Académique Documents

Professionnel Documents

Culture Documents

Engineermind.com

Transféré par

Erwiyan Fajar AnsoriCopyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Engineermind.com

Transféré par

Erwiyan Fajar AnsoriDroits d'auteur :

Formats disponibles

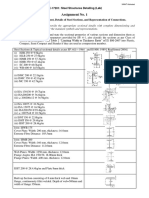

ISO 2553:2013(E)

Table 3 — Supplementary symbols

No. Designation Symbola Application examplea Illustration of weld

Flat-finished

1

flushb

2 Convexb

3 Concaveb

Toes blended

4 No example

smoothlyc

a) Back rund

(made after the

single-V butt

weld)

5

b) Backing weldd

(made before

the single-V butt

weld)

Specified root

6 reinforcement

(butt welds)e

Backing (unspeci-

7a

fied)

Permanent back-

7b

ing f

Removable/tem-

7c

porary backing f

8 Spacer

a The grey line is not part of the symbol and is included to show the position of symbol on reference line and/or the arrow

line only.

b Welds that require approximately flush or convex faces without post weld finishing are specified by use of the flush or

convex contour symbol.

Welds to be finished flush or convex by post weld finishing or that require a flat but not flush surface require additional

information, e.g. addition of a note in the tail of the welding symbol

Other symbols in accordance with ISO 1302 may be used to specify surface finish.

c The toes shall be blended smoothly by welding or finishing. Processing details may be specified in the work instructions

or WPS.

d The weld run sequence may be indicated on the drawing e.g. by use of multiple reference lines, a note in the tail or by

reference to a weld procedure specification.

e In system B, also used to designate flanged butt/corner welds (see 4.5.5.6)

f M = material to be part of the final welded joint, MR = material to be removed after welding. Further information on the

material can be included in the tail or elsewhere.

g Explanations of a, z, n, l and (e) are given in Clause 5.

10 © ISO 2013 – All rights reserved

ISO 2553:2013(E)

Table 3 (continued)

No. Designation Symbola Application examplea Illustration of weld

a) Joint showing insert in place

Consumable

9

insert

b) Welded joint showing root

bead (insert incorporated into

root). Single V but weld not

shown

Example A

10 Weld all-around

Example B

Example C

a The grey line is not part of the symbol and is included to show the position of symbol on reference line and/or the arrow

line only.

b Welds that require approximately flush or convex faces without post weld finishing are specified by use of the flush or

convex contour symbol.

Welds to be finished flush or convex by post weld finishing or that require a flat but not flush surface require additional

information, e.g. addition of a note in the tail of the welding symbol

Other symbols in accordance with ISO 1302 may be used to specify surface finish.

c The toes shall be blended smoothly by welding or finishing. Processing details may be specified in the work instructions

or WPS.

d The weld run sequence may be indicated on the drawing e.g. by use of multiple reference lines, a note in the tail or by

reference to a weld procedure specification.

e In system B, also used to designate flanged butt/corner welds (see 4.5.5.6)

f M = material to be part of the final welded joint, MR = material to be removed after welding. Further information on the

material can be included in the tail or elsewhere.

g Explanations of a, z, n, l and (e) are given in Clause 5.

© ISO 2013 – All rights reserved 11

ISO 2553:2013(E)

Table 3 (continued)

No. Designation Symbola Application examplea Illustration of weld

Weld between

11

two points

12 Field weld No example

Staggered inter-

13 Or

mittent weldsg

a The grey line is not part of the symbol and is included to show the position of symbol on reference line and/or the arrow

line only.

b Welds that require approximately flush or convex faces without post weld finishing are specified by use of the flush or

convex contour symbol.

