Académique Documents

Professionnel Documents

Culture Documents

Graphite Paint

Transféré par

Honeylet Recaña TayactacDescription originale:

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Graphite Paint

Transféré par

Honeylet Recaña TayactacDroits d'auteur :

Formats disponibles

Graphite Paints

Graphite paints -Graphite is a natural form of carbon consisting of layers of closely spaced

carbon atoms, and a very large space between the layers. This gives it different properties if

measured in different directions. It also allows the layers to slide relative to each other, and

this makes it nature’s perfect lubricant. It is rather difficult to make a paint out of graphite,

but it is possible. Graphite paint is a coating which is not fixed in place. It will move if

something slides across it. It is pointless to try to get a graphite paint smooth. The paint

will redistribute itself to fill voids. The important thing is to have enough thickness of paint

to be able to fill voids and still cover the highest protrusions. The thickness of coating

required is therefore a few microns on flat polished surfaces and several millimeters on rough

refractory castings.

Graphite is an effective, low-cost additive that is multi-functional when utilized in paints,

coatings and a myriad of other industrial applications. Graphite provides chemical inertness,

refractoriness, electrical conductivity, thermal conductivity, lubricity, UV stability, and in the

case of "expandable" graphite, fire-retardant properties. Graphite is non-toxic. With proper

rheological adjustment, graphite is compatible with most aqueous and non-aqueous coating

systems. Graphite is available in "off-the-shelf" purities from 80% to 99+% carbon, and sizes

from large grains down to 3-micron powder. Particle distributions can be tailored to meet

almost any liquid system requirement.

Graphite low friction coatings are regarded some of the more widely used forms of solid film

lubrication today.

Similar to molybdenum disulfide (MoS2) or tungsten disulfide (WS2) dichalcogenides,

graphite also has a layered lattice, a hexagonal structure, with stronger (covalent) bonds

within the structure (closely packed carbon atoms within the basal plane) than with

neighboring ‘sheets’ (carbon atoms between basal planes).

But unlike the other lubricants, carbon graphite low friction coatings are not intrinsically

lubricated. Graphite properties rely on adsorption of moisture or other condensable vapor

such as hydrocarbons to develop the capability of lubrication. Consequently, graphite

lubricates well in a normal air atmosphere, but not at high altitudes or in vacuum. And once

temperatures are high enough to create desorption, unless in the presence of relevant oxides,

dry graphite will result in higher friction.

Application:

Lubrication of surfaces where refractories need to slide over each other or against steel. It

was developed for sliding gate plates where the refractories are pressed against each other

under very high pressure and the temperature reaches 1650°C. Used on doors, undercuts on

very damaged casting dies, crack filling in almost unusable ingot moulds.

Composition;

High quality natural Ceylon flake graphite with binders, carriers, wetting agent and biocide.

Maximum service temperature;

1000°C in exposed oxidizing atmospheres.

2000°C in reducing atmospheres.

Painting;

Graphite Paint sticks to all surfaces except polyethylene. Preparation of substrate is only

necessary if there is a lot of oil, grease etc. present. Small gaps in the coating are not a

problem, they will get smeared over in use. Drying will be rapid on porous refractory

surfaces, much like normal paints on steel. Sprayed Graphite Paint looks neat but works no

better than very badly brush painted graphite.

Ref:

http://www.keramicalia.co.za/paints/109-graphite-paints.html

https://www.pcimag.com/articles/83004-graphite-a-multifunctional-additive-for-paint-and-

coatings

http://industrialcoatingsworld.com/low-friction-coatings/graphite-low-friction-coatings

Vous aimerez peut-être aussi

- Gpio Linux TutorialDocument3 pagesGpio Linux TutorialShuyangPas encore d'évaluation

- Decentralised Solid Waste Management in Zanzibar, TanzaniaDocument9 pagesDecentralised Solid Waste Management in Zanzibar, TanzaniagitaPas encore d'évaluation

- Ledset User 'S Manual: Linsn TechnologyDocument42 pagesLedset User 'S Manual: Linsn TechnologyPha Lê TímPas encore d'évaluation

