Académique Documents

Professionnel Documents

Culture Documents

Calculation of Sag

Transféré par

Engr RomanDescription originale:

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Calculation of Sag

Transféré par

Engr RomanDroits d'auteur :

Formats disponibles

st

51 Internationales Wissenschaftliches Kolloquium

Technische Universität Ilmenau

September 11 – 15, 2006

M. Muhr, S. Pack, R. Schwarz, S. Jaufer

Calculation of Overhead Line Sags

Power Engineering

Abstract: The liberalisation of the energy market in Europe leads to change in operation

of the transmission network. Diagnostic tools for the condition evaluation get more

importance. Based on the changed stress and the large expansion of the network of the

line components a considerable effort for condition evaluation and maintenance is

necessary.

In the centre of Europe the Austrian transmission line system at the level 230kV and

400kV has an important role for the energy exchange and was built up in 50’s to the70’s

of the last century, therefore parts of the system are more than 40 years old.

Based on this situation this paper focuses on the operation behaviour of ageing

overhead lines with special regard to the sag calculation of span sections.

The sag of a transmission line will increase by increasing conductor temperature caused

by the electrical load and specific environmental conditions or additional rope forces

(e.g. ice load). In addition, the permanent mechanical forces (everyday stress) elongate

the conductor irreversible during its live time.

Key Words: Overhead line, Aging, Sag, Calculation

INTRODUCTION

Overhead lines are the backbone in every electrical power transmission system.

Because the consumers are not concentrated at the location of the generation it is not

possible to use power plants with high output. For the connection between the power

plants and the consumers integrated network consists of transmission line systems like

overhead lines or power cable are in use.

In the past the regional operators worked together, electric energy was generated

A...

B

iii

HOME IWK E ...Z D E F

nearby the consumer and the network was used as back up. Today by the liberalisation

of the European energy marked the trading at the spot marked gives the power flow. So

the transferred electrical power varies over the transmission lines. In addition, the cost

pressure is increasing, and the grid operators have to save investments to make their

transmission lines most economical. Therefore, they use their lines near the nominal

limits and the maintenance strategy has changed from a time based to a condition base

strategy. For the usage of an overhead line, the ground clearance of the ropes is one of

the important parameters, because a safety margin has to maintain over the whole

expected useful life [7].

In general, the conductor elongates by the permanent mechanical forces (everyday

stress) during its live time. Additionally to this irreversible elongation, the sag of a

transmission line will increase by the conductor temperature caused by the electrical

load and specific environmental conditions or other conductor forces (e.g. ice load).

ELONGATION MECHANISM

The sag curve of a conductor, which is spanned between to points, is depending on the

distance between the fixed points and the tension in the conductor and can be specified

by the funicular curve. The always presented wire tension is variable by the wire

temperature and the additional load. This permanent stress leads to an irreversible

elongation. Additional the elastic and thermal elongation occurs, depending of used wire

materials. Mostly high conduction aluminium as conductor and a high strength material

as mechanical support (steel, aldrey) are used. For the common type ACSR overhead

lines, galvanize steel wires used as support. The composite of this two material with

different material properties leads to an average behaviour of wire. So the mechanical

tension is not equal during mechanical stress in aluminium and steel.

The lower elasticity module causes a lower Table 1: Load distribution of different

conductor types

tension in the aluminium than in the steel.

Area ratio

Based on this circumstance the load Al/St 1:1 3:1 4:1 6:1 11:1

Al 22.5% 45.5% 53.7% 65.3% 76.1%

distribution is also different depending on the St 77.5% 53.5% 46.3% 36.5% 23.9%

construction and the strength of used materials as shown in Table 1.

In addition, the different thermal expansion of the used material leads to a thermal

influenced changing of the load and tension ratio. Aluminium has a higher thermal

expansion coefficient than the used steel.

A...