Welds to be finished flush or convex by post weld finishing or that require a flat but not flush surface require additional

information, e.g. addition of a note in the tail of the welding symbol

Other symbols in accordance with ISO 1302 may be used to specify surface finish.

c The toes shall be blended smoothly by welding or finishing. Processing details may be specified in the work instructions

or WPS.

d The weld run sequence may be indicated on the drawing e.g. by use of multiple reference lines, a note in the tail or by

reference to a weld procedure specification.

e In system B, also used to designate flanged butt/corner welds (see 4.5.5.6)

f M = material to be part of the final welded joint, MR = material to be removed after welding. Further information on the

material can be included in the tail or elsewhere.

g Explanations of a, z, n, l and (e) are given in Clause 5.

4.5.2 Weld all-around symbol

The weld all-around symbol, added at the junction of the arrow and reference lines, may be used to designate

a continuous weld, single or double-sided, extending around a series of connected joints (see Table 3).

The series of joints may involve different directions and may lie in more than one plane but the weld

shall always be of the same type and dimensions.

The weld all-around symbol shall not be used if:

a) the weld does not start and end at the same point, i.e. it is not continuous;

b) the weld type changes, for example from a fillet weld to a butt weld;

c) the dimensions change, for example the nominal throat thickness of a fillet weld. In this case, each

weld shall be identified using a separate welding symbol;

NOTE The weld all-around symbol is not used to indicate that welds are to be made everywhere.

12 © ISO 2013 – All rights reserved

Vous aimerez peut-être aussi

- Cswip - Section 09-Welding SymbolsDocument14 pagesCswip - Section 09-Welding SymbolsNsidibe Michael Etim100% (1)

- Welding symbols and standards quizDocument3 pagesWelding symbols and standards quizrinhycra100% (1)

- 08 Welding Symbols 30-03-07 - NoRestrictionDocument14 pages08 Welding Symbols 30-03-07 - NoRestrictionMohammed ShaffiPas encore d'évaluation

- Simboluri SudareDocument8 pagesSimboluri SudarecornelutsPas encore d'évaluation

- Welding SymbolsDocument13 pagesWelding Symbolsm_ilahi9296100% (1)

- Multiple Choice 9 Welding SymbolDocument3 pagesMultiple Choice 9 Welding SymbolPradeepPas encore d'évaluation

- Welding SymbolsDocument8 pagesWelding SymbolsSantosh Kumar100% (1)

- ti!?eSS: For Symmetrical Welds OnlyDocument1 pageti!?eSS: For Symmetrical Welds OnlySvapneshPas encore d'évaluation

- Welding SymbolsDocument16 pagesWelding Symbolspurab gusainPas encore d'évaluation

- A Review of The Application of Weld Symbols On Drawings - Part 2 - Job Knowledge 65Document5 pagesA Review of The Application of Weld Symbols On Drawings - Part 2 - Job Knowledge 65tuanPas encore d'évaluation

- Basic Requirements WeldingDocument7 pagesBasic Requirements Weldingbrpnaidu2157100% (1)

- Q2-03, Smaw Teacher's Made LMTDocument6 pagesQ2-03, Smaw Teacher's Made LMTFelix MilanPas encore d'évaluation

- 9 Welding SymbolsDocument15 pages9 Welding SymbolsSampath KumarPas encore d'évaluation

- Weld SymbolsDocument14 pagesWeld SymbolsSureshraaviPas encore d'évaluation

- 13 Symbols DrawingsDocument13 pages13 Symbols DrawingsAlie AlbantaniPas encore d'évaluation

- PART 08 SYMBOLS AND WELDING PROCESSESDocument9 pagesPART 08 SYMBOLS AND WELDING PROCESSESRohit MalhotraPas encore d'évaluation

- Lesson 6 - Weld SymbolsDocument6 pagesLesson 6 - Weld SymbolsMidhun K Chandrabose100% (1)

- 4 Welding Symbols 2: Fillet and Edge Welds, Backing Run or Weld, Flare Groove and Bevel Welds, and Plug or Slot WeldDocument2 pages4 Welding Symbols 2: Fillet and Edge Welds, Backing Run or Weld, Flare Groove and Bevel Welds, and Plug or Slot WeldEdo DestradaPas encore d'évaluation