- Conductive Ink Patent US2851380BerlinghofDocument4 pagesConductive Ink Patent US2851380BerlinghofAndrea CalderaPas encore d'évaluation

- Redox Rust Converter InformationDocument15 pagesRedox Rust Converter InformationM Subhan FauziPas encore d'évaluation

- 1.deposition of Tantalum Nitride Thin Films by D.C. Magnetron SputteringDocument6 pages1.deposition of Tantalum Nitride Thin Films by D.C. Magnetron SputteringNishat ArshiPas encore d'évaluation

- 1 - Introduction Installation Node-REDDocument5 pages1 - Introduction Installation Node-REDIrwan WahyudiPas encore d'évaluation

- Wilder GetterDocument13 pagesWilder GetterFerhat Bozduman100% (1)

- Manufactured Carbon and Graphite: Standard Terminology Relating ToDocument4 pagesManufactured Carbon and Graphite: Standard Terminology Relating ToLabeed ShamilPas encore d'évaluation

- Aluminizing Nickel Foam by A Slurry Coating ProcessDocument3 pagesAluminizing Nickel Foam by A Slurry Coating ProcessFatih BozkurtPas encore d'évaluation

- Pitzer Model 1987Document84 pagesPitzer Model 1987Ram KumarPas encore d'évaluation

- Transparent Conducting Oxides.Document8 pagesTransparent Conducting Oxides.ladycharlotPas encore d'évaluation

- Surface Protection External Coating of Claas ProductsDocument1 pageSurface Protection External Coating of Claas ProductsTomaszPas encore d'évaluation

- Catalogo IusaDocument190 pagesCatalogo IusaAlfa CentauroPas encore d'évaluation

- Electrodeposition Andreas Tolz PPGDocument14 pagesElectrodeposition Andreas Tolz PPGAndi MusdalifahPas encore d'évaluation

- Bearing Area CurveDocument2 pagesBearing Area CurveNiraj Suroopjeet100% (1)

- Mcs 2018Document204 pagesMcs 2018felix angel rivera garciaPas encore d'évaluation

- Breakdown in GasesDocument49 pagesBreakdown in GasesQais AlsafasfehPas encore d'évaluation

- Mit PDFDocument80 pagesMit PDFHIRA SHABBIRPas encore d'évaluation

- Samudayik BhawanDocument13 pagesSamudayik BhawanManish PatelPas encore d'évaluation

- Types of EpoxyDocument5 pagesTypes of EpoxybalsamPas encore d'évaluation

- Sputtering 1Document64 pagesSputtering 1.. ..Pas encore d'évaluation

- Effect of Chemical Composition of Zinc Phosphating Solution On Phosphate Coating PropertiesDocument12 pagesEffect of Chemical Composition of Zinc Phosphating Solution On Phosphate Coating PropertiesJhon QsacPas encore d'évaluation

- Read Me WindowsDocument1 pageRead Me WindowssareddyPas encore d'évaluation

- Technology of Coating Resins Pigments and Inks IndustriesDocument15 pagesTechnology of Coating Resins Pigments and Inks IndustriesPravin Tandel100% (1)

- EfflorescenceDocument2 pagesEfflorescenceMihaiu AdrianPas encore d'évaluation

- Flux MethodDocument3 pagesFlux MethodRekhaPas encore d'évaluation

- Increasing Sustainability of Industrial Coatings With Imerys Functional MineralsDocument28 pagesIncreasing Sustainability of Industrial Coatings With Imerys Functional Mineralss0n1907Pas encore d'évaluation

- Thin Film Deposition ProcessDocument42 pagesThin Film Deposition ProcessVivek Bela100% (2)

- Latapoxy SP 100 TDSDocument3 pagesLatapoxy SP 100 TDSBithika DattaPas encore d'évaluation

- High Voltage Chapter 1 - InTRODUCTIONDocument18 pagesHigh Voltage Chapter 1 - InTRODUCTIONZiyan SinPas encore d'évaluation

- DiclorosilanoDocument15 pagesDiclorosilanoLeo GatesPas encore d'évaluation

- Nano GeneratorsDocument23 pagesNano GeneratorsRajendran HarikrishnanPas encore d'évaluation