B

iii

HOME IWK E ...Z D E F

Under this circumstance during

100%

Steel Al/St 340/110mm²

increasing temperatures the aluminium 90%

Al/St 685/85 mm²

80%

is released and the steel core will get a 70%

60%

load ratio

higher mechanic load. At a certain 50% Knee temperature

temperature called knee-temperature, 40%

30%

the steel core will carry the whole load 20%

Aluminium

10%

and the aluminium has no mechanic 0%

-40 -20 0 20 40 60 80 100 120

load anymore. This temperature Δϑ in K

depends on the mechanical structure of Fig. 1: Thermal behaviour of the load ratio

the ACSR conductor. In Figure 1 some examples are shown.

AGING EFFECTS

The low melting point of aluminium with a level of 660°C leads to a creeping of overhead

lines [1] [2] [3] at the normal operating temperatures. This creeping is also temperature

depending and will increase at higher temperatures. Influence parameters for this

creeping are the mechanical structure, the conductor tension, the maximum mechanical

load and the temperature.

Due to missing monitoring systems for overhead lines for most existing lines conductor

temperatures or maximum loads are not available. For a new line, the measurement

effort for the monitoring is very high and expensive. So it is easier to measure the sag

and the conductor temperature in certain intervals to achieve the elongation of the

overhead line conductor and the ground clearance [4].

The elongation of the conductor caused by thermal or aging effects has different effects

on the sags of a line section.

OVERHEAD LINE MODEL

In Austria, the length between two overhead line rods is typical between 200 and 350m

and depends on the geographic situation. The 400kV network is typical equipped with

two or four conductors per phase and the 230kV network with one conductor per phase.

The in the calculation used model is based on a typical Austrian overhead line for the

system voltage of 230kV and 400kV. Table 2 shows the technical data of the modelled

overhead line types.

A...

B

iii

HOME IWK E ...Z D E F

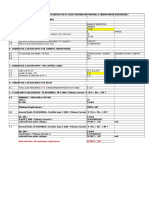

Table 2: Conductor data and isolator data

ACSR 340/110 ACSR 680/85

Al area 341.2mm² 678.6mm²

St area 108.8mm² 85.95mm²

Weight 1815kg/km 2564kg/km

Modulus of elasticity 8400daN/mm² 6800daN/mm²

E-modulus Al 6000daN/mm² 6000daN/mm²

E-modulus St 20700daN/mm² 20700daN/mm²

Coeff. of linear expansion 1.67 10-05K-1 1.94 10-05K-1

Isolator type 2 long rods 3 long rods

Weight (tension/suspension) 130/60kg 240/180kg

Total length (tension/suspension) 3.5/2.85m 6.7/5m

Two different rod arrangements for a flat terrain were calculated:

1. Symmetric rod distribution (free flat terrain without rivers, roads or building)

2. Asymmetric rod distribution (realistically situation in flat terrain with hindrances).

CASE STUDY 230KV SYSTEM

Overhead lines with symmetric and asymmetric rod distribution in a flat terrain are

calculated in this case study. The mechanical construction represents a typical Austrian

overhead line of the 230kV network with an ACSR 340/110mm² conductor.

The initial state for the sag calculations is shown in figure 2. The horizontal forces are in

each span equal at this temperature and so the suspension insulators (T1...T4) hang

perpendicular. The tension insulators (AB1 and AB2) will be linked depending on their

own weight and the conductor forces.

Section: AB1 ↔ AB2

30

T1

T2

T3

T4

25

AB1

AB2

20

height in m

15

10

0

0 250 500 750 1000 1250 1500

length in m

Fig. 2: Initial state at 10°C conductor temperature

During the load current, the conductor temperature will increase so the sag will increase

too, as shown in Figure 3.

A...

B

iii

HOME IWK E ...Z D E F

Section: AB1 ↔ AB2

30

T1

T2

T3

T4

25

AB1

AB2

20

9.5cm 9.5cm

height in m

15

10

0

0 250 500 750 1000 1250 1500

length in m

Fig. 3: Sag calculation at 80°C without elongation

Caused by the temperature rise, the horizontal forces in the conductor will decrease

(-16.2%). Additional the clamping points at the end of the tension insulator are lowered

at 9.5cm. This system has now an inhomogeneous horizontal force distribution with is

linked by the suspension insulators. Their deflections are insignificant and have small

effect. A significant effect on the sag has only the deflection of the tension insulators.

In this case study, an elongation caused by the everyday stress of 0.336‰ and 0.435‰

was assumed which will accords an used period of 50 and 120 years. According to the

elongation, the sag increases in all spans about 0.47÷0.6m (see Figure 4).

Section: AB1 ↔ AB2

T1

T2

T3

T4

24

22

AB1

AB2

20

18

height in m

16

14

12

10

8

0 200 400 600 800 1000 1200 1400

length in m

Fig. 4: Sag calculation at 80°C with elongation (0.336‰ – 50years)

A...

B

iii

HOME IWK E ...Z D E F

In figure 5, the initial case with asymmetric rod distribution with the same overhead line

conductor is shown. A heavy asymmetrical rod distribution (minimum 200m, maximum

400m) is the basis for the calculations.

Section: AB1 ↔ AB2

35

AB2

T4

30

T2

T3

25

height in m

T1

20

AB1

15

10

0

0 250 500 750 1000 1250 1500

length in m

Fig. 5: Initial state at 10°C conductor temperature

Section: AB1 ↔ AB2

35

AB2

T4

30 16cm 18cm

13cm

T2

T3

25

9.5cm

height in m

T1

20

AB1

15

10

0.51m 0.36m

0.18m 0.47m

5

0

0 250 500 750 1000 1250 1500

length in m

Fig. 6: Sag calculation at 80°C without elongation with and without suspension insulator

deflection

The sag will increase unequal as shown in Figure 6 by rising conductor temperatures.

Similar to the symmetrical rod distribution, the tension insulators shows a deflection

about 10cm. In addition, all suspension insulates have now a significant deflection

pointing to the span with the greatest distance between the mounting. With this

deflection, the sags of the short spans are reduced and the longer spans will increase.

A...

B

iii

HOME IWK E ...Z D E F

Section: AB1 ↔ AB2

35

AB2

T4

30

T2

T3

25

height in m

T1

20

AB1

15

10

0.33m 0.47m 0.61m 0.69m 0.78m

5

0

0 250 500 750 1000 1250 1500

length in m

Fig. 7: Sag calculation at 80°C with elongation (0.336‰ – 50years)

In Figure 7, the identical elongation is assumed as in the prior examples and the sag

increases by elongation about 0.26÷0.78cm asymmetric depending on the span.

CASE STUDY 400KV SYSTEM

A 400kV overhead line with an ACSR 685/85mm² conductor is modelled in this example.

The rod distribution is the same as in the 230kV case.

Section: AB1 ↔ AB2

35

T1

T2

T3

T4

30

AB1

AB2

25

16cm 16cm

height in m

20

15

10

0

0 250 500 750 1000 1250 1500

length in m

Fig. 8: Initial state at 10°C conductor temperature and sag calculation at 80°C without

elongation

The deflection in this model is higher than in the 230kV example with the longer and

heavier tension insulators. The suspension insulators are neglect able deflected. The

temperature caused sag increase is now lower than in the previous case study (1.57m

A...

B

iii

HOME IWK E ...Z D E F

than 1.78m). The lower elastic modulus is the reason for this circumstance and

compensates the higher coefficient of linear expansion of the ACSR 685/85mm²

conductor. By the lower steel fraction, the elongation is higher than at the

ACSR 340/110mm² conductor. According to an age of 20, 50 and 120 years, an

elongation of 0.331‰, 0.435‰ and 0.567‰ was assumed. Depending on the age, the

elongation sag increase is in a region from 0.36÷0.62m.

Section: AB1 ↔ AB2

45

AB2

T4

40

35

T3

T2

30

T1

height in m

25

AB1

20

15

10

0

0 250 500 750 1000 1250 1500

length in m

Fig. 9: Initial state at 10°C conductor temperature

An asymmetric rod distribution is shown in Figure 9. The sag is increasing asymmetric

with rising the temperature and the suspension insulators deflect as shown in Figure 10.

Section: AB1 ↔ AB2

45

AB2

T4

40

10cm

35

T3

14cm

T2

30

T1

height in m

25 19cm

17cm

AB1

20 10cm 10cm

15

10

0.41m 0.32m 0.14m 0.37m

5

0

0 250 500 750 1000 1250 1500

length in m

Fig. 10: Sag calculation at 80°C without elongation, with and without suspension insulator

deflection

A...

B

iii

HOME IWK E ...Z D E F

The effect of the deflection of the suspension insulators is marginal lower than at the

ACSR 340/110mm² but big enough to affect the sag calculation.

Section: AB1 ↔ AB2

45

AB2

T4

40

35

T3

T2

30 T1

height in m

25

AB1

20

15

10

0.36m 0.50m 0.62m 0.70m 0.76m

5

0

0 250 500 750 1000 1250 1500

length in m

Fig. 11: Sag calculation at 80°C with elongation (0.435‰ – 50years)

With an aging depending elongation the sags increase from 36cm to 76cm depending on

the span dimensions of the modelled overhead line.

CONCLUSION

In this paper, sag calculations of two different overhead lines are presented. The results

show, that the sag behaviour of the close-by spans is affected by the deflection of the

tension insulators. The deflection of the suspension insulators is negligible in a

symmetrical rod distributed flat overhead line, and has insignificant effects on the sag

calculation. In an asymmetrical rod distribution case the deflection of the suspension

insulators is not negligible. The sag of the span with the largest distance between the

rods will increase much more than in smaller spans. The safety distance will reduced by

the elongation of the overhead conductors.

In this example, the sag will increase in magnitude of 26 to 78cm by aging elongation.

This effect can be compensated by a reduction (approximate 28K) of the conductor

steady-state temperature. The transmission capability is also reduced by the lower

permissible conductor temperature [5] [6].

This capability limitation may cause negative effects on the power quality especially in

the hot summer time.

A...

B

iii

HOME IWK E ...Z D E F

SUMMARY

In this case study, based on typical Austrian overhead lines of a 230kV and 400kV

system voltage, a sag calculation was carried out.

The most important result of the calculations is that the deflection of the suspension

insulators affects the sag in the case of an asymmetrical rod distribution. With

symmetrical distribution, only defection of the tension insulator affects the result. An

aging depending sag increase is caused by the elongation of the overhead conductors

due to the everyday stress.

Based on this circumstance, a safety reserve for the phase to earth clearance must be

considered for the planning and construction.

The reliability of an aged overhead line can be improved by sag verification with can be

done by measurement or calculation. So depending on the system voltage and the

object type, the minimum phase to earth clearance can be assured.

References:

[1] WG 05 Electra N°24, “A Practical Method of Conductor Creep Determination”, page 105ff, Paris

October 1972

[2] WG 22.05 Electra N°75, “Permanent Elongation of Conductors, Predictor Equation and Evaluation

Methods”, page 105ff, Paris March 1981

[3] H. Pohlmann, R. Thomas; “Sag increases resulting from conductor creep on medium-voltage

transmission lines, and the problem of measuring sag on live overhead lines”, Electricity Distribution,

1993 CIRED, 12th International Conference on 17-21 May 1993 page(s):3.20/1 - 3.20/5 vol.3

[4] F. Kießling, P.Nefzger, U. Kaintzyk, „Freileitungen, Planung Berechnung Ausführung“, 5te Auflage,

Springer Verlag Berlin, ISBN 3-540-42255-2

[5] IEEE Std. 738-1993, „IEEE standard for calculating the current-temperature relationship of bare

overhead conductors“, IEEE 8 Nov 1993

[6] M. Muhr, S. Pack, S. Jaufer: Sag Calculation of Aged Overhead Lines, 14th International Symposium

on High Voltage Engineering 2005, Peking, S206

[7] H. Pohlmann, Alterung von Komponenten der Stromkreise in Freileitungen, i-Tagung, Mosdorfer

Weiz 16.09.2004

Authors:

Michael Muhr, Dr. techn, Univ.-Prof.

Stephan Pack, Dr. techn, Univ.-Prof.

Robert, Schwarz, Dr. techn, Ass.

Stefan Jaufer, Dipl.-Ing., Wiss.-Ass.

Institute of High Voltage Engineering and System Management

Graz University of Technology,

Inffeldgasse 18,

8010 Graz, Austria, Europa

Tel.: +43/ (0)316/873-7400

Fax.: +43/ (0)316/873-7408

Email: surname@HSPT.TU-Graz.ac.at

A...

B

iii

HOME IWK E ...Z D E F

Vous aimerez peut-être aussi

- ETAP Module List NewDocument4 pagesETAP Module List Newb33law100% (1)

- Busbar Size CalculationDocument5 pagesBusbar Size Calculationdermasdemo100% (6)

- GE-Guide To Instantaneous SelectivityDocument19 pagesGE-Guide To Instantaneous SelectivityJOSE LUIS FALCON CHAVEZPas encore d'évaluation

- Distribution Hand BookDocument157 pagesDistribution Hand BooksedianpoPas encore d'évaluation

- Cable Thermal Analysis Short Circuits EADocument19 pagesCable Thermal Analysis Short Circuits EAErsiAgoPas encore d'évaluation

- IEEE Application Guide For Transient Recovery Voltage For AC High-Voltage Circuit Breakers Rated On A Symmetrical Current BasisDocument47 pagesIEEE Application Guide For Transient Recovery Voltage For AC High-Voltage Circuit Breakers Rated On A Symmetrical Current BasisFrancir EscobPas encore d'évaluation

- Design of Electrical System Based On Short Circuit PDFDocument6 pagesDesign of Electrical System Based On Short Circuit PDFDeri Rio HeryantoPas encore d'évaluation

- PPC Insulator - Solid CoreDocument16 pagesPPC Insulator - Solid CoreAriel Ghigliotto100% (1)

- JD-132-QH-E41-03 - Strand Conductor SizingDocument15 pagesJD-132-QH-E41-03 - Strand Conductor SizingRami The OnePas encore d'évaluation

- Knowledge is "Real Power": Introduction to Power QualityD'EverandKnowledge is "Real Power": Introduction to Power QualityPas encore d'évaluation

- Tower Foundation - Chapter 5Document45 pagesTower Foundation - Chapter 5kayshephPas encore d'évaluation

- Users Guide: Electrical Distribution and Transmission Systems Analyses and Design ProgramsDocument52 pagesUsers Guide: Electrical Distribution and Transmission Systems Analyses and Design ProgramsgilbertomjcPas encore d'évaluation

- PDI+1000 am1+-+Protection+of+High+Voltage+PlantDocument75 pagesPDI+1000 am1+-+Protection+of+High+Voltage+PlantTosikur Rahman100% (1)

- Pathlaiya SS 132kV Busbar DesignDocument9 pagesPathlaiya SS 132kV Busbar DesignSantosh GairhePas encore d'évaluation

- CT Requirements of Siemens-7sjDocument3 pagesCT Requirements of Siemens-7sjshanthikumaravel100% (1)

- CT Requirement For MicomsDocument50 pagesCT Requirement For Micomsjaved shaikh chaandPas encore d'évaluation

- 236 CT PDFDocument3 pages236 CT PDFHimanshu RanjanPas encore d'évaluation

- Earthing Transformer Sizing Rev 00Document4 pagesEarthing Transformer Sizing Rev 00Ahmed Saber0% (1)

- Fault Location PLN MD 032012BDocument54 pagesFault Location PLN MD 032012BSatria RizkyPas encore d'évaluation

- Catenary Sag-Tension Calculator (Even and Uneven)Document2 pagesCatenary Sag-Tension Calculator (Even and Uneven)mohsin160Pas encore d'évaluation

- Current Transformers Selection Guide PDFDocument20 pagesCurrent Transformers Selection Guide PDFsdvijayPas encore d'évaluation

- CT VT SizingDocument5 pagesCT VT SizingRahil Tasawar0% (1)

- Engineering Method For Calculation of Short-CircuitDocument8 pagesEngineering Method For Calculation of Short-CircuitHakkim Sheik Thauth J100% (1)

- E474content PDFDocument64 pagesE474content PDFbhavikPas encore d'évaluation

- Substation Design DataDocument23 pagesSubstation Design DataHugh cab100% (1)

- ClearanceDocument42 pagesClearanceVijaya RekhaPas encore d'évaluation

- Microgrid ProtectionDocument22 pagesMicrogrid ProtectionEleanyRestrepoPas encore d'évaluation

- Tower Loading Trees For Preliminary DesignDocument22 pagesTower Loading Trees For Preliminary DesignJetn SrisuthumPas encore d'évaluation

- 2240 162 Pve U 004 SHT 3 3 01Document13 pages2240 162 Pve U 004 SHT 3 3 01Anagha DebPas encore d'évaluation

- 132kv Malana Ekd-Section-Rev01 ModifiedDocument1 page132kv Malana Ekd-Section-Rev01 ModifiedannuvyasPas encore d'évaluation

- CT Sizing For MalawiDocument2 pagesCT Sizing For MalawiDharmenderSinghChoudharyPas encore d'évaluation

- Earthing Grid Design Calculations Rev 0Document10 pagesEarthing Grid Design Calculations Rev 0Vikram SinghPas encore d'évaluation

- Surge Arresters: Subject Document Revision No. Sheet No. Equipment Specification Surge Arresters 1 1Document5 pagesSurge Arresters: Subject Document Revision No. Sheet No. Equipment Specification Surge Arresters 1 1PRAKASH SPas encore d'évaluation

- 110kV SubstationDocument94 pages110kV SubstationExcel power100% (3)

- Volume 2 of 3 (Substation Part)Document554 pagesVolume 2 of 3 (Substation Part)bei beiPas encore d'évaluation

- 6305 EL MCA 7050 A00 - AC&DC Maitenes DischargeDocument29 pages6305 EL MCA 7050 A00 - AC&DC Maitenes Dischargevicesuza87Pas encore d'évaluation

- Evaluation of Transformer Loading Above Nameplate RatingDocument13 pagesEvaluation of Transformer Loading Above Nameplate RatingMuhammad Ali Masood CheemaPas encore d'évaluation

- Aluminium Tubular Busbars For HV SubstatDocument5 pagesAluminium Tubular Busbars For HV Substatasi midobarPas encore d'évaluation

- CIGRE 2008 A3-207 Int ArcDocument10 pagesCIGRE 2008 A3-207 Int Arcdes1982Pas encore d'évaluation

- ABB LMU 574 - mcd80Document12 pagesABB LMU 574 - mcd80gadware2011bplPas encore d'évaluation

- Substation Earthing Grid Design Calculation Substation Pmu 275/132/33Kv Shah Alam Seksyen 18 Gis Contract No. Tender No. Project Revision DateDocument14 pagesSubstation Earthing Grid Design Calculation Substation Pmu 275/132/33Kv Shah Alam Seksyen 18 Gis Contract No. Tender No. Project Revision Dateadani123Pas encore d'évaluation

- DSLP 11 3mDocument7 pagesDSLP 11 3msureshn829Pas encore d'évaluation

- Technical Note - Foundation Design For High Voltage Induction Motors PDFDocument2 pagesTechnical Note - Foundation Design For High Voltage Induction Motors PDFMashudi FikriPas encore d'évaluation