- M1 - 2 Welding Symbols and DrawingsDocument13 pagesM1 - 2 Welding Symbols and DrawingsGiurcanas AndreiPas encore d'évaluation

- Welding SymbolsDocument8 pagesWelding SymbolsRaoFarhan100% (1)

- Advanced welding symbols guideDocument28 pagesAdvanced welding symbols guideMark D VillanuevaPas encore d'évaluation

- New Microsoft Office Word DocumentDocument9 pagesNew Microsoft Office Word DocumentKhalid PerwezPas encore d'évaluation

- Weld SymbolsDocument8 pagesWeld SymbolsM.IBRAHEEMPas encore d'évaluation

- Symbol of Weld PDFDocument28 pagesSymbol of Weld PDFSyarif IrwantoPas encore d'évaluation

- Welded Joint Symbols Guide (BS EN 22553Document8 pagesWelded Joint Symbols Guide (BS EN 22553tudorteu100% (1)

- Welding Symbol B231013Document29 pagesWelding Symbol B231013Dwi DarsonoPas encore d'évaluation

- M1 - 2 Welding Symbols and DrawingsDocument13 pagesM1 - 2 Welding Symbols and DrawingsmullanjiPas encore d'évaluation

- BS 499 PT2-1980Document23 pagesBS 499 PT2-1980Krishna KumarPas encore d'évaluation

- (Doi 10.1016 - b978-0-408-00078-9.50014-8) JONES, E.J.H. - Production Engineering - Jig and Fixture Details PDFDocument9 pages(Doi 10.1016 - b978-0-408-00078-9.50014-8) JONES, E.J.H. - Production Engineering - Jig and Fixture Details PDFAsep SaepullohPas encore d'évaluation

- Advandced Welding SymbolsDocument24 pagesAdvandced Welding Symbolswvandamme100% (1)

- Smaw 9 Q3 W6-7Document6 pagesSmaw 9 Q3 W6-7Words Wero MascarinasPas encore d'évaluation

- A Brief Synopsis ofDocument54 pagesA Brief Synopsis ofNO ONEPas encore d'évaluation

- American Welding Society (AWS)Document26 pagesAmerican Welding Society (AWS)ramprakash202Pas encore d'évaluation

- Advanced Welding SymbolsDocument28 pagesAdvanced Welding SymbolsПМ ДитсPas encore d'évaluation

- Welded Joint Types and SymbolsDocument10 pagesWelded Joint Types and SymbolsShaina MusaPas encore d'évaluation

- Welded Joint Types and SymbolsDocument8 pagesWelded Joint Types and SymbolssameertamboliPas encore d'évaluation

- Ut-Soldadura simbolosDocument5 pagesUt-Soldadura simbolosluisescamilla.oviaraPas encore d'évaluation

- Welding Symbols: A Useful System or Undecipherable Hieroglyphics?Document7 pagesWelding Symbols: A Useful System or Undecipherable Hieroglyphics?Lahiru Prabhatha AmarasenaPas encore d'évaluation

- Welding symbols 1 guide to butt/groove welds and symbolsDocument3 pagesWelding symbols 1 guide to butt/groove welds and symbolsEdo DestradaPas encore d'évaluation

- Assignment No 1Document5 pagesAssignment No 1RitikPas encore d'évaluation

- Smaw-12 Q1 Week5-6Document9 pagesSmaw-12 Q1 Week5-6Normina ibrahimPas encore d'évaluation

- 9 Basic Steps To Reading Welding Symbols For Groove WeldsDocument6 pages9 Basic Steps To Reading Welding Symbols For Groove WeldsArnelson DerechoPas encore d'évaluation

- Aisc Tablas 8Document34 pagesAisc Tablas 8Juan Carlos Espinosa CoronaPas encore d'évaluation

- Part 05riskd EN ISO 2553 2014Document13 pagesPart 05riskd EN ISO 2553 2014Davorin IvićPas encore d'évaluation

- Welding SymbolsDocument9 pagesWelding Symbolsjojo_323100% (3)

- B231013-Welding SymbolDocument29 pagesB231013-Welding SymbolAsep DarojatPas encore d'évaluation

- Weld Symbols-2Document4 pagesWeld Symbols-2SatyaPas encore d'évaluation

- WELDING SYMBOL GUIDEDocument40 pagesWELDING SYMBOL GUIDETITUS YUSUFPas encore d'évaluation

- BS Weld SymbolsDocument6 pagesBS Weld SymbolsPham Duc HoaPas encore d'évaluation

- TWI Cswip 3.1wis 5 Welding Inspection Welding Symbols BSEN ISO 22553 /AWS A2Document68 pagesTWI Cswip 3.1wis 5 Welding Inspection Welding Symbols BSEN ISO 22553 /AWS A2Ali ClubistPas encore d'évaluation

- Simboluri SuduriDocument32 pagesSimboluri SuduriGabriel MateiPas encore d'évaluation

- Electro-Motive Standard Welding Symbols AI01046Document9 pagesElectro-Motive Standard Welding Symbols AI01046eraman_mePas encore d'évaluation

- NEWREVB-lecture-welding Symbols-To Drawing-Vis3100Document86 pagesNEWREVB-lecture-welding Symbols-To Drawing-Vis3100krishnaPas encore d'évaluation

- Everything You Need to Know About Welding SymbolsDocument32 pagesEverything You Need to Know About Welding Symbolsnzc_laurPas encore d'évaluation

- 9 Welding SymbolsDocument41 pages9 Welding SymbolsPraviBeetlesPas encore d'évaluation

- Structural Steel Design to Eurocode 3 and AISC SpecificationsD'EverandStructural Steel Design to Eurocode 3 and AISC SpecificationsPas encore d'évaluation

- Composite Structures of Steel and Concrete: Beams, Slabs, Columns and Frames for BuildingsD'EverandComposite Structures of Steel and Concrete: Beams, Slabs, Columns and Frames for BuildingsPas encore d'évaluation

- The Fracture of Brittle Materials: Testing and AnalysisD'EverandThe Fracture of Brittle Materials: Testing and AnalysisPas encore d'évaluation

- En13445-2 V35Document90 pagesEn13445-2 V35Kostas Menagias100% (2)

- Welding Symbol Guide (ISO 2553Document32 pagesWelding Symbol Guide (ISO 2553Marcelo CunhaPas encore d'évaluation

- Perhitungan Struktur TangkiDocument12 pagesPerhitungan Struktur TangkiNelson Panjaitan100% (1)

- Perhitungan Struktur TangkiDocument12 pagesPerhitungan Struktur TangkiNelson Panjaitan100% (1)

- Welding Symbol Guide (ISO 2553Document32 pagesWelding Symbol Guide (ISO 2553Marcelo CunhaPas encore d'évaluation

- Wireshark Lab: 802.11: Approach, 6 Ed., J.F. Kurose and K.W. RossDocument5 pagesWireshark Lab: 802.11: Approach, 6 Ed., J.F. Kurose and K.W. RossN Azzati LabibahPas encore d'évaluation

- A&F Method OfInspectionDocument26 pagesA&F Method OfInspectionzoomerfins22100% (1)

- 2017 Advanced Computer Networks Homework 1Document6 pages2017 Advanced Computer Networks Homework 1Fadhli RahimPas encore d'évaluation

- Acuite-India Credit Risk Yearbook FinalDocument70 pagesAcuite-India Credit Risk Yearbook FinalDinesh RupaniPas encore d'évaluation

- Data Science Machine LearningDocument15 pagesData Science Machine LearningmagrinraphaelPas encore d'évaluation

