Académique Documents

Professionnel Documents

Culture Documents

Troubleshooting: Injection Molding Seven Steps Toward Scientific Troubleshooting

Transféré par

Selvaraj Balasundram0 évaluation0% ont trouvé ce document utile (0 vote)

25 vues5 pagesThe document outlines seven steps for scientific troubleshooting of injection molding processes:

1. Establish a scientific process through decoupled molding or intelligent molding to reduce variability. Document process outputs like temperature and weight.

2. Compare current process outputs to documented standards when defects occur. Check parameters related to the defect.

3. Make changes to return deviated parameters to documented standards in order to fix the defect and return the process to a stable state.

4. Verify that parts and process conform to standards after the process is adjusted. Document all changes made for future reference.

Description originale:

Injection Molding

Titre original

Troubleshooting Steps

Copyright

© © All Rights Reserved

Formats disponibles

DOCX, PDF, TXT ou lisez en ligne sur Scribd

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentThe document outlines seven steps for scientific troubleshooting of injection molding processes:

1. Establish a scientific process through decoupled molding or intelligent molding to reduce variability. Document process outputs like temperature and weight.

2. Compare current process outputs to documented standards when defects occur. Check parameters related to the defect.

3. Make changes to return deviated parameters to documented standards in order to fix the defect and return the process to a stable state.

4. Verify that parts and process conform to standards after the process is adjusted. Document all changes made for future reference.

Droits d'auteur :

© All Rights Reserved

Formats disponibles

Téléchargez comme DOCX, PDF, TXT ou lisez en ligne sur Scribd

0 évaluation0% ont trouvé ce document utile (0 vote)

25 vues5 pagesTroubleshooting: Injection Molding Seven Steps Toward Scientific Troubleshooting

Transféré par

Selvaraj BalasundramThe document outlines seven steps for scientific troubleshooting of injection molding processes:

1. Establish a scientific process through decoupled molding or intelligent molding to reduce variability. Document process outputs like temperature and weight.

2. Compare current process outputs to documented standards when defects occur. Check parameters related to the defect.

3. Make changes to return deviated parameters to documented standards in order to fix the defect and return the process to a stable state.

4. Verify that parts and process conform to standards after the process is adjusted. Document all changes made for future reference.

Droits d'auteur :

© All Rights Reserved

Formats disponibles

Téléchargez comme DOCX, PDF, TXT ou lisez en ligne sur Scribd

Vous êtes sur la page 1sur 5

Troubleshooting: Injection Molding Seven Steps

Toward Scientific Troubleshooting

A scientific troubleshooter is not someone who pushes

buttons faster or has more tricks up his or her sleeve.

Click Image to Enlarge

All troubleshooters must document the process. A trail of documentation, beginning

when the process was established and approved, that continues to build as the

process is adjusted, creates a portfolio of information to draw upon when trouble

arises.

With accurate knowledge about which processing parameters have changed, the

scientific troubleshooter can begin to make changes to return the process outputs to

the documented standard.

The scientific troubleshooter documents the process outputs, such as melt

temperature, when acceptable parts are produced.

A scientific troubleshooter is not someone who pushes buttons

faster or has more tricks up his or her sleeve. Rather, a scientific

troubleshooter knows the history of a properly documented process,

makes each adjustment based on knowledge, and verifies and

documents the result of each change.

Good troubleshooting does not begin when a non-conformance

occurs. It starts prior to first-piece-approval. If you are more of a

traditional troubleshooter—one who has little use for process

documentation, makes adjustments based on learned behavior, and

does not verify the effectiveness of each change—you might want

to adjust your approach. Here are seven steps to get you going:

STEP 1—SCIENTIFIC MOLDING

Merriam-Webster defines science as “the state of knowing.” The

purpose of establishing a scientific process is to create the most

stable and reliable process possible, based on good fundamental

knowledge of the mold, machine, material, and process.

