Académique Documents

Professionnel Documents

Culture Documents

Install Grounding at S-Plant

Transféré par

iwd_smTitre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Install Grounding at S-Plant

Transféré par

iwd_smDroits d'auteur :

Formats disponibles

Project : KAO INDONESIA - KKD PROJECT

Jakarta Office, 5F. MidPlaza 2 . Jl. Jend. Sudirman Kav. 10-11 Jakarta 10220, Indonesia

REQUEST FOR SITE INSPECTION ( RFSI )

Report No. : SHIMS-RFSI-KAO KKD IND-07-2013

Sub-Contractor : Kinden Indonesia

Services : Electrical

The following works / tests are ready for inspection / will be conducted

at ________ on April ____, 2013.

DESCRIPTION OF WORKS

Location : S-Plant area ( SX5, SY1 )

Nature of Work : Install cooper plate for lightning protection grounding system.

Drawing / Sketches No. : SD-E-SH-148, SD-E-SH-149.

Attach Checklist No. : SHIMS-E.01-KAO-13-2013

(Note: Where required, include details of products, labour and equipment to be used)

Submitted by Received by

Signature : Signature :

Name : Name :

Time / Date : Time / Date :

INSPECTION / TEST RESPONSE

Inspection acceptable / test passed*, with / without* comment. Works are allowed to proceed

Inspection unacceptable / test failed*. Contractor to carry out remedial works

Re-inspection is required / Re-Testing is required

Signature : Shimizu Corporation Date:

Name :

FORM NO.: F-SHIMS-QCME-PO5-RFSI REV.0 ISSUED DATE: 5-09-12

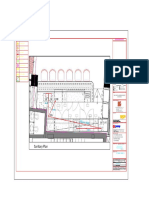

Project : KAO INDONESIA - KKD PROJECT.

Jakarta Office, 5F. MidPlaza 2 . Jl. Jend. Sudirman Kav. 10-11 Jakarta 10220, Indonesia

SITE GENERAL REPORT

Inspection Date : April 1, 2013. Report No. : SHIMS-M.03-KAO KKD Ind.-13-13

Location : S-Plant area ( SX5-SY23 ). Inspected By : Sonny U.

No. Install copper plate for lightning protection. No. Install copper plate for lightning protection.

1 2

Comfirmed by Comfirmed by

Shimizu Shimizu

(Sign) (Sign)

Description : Install copper plate for lightning Description : location of escavation.

protection.

3 4

Comfirmed by Comfirmed by

Shimizu Shimizu

(Sign) (Sign)

Description : Install copper plate for lightning Description : Inspect and test with Shimizu staff.

protection.

5 6

Comfirmed by Comfirmed by

Shimizu Shimizu

(Sign) (Sign)

Description : Install copper plate for lightning Description : Visual check by shimizu staff.

protection.

7 8

Comfirmed by Comfirmed by

Shimizu Shimizu

(Sign) (Sign)

Description : measurement for grounding Description : Resistance value.

resistance.

FORM NO.: F-SHIMS-QCME-PO5-M.03 REV.0 ISSUED DATE: 05-09-12

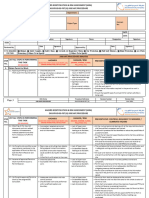

Project :

Jakarta Office, 5F. MidPlaza 2 . Jl. Jend. Sudirman Kav. 10-11 Jakarta 10220, Indonesia

GROUNDING WORK INSPECTION TEST REPORT

Report No. : SHIMS-E.01-KAO-13-2013

Date : Stage 1 - Stage 2 - Stage 3

Location / Gridline : Drwg Reff. :

TYPE OF GROUNDING WORK :- (Mark where applicable)

LV/MV Electrical Grounding Computer / IT System Grounding

LV/MV Frame/Neutral Grounding Telephone / ELV Grounding

Lightning Protection/Structural Grounding Others :-

PARTICULARS OF GROUNDING MATERIAL :- (Delete where not applicable, Ensure )

Type of Joint : Exorthermic Weld / Mechanical Clamp

Grounding Conductor Material Copper / GI / Alum / Others :-

Rod, Coupler and Clamp Type :- : Copper / Steel / Others :-

Grounding Pit Material / Type (Stage 3) : Polymer / R.Concrete, Heavy Duty / Light Dity

Earth Resistance Tester(Calibration Expiry date) : (Exp Date : )

STAGE 1 - Inspection (Exorthemic Weld to Pilecap/Stump Column) :-

1). Ensure Material use according to approved type, specification. YES NO NA

2). Check Welding work are conducted according to Method Statement. YES NO NA

3). Ensure cable is in place, tied properly, lenght is sufficient for next procedure. YES NO NA

4). Record with Photo. Proceed to next stage if requirement of item 1, 2 & 3 complied YES NO NA

STAGE 2- Inspection (Exorthemic Weld to Steel Column base) :-

1). Check Welding work are conducted according to Method Statement. YES NO NA

2). Ensure cable lengh are not too long, cable insulation are intact. YES NO NA

3). Record with Photo. Proceed to next stage if requirement of item 1 & 2 complied YES NO NA

STAGE 3 - Installation of Grounding Rod, Testing of earth resistance :-

1). Ensure location and distance of grounding point as per approved drawing YES NO

2). Test Individual point according to Manual shown in Tester. Ensure all points are not connected

EARTH TEST RESULT :- Total Grounding Point :-

Grounding Depth Resistance Value Grounding Depth Resistance Value

Point of Rod (Ohm) Point of Rod (Ohm)

Earth pit No.1. Earth pit No.3.

