embankment, that no materials from

dams: (2) the methods used to study

excavations should be wasted unneces

the permeability and seepage charac

sarily, and only such materials should

teristics of the proposed structure on

be obtained from borrowpits as are

its foundations: and (3) the methods

necessary to complete the construction.

used to analyze the structural charac

Where excavation materials can all be

teristics of the foundation from the

used in the construction of the embank

viewpoints of consolidation, strength

ment, it is frequently possible to use

and stress intensity and distribution.

verv large spillway excavations with

This final article in the series will dis

great economy. The seepage model test

cuss the selection and control of

previously described was extensively

embankment materials and will present

F IG . 19— U N D IS T U R B E D E M B A N K M E N T SAM PLES, from which degree of con

solidation and the weight of embankment are determined, are secured by the simple

hand tools illustrated here.

F IG . 20— D E V IC E simulating action of

sheepsfoot roller, used to prepare samples

to determine moisture content for optimum

consolidation.

used in working out practicable designs

which would utilize for various pur

poses materials that were available at

the different sites.

Generally speaking, almost any ma

terial can be used somewhere in the

embankment if it can be properly placed,

providing that it will not dissolve in

water. It is important to know, how

ever, the characteristics of the various

materials. For example, when rolling

with sheepsfoot rollers, we must deter

mine at what moisture content optimum

consolidation will occur. Obviously, a

deficiency in moisture content can be

met by the addition of water before

placing or spreading. However, if the

material has an excess of water, it must

either be wasted or dried out before it

can be used in the embankment. This

last requirement frequently determines

the depth to which excavations may be

made in borrowpits and the depths of

required excavations that can be

utilized. Where large amounts of

necessary excavations must be wasted,

a change ill the design may result in

saving.

Embankment consolidation

in the last few years methods of em

bankment consolidation have received

E n g i n e e r i n g N e w s - R e c o r d , May 7, 1936

L A B O R A T O R Y S E C T IO N types, the optimum water content is

ASS OC. ENG’R. just slightly less than the water content

at Atterberg’s plastic limit. For the

type of equipment used— that is, sheeps

O F F IC E ASS’T.

foot rollers— this gives a quick method

inspector of checking the condition of the ma

P o rte r terial in the field. Practice has indicated

P o rter

that by varying the limiting dimension

of the test for plastic limit suitable con

trol of water content will result.

r~ Where uniform materials of silt and

Z I clay type are used, the weight of the

TESTING TESTING

SUB-SECTION No. 1 SUB-SECTION No.2 material in the embankment usually

Ass’t. Eng’r. Ass’t. Eng'r. varies from 118 to 125 lb. per cu.ft.

Where well-graded material running

COMPUTING CLASSIFYING .J from rock fragments or gravels on down

—

SECTION SECTION through clay size is obtainable, weights

Computor Inspector varying from 125 to 145 lb. will result,

Ass’t. Computor Inspector

Draftsman with a few reading as high as 156 lb.

Draftsman

I

, per cu.ft. Materials running high in

PHOTO-ELASTIC

’.».silt sizes and running more than 25

SIEVE PERMEABILITY SHEAR AMO COtlSOUDATIOM

ANALYSIS TESTS TESTS TESTS per cent in the clay sizes are difficult

UnderScientific Aid Junior Scientffic Aid Jiunior Scientific Aid Scientific Aid to handle and should be avoided. Be

Untier Scientific Aid JuniorScientific Aid Jiunior Scientific A id Scientific Aid cause of the wide variation of the ma

terials obtained from the excavations

and borrowpits in this locality, it was

HYDROM ETER MODEL not found practicable to add water in

TESTS TESTS the borrowpits, and further, it is not

Junior Scientific Aid Asst. Scientific Aid feasible to add any specified amount of

Junior Scientific Aid Asst; Scientific Aid

water in the embankment.