You are likely familiar by now with terms such as “Decoupled

Molding,” “Intelligent Molding,” or “Scientific Molding.” To demystify

these terms: Each methodology applies to a process that separates

first-stage filling from second-stage packing by using a short-shot

during injection. In each case, the intent is to build a strong, reliable

process that best compensates for the inherent variability of plastics

and thus reduces the overall need for troubleshooting. Although

there are many factors that contribute to a good process, these

attributes are most common:

Filling: First-stage fill uses velocity control to inject with as few

velocity steps as possible. There must be adequate maximum

pressure to avoid a pressure-limited process. First-to-second

stage transfer should take place using screw position. The part

should have a visible short shot at this time.

Packing: Second-stage packing pressure should be high enough

to finish filling the mold cavity and compensate for material

shrinkage during cooling. This pressure is traditionally 50% to

75% of the pressure used during the first stage, though it can

drop as low as 25% for some thick parts and may exceed 100%

for many thin-walled parts. Second-stage packing time should be

determined by graphing part weight versus second-stage time.

The optimal second stage time is the time at which the part

weight does not increase with an increase in second-stage time.

Recovery: Screw delay or decompression must be used prior to

screw recovery to relieve the packing pressure. Screw recovery

should take approximately 80% of the cooling time. Screw

decompression must be used after recovery whenever a check

ring is used. For most screws, the optimal amount of

decompression is equal to the check-ring travel.

STEP 2—DOCUMENT PROCESS OUTPUTS

The traditional troubleshooter documents the process inputs, which

are machine-specific parameters that are entered into the machine.

The scientific troubleshooter documents the process outputs, which

are the results of the process when acceptable parts are produced.

Many of these parameters are the same as the process input, but

each of these parameters would be consistent from one machine to

another.

Examples of machine-independent process parameters include

melt temperature, coolant temperature entering and leaving the

mold, coolant flow, first-stage fill time, first-stage fill weight, second-

stage packing time, second-stage plastic pressure, gate-seal time,

cooling time, plastic backpressure, screw recovery time, overall

cycle time, final part weight, clamp tonnage, and dewpoint. You can

also document any important information such as photographs,

observations, and quality information.

STEP 3—RULE OUT OBVIOUS CAUSES

Once a non-conformance occurs, the first thing to do is to

thoroughly inspect the part to make sure that other defects are not

present. If any aspect of the process, mold, machine, or material is

obviously suspect, then this should be investigated first.

For example, let’s suppose a part may have flash. With only this

information, the traditional troubleshooter might investigate the

clamp tonnage, transfer position, packing pressure, or barrel

temperatures. Now, let’s assume further inspection by the scientific

troubleshooter, which determines that the part also has splay. With

this additional information, it may be possible to suppose that both

the flash and splay could be the result of moisture in the material.

STEP 4—ACTUAL VS. ‘IDEAL’ PROCESSES

Once obvious causes are ruled out, the next logical step is to

compare the current process with the documented standard. Since

a well-documented process contains a variety of parameters, it is

best to start by reviewing the parameters that most likely relate to

your defect. As you compare the documented standard to the

current process, you will determine which aspects of the process

have deviated from the standard. A scientific troubleshooter can

use this information to help make educated decisions about what

parameters need to be changed to bring the process back to the

documented standard.

For example, if the part is showing material degradation, you should

first compare actual vs. documented parameters such as melt

temperature, backpressure, and first-stage injection time. Likewise,

if flash, short shots, or sinks are present, it is best to turn off

second-stage packing to verify all the process outputs related to

injection such as first-stage fill time, first- stage fill weight, and

plastic pressure at transfer from first to second stage.

STEP 5—RETURN TO STANDARD PROCESS

With accurate knowledge about which processing parameters have

changed, the scientific troubleshooter can begin to make changes

to return the process outputs to the documented standard. Always

be careful of related process parameters. For example, if the first-

stage fill time is too high and the first-stage fill weight is too low,

then an increase in the injection speed may bring both parameters

back to the documented standard.