Earth pit No.2. Earth pit No.4.

1). Loop all point together with copper wire and conduct test for overall grounding resistance value.

2). Overall Grounding Resistance Value : Ohm. Requirement : < 5 Ohm (standar IEC)

3). Test Result is acceptable or not. * YES NO *Proceed with looping cable and welding work.

4). Check Welding work are conducted according to Method Statement. YES NO NA

5). Keep all record with photo. YES NO

SUB CONTRACTOR SHIMIZU CORPORATION

Tested by : Inspected by : Reviewed by :

1) Name : 1) Name : 2) Name :

Position : ME Engineer Position : ME Engineer Position : Sr. ME Engineer (QAQC)

Date : Date : Date :

Reviewed by :

2) Name : 3) Name :

Position : Project Manager Position : Site ME Manager

Date : Date :

OWNER/CLIENT'S REP. (If Necessary) :

Witnessed by : Position :

Name : Date :

FORM NO.: F-SHIMS-QCME-PO5-E.01 REV.0 ISSUED DATE: 05-09-12

Vous aimerez peut-être aussi

- Site General Report: Jakarta Office, 6Fl. Setiabudi Atrium Building Suite 601, Jl. HR Rasuna Said Kav 62Document2 pagesSite General Report: Jakarta Office, 6Fl. Setiabudi Atrium Building Suite 601, Jl. HR Rasuna Said Kav 62Harits Angga KusumaPas encore d'évaluation

- 1.RFI COVER-combinedDocument3 pages1.RFI COVER-combinednatamas systemsPas encore d'évaluation

- JSA Sample 0Document13 pagesJSA Sample 0Razi KhanPas encore d'évaluation

- Saic D 2024Document9 pagesSaic D 2024Md ShariquePas encore d'évaluation

- Saic M 1014Document3 pagesSaic M 1014Hussain Nasser Al- NowiesserPas encore d'évaluation

- SD-S5564-XX-SGA0 - Rev.6 (Beams)Document3 pagesSD-S5564-XX-SGA0 - Rev.6 (Beams)Anonymous koR9VtfPas encore d'évaluation

- Method Statement For Jockey Pump SleeveDocument6 pagesMethod Statement For Jockey Pump SleeveXen AnoyoPas encore d'évaluation

- Roof Pipe Line Fire Safety Other: 1. Descrption and Location of Work: UteduaioDocument1 pageRoof Pipe Line Fire Safety Other: 1. Descrption and Location of Work: UteduaioTushar AgarwalPas encore d'évaluation

- L021 - OHSE Piling Work Permit Cum Checklist FormatDocument1 pageL021 - OHSE Piling Work Permit Cum Checklist FormatRajib MondalPas encore d'évaluation

- Daily Progress Report HSM Project Utility PipingDocument3 pagesDaily Progress Report HSM Project Utility PipingGopakumar KPas encore d'évaluation

- Lifting Lug Design (3064)Document37 pagesLifting Lug Design (3064)Ganesh Bhardwaj50% (2)

- F-EQC-12 Bottom Liner Inspection ReportDocument1 pageF-EQC-12 Bottom Liner Inspection Reportsamir ranjan dhalPas encore d'évaluation

- Daily Welding Chamber Skirt AssemblyDocument1 pageDaily Welding Chamber Skirt AssemblyMa'ruf firmansyahPas encore d'évaluation

- Wa-07 Visibility Calculation, Showing Compliance With Panama Canal Autority VisibilityDocument5 pagesWa-07 Visibility Calculation, Showing Compliance With Panama Canal Autority VisibilitypawanPas encore d'évaluation

- JSP For SS No. 1 Battery Charging and TestingDocument11 pagesJSP For SS No. 1 Battery Charging and TestingmohammedtofiqahmedPas encore d'évaluation

- AozayDocument11 pagesAozayheryfiononanapierrette01Pas encore d'évaluation

- DRP001 Ouf Gal Pro Q 000 063 S2Document66 pagesDRP001 Ouf Gal Pro Q 000 063 S2Rafat KhanPas encore d'évaluation