F IG . 21— A SIM PLE W O R K IN G O R G A N IZ A T IO N is sufficient to handle many Water is added to the surface of the

varieties of tests at the M uskingum laboratory. previous layer immediately prior to

dumping and spreading. Layers are

spread about 6 in. thick before rolling.

critical attention from the engineering the sample in the field. The samples

An inspector supervises the addition of

profession. It has been generally are obtained by forcing the beveled edge

water to bring the material to the water

recognized that the proper consolidation of the cylinder down into the ground

content, which gives the maximum con

of embankments during construction is and digging away around it as the

solidation. After a certain amount of

highly desirable. Proctor, in a series of cylinder is lowered. As a check against

experience, inspectors become adept at

articles in Engineering News-Record, this method and for cases where too

determining the amount of moistening

established certain rules and methods for many pebbles, gravel or rock fragments

needed. They check their results by

obtaining embankments of highest pos are present, the sample is taken by

weighing frequent samples of embank

sible density. His methods establish what levelling off a space on the embankment,

ment material. They are guided by the

relations exist between the moisture con carefully cutting out a sample, weighing

Atterberg plastic limit test and by the

tent, the weight of sheepsfoot rollers and it and measuring the volume by pouring

way the material acts under the rollers

the number of trips of the rollers, which into the excavation dry sand of known

and hauling equipment-. •, It must be

determines the degree of consolidation weight per unit volume. Generally

added that weathered shales nave proved

to be obtained for any particular speaking, the two methods check very

to be very satisfactory impervious em

material. closely.

bankment materials when so treated.

As a general rule, we have aimed to

place materials in the embankment to Determining moisture content

such a degree of consolidation that the f l G . 22— P R O C T O R C U R V E , showing the

compaction characteristic of a soil under

embankment will take no shrinkage To determine the proper moisture a given load and a specified treatment.

after construction. This degree of con content at which optimum consolidation

solidation can be determined by molding may be obtained, a device was developed

a sample of borrowpit material and then in the laboratory for tamping the ma

consolidating it in the consolidation de terial so as to simulate the action of the

vice under various increments of load. sheepsfoot roller. Fig. 20 shows this

The dry weight of the material per machine. The material of uniform and

cubic foot may then be determined for known water content is placed in 3-in.

any height of superimposed embank layers, and each layer is tamped three

ment. By correcting for the water con times with a tamper foot. The top

tent, the minimum permissible embank collar is then removed from the cylinder,

ment weight may be determined. This the material shaved off to the exact

weight is furnished to the inspectors in dimension of the cylinder, and the

the field to check the embankment sample weighed. When the known

weights by taking undisturbed cylinder weight of the cylinder is deducted,

samples in the field with equipment knowing the water content, the dry

illustrated in Fig. 19. Generally speak weight may be obtained from the total

ing, very little difficulty is met in weight of the sample. This process is

getting the weights in excess of the run through for a number of water con

minimum required. tents, and a curve illustrated in Fig. 22

The sampling device consists of a is prepared, which shows the degree of

piece of stiff seamless tubing with one consolidation obtained by the method of

end beveled, exactly 1/10 cu.ft. in test for each water content. It may be

volume. A steelyard is used to weigh noted that for materials of clay or silt

E n g i n e e r i n g N e w s - R e c o r d , May 7, 1936

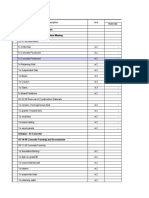

T A B L E O F IN IT IA L COST TO SET U P A SO ILS L A B O R A T O R Y Arthur, Jr., district engineer, with one

-Zanesville Laboratory- Laboratory for Single D am of the authors, Theodore T. Knappen,

U n it Total Unit Total in charge of the engineering division as

E quipm ent No. Cost Costs No. Cost Costs

$230.96 $95. 00

senior engineer. The soils mechanics

F u rn itu re .. . . ........

Scales and weights.. $66.44 132.88 $ 66.44 6 6 . 44 laboratory of the engineering division is

Glassware................ 166.80 80. 00

Miscellaneous......... 26.62 15. 00 under the direction of the other author,

Sieve A nalysis Robert R. Philippe, associate engineer.

R o ta p ....................................................... 2 237. 10 474.20 237.10 237. 10 Dr. Glennon Gilboy, association profes

Sieves (29 sieves, top and pan)........... 3 sets 83.45 250.35 set 83.45 83. 45

Furniture: sinks ana ovens.................. 273.47 130. 00 sor of soil mechanics at the Massa

Balances and weights............................ sets 22.24 44.48 set 22.24 2 2 . 24

Miscellaneous..........................................

2

46.77 25. 50 chusetts Institute of Technology, was

H y d ro m e te r A nalysis consulting engineer on the design and

Furniture: sinks and ovens.................. 498.16 217. 35 construction of the laboratory and has

Glassware hydrometers........................ 505.24 155. 20

Balances» weights and watches............ 225.87 10 0 . 00 advised in the development of much of

P e rm e a b ility Tests the technique. Associate professor Fred

Furniture: sinks, e tc ............................ 226.06 2 0 0 . 00

Glass and rubber tubing, etc............... 202.53 10 0 . 00 L. Plummer, of the Case School of

2 0 . 00

Lumber.................................................... 56.84

74.25 30. 00

Applied Science, assisted in the de

Miscellaneous.........................................