The goal here is not to just fix the defect, but to return the machine-

independent process outputs back to the documented standard.

When steps 1 and 2 are conducted properly, the scientific

troubleshooter has confidence that the parts will be acceptable

when the process is returned to the documented standard, if the

mold, machine, and material are behaving properly. This

troubleshooting method will also help the scientific troubleshooter to

quickly identify and isolate a problem with the equipment or

material.

STEP 6—VERIFY THE PART & PROCESS

After the parts are brought into conformance, it is best to ensure

that the part and process conform to the standard. This means the

scientific troubleshooter should take a few minutes to check each of

the parameters that are easy to verify. It may be impractical to

check every process output, but any information that is easily

obtained, such as first-stage fill time, first-stage fill weight, cycle

time, and cooling time, will help increase the confidence that the

process will remain stable and reliable over time.

STEP 7—DOCUMENT ALL CHANGES

This is one step any troubleshooter—scientific or traditional—

should take. A trail of documentation, beginning when the process

was established and approved, that continues to build as the

process is adjusted, creates a portfolio of information to draw upon

when trouble arises. A scientific troubleshooter should be able to

see the full history of the process, machine, and mold. For example,

if an employee on the first shift corrected the process by increasing

transfer position, this would be invaluable information for the

second-shift technician who encounters a defective part such as a

sink.

If a systematic approach to processing and documentation is used

when the process is established, a scientific troubleshooter will be

able to correct the problem in a relatively short time with a

significantly high degree of confidence. Ultimately, good

troubleshooting is just an extension of good processing. The more

effectively your technicians and engineers process and document

what they do, the more efficiently they will troubleshoot when non-

conformances occur.

Vous aimerez peut-être aussi

- Plastic Injection Mold Design ChecklistDocument2 pagesPlastic Injection Mold Design ChecklistSelvaraj Balasundram100% (1)

- Plastic Parts & Tooling Surface Finish - VDI 3400Document4 pagesPlastic Parts & Tooling Surface Finish - VDI 3400Selvaraj BalasundramPas encore d'évaluation

- MAN TGX D38 Broschuere D38 EN PDFDocument12 pagesMAN TGX D38 Broschuere D38 EN PDFMAN Truck & Bus AG100% (1)

- Longxi Machinery Works - Mar 4Document1 pageLongxi Machinery Works - Mar 4Liby SantosPas encore d'évaluation

- Process DevelopmentDocument8 pagesProcess DevelopmentJesus DanielPas encore d'évaluation

- Validating and Monitoring A Form-Fill-Seal Operation - Pharmaceutical & Medical Packaging NewsDocument3 pagesValidating and Monitoring A Form-Fill-Seal Operation - Pharmaceutical & Medical Packaging NewsJanna Hendrix BabsonPas encore d'évaluation

- GUIDE MQA 007 007 (Non Sterile Process Validation)Document9 pagesGUIDE MQA 007 007 (Non Sterile Process Validation)William ChandraPas encore d'évaluation

- Manned Space Flight, 1963Document89 pagesManned Space Flight, 1963Bob Andrepont100% (5)

- Selection of DOE Parameters in Injection Molding - Suhas Kulkarni FIMMTECH Inc PDFDocument8 pagesSelection of DOE Parameters in Injection Molding - Suhas Kulkarni FIMMTECH Inc PDFAnonymous fCp1HRwpPas encore d'évaluation

- Injection Molding - Why & How To Do Gate-Seal Experiments - Plastics TechnologyDocument4 pagesInjection Molding - Why & How To Do Gate-Seal Experiments - Plastics TechnologySandeep LeePas encore d'évaluation

- ME 554 Problem Set-05-Rocket Flight PerformanceDocument3 pagesME 554 Problem Set-05-Rocket Flight Performancerahul prakashPas encore d'évaluation