- 09 RivettingDocument3 pages09 Rivettingv.bhamidiPas encore d'évaluation

- TMG Sdarch 001Document1 pageTMG Sdarch 001Karim SandPas encore d'évaluation

- Request For Inspection: Project: TEP - Tree Harvesting & Site PreparationDocument1 pageRequest For Inspection: Project: TEP - Tree Harvesting & Site PreparationulfaPas encore d'évaluation

- Zbp-V3-Alsaad-hq-dwg-sd-Ar-0116-Rev01 - Headquarter Mf.35 Ablution, Corridor and Mf.36 Enlarged PlanDocument3 pagesZbp-V3-Alsaad-hq-dwg-sd-Ar-0116-Rev01 - Headquarter Mf.35 Ablution, Corridor and Mf.36 Enlarged PlanThe Saudi TamizhanPas encore d'évaluation

- Checklist by Girish MishraDocument30 pagesChecklist by Girish MishraDeepak Kaushik100% (1)

- Saic-N - 2017Document2 pagesSaic-N - 2017SUNIL RAJPUTPas encore d'évaluation

- ITP-SF (Rev 0) - Installation of Sanitary Fittings PDFDocument1 pageITP-SF (Rev 0) - Installation of Sanitary Fittings PDFJackPas encore d'évaluation

- EQUIPMENT MATERIAL TECHNICAL DATA FORM (MEP) - BON Welded FittingsDocument1 pageEQUIPMENT MATERIAL TECHNICAL DATA FORM (MEP) - BON Welded FittingskkmsPas encore d'évaluation

- Tower - Lightening Protection: ElectricalDocument1 pageTower - Lightening Protection: ElectricalhrimklimPas encore d'évaluation

- JSP For SS No. 6 Loading and Installation of Panel Board (Manual Lifting)Document16 pagesJSP For SS No. 6 Loading and Installation of Panel Board (Manual Lifting)mohammedtofiqahmedPas encore d'évaluation

- H.M.W.S. & S.Board: Stores IndentDocument3 pagesH.M.W.S. & S.Board: Stores IndentMir AliPas encore d'évaluation

- JSP For OHTL No. 19 Excavation Works For Tower Foundation Pad and ChimneyDocument10 pagesJSP For OHTL No. 19 Excavation Works For Tower Foundation Pad and ChimneyJaafar LagayanPas encore d'évaluation

- Cigar Bar SanitaryDocument1 pageCigar Bar SanitaryDennis AngPas encore d'évaluation

- Confined Space PermitDocument3 pagesConfined Space PermitDhaneswar SwainPas encore d'évaluation

- Jassor Factory - 0001Document1 pageJassor Factory - 0001Muhammad BiLALPas encore d'évaluation

- Soil Resistance Earth For High ValueDocument1 pageSoil Resistance Earth For High ValuetrichysayeePas encore d'évaluation

- ITEM NO. (Service) : Inspection Report Hot Oil Heater (Vertical On Ground)Document2 pagesITEM NO. (Service) : Inspection Report Hot Oil Heater (Vertical On Ground)Alif Rahmat FebriantoPas encore d'évaluation

- RF003 Road MarkingsDocument1 pageRF003 Road MarkingsSyerifaizal Hj. MustaphaPas encore d'évaluation

- TMG SD Arch 002Document3 pagesTMG SD Arch 002Karim SandPas encore d'évaluation

- Pressure Test PermitDocument2 pagesPressure Test PermitRajesh KumarPas encore d'évaluation

- HSE Report Makhazen S/SDocument6 pagesHSE Report Makhazen S/SAnonymous kWfNFbPas encore d'évaluation

- Indorama Ventures Inspection ReportDocument2 pagesIndorama Ventures Inspection ReportSales Creative EngineeringPas encore d'évaluation

- Tack Welding ProcedureDocument3 pagesTack Welding Procedureiftekhar ahmed0% (1)

- 5) IN MAR SMNSSI-AP - 21.03.2023Document8 pages5) IN MAR SMNSSI-AP - 21.03.2023Nitesh KumarPas encore d'évaluation

- OrganizedDocument1 pageOrganizedIkhsan BakhrullohPas encore d'évaluation

- JSP For OHTL No. 17 Underline Gantry Installation and ErectionDocument15 pagesJSP For OHTL No. 17 Underline Gantry Installation and ErectionJaafar LagayanPas encore d'évaluation

- Precision component inspection reportDocument1 pagePrecision component inspection reportYash UpadhyayPas encore d'évaluation

- Mu Mod Report 1 2002Document1 pageMu Mod Report 1 2002Brahmananda ChakrabortyPas encore d'évaluation

- SAFETY WORK METHOD Temporary-Fencing-InstallationDocument15 pagesSAFETY WORK METHOD Temporary-Fencing-Installationusman khalid100% (1)

- JSP For SS No. 4 Commissioning of High Voltage EquipmentDocument21 pagesJSP For SS No. 4 Commissioning of High Voