Académique Documents

Professionnel Documents

Culture Documents

IQ, OQ, PQ in Pharma Industry Validate Equipment Performance

Transféré par

Selvaraj Balasundram0 évaluation0% ont trouvé ce document utile (0 vote)

101 vues2 pagesThe document discusses IQ, OQ, and PQ which refer to equipment qualification processes required in the pharmaceutical industry. IQ is installation qualification which evaluates the equipment materials and installation. OQ is operational qualification which tests if the equipment operates as specified. PQ is performance qualification which challenges the equipment under load to ensure it can still perform as required when in use. These qualification processes give assurance that manufacturing processes will consistently produce high quality products and help expedite bringing new equipment online for clients' needs.

Description originale:

Process Validation

Titre original

Process Validation - IQ, OQ, PQ

Copyright

© © All Rights Reserved

Formats disponibles

DOCX, PDF, TXT ou lisez en ligne sur Scribd

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentThe document discusses IQ, OQ, and PQ which refer to equipment qualification processes required in the pharmaceutical industry. IQ is installation qualification which evaluates the equipment materials and installation. OQ is operational qualification which tests if the equipment operates as specified. PQ is performance qualification which challenges the equipment under load to ensure it can still perform as required when in use. These qualification processes give assurance that manufacturing processes will consistently produce high quality products and help expedite bringing new equipment online for clients' needs.

Droits d'auteur :

© All Rights Reserved

Formats disponibles

Téléchargez comme DOCX, PDF, TXT ou lisez en ligne sur Scribd

0 évaluation0% ont trouvé ce document utile (0 vote)

101 vues2 pagesIQ, OQ, PQ in Pharma Industry Validate Equipment Performance

Transféré par

Selvaraj BalasundramThe document discusses IQ, OQ, and PQ which refer to equipment qualification processes required in the pharmaceutical industry. IQ is installation qualification which evaluates the equipment materials and installation. OQ is operational qualification which tests if the equipment operates as specified. PQ is performance qualification which challenges the equipment under load to ensure it can still perform as required when in use. These qualification processes give assurance that manufacturing processes will consistently produce high quality products and help expedite bringing new equipment online for clients' needs.

Droits d'auteur :

© All Rights Reserved

Formats disponibles

Téléchargez comme DOCX, PDF, TXT ou lisez en ligne sur Scribd

Vous êtes sur la page 1sur 2

What Are IQ, OQ, and PQ, and Why

Are They Required In The

Pharmaceutical Industry?

Posted by Wellspring Pharma Services

May 15, 2014 10:25:00 AM

Pardon the alphabet soup, but these acronyms identify common terms

that you’ll see in many FDA and Health Canada guidance documents,

and typically refer to equipment. IQ stands for Installation

Qualification. OQ is Operational Qualification and PQ is

Performance Qualification.

Before you even get to IQ, OQ, PQ, if you’re acquiring a new piece of

equipment, you’ll need design specifications that define exactly what’s

in that piece of equipment. Everything from the type of power source

it will utilize to the exact materials used in its construction.

Once you have your final/approved design specs, you order the

equipment, it comes in and now you’re developing your IQ and OQ.

Quite often, the basis for the IQ and OQ will be the equipment manual

itself. To save time and, prior to delivery, we’ll ask the equipment

manufacturer for the manual and we’ll use the manual as the basis of

our protocols.

Installation Qualification (IQ)

Evaluates Means Of Accomodating

New Equipment And Testing Its

Materials

For installation qualification, we’ll first look at the equipment

material. For example, if we specified 316 stainless, we’ll test to

verify it is in fact 316 stainless. Sometimes stainless steel is passivated

and you can test to verify there are no further residues from the

passivation process.

You might have specified a 5 force power motor in your equipment, for example. You want to check to ensure it’s a 5 force pow er motor.

You’ll also confirm that the power output and the power requirements are consistent with your specifications, and the room that the

equipment is installed in can accommodate that power source. Once you have completed your review of the installation and ever ything is in

order, you can trust that the equipment is going to operate the way in which it was designed.

Operational Qualification (OQ) Is Essential In Challenging Your

Equipment Parameters

The next phase is OQ, operational qualification. At this stage, if you’ve specified that your equipment is going t o run in a range of 50-150

RPM and will draw a specific amount of power, you want to verify that the equipment is achieving those operational requiremen ts. So,

review those parameters and challenge them. Again, make sure your equipment actually runs the wa y it’s supposed to run.

Performance Qualification (PQ) Puts Your Equipment To The Final

Test

In the PQ - performance qualification – phase, we like to challenge the equipment, much like in the OQ phase, but now under load. While

it’s great that it runs at 50 RPM or 150 RPM when it’s empty, what happens when there’s 300 kilos of material in it? Can it still achieve

those speed ranges? That’s the essence and focus of the PQ phase. Once you’ve completed these three phases, the equipment is available for

use in whatever process you intended for it.

Qualification Processes Will Give You, And Your Client, Peace Of

Mind

Why does the pharmaceutical manufacturing industry need this qualification

process? Validation executed as a global exercise, is a method of establishing

documented evidence that shows that we have a high degree of assurance that

our manufacturing process will consistently yield a product of

predetermined quality. If a manufacturer fails to do that, the results can be

disastrous. It can cost the client hundreds of thousands of dollars, increase the

risk of product recall and potentially contribute to a loss of market share. We

try to prevent that, and we do so by controlling change and ensuring that we

account for change in our day to day operations.

Occasionally, we get clients who ask, “can you make this product for us?” We

may not have the specific equipment needed, but the client wants our

involvement and would like us to bring the equipment in. The IQ, OQ, PQ

process is very important here. We’ve helped clients spec out the equipment

they need and then quickly and efficiently bring that equipment in, install it,

set it up, and get it ready to go. The way we run the IQ, OQ, PQ process really

expedites the transfer of a product into our facility.

In one case, we obtained approval from a client in February, spec’d out the

equipment, received it in March, set it up and began manufacturing clinical

trial batches and brought them to the clinical site by September 1st. Due to the rigorous process we go thro ugh, we identified the equipment,

knew what we had to do to get it up and running optimally and did it quickly. That really helped our client.

Vous aimerez peut-être aussi

- What Are IQ, OQ, and PQ, and Why Are They Required in The Pharmaceutical Industry?Document7 pagesWhat Are IQ, OQ, and PQ, and Why Are They Required in The Pharmaceutical Industry?Karthi KeyanPas encore d'évaluation

- IQ, OQ, PQ: A Quick Guide To Process ValidationDocument9 pagesIQ, OQ, PQ: A Quick Guide To Process ValidationGonzalo MazaPas encore d'évaluation

- QA Interview Q & ADocument18 pagesQA Interview Q & AMohd RaqeebuddinPas encore d'évaluation

- Study For Medical DevicesDocument5 pagesStudy For Medical Deviceseduardo dominguezPas encore d'évaluation

- QA Processes, Tools and Metrics: Group 1Document18 pagesQA Processes, Tools and Metrics: Group 1Rhea AgulayPas encore d'évaluation

- CH 1 Software Quality Assurance Fundamentals-KMDocument19 pagesCH 1 Software Quality Assurance Fundamentals-KMakash chandankarPas encore d'évaluation

- Software Quality AssuranceDocument23 pagesSoftware Quality AssuranceAbhishek sonunePas encore d'évaluation

- CBMEC 1 - Assignment 3Document4 pagesCBMEC 1 - Assignment 3Tibay, Genevive Angel Anne A.Pas encore d'évaluation

- SOP Equipment ValidationDocument15 pagesSOP Equipment Validationfarjana100% (6)

- And Where It Fits in Your Product Cycle: A Simple Guide To CertificationDocument1 pageAnd Where It Fits in Your Product Cycle: A Simple Guide To CertificationSatadeep DattaPas encore d'évaluation

- Software Quality: What is it and Why is it ImportantDocument28 pagesSoftware Quality: What is it and Why is it ImportantMashal KianiPas encore d'évaluation

- Software Quality ConceptsDocument38 pagesSoftware Quality Conceptskiran reddyPas encore d'évaluation

- Software Quality Assurance - For - AppraisalDocument5 pagesSoftware Quality Assurance - For - AppraisalPravin ThoratPas encore d'évaluation

- Unit 2,3Document113 pagesUnit 2,3Madhav ChablaniPas encore d'évaluation

- Steritest Services DS MKDocument4 pagesSteritest Services DS MKDiana del PilarPas encore d'évaluation