- Sounding RocketDocument16 pagesSounding RocketFrancesca LazzarottiPas encore d'évaluation

- C: P: D: Factory Acceptance Test Procedure For Control Valve C - D N .: - Ptcs D N .: FCS-SOP-001. R 01 S: 1 10Document13 pagesC: P: D: Factory Acceptance Test Procedure For Control Valve C - D N .: - Ptcs D N .: FCS-SOP-001. R 01 S: 1 10Hicham BelmaatiPas encore d'évaluation

- Mold ChecklistDocument5 pagesMold ChecklistSelvaraj BalasundramPas encore d'évaluation

- Rocket Lab Launch Payload Users Guide 6.5Document63 pagesRocket Lab Launch Payload Users Guide 6.5Atmozfears JosePas encore d'évaluation

- Die Casting Defects - Identification Causes and CuresDocument12 pagesDie Casting Defects - Identification Causes and CuresjosuecncPas encore d'évaluation

- 2845 Classic Collection TR-TN Estes Tech ReportsDocument46 pages2845 Classic Collection TR-TN Estes Tech Reportsns4gguyPas encore d'évaluation

- Mold Validation Procedure PartDocument16 pagesMold Validation Procedure PartGopinath Ve100% (2)

- Chemical Process Pilot Plants.Document5 pagesChemical Process Pilot Plants.saverrPas encore d'évaluation

- WT Training ManualDocument429 pagesWT Training Manualbilmard100% (4)

- Know How Technology Transfer 6c RZDocument4 pagesKnow How Technology Transfer 6c RZSaurabh VijPas encore d'évaluation

- Robustness Valdiation Step by StepDocument36 pagesRobustness Valdiation Step by StepGreenheart OussamaPas encore d'évaluation

- Valve Magazine Fall-2006 PSVs SizingDocument5 pagesValve Magazine Fall-2006 PSVs Sizingpiolinwalls100% (1)

- Inspection Inspection and Test Plan For Pressure Safety Valve and Test Plan For Pressure Safety ValveDocument4 pagesInspection Inspection and Test Plan For Pressure Safety Valve and Test Plan For Pressure Safety ValveTri Budiman Jabarti100% (1)

- Control Engineering For Chemical EngineersDocument11 pagesControl Engineering For Chemical EngineersYoga WiranotoPas encore d'évaluation

- Rubrics For Water Bottle Rocket ProjectDocument6 pagesRubrics For Water Bottle Rocket ProjectMelleme Dantes100% (3)

- Elgi Screw CompressorDocument12 pagesElgi Screw CompressorRAVINDER DHINGRAPas encore d'évaluation

- Chapter 7 Plant Layout SafetyDocument20 pagesChapter 7 Plant Layout SafetyaminPas encore d'évaluation

- CHAPTER 8 Hazop StudyDocument7 pagesCHAPTER 8 Hazop StudyNethiyaa50% (2)

- Prospective, Concurrent and Retrospective Validation-GOOD ARTICLEDocument8 pagesProspective, Concurrent and Retrospective Validation-GOOD ARTICLEraju1559405Pas encore d'évaluation

- 1 Pilot Plant PDFDocument16 pages1 Pilot Plant PDFSwapnil ParabPas encore d'évaluation

- Steps For Conducting GR&RDocument4 pagesSteps For Conducting GR&RSelvaraj BalasundramPas encore d'évaluation

- Validate A Packaging ProcessDocument3 pagesValidate A Packaging ProcessIndra D. WinarkoPas encore d'évaluation

- Wonderlic QuesDocument20 pagesWonderlic QuesCharu SharmaPas encore d'évaluation

- Yokogawa PID Tuning Guide - CsTunerDocument28 pagesYokogawa PID Tuning Guide - CsTunerZohaib Alam100% (2)