- SDS - Expancel 930 MB 120 - 20190626Document13 pagesSDS - Expancel 930 MB 120 - 20190626bobPas encore d'évaluation

- Vacuum Soldering Using Formic Acid PaperDocument6 pagesVacuum Soldering Using Formic Acid PaperZine-Eddine BoutaghouPas encore d'évaluation

- Book - Nanotechnology in CoatingsDocument20 pagesBook - Nanotechnology in CoatingsmitrasatapathyPas encore d'évaluation

- Ceramic OsDocument5 pagesCeramic OsBlank FajardoPas encore d'évaluation

- NipponDocument30 pagesNipponBiswanath SahaPas encore d'évaluation

- Atmospheric Corrosion of Copper and The Colour Structure and Composition of Natural Patinas On Copper 2006 Corrosion ScienceDocument30 pagesAtmospheric Corrosion of Copper and The Colour Structure and Composition of Natural Patinas On Copper 2006 Corrosion ScienceEmanuela Leite FragosoPas encore d'évaluation

- Alternative To Conventional Aluminum Anodize Seals With An Environmentally-Friendly Seal ProcessDocument5 pagesAlternative To Conventional Aluminum Anodize Seals With An Environmentally-Friendly Seal ProcessKamila Freitas Garcia0% (1)

- Row Schott Technical Glasses View 2020-04-14Document80 pagesRow Schott Technical Glasses View 2020-04-14Oleg ChernovPas encore d'évaluation

- Oxidation Behaviour of Silicon Carbide - A Review PDFDocument11 pagesOxidation Behaviour of Silicon Carbide - A Review PDFcleitononline4599Pas encore d'évaluation

- Chemical Composition of A Fountain Pen InkDocument4 pagesChemical Composition of A Fountain Pen InkmynamecoolPas encore d'évaluation

- FRP BasicsDocument13 pagesFRP Basicsshaharyar100% (1)

- Graphene: A Comprehensive ReviewDocument10 pagesGraphene: A Comprehensive ReviewdogukanhazarozbeyPas encore d'évaluation

- Gamma Radiography With Iridium-192Document5 pagesGamma Radiography With Iridium-192snndhkPas encore d'évaluation

- Basic Sheet and Coil Training Edit VersionDocument35 pagesBasic Sheet and Coil Training Edit VersioncuongdcPas encore d'évaluation

- Polyester and Vinyl Ester CoatingsDocument14 pagesPolyester and Vinyl Ester Coatingsrasool100% (2)

- Electrochemical Methods of TestingDocument20 pagesElectrochemical Methods of TestingAnil Kumar TPas encore d'évaluation

- Natural PolymersDocument2 pagesNatural PolymersRoshdy AbdelRassoulPas encore d'évaluation

- Carbon Conductive Inks AplicacionesDocument16 pagesCarbon Conductive Inks AplicacionesCarlos Alberto Quijano AcevedoPas encore d'évaluation

- Conductiv Polymer: Soran University Faculty of Engineering Chemical Engineering DepartmentDocument12 pagesConductiv Polymer: Soran University Faculty of Engineering Chemical Engineering DepartmentMuhammad Hussein100% (1)

- Epiclon Epiclon: Standard Products Epoxy Resins & Curing AgentsDocument17 pagesEpiclon Epiclon: Standard Products Epoxy Resins & Curing AgentskamalnandrePas encore d'évaluation

- FR 4Document6 pagesFR 4Libu JacobPas encore d'évaluation

- Jan 2010 Oxylink Updated Sales Presentation PDFDocument44 pagesJan 2010 Oxylink Updated Sales Presentation PDFdainguyenlamPas encore d'évaluation

- Ferroic Materials For Smart Systems From Fundamentals To Device Applications PDFDocument253 pagesFerroic Materials For Smart Systems From Fundamentals To Device Applications PDFAndy ChanPas encore d'évaluation

- TDS Vinnapas EZ 3112Document2 pagesTDS Vinnapas EZ 3112ajoilhamPas encore d'évaluation