M o d e l T an k s velopment of the photo-elastic method

Steel tank (40x7x3 f t .) ..........................

Glass tank (14x2ft.x j in.) by contact..

1,850.00

216.19 216. 19

of foundation analyses.

Wooden flume (piping)......................... 75.00 Fig. 23 is a plan of the laboratory,

C o n s o lid a tio n Tests

117.14 468.16 117.14 234,.08

showing the distribution of the equip

Consolidation machines........................

Glassware, tools, etc.............................. 53.02 26..00 ment and the floor-space requirements

S h e a r Tests for the different items. The total cost

Shear machine........................................ 343.45 343.45 343,.45

Glassware, tools, etc.............................. 38.90 2 0 ,. 00 of all equipment in the laboratory, in

Polarimeter and E q u ip m e nt................ 127.50 127.50 cluding the cost of erection and con

H u m id R o o m

26..05

struction, was approximately $9,000.

Hum idifier............................................... 26.05 26.05 26.05

Lumber, paint and hardware............... 102.03 102.03 102.03 1 0 2 . 03 The accompanying table lists the major

Electrical w ork...................................... 228.60 150 .00 classifications of equipment giving their

P lu m bing ................................................ 250.00 150 .00

Office furniture...................................... 313.50 175 .00 costs. The total operating and con

$7,595.88 $3,020.08 struction cost of the laboratory to the

end of the design period was $32,000.

The optimum moisture content varies large coefficient of expansion when so It should be noted that this laboratory

for the materials in these embankments placed, serious results may ensue. Ma was designed to handle the design and

under the methods of rolling specified terials containing a high percentage of construction of fourteen reservoirs esti

(six trips of a water-ballasted sheeps- clay fall in this class. Unless adequate mated to cost $40,000,000. Core borings,

foot roller), from 10 per cent for sandy rock or gravel shells are provided, ex auger borings and test pits cost $225,000

material to 35 per cent for materials treme caution should be exercised in for the project. The $32,000 plus

running around 25 per cent clay sizes. consolidating such materials. These $12,000 for geological studies represents

The discussion of methods controlling materials are highly impervious even the cost of reducing the data obtained

embankment consolidation applies to with very light rolling, so there is little from these explorations for application

materials that are relatively impervious need for their thorough consolidation in to the design of the project. For

such as well-graded materials, or ma dams of proper design. projects with less volume of work,

terials high in silt or clay content. For laboratory installation and operating

the proper consolidation of sandy and Laboratory plan and costs costs would be much less. The mini

gravelly material used in the shells of mum installation cost for a laboratory

the embankment, a liberal use of water The organization of the laboratory is to handle one or two dams would be

and plain rollers will serve. For rock illustrated by the chart, Fig. 21. The about $4,500, details of material costs

fills the practice is to dump in 5-ft. lifts investigation, design and construction being given in the accompanying table.

working over the lifts with the hauling of the project are under the direction of In carrying out the design of the

equipment. The use of a good stream the U. S. Engineer Department, Major Muskingum project, the laboratory has

of water is helpful in insuring a dense General E. .M. Markham, chief of en been considered and used as an integral

fill. gineers, and Col. Roger Powell, division part of the design organization. It was

It should be pointed out that where engineer. The Zanesville Engineer designed and built to meet the needs of

material is over-consolidated there is a district, which handled the work, is this project, which presented widely

tendency to rebound, which may take under the direction of Major J. D. varying problems. Even so, certain

the form of lateral expansion. With ma phases of soil mechanics work had little

terials that can be considered to have a F IG . 23— P L A N of soils laboratory for application in our set-up. The liquid

M uskingum Valley dams.

~T

Bluep rin t supplies '■Hydrometer -fables'

139-/?-

E n g i n e e r i n g N e w s - R e c o r d , M a y 7, 1936

limit and shrinkage limits tests exten experience has brought home to us the the intelligent use of the laboratory,

sively used in highway work did not fact that there is an answer that can guesswork may be pushed out of its

concern us. As there were no be worked out in the laboratory to every dominating position in earth engineer

hydraulic-fill dams in this project, no problem in soil mechanics, and that the ing, and the solution of such problems

special equipment was developed for laboratory solution of these problems can be put on the same rational basis

their control, although it is felt that pays many times over in the proper de as the more advanced branches of en

most of what is needed is on hand. Our sign and construction of earthworks. By gineering design.