- Prevalidation Study of A Form-Fill-Seal Packaging Machine - Pharmaceutical & Medical Packaging NewsDocument3 pagesPrevalidation Study of A Form-Fill-Seal Packaging Machine - Pharmaceutical & Medical Packaging NewsJanna Hendrix BabsonPas encore d'évaluation

- Scale Up of Chemical ReactorsDocument51 pagesScale Up of Chemical ReactorsMilton MizrainPas encore d'évaluation

- Dimensional Analysis: Practical Guides in Chemical EngineeringD'EverandDimensional Analysis: Practical Guides in Chemical EngineeringPas encore d'évaluation

- Chapter 6 ControlDocument148 pagesChapter 6 Control.ılı.Govíиð ЯäJ.ılı.Pas encore d'évaluation

- A Scientific Troubleshooter Is Not Someone Who Pushes Buttons Faster or Has More Tricks Up His or Her SleeveDocument4 pagesA Scientific Troubleshooter Is Not Someone Who Pushes Buttons Faster or Has More Tricks Up His or Her SleeveArturo AguilarPas encore d'évaluation

- Strategies of Succesful Distillation Equipment Revamps PDFDocument6 pagesStrategies of Succesful Distillation Equipment Revamps PDFJose DavalilloPas encore d'évaluation

- Scientific Injection Molding: A Tool For Lean Manufacturing: by Frank Staples and Alpesh PatelDocument4 pagesScientific Injection Molding: A Tool For Lean Manufacturing: by Frank Staples and Alpesh PatelSofiaProtopsaltiPas encore d'évaluation

- 4 - Janela de ProcessoDocument4 pages4 - Janela de Processomario mowatPas encore d'évaluation

- Article Failure AnalysisDocument25 pagesArticle Failure AnalysisMd KalamuddinPas encore d'évaluation

- Mohd Khairul Azmi - PM - TUGASANDocument6 pagesMohd Khairul Azmi - PM - TUGASANSyafiz NawawiPas encore d'évaluation

- Approval of Calibration Certificates and Permissible Error Limits - A Process ApproachDocument4 pagesApproval of Calibration Certificates and Permissible Error Limits - A Process ApproachProvedor AnalistaPas encore d'évaluation

- Autoclave SimulationDocument9 pagesAutoclave SimulationRocío NapanPas encore d'évaluation

- Key Process Indicators-Falling Film EvaporatorsDocument20 pagesKey Process Indicators-Falling Film Evaporatorscgoveia3Pas encore d'évaluation

- Plant Design 101Document6 pagesPlant Design 101apiskaiPas encore d'évaluation

- Tell Me Why: Dennis C. HendershotDocument7 pagesTell Me Why: Dennis C. HendershotJie DengPas encore d'évaluation

- WP Online Safety Valve Testing 04.2008 PDFDocument10 pagesWP Online Safety Valve Testing 04.2008 PDFAntonio PerezPas encore d'évaluation

- A Rational, Step-Wise Approach To Process CharacterizationDocument16 pagesA Rational, Step-Wise Approach To Process CharacterizationgcbPas encore d'évaluation

- Eight Steps For Safer LockoutDocument3 pagesEight Steps For Safer LockoutsharathPas encore d'évaluation

- PHD Thesis Newcastle UniversityDocument5 pagesPHD Thesis Newcastle Universityrehyfnugg100% (2)

- Corrective Action David Russo Sep 2011Document24 pagesCorrective Action David Russo Sep 2011Sham AranPas encore d'évaluation

- Effective Troubleshooting of Extrusion ProblemsDocument11 pagesEffective Troubleshooting of Extrusion ProblemsAntonius PrakosaPas encore d'évaluation

- How To Improve Industrial Productivity With Loop CalibrationDocument6 pagesHow To Improve Industrial Productivity With Loop Calibrationابوالحروف العربي ابوالحروفPas encore d'évaluation

- Process Validation-Aseptic Process For Pharmaceuticals (June 1, 2003)Document24 pagesProcess Validation-Aseptic Process For Pharmaceuticals (June 1, 2003)อิอิ อิอิPas encore d'évaluation