- Conductive Polymers or More Precisely Intrinsically Conducting PolymersDocument5 pagesConductive Polymers or More Precisely Intrinsically Conducting PolymersVishwath RamPas encore d'évaluation

- Radio Test Procedure ManualDocument161 pagesRadio Test Procedure ManualQll Communications100% (1)

- B. Current Market and DemandDocument2 pagesB. Current Market and DemandHoneylet Recaña TayactacPas encore d'évaluation

- Observation of Magnetic Field Lines: Abstract. This Experiment Aims To Compare andDocument2 pagesObservation of Magnetic Field Lines: Abstract. This Experiment Aims To Compare andHoneylet Recaña TayactacPas encore d'évaluation

- Experiment No. 7 Measurement of Reaction ConversionDocument8 pagesExperiment No. 7 Measurement of Reaction ConversionHoneylet Recaña TayactacPas encore d'évaluation

- Student Copy T1 Topic 2.3 Jesus of Nazareth Full-1Document26 pagesStudent Copy T1 Topic 2.3 Jesus of Nazareth Full-1Honeylet Recaña TayactacPas encore d'évaluation

- 2.6 Review of Related Literature On Production EquipmentDocument4 pages2.6 Review of Related Literature On Production EquipmentHoneylet Recaña TayactacPas encore d'évaluation

- Hydrochloric Acid AND Miscellaneous Inorganic ChemicalsDocument9 pagesHydrochloric Acid AND Miscellaneous Inorganic ChemicalsHoneylet Recaña TayactacPas encore d'évaluation

- Powdered Detergent: Adamson University College of Engineering Department of Chemical EngineeringDocument6 pagesPowdered Detergent: Adamson University College of Engineering Department of Chemical EngineeringHoneylet Recaña TayactacPas encore d'évaluation

- EXPERIMENT9Document5 pagesEXPERIMENT9Honeylet Recaña TayactacPas encore d'évaluation

- DetergentDocument16 pagesDetergentHoneylet Recaña TayactacPas encore d'évaluation

- Fig. 1 Lineweaver BurkDocument3 pagesFig. 1 Lineweaver BurkHoneylet Recaña TayactacPas encore d'évaluation

- RRLDocument3 pagesRRLHoneylet Recaña TayactacPas encore d'évaluation

- PrintDocument2 pagesPrintHoneylet Recaña TayactacPas encore d'évaluation

- Emissivity: Experiment No. 3Document7 pagesEmissivity: Experiment No. 3Honeylet Recaña TayactacPas encore d'évaluation

- Inverse Square Law For Heat and Stefan-Boltzmann Law: Experiment No. 2Document6 pagesInverse Square Law For Heat and Stefan-Boltzmann Law: Experiment No. 2Honeylet Recaña TayactacPas encore d'évaluation

- Print 1Document2 pagesPrint 1Honeylet Recaña TayactacPas encore d'évaluation

- Marplex - Injection Moulding of ThermoplasticsDocument24 pagesMarplex - Injection Moulding of ThermoplasticsStarchyLittleOleMePas encore d'évaluation

- 6312 Open Product Comparison - SKFDocument1 page6312 Open Product Comparison - SKFWahyuPas encore d'évaluation

- Calorimetry - Specific Heat and Latent Heat: 3.1 PurposeDocument6 pagesCalorimetry - Specific Heat and Latent Heat: 3.1 PurposeRajesh JadhavPas encore d'évaluation

- General: Title Design of Corbel Cl. No. Design Calculations ReferencesDocument15 pagesGeneral: Title Design of Corbel Cl. No. Design Calculations ReferencesGovendan GopalakrishnanPas encore d'évaluation

- ASTM F1554 - Portland BoltDocument1 pageASTM F1554 - Portland BoltjacquesmayolPas encore d'évaluation

- High-Yield-Strength, Quenched and Tempered Alloy Steel Plate, Suitable For WeldingDocument2 pagesHigh-Yield-Strength, Quenched and Tempered Alloy Steel Plate, Suitable For WeldingFRANZ RICHARD SARDINAS MALLCOPas encore d'évaluation

- Processing Guidelines: Laminate: S7439C Prepreg: S7439CB Low Loss & Heat Resistance Multilayer MaterialDocument5 pagesProcessing Guidelines: Laminate: S7439C Prepreg: S7439CB Low Loss & Heat Resistance Multilayer MaterialSuleymanPas encore d'évaluation

- Tong Hop BuiddingDocument122 pagesTong Hop BuiddingTrần ViệtPas encore d'évaluation

- The Influence of Negative Skin Friction On Piles and Pile GroupsDocument7 pagesThe Influence of Negative Skin Friction On Piles and Pile GroupsViet Anh PhamPas encore d'évaluation

- 6 Unconventional Structure SystemsDocument12 pages6 Unconventional Structure SystemsMouhamad WehbePas encore d'évaluation

- 1sty With ToiletDocument22 pages1sty With ToiletcimpstazPas encore d'évaluation

- Lubrication Failure AnalysisDocument59 pagesLubrication Failure AnalysisMahaveer Singh100% (1)

- Carbon Alloy SteelDocument2 pagesCarbon Alloy SteelDeepak HolePas encore d'évaluation

- Etag 002 PT 2 PDFDocument13 pagesEtag 002 PT 2 PDFRui RibeiroPas encore d'évaluation

- Alucobest Aluminum Composite Panel For Architectural & BuildingDocument12 pagesAlucobest Aluminum Composite Panel For Architectural & BuildingAli ZhangPas encore d'évaluation

- Pressure Vessel Calculation Report PDFDocument12 pagesPressure Vessel Calculation Report PDFVictor Fakoya50% (2)

- Design of Hollow Block Slabs: Dr. Hamed HadhoudDocument19 pagesDesign of Hollow Block Slabs: Dr. Hamed HadhoudFady Abdel AzizPas encore d'évaluation

- TaraNath - Reinforced - Concrete - Design - of - Tall - Build 8Document1 pageTaraNath - Reinforced - Concrete - Design - of - Tall - Build 8jcvalenciaPas encore d'évaluation

- Preboard-4-Practical-Problem (Answer Key) PDFDocument8 pagesPreboard-4-Practical-Problem (Answer Key) PDFMartin L T. SantosPas encore d'évaluation

- Lee Et Al (2007) PDFDocument11 pagesLee Et Al (2007) PDFMarco F. GallegosPas encore d'évaluation

- Manual LabelDocument16 pagesManual Labelphuong0% (1)

- JO003-10-LB - MDD-IDM-001-3 P&ID Steam and Bypass SystemDocument9 pagesJO003-10-LB - MDD-IDM-001-3 P&ID Steam and Bypass SystemHasan MustafaPas encore d'évaluation

- Pratik Pawar Physics ProjectDocument8 pagesPratik Pawar Physics ProjectaagneysuchitaPas encore d'évaluation

- Tables SaturationDocument9 pagesTables SaturationGuilmar Moncayo PoncePas encore d'évaluation

- Etag004 Fg004 Etics Fin2Document87 pagesEtag004 Fg004 Etics Fin2Serban RaduPas encore d'évaluation

- PHD 2016 Zoran PerovicDocument141 pagesPHD 2016 Zoran PerovicDejan Deki MaticPas encore d'évaluation

- CS1-2010 Vol 2 Rev 00-101130 PDFDocument98 pagesCS1-2010 Vol 2 Rev 00-101130 PDFbaxterPas encore d'évaluation

- Achieving Perfect Plastification April - 2010Document2 pagesAchieving Perfect Plastification April - 2010Anonymous nsmzJNLoPas encore d'évaluation

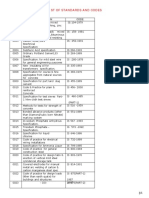

- List of Standards and Codes For Power PlantDocument3 pagesList of Standards and Codes For Power PlantS.KAMBANPas encore d'évaluation

- Precast Modular Block For Retaining Wall SystemsDocument10 pagesPrecast Modular Block For Retaining Wall SystemsMahdi ValaeePas encore d'évaluation