Vous aimerez peut-être aussi

- 1Document13 pages1Anonymous GnfGTwPas encore d'évaluation

- Failure Analysis of Malin LandslideDocument16 pagesFailure Analysis of Malin LandslideAnonymous GnfGTwPas encore d'évaluation

- Observations During Recent Earthquakes and Developments in Liquefaction AnalysisDocument8 pagesObservations During Recent Earthquakes and Developments in Liquefaction AnalysisAnonymous GnfGTwPas encore d'évaluation

- New Generation Geo Engineering BarendsDocument12 pagesNew Generation Geo Engineering BarendsAnonymous GnfGTwPas encore d'évaluation

- Back Calculation of A Flow Slide in Sensitive Clays-ThakurDocument18 pagesBack Calculation of A Flow Slide in Sensitive Clays-ThakurAnonymous GnfGTw100% (1)

- A.B. Huang - Pg. 3 - Chatacterization of Silt-Sand SoilsDocument16 pagesA.B. Huang - Pg. 3 - Chatacterization of Silt-Sand SoilsLisa HigginsPas encore d'évaluation

- New Generation Geo Engineering BarendsDocument12 pagesNew Generation Geo Engineering BarendsAnonymous GnfGTwPas encore d'évaluation

- Perspectives in Forensic Geotechnical EngineeringDocument8 pagesPerspectives in Forensic Geotechnical EngineeringAnonymous GnfGTwPas encore d'évaluation

- Indian National Report On Codes, Regulations and Practices of Braced Excavations in Soft GroundDocument5 pagesIndian National Report On Codes, Regulations and Practices of Braced Excavations in Soft GroundAnonymous GnfGTwPas encore d'évaluation

- Teaching Rock Mechanics in The Classroom and On The UNI-Nettuno Network-BarlaDocument10 pagesTeaching Rock Mechanics in The Classroom and On The UNI-Nettuno Network-BarlaAnonymous GnfGTwPas encore d'évaluation

- Practical Soil Mechanics at Muskingum III-Knappen & PhilippeDocument4 pagesPractical Soil Mechanics at Muskingum III-Knappen & PhilippeAnonymous GnfGTwPas encore d'évaluation

- Modern Methods of Design and Construction of Foundations-ProctorDocument55 pagesModern Methods of Design and Construction of Foundations-ProctorAnonymous GnfGTwPas encore d'évaluation

- Practical Soil Mechanics at Muskingum II-Knappen & PhilippeDocument4 pagesPractical Soil Mechanics at Muskingum II-Knappen & PhilippeAnonymous GnfGTwPas encore d'évaluation

- What Should Geotechnical Engineers Be Able To Do and How Should They Acquire These SkillsDocument6 pagesWhat Should Geotechnical Engineers Be Able To Do and How Should They Acquire These SkillsAnonymous GnfGTwPas encore d'évaluation

- Back Calculation of A Flow Slide in Sensitive Clays-ThakurDocument18 pagesBack Calculation of A Flow Slide in Sensitive Clays-ThakurAnonymous GnfGTw100% (1)

- Bearing Capacity of Piles-CrandallDocument21 pagesBearing Capacity of Piles-CrandallAnonymous GnfGTwPas encore d'évaluation

- Practical Soil Mechanics at Muskingum I-Knappen & PhilippeDocument3 pagesPractical Soil Mechanics at Muskingum I-Knappen & PhilippeAnonymous GnfGTwPas encore d'évaluation

- Comparing Methods for Compacting Cohesionless SoilsDocument9 pagesComparing Methods for Compacting Cohesionless SoilsAnonymous GnfGTwPas encore d'évaluation

- Groundwater Movement and Seepage-JustinDocument6 pagesGroundwater Movement and Seepage-JustinAnonymous GnfGTwPas encore d'évaluation

- Earth Pressure Against Retaining Walls, Excavation Sheeting, Tunnel Linings, Etc-CasagrandeDocument9 pagesEarth Pressure Against Retaining Walls, Excavation Sheeting, Tunnel Linings, Etc-CasagrandeAnonymous GnfGTwPas encore d'évaluation

- Exploration of Soil Condition and SamplingDocument1 pageExploration of Soil Condition and SamplingAnonymous GnfGTwPas encore d'évaluation

- Report On A Joint Meeting of The Committe of Foundations and Soil MechanicsDocument11 pagesReport On A Joint Meeting of The Committe of Foundations and Soil MechanicsAnonymous GnfGTwPas encore d'évaluation

- Soil Problems in Highway Engineering Including Frost Action in SoilsDocument7 pagesSoil Problems in Highway Engineering Including Frost Action in SoilsAnonymous GnfGTwPas encore d'évaluation

- Soil Problems in Highway Engineering Including Frost Action in SoilsDocument7 pagesSoil Problems in Highway Engineering Including Frost Action in SoilsAnonymous GnfGTwPas encore d'évaluation

- Description of An Apparatus To Register Graphically The Settlements of A Plame Plate Resting Upon A Subsoil and ChargedDocument7 pagesDescription of An Apparatus To Register Graphically The Settlements of A Plame Plate Resting Upon A Subsoil and ChargedAnonymous GnfGTwPas encore d'évaluation

- Exploration of Soil Conditions and Samplig Operations-HannaDocument2 pagesExploration of Soil Conditions and Samplig Operations-HannaAnonymous GnfGTwPas encore d'évaluation

- Short Description of A Field-Testing Method With Cone Shaped Sounding ApparatusDocument4 pagesShort Description of A Field-Testing Method With Cone Shaped Sounding ApparatusAnonymous GnfGTwPas encore d'évaluation

- Sampling and Testing Undisturbed Sands From BoreholesDocument4 pagesSampling and Testing Undisturbed Sands From BoreholesAnonymous GnfGTwPas encore d'évaluation

- Improved Type of Soil Sampler For Explorations of Soil Conditions and Sampling Operations-StantonDocument3 pagesImproved Type of Soil Sampler For Explorations of Soil Conditions and Sampling Operations-StantonAnonymous GnfGTwPas encore d'évaluation

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeD'EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeÉvaluation : 4 sur 5 étoiles4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingD'EverandThe Little Book of Hygge: Danish Secrets to Happy LivingÉvaluation : 3.5 sur 5 étoiles3.5/5 (399)

- Shoe Dog: A Memoir by the Creator of NikeD'EverandShoe Dog: A Memoir by the Creator of NikeÉvaluation : 4.5 sur 5 étoiles4.5/5 (537)

- Never Split the Difference: Negotiating As If Your Life Depended On ItD'EverandNever Split the Difference: Negotiating As If Your Life Depended On ItÉvaluation : 4.5 sur 5 étoiles4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceD'EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceÉvaluation : 4 sur 5 étoiles4/5 (895)

- The Yellow House: A Memoir (2019 National Book Award Winner)D'EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Évaluation : 4 sur 5 étoiles4/5 (98)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryD'EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryÉvaluation : 3.5 sur 5 étoiles3.5/5 (231)

- Grit: The Power of Passion and PerseveranceD'EverandGrit: The Power of Passion and PerseveranceÉvaluation : 4 sur 5 étoiles4/5 (588)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureD'EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureÉvaluation : 4.5 sur 5 étoiles4.5/5 (474)

- On Fire: The (Burning) Case for a Green New DealD'EverandOn Fire: The (Burning) Case for a Green New DealÉvaluation : 4 sur 5 étoiles4/5 (73)

- Team of Rivals: The Political Genius of Abraham LincolnD'EverandTeam of Rivals: The Political Genius of Abraham LincolnÉvaluation : 4.5 sur 5 étoiles4.5/5 (234)

- The Emperor of All Maladies: A Biography of CancerD'EverandThe Emperor of All Maladies: A Biography of CancerÉvaluation : 4.5 sur 5 étoiles4.5/5 (271)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersD'EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersÉvaluation : 4.5 sur 5 étoiles4.5/5 (344)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaD'EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaÉvaluation : 4.5 sur 5 étoiles4.5/5 (266)

- The Unwinding: An Inner History of the New AmericaD'EverandThe Unwinding: An Inner History of the New AmericaÉvaluation : 4 sur 5 étoiles4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyD'EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyÉvaluation : 3.5 sur 5 étoiles3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreD'EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreÉvaluation : 4 sur 5 étoiles4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)D'EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Évaluation : 4.5 sur 5 étoiles4.5/5 (120)