- VVIP Circuit House achieves 5-star GRIHA ratingDocument1 pageVVIP Circuit House achieves 5-star GRIHA ratingmallikaPas encore d'évaluation

- Mr. Arshad Nazer: Bawshar, Sultanate of OmanDocument2 pagesMr. Arshad Nazer: Bawshar, Sultanate of OmanTop GPas encore d'évaluation

- Swilliams Lesson6Document11 pagesSwilliams Lesson6api-276783092Pas encore d'évaluation

- MS For The Access Control System Installation and TerminationDocument21 pagesMS For The Access Control System Installation and Terminationwaaji snapPas encore d'évaluation

- Kinetics of Acetone Hydrogenation For Synthesis of Isopropyl Alcohol Over Cu-Al Mixed Oxide CatalystsDocument9 pagesKinetics of Acetone Hydrogenation For Synthesis of Isopropyl Alcohol Over Cu-Al Mixed Oxide Catalysts李国俊Pas encore d'évaluation

- Understanding Nominal Pipe Sizes (NPS) and Pipe DimensionsDocument39 pagesUnderstanding Nominal Pipe Sizes (NPS) and Pipe DimensionsprathikPas encore d'évaluation

- Norlys 2016Document124 pagesNorlys 2016elektrospecPas encore d'évaluation

- Py Py y Py Y: The Second-Order Taylor Approximation GivesDocument4 pagesPy Py y Py Y: The Second-Order Taylor Approximation GivesBeka GurgenidzePas encore d'évaluation

- Duratone eDocument1 pageDuratone eandreinalicPas encore d'évaluation

- Lecture Notes in Airport Engineering PDFDocument91 pagesLecture Notes in Airport Engineering PDFMaya RajPas encore d'évaluation

- MODEL QUESTION PAPER OF HRM Open CourceDocument2 pagesMODEL QUESTION PAPER OF HRM Open CourceTitus Clement100% (3)

- Financial Market and Portfolio Management Assignment 2Document6 pagesFinancial Market and Portfolio Management Assignment 2leeroy mekiPas encore d'évaluation

- Optimization TheoryDocument18 pagesOptimization TheoryDivine Ada PicarPas encore d'évaluation

- An - APX18 206516L CT0Document2 pagesAn - APX18 206516L CT0Maria MartinsPas encore d'évaluation

- Project 863 EvidenceDocument5 pagesProject 863 EvidenceMilan TolhuisenPas encore d'évaluation

- CS547Document11 pagesCS547Usman Suleman AhmadPas encore d'évaluation

- Parts 3121106 1-2-12 ANSI EnglishDocument246 pagesParts 3121106 1-2-12 ANSI EnglishAndres JimenezPas encore d'évaluation

- Research On Ignorance of The Law Excuses No One From ComplianceDocument12 pagesResearch On Ignorance of The Law Excuses No One From ComplianceAnonymous iOYkz0wPas encore d'évaluation

- Regulations 2020: Mechanical Engineering CurriculumDocument162 pagesRegulations 2020: Mechanical Engineering CurriculumdsathiyaPas encore d'évaluation

- EG3000 ManualDocument7 pagesEG3000 ManualJose Armando Perez AcostaPas encore d'évaluation

- What is Software Development Life Cycle (SDLC)? Key Phases and ActivitiesDocument11 pagesWhat is Software Development Life Cycle (SDLC)? Key Phases and ActivitiessachinPas encore d'évaluation

- Indian companies involved in trade dispute caseDocument15 pagesIndian companies involved in trade dispute caseakshay daymaPas encore d'évaluation

- Elasticity of DemandDocument64 pagesElasticity of DemandWadOod KhAn100% (1)

- Sonydsp v77 SM 479622 PDFDocument41 pagesSonydsp v77 SM 479622 PDFmorvetrPas encore d'évaluation

- LL Baby Carrier Corner Drool Pads TutorialDocument9 pagesLL Baby Carrier Corner Drool Pads TutorialBryan DerryPas encore d'évaluation