- Eight Things You Should Know About Leak Testing EquipmentDocument2 pagesEight Things You Should Know About Leak Testing EquipmentCatalinPas encore d'évaluation

- Process Control Homework SolutionsDocument6 pagesProcess Control Homework Solutionsafmsqcodt100% (1)

- Outcome 1 Tutorial 1 - Plant Operations: UNIT 47: Engineering Plant TechnologyDocument6 pagesOutcome 1 Tutorial 1 - Plant Operations: UNIT 47: Engineering Plant TechnologyHakiimuddin ShaariPas encore d'évaluation

- ProcessDocument1 pageProcessShani RajaPas encore d'évaluation

- Intuition Operations Logbook Whitepaper PDFDocument8 pagesIntuition Operations Logbook Whitepaper PDFshakPas encore d'évaluation

- Quality & Productivity Journal: Technique Review - Short-Run SPCDocument3 pagesQuality & Productivity Journal: Technique Review - Short-Run SPCseetharamannPas encore d'évaluation

- Running The Operation: Chapter EightDocument10 pagesRunning The Operation: Chapter EightrambhadesiPas encore d'évaluation

- BAS As PAT BioPharmArticleDocument6 pagesBAS As PAT BioPharmArticleAmet koko TaroPas encore d'évaluation

- Syllabus QuestionDocument4 pagesSyllabus QuestionHdhd HdhhdPas encore d'évaluation

- Process Control for Sheet-Metal Stamping: Process Modeling, Controller Design and Shop-Floor ImplementationD'EverandProcess Control for Sheet-Metal Stamping: Process Modeling, Controller Design and Shop-Floor ImplementationPas encore d'évaluation

- Aeration Control System Design: A Practical Guide to Energy and Process OptimizationD'EverandAeration Control System Design: A Practical Guide to Energy and Process OptimizationPas encore d'évaluation

- Process Validation - IQ, OQ, PQDocument2 pagesProcess Validation - IQ, OQ, PQSelvaraj BalasundramPas encore d'évaluation

- Tool Steel SelectionDocument11 pagesTool Steel SelectionSelvaraj BalasundramPas encore d'évaluation

- CZ - Common ZoneDocument1 pageCZ - Common ZoneSelvaraj BalasundramPas encore d'évaluation

- PC MaterialsDocument1 pagePC MaterialsSelvaraj BalasundramPas encore d'évaluation

- TPM 8 PillarsDocument6 pagesTPM 8 PillarsSelvaraj BalasundramPas encore d'évaluation

- Eliminate These Obstacles Before You Implement Predictive Maintenance-GoodDocument3 pagesEliminate These Obstacles Before You Implement Predictive Maintenance-GoodSelvaraj BalasundramPas encore d'évaluation

- Productivity A Better Way From Stratex HubDocument17 pagesProductivity A Better Way From Stratex HubSelvaraj BalasundramPas encore d'évaluation

- Bonus Tolerance - Formula & ExamplesDocument2 pagesBonus Tolerance - Formula & ExamplesSelvaraj Balasundram100% (1)

- Statistical Tolerance AnalysisDocument2 pagesStatistical Tolerance AnalysisSelvaraj BalasundramPas encore d'évaluation

- 5 Steps To GDT ApplicationDocument4 pages5 Steps To GDT ApplicationSelvaraj BalasundramPas encore d'évaluation

- CZ - Common ZoneDocument1 pageCZ - Common ZoneSelvaraj BalasundramPas encore d'évaluation

- Conference Call TipsDocument7 pagesConference Call TipsSelvaraj BalasundramPas encore d'évaluation

- Critical Dimensions TolerancingDocument3 pagesCritical Dimensions TolerancingSelvaraj BalasundramPas encore d'évaluation