- Lecture 5Document28 pagesLecture 5Yong Hao Jordan JinPas encore d'évaluation

- QA - QC Basic Knowledge For Civil EngineersDocument58 pagesQA - QC Basic Knowledge For Civil EngineersMahar FarooqPas encore d'évaluation

- Mastercontrol Validation Strategy FaqDocument4 pagesMastercontrol Validation Strategy Faqcsvspcal143Pas encore d'évaluation

- Important Questions of Cpa EditedDocument58 pagesImportant Questions of Cpa EditedMohammed TayyabPas encore d'évaluation

- PM-Software Quality AssuranceDocument22 pagesPM-Software Quality AssuranceHusnainPas encore d'évaluation

- Software Quality Assurance and QA IssuesDocument21 pagesSoftware Quality Assurance and QA IssuesLij Melkam AbuhayPas encore d'évaluation

- Lect 1 2010Document20 pagesLect 1 2010Mona FatimaPas encore d'évaluation

- Above Beyond and Below Pressure Control HandbookDocument30 pagesAbove Beyond and Below Pressure Control HandbookAlex MillerPas encore d'évaluation

- VALIDATIONDocument127 pagesVALIDATIONSubhash Chandra Bose Penjuri100% (2)

- Software Testing FoundationsDocument25 pagesSoftware Testing FoundationsMartin ObretenovPas encore d'évaluation

- Software Quality Assurance: Rakibul Hassan Lecturer Dept. of ECE, RUETDocument13 pagesSoftware Quality Assurance: Rakibul Hassan Lecturer Dept. of ECE, RUETRUET Persistenet TrioPas encore d'évaluation

- Pharmaceutical Manufacturing (With QA With GMP) Lecture: Activity 7Document4 pagesPharmaceutical Manufacturing (With QA With GMP) Lecture: Activity 7Rona MalagambaPas encore d'évaluation

- Equipment ValidationDocument20 pagesEquipment ValidationIglesias Laura100% (2)

- QA Interview QuestionsDocument45 pagesQA Interview Questionsmagiofficial97Pas encore d'évaluation

- The Complexity of Process ValidationDocument10 pagesThe Complexity of Process ValidationMiguel Angel Pacahuala CristobalPas encore d'évaluation

- Validation TutorialDocument20 pagesValidation TutorialbahrulPas encore d'évaluation

- Six SigmaValidation TutorialDocument20 pagesSix SigmaValidation TutorialRutvij KotechaPas encore d'évaluation

- Comissionamento FarmaceuticoDocument4 pagesComissionamento FarmaceuticoUrsula HillePas encore d'évaluation

- Iqoqpq RMGDocument11 pagesIqoqpq RMGjpmaurya7750% (4)

- Quality Management Techniques and ProcessesDocument49 pagesQuality Management Techniques and ProcessesnnoumanPas encore d'évaluation

- Quality Assurance Quality Control and Testing WhitepaperDocument39 pagesQuality Assurance Quality Control and Testing WhitepaperJairo Israel Alvarez CordovaPas encore d'évaluation

- How Does Testing Differ From QADocument4 pagesHow Does Testing Differ From QAMuhammad AliPas encore d'évaluation

- IVT Network - 4 Indispensable Pre-Inspection Actions - 2014-02-27Document2 pagesIVT Network - 4 Indispensable Pre-Inspection Actions - 2014-02-27Mohammed YousffiPas encore d'évaluation

- Group 5 - Quality ControlDocument31 pagesGroup 5 - Quality Controlkingfearless27Pas encore d'évaluation

- Navigating Validation RequirementsDocument14 pagesNavigating Validation RequirementsPhillip RautenbachPas encore d'évaluation

- Quality Assurance - What Is ItDocument5 pagesQuality Assurance - What Is ItABI Alco QAPas encore d'évaluation

- Quality Assurance and Quality ControlDocument23 pagesQuality Assurance and Quality Controlamitywave1Pas encore d'évaluation

- Quality Control Quality Assurance: Q60) Difference Between QA & QC?Document4 pagesQuality Control Quality Assurance: Q60) Difference Between QA & QC?Somanath RugePas encore d'évaluation

- Concepts of Process Validation in Solid Dosage Form (Tablet) - An Overview - SAJ Pharmacy and Pharmacology - Open Access Journals - ScholarenaDocument10 pagesConcepts of Process Validation in Solid Dosage Form (Tablet) - An Overview - SAJ Pharmacy and Pharmacology - Open Access Journals - Scholarenaedgar palominoPas encore d'évaluation

- Process Validation of Tablets An OverviewDocument9 pagesProcess Validation of Tablets An OverviewGaurav ZaveriPas encore d'évaluation

- Prod ManDocument32 pagesProd ManJoy DimaculanganPas encore d'évaluation

- Unit-3 Se NotesDocument33 pagesUnit-3 Se Notesjai kumarPas encore d'évaluation

- 1 Production & Operational Objectives: I. Productions and Operations PlanDocument8 pages1 Production & Operational Objectives: I. Productions and Operations PlanFrances JalandoniPas encore d'évaluation

- Role of Testing Team in SDLCDocument17 pagesRole of Testing Team in SDLCRajiv ChadhaPas encore d'évaluation

- Unit 1:basic of Software TestingDocument32 pagesUnit 1:basic of Software TestingMayur NarsalePas encore d'évaluation

- Commissioning and Qualification From TraditionalDocument28 pagesCommissioning and Qualification From TraditionalCarlos Herrera ArenasPas encore d'évaluation

- 4 Common Misconceptions About Product Inspection ServicesDocument6 pages4 Common Misconceptions About Product Inspection ServicesAevin LuoPas encore d'évaluation

- Tuv Rheinland Retail Services Postcard enDocument2 pagesTuv Rheinland Retail Services Postcard en石茂林Pas encore d'évaluation

- SQAT - Question BankDocument21 pagesSQAT - Question BankmalathiPas encore d'évaluation

- 1,2&3 SQandSQADocument25 pages1,2&3 SQandSQASandy CyrusPas encore d'évaluation

- A Simple Guide To Product Certification StaticDocument1 pageA Simple Guide To Product Certification StaticJessica Ballarta PérezPas encore d'évaluation

- Apply Quality StandardsDocument41 pagesApply Quality StandardsMher RiveroPas encore d'évaluation

- Unit4 QualityAssuranceDocument26 pagesUnit4 QualityAssurancekenmagcuyaoPas encore d'évaluation

- Agile Quality Assurance: Deliver Quality Software- Providing Great Business ValueD'EverandAgile Quality Assurance: Deliver Quality Software- Providing Great Business ValuePas encore d'évaluation

- The IT Manager’s Guide to Continuous Delivery: Delivering Software in DaysD'EverandThe IT Manager’s Guide to Continuous Delivery: Delivering Software in DaysPas encore d'évaluation

- Advance Injection Mould Split DesignDocument175 pagesAdvance Injection Mould Split DesignAkash SinghPas encore d'évaluation

- Iso 2768-1: 1989Document7 pagesIso 2768-1: 1989jferreiraPas encore d'évaluation

- Iso 2768 1Document7 pagesIso 2768 1Gary Ren100% (2)

- High Gate - Hot RunnerDocument2 pagesHigh Gate - Hot RunnerSelvaraj BalasundramPas encore d'évaluation

- INTRODUCTION TO THE TRIZ INVENTIVE PROBLEM SOLVING PROCESS - Excellent 1Document162 pagesINTRODUCTION TO THE TRIZ INVENTIVE PROBLEM SOLVING PROCESS - Excellent 1Selvaraj BalasundramPas encore d'évaluation

- INTRODUCTION TO THE TRIZ INVENTIVE PROBLEM SOLVING PROCESS - Excellent 1Document162 pagesINTRODUCTION TO THE TRIZ INVENTIVE PROBLEM SOLVING PROCESS - Excellent 1Selvaraj BalasundramPas encore d'évaluation

- Color in Plastic Parts Part 3Document3 pagesColor in Plastic Parts Part 3Nitin PatilPas encore d'évaluation

- Troubleshooting: Injection Molding Seven Steps Toward Scientific TroubleshootingDocument5 pagesTroubleshooting: Injection Molding Seven Steps Toward Scientific TroubleshootingSelvaraj BalasundramPas encore d'évaluation

- Statistical Tolerance AnalysisDocument2 pagesStatistical Tolerance AnalysisSelvaraj BalasundramPas encore d'évaluation

- Tool Steel SelectionDocument11 pagesTool Steel SelectionSelvaraj BalasundramPas encore d'évaluation

- Measuring Internal Stress Using Polarised LightDocument5 pagesMeasuring Internal Stress Using Polarised LightSelvaraj BalasundramPas encore d'évaluation

- Measuring Internal Stress Using Polarised LightDocument5 pagesMeasuring Internal Stress Using Polarised LightSelvaraj BalasundramPas encore d'évaluation

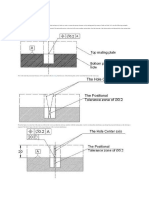

- What Is Projected Tolerance ZoneDocument2 pagesWhat Is Projected Tolerance ZoneSelvaraj BalasundramPas encore d'évaluation

- PC materials guide for injection moldingDocument1 pagePC materials guide for injection moldingSelvaraj BalasundramPas encore d'évaluation

- How To Get Better MFI ResultsDocument5 pagesHow To Get Better MFI ResultsSelvaraj BalasundramPas encore d'évaluation

- CZ - Common ZoneDocument1 pageCZ - Common ZoneSelvaraj BalasundramPas encore d'évaluation

- How Nestle Fought Back - Business News Aug 2016Document9 pagesHow Nestle Fought Back - Business News Aug 2016Selvaraj BalasundramPas encore d'évaluation

- How To PERSUADE Your BossDocument8 pagesHow To PERSUADE Your BossSelvaraj BalasundramPas encore d'évaluation

- GD&T Guide Symbols TermsDocument6 pagesGD&T Guide Symbols TermsvasantPas encore d'évaluation

- Implement TPM Successfully for Increased ProductivityDocument6 pagesImplement TPM Successfully for Increased ProductivitySelvaraj BalasundramPas encore d'évaluation

- 5 Steps To GDT ApplicationDocument4 pages5 Steps To GDT ApplicationSelvaraj BalasundramPas encore d'évaluation

- Six Steps To Condition Based Maintenance - GoodDocument3 pagesSix Steps To Condition Based Maintenance - GoodSelvaraj BalasundramPas encore d'évaluation

- 8 Steps To Ensure PDM Success - Excellent - Not Taken Yet !!!Document5 pages8 Steps To Ensure PDM Success - Excellent - Not Taken Yet !!!Selvaraj BalasundramPas encore d'évaluation

- GD&T Guide Symbols TermsDocument6 pagesGD&T Guide Symbols TermsvasantPas encore d'évaluation

- 4 Obstacles to Effective Predictive Maintenance ProgramsDocument3 pages4 Obstacles to Effective Predictive Maintenance ProgramsSelvaraj BalasundramPas encore d'évaluation

- A Letter On Good and Bad Kaizen Practices - TakenDocument5 pagesA Letter On Good and Bad Kaizen Practices - TakenSelvaraj BalasundramPas encore d'évaluation

- Tutorials - 1st Angle Vs 3rd AngleDocument6 pagesTutorials - 1st Angle Vs 3rd AngleSelvaraj BalasundramPas encore d'évaluation

- Conference Call TipsDocument7 pagesConference Call TipsSelvaraj BalasundramPas encore d'évaluation

- Productivity A Better Way From Stratex HubDocument17 pagesProductivity A Better Way From Stratex HubSelvaraj BalasundramPas encore d'évaluation

- Educating The PosthumanDocument50 pagesEducating The PosthumanCatherine BrugelPas encore d'évaluation

- WP1019 CharterDocument5 pagesWP1019 CharternocnexPas encore d'évaluation

- Cognitive Clusters in SpecificDocument11 pagesCognitive Clusters in SpecificKarel GuevaraPas encore d'évaluation

- Balajit Nath Pandita-Specific Principles of Kashmir Saivism-Munshiram Manoharlal Publishers (1998) PDFDocument228 pagesBalajit Nath Pandita-Specific Principles of Kashmir Saivism-Munshiram Manoharlal Publishers (1998) PDFvramaniitkPas encore d'évaluation

- Linear Programming Models: Graphical and Computer MethodsDocument91 pagesLinear Programming Models: Graphical and Computer MethodsFaith Reyna TanPas encore d'évaluation

- What Are Your Observations or Generalizations On How Text/ and or Images Are Presented?Document2 pagesWhat Are Your Observations or Generalizations On How Text/ and or Images Are Presented?Darlene PanisaPas encore d'évaluation