- According To The IEC 61660 - Open ElectricalDocument5 pagesAccording To The IEC 61660 - Open ElectricalZar ChiPas encore d'évaluation

- Calculation of Lightning: Current ParametersDocument6 pagesCalculation of Lightning: Current ParametersMarcelo VillarPas encore d'évaluation

- 11kV SPBD General ArrangementDocument12 pages11kV SPBD General ArrangementNihar SenapatiPas encore d'évaluation

- Statement of The Problem: Figure No. 1 Current TransformerDocument12 pagesStatement of The Problem: Figure No. 1 Current TransformerAngelo Caimol Sergantes100% (1)

- Conductors For Overhead Lines Aluminium Conductor Steel Reinforced (ACSR)Document13 pagesConductors For Overhead Lines Aluminium Conductor Steel Reinforced (ACSR)Sirous EghlimiPas encore d'évaluation

- Current Rating CalculationDocument3 pagesCurrent Rating CalculationArifin TriyantoPas encore d'évaluation

- Transformer DesigneDocument6 pagesTransformer Designemhm770077100% (1)

- 3FL Long Rod Insulators PDFDocument12 pages3FL Long Rod Insulators PDFanand_girgaonkarPas encore d'évaluation

- Is 13235.1991 PDFDocument32 pagesIs 13235.1991 PDFAnil MarturiPas encore d'évaluation

- AEI PVC Cable Data Sheet (6181)Document2 pagesAEI PVC Cable Data Sheet (6181)tidy4567Pas encore d'évaluation

- Analytic Method To Calculate and Characterize The Sag and Tension of Overhead Lines - IEEE Journals & MagazineDocument4 pagesAnalytic Method To Calculate and Characterize The Sag and Tension of Overhead Lines - IEEE Journals & MagazinesreedharPas encore d'évaluation

- Chapter 3 Iec 60909Document6 pagesChapter 3 Iec 60909Fran R JayPas encore d'évaluation

- ABB Busbar Protection REB670 2.0 ANSIDocument498 pagesABB Busbar Protection REB670 2.0 ANSIksg9731Pas encore d'évaluation

- Unit 1Document19 pagesUnit 1SafjrocnPas encore d'évaluation

- Automatic Projectile Propulsion System: AbstractDocument58 pagesAutomatic Projectile Propulsion System: AbstractstroxPas encore d'évaluation

- Ampacity of 230kV Taungoo-Loikaw LineDocument6 pagesAmpacity of 230kV Taungoo-Loikaw Line정상진Pas encore d'évaluation

- fr18 08 PDFDocument6 pagesfr18 08 PDFARCC2030Pas encore d'évaluation

- Aluminum Vs CopperDocument7 pagesAluminum Vs Copperc.a.g.p.Pas encore d'évaluation

- 75°c Temperatura Maxima de Diseño para Conductores de AluminioDocument22 pages75°c Temperatura Maxima de Diseño para Conductores de AluminioVICTORMARCEPas encore d'évaluation

- Cigreb2 4Document4 pagesCigreb2 4Nguyễn Tăng LâmPas encore d'évaluation

- TafirifezaDocument2 pagesTafirifezazafrikhan875Pas encore d'évaluation

- Comparative Studies of The Susceptibility of Copper and Aluminum To Processing in Wire Drawing ProcessDocument7 pagesComparative Studies of The Susceptibility of Copper and Aluminum To Processing in Wire Drawing ProcessIJAR JOURNALPas encore d'évaluation

- Bushing High VoltageDocument3 pagesBushing High VoltageRavi K NPas encore d'évaluation

- Coastal Education & Research Foundation, Inc. Journal of Coastal ResearchDocument4 pagesCoastal Education & Research Foundation, Inc. Journal of Coastal ResearchAnnisa DwiPas encore d'évaluation

- TES P 119 10 R0 1 GroundingpdfDocument43 pagesTES P 119 10 R0 1 Groundingpdftino cardaPas encore d'évaluation