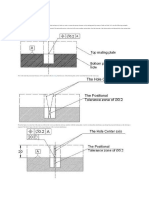

- What Is Projected Tolerance ZoneDocument2 pagesWhat Is Projected Tolerance ZoneSelvaraj BalasundramPas encore d'évaluation

- CZ - Common ZoneDocument1 pageCZ - Common ZoneSelvaraj BalasundramPas encore d'évaluation

- Gas Gun Dynamics: Home Search Collections Journals About Contact Us My IopscienceDocument11 pagesGas Gun Dynamics: Home Search Collections Journals About Contact Us My IopscienceGülden ÇİMENPas encore d'évaluation

- Aprendiz de TodoDocument19 pagesAprendiz de Todofabian lopezPas encore d'évaluation

- Chapter 5 - Launch Vehicle Guidance Present Scenario and Future TrendsDocument20 pagesChapter 5 - Launch Vehicle Guidance Present Scenario and Future TrendsAdrian ToaderPas encore d'évaluation

- Falcon9 Users Guide 2009Document70 pagesFalcon9 Users Guide 2009David Soto SedanoPas encore d'évaluation

- 2TP - Payload Planners Guide - Delta II PPG 2000Document323 pages2TP - Payload Planners Guide - Delta II PPG 2000Rafael F. BellottPas encore d'évaluation

- Rocket Staging and Need of Rocket BoostersDocument6 pagesRocket Staging and Need of Rocket BoostersJagannath Prasad SahooPas encore d'évaluation

- A258926 PDFDocument372 pagesA258926 PDFEsteban LoboPas encore d'évaluation

- Launching of Satellites: Expendable Launch VehiclesDocument4 pagesLaunching of Satellites: Expendable Launch VehiclesHARIPRASATH ECEPas encore d'évaluation

- FDNY Engine Ops Complete Updated and Issued 8-5-2021Document255 pagesFDNY Engine Ops Complete Updated and Issued 8-5-2021Adam ThimmigPas encore d'évaluation

- Transportation Research Part A: Ming-Miin Yu, Li-Hsueh ChenDocument22 pagesTransportation Research Part A: Ming-Miin Yu, Li-Hsueh ChenZen ZeePas encore d'évaluation

- Tsiolkovsky Rocket Equation - Wikipedia, The Free EncyclopediaDocument8 pagesTsiolkovsky Rocket Equation - Wikipedia, The Free Encyclopediamechmaster4uPas encore d'évaluation

- Shourya MissileDocument4 pagesShourya MissileGrapes als Priya100% (2)

- IBPS PO Preliminary Practice Set 3Document40 pagesIBPS PO Preliminary Practice Set 3Nive AdmiresPas encore d'évaluation

- Preliminary Sizing: Launch Vehicle MassDocument10 pagesPreliminary Sizing: Launch Vehicle Massa320neoPas encore d'évaluation

- Staging and Control of Rockets and Missiles - PritamashutoshDocument9 pagesStaging and Control of Rockets and Missiles - PritamashutoshUma MageshwariPas encore d'évaluation

- Continuous Percolation Rate Measurement in A Sugarcane DiffuserDocument18 pagesContinuous Percolation Rate Measurement in A Sugarcane DiffuserEverton CarpaneziPas encore d'évaluation

- VG B SFO-flyerDocument2 pagesVG B SFO-flyerMarko Altamirano DuranPas encore d'évaluation

- Improving The Process For Sizing Reciprocating CompressorsDocument7 pagesImproving The Process For Sizing Reciprocating CompressorsKong LingweiPas encore d'évaluation

- Variable Mass SystemDocument22 pagesVariable Mass SystemJack HydePas encore d'évaluation

- Team Gargatua ReportDocument50 pagesTeam Gargatua ReportGokulPas encore d'évaluation

- Notes On Lesson EC2045-SatelliteCommunicationDocument157 pagesNotes On Lesson EC2045-SatelliteCommunicationindumathyprabuPas encore d'évaluation