- LaQshya Labour Room Quality Improvement InitiativeDocument2 pagesLaQshya Labour Room Quality Improvement InitiativeHimanshu SharmaPas encore d'évaluation

- Case Briefing and Case SynthesisDocument3 pagesCase Briefing and Case SynthesisKai RaguindinPas encore d'évaluation

- 2021.01.28 - Price Variation of Steel Items - SAIL Ex-Works Prices of Steel - RB-CivilDocument2 pages2021.01.28 - Price Variation of Steel Items - SAIL Ex-Works Prices of Steel - RB-CivilSaugata HalderPas encore d'évaluation

- Assessing Student Learning OutcomesDocument20 pagesAssessing Student Learning Outcomesapi-619738021Pas encore d'évaluation

- معامل الاسفلتDocument32 pagesمعامل الاسفلتMohammed AbbasPas encore d'évaluation

- Motor Electrico Bojin J4103 - B User ManualDocument6 pagesMotor Electrico Bojin J4103 - B User ManualJordan BonnettPas encore d'évaluation

- Picco Tac 1095 N Hydrocarbon ResinDocument2 pagesPicco Tac 1095 N Hydrocarbon ResindevanandamqaPas encore d'évaluation

- Analogue Lab Manual AL7212 V2.1-Panduan Praktek DSR Elektronika-DikonversiDocument235 pagesAnalogue Lab Manual AL7212 V2.1-Panduan Praktek DSR Elektronika-DikonversiAl-FarabiPas encore d'évaluation

- Vivaldi - Genuis of BaroqueDocument279 pagesVivaldi - Genuis of Baroqueilcanto100% (4)

- Open MPDocument30 pagesOpen MPmacngocthanPas encore d'évaluation

- Gabriel Nobre de Souza - Groningen Mini-MetropolisDocument9 pagesGabriel Nobre de Souza - Groningen Mini-MetropolisGabrielNobredeSouzaPas encore d'évaluation

- Auerbach Slideshow How To Write A ParagraphDocument22 pagesAuerbach Slideshow How To Write A ParagraphFreakmaggotPas encore d'évaluation

- Semi Detailed Lesson Plan ElementaryDocument3 pagesSemi Detailed Lesson Plan ElementaryJinky JunioPas encore d'évaluation

- 60Hz Axial-Fan Centrifugal-Fan AC EN (2009) PDFDocument136 pages60Hz Axial-Fan Centrifugal-Fan AC EN (2009) PDFRodrigo GonçalvesPas encore d'évaluation

- ENVPEP1412003Document5 pagesENVPEP1412003south adventurePas encore d'évaluation

- Karan Chawla and Joshua Lee November 21, 2016 MEDS 3020 - Fall 2016 Dr. Rosevear, Dr. Cartwright, Dr. LiebermanDocument2 pagesKaran Chawla and Joshua Lee November 21, 2016 MEDS 3020 - Fall 2016 Dr. Rosevear, Dr. Cartwright, Dr. LiebermanJeremy DelaneyPas encore d'évaluation

- Soil Testing Lab Results SummaryDocument2 pagesSoil Testing Lab Results SummaryMd SohagPas encore d'évaluation

- 1HMEE5013 Exam Q JAN2017 S14Document5 pages1HMEE5013 Exam Q JAN2017 S14kumar6125100% (1)

- Key Elements of Participation and Conflict Resolution in a DemocracyDocument6 pagesKey Elements of Participation and Conflict Resolution in a DemocracyAbhinayPas encore d'évaluation

- ZJJ 3Document23 pagesZJJ 3jananiwimukthiPas encore d'évaluation

- Linear Piston Actuators: by Sekhar Samy, CCI, and Dave Stemler, CCIDocument18 pagesLinear Piston Actuators: by Sekhar Samy, CCI, and Dave Stemler, CCIapi-3854910Pas encore d'évaluation

- Solwezi General Mental Health TeamDocument35 pagesSolwezi General Mental Health TeamHumphreyPas encore d'évaluation

- Argenti, P. Corporate Communication. Cap. 8-9Document28 pagesArgenti, P. Corporate Communication. Cap. 8-9juan100% (1)

- Adjutant-Introuvable BASIC VERSIONDocument7 pagesAdjutant-Introuvable BASIC VERSIONfurrypdfPas encore d'évaluation