- Analysis of Transit AC and DC Traction Power NetworksDocument11 pagesAnalysis of Transit AC and DC Traction Power Networks曾乙申Pas encore d'évaluation

- Ficj': Date: 02/1112019Document28 pagesFicj': Date: 02/1112019Sumaiya Binte YousufPas encore d'évaluation

- Mitsubishi Electric Air To Water (ATW) Heat Pump EngDocument96 pagesMitsubishi Electric Air To Water (ATW) Heat Pump EnghcnesaPas encore d'évaluation

- Experiment 1 PDFDocument5 pagesExperiment 1 PDFJarin TasnimPas encore d'évaluation

- Energy Storage Systems For Advanced Power Applications: Calvin CollegeDocument41 pagesEnergy Storage Systems For Advanced Power Applications: Calvin College98_kingsukPas encore d'évaluation

- Your Friendly Neighborhood Quadcopter Platform: A Build TutorialDocument29 pagesYour Friendly Neighborhood Quadcopter Platform: A Build TutorialriofelizPas encore d'évaluation

- Physics ProblemsDocument9 pagesPhysics ProblemsimpacttutorialsPas encore d'évaluation

- Cost Benefit Analysis MethodologyDocument51 pagesCost Benefit Analysis MethodologyJason KemboiPas encore d'évaluation

- PJM Transmission Owner Reliability Audit ProgramDocument34 pagesPJM Transmission Owner Reliability Audit Programschaefer1015719Pas encore d'évaluation

- 543SDocument270 pages543SregnieeePas encore d'évaluation

- Quelques Éléments de Synthèse Upfc: Année Universitaire 2020-2021Document15 pagesQuelques Éléments de Synthèse Upfc: Année Universitaire 2020-2021slomczynskiPas encore d'évaluation

- 11 KV Network ElementDocument11 pages11 KV Network ElementKuldip PrasadPas encore d'évaluation

- Syllabus and Questionbank Electrical Power System I 19 20Document12 pagesSyllabus and Questionbank Electrical Power System I 19 20dhyan shahPas encore d'évaluation

- Eighty Years of Polish Experiences in Technology of Live-Line Working and Impressions From All 10 ICOLIM ConferencesDocument13 pagesEighty Years of Polish Experiences in Technology of Live-Line Working and Impressions From All 10 ICOLIM Conferencesmody100Pas encore d'évaluation

- Transmission Tower Presentation PDFDocument27 pagesTransmission Tower Presentation PDFIlham HusseinPas encore d'évaluation

- Optimum Phasing Power LinesDocument6 pagesOptimum Phasing Power LinesiaessackjeePas encore d'évaluation

- Homework For Magnetic Effects ..Document72 pagesHomework For Magnetic Effects ..Kids World School SystemPas encore d'évaluation

- Application Note An-00500: Antennas: Design, Application, PerformanceDocument7 pagesApplication Note An-00500: Antennas: Design, Application, PerformanceAnonymous 0qYv7WpgPas encore d'évaluation

- PSOC Assignment-1 I. Short Answer QuestionsDocument3 pagesPSOC Assignment-1 I. Short Answer Questionssurisetti amruthaPas encore d'évaluation

- Capacity Projection 2009-2018Document105 pagesCapacity Projection 2009-2018MuratPas encore d'évaluation

- Republic of The Philippines Pablo Borbon Main II, Alangilan, Batangas City WWW - Batstate-U.edu - PH Tel. No. (043) 425-0139 Loc. 118Document6 pagesRepublic of The Philippines Pablo Borbon Main II, Alangilan, Batangas City WWW - Batstate-U.edu - PH Tel. No. (043) 425-0139 Loc. 118Harold De ChavezPas encore d'évaluation

- Article CIGRE 22 - 206E PDFDocument6 pagesArticle CIGRE 22 - 206E PDFIsaac DiazPas encore d'évaluation