- Her Body and Other Parties: StoriesD'EverandHer Body and Other Parties: StoriesÉvaluation : 4 sur 5 étoiles4/5 (821)

- CS310 Sample PaperDocument10 pagesCS310 Sample PaperMohsanPas encore d'évaluation

- Compare The Political System of Kazakhstan, USA, UK PresentationDocument19 pagesCompare The Political System of Kazakhstan, USA, UK PresentationAiganym OmiraliPas encore d'évaluation

- Phy Worksheet IG 3 Phase 2Document6 pagesPhy Worksheet IG 3 Phase 2Umair RazaPas encore d'évaluation

- Ce Brochure 20july16Document76 pagesCe Brochure 20july16Yogesh SharmaPas encore d'évaluation

- Unit Rates and Cost Per ItemDocument213 pagesUnit Rates and Cost Per ItemDesiree Vera GrauelPas encore d'évaluation

- Notes (Net) para Sa KritikaDocument4 pagesNotes (Net) para Sa KritikaClaire CastillanoPas encore d'évaluation

- Ap4955 PDFDocument4 pagesAp4955 PDFGilvan HenriquePas encore d'évaluation

- 2iccas2005 Paper 377Document5 pages2iccas2005 Paper 377Cristian BandilaPas encore d'évaluation

- Annual Report 18Document363 pagesAnnual Report 18Safeer UllahPas encore d'évaluation

- An Introduction To Log ShootingDocument10 pagesAn Introduction To Log ShootingSorin GociuPas encore d'évaluation

- Reporte Corporativo de Louis Dreyfus Company (LDC)Document21 pagesReporte Corporativo de Louis Dreyfus Company (LDC)OjoPúblico Periodismo de InvestigaciónPas encore d'évaluation

- MIZAT PWHT Procedure Ensures Welded Joints Meet StandardsDocument9 pagesMIZAT PWHT Procedure Ensures Welded Joints Meet StandardsM. R. Shahnawaz KhanPas encore d'évaluation

- Adms OneAdms One ClassDocument9 pagesAdms OneAdms One ClasssafwatPas encore d'évaluation

- RTR Piping Inspection GuideDocument17 pagesRTR Piping Inspection GuideFlorante NoblezaPas encore d'évaluation

- Curriculam VitaeDocument3 pagesCurriculam Vitaeharsha ShendePas encore d'évaluation

- EBSD Specimen Prep PaperDocument36 pagesEBSD Specimen Prep PaperPaul RosiahPas encore d'évaluation

- Deutsche BankDocument4 pagesDeutsche BankMukesh KumarPas encore d'évaluation

- CARP Law NotesDocument5 pagesCARP Law NotesJustisia KaunlaranPas encore d'évaluation

- Analects of A.T. Still-Nature Quotes-UnboundedDocument8 pagesAnalects of A.T. Still-Nature Quotes-UnboundedBruno OliveiraPas encore d'évaluation

- Definition and Scope of Public FinanceDocument2 pagesDefinition and Scope of Public FinanceArfiya MubeenPas encore d'évaluation

- Pick Pack Ship Public APIDocument19 pagesPick Pack Ship Public APIgauravpuri198050% (2)

- SMC Dialog Plus Conversion To Another SMC 8 - 22 - 2014Document15 pagesSMC Dialog Plus Conversion To Another SMC 8 - 22 - 2014vivek kumarPas encore d'évaluation

- Basic Facts in EventDocument1 pageBasic Facts in EventAllan AgpaloPas encore d'évaluation

- Unit 7 Noun ClauseDocument101 pagesUnit 7 Noun ClauseMs. Yvonne Campbell0% (1)

- Research on Comparisons between Sabah and Diesel CyclesDocument8 pagesResearch on Comparisons between Sabah and Diesel CyclesjorgePas encore d'évaluation

- ForwardMails PDFDocument7 pagesForwardMails PDFJesús Ramón Romero EusebioPas encore d'évaluation

- Parts of The Analog MultitesterDocument4 pagesParts of The Analog MultitesterDestiny Marasigan CanacanPas encore d'évaluation

- Comparative Media SystemsDocument10 pagesComparative Media SystemsJoram MutwiriPas encore d'évaluation

- Spare Parts List: WarningDocument5 pagesSpare Parts List: WarningÃbdøū Èqúípmeńť MédîcàlPas encore d'évaluation

- Mycophenolic Acid Chapter-1Document34 pagesMycophenolic Acid Chapter-1NabilaPas encore d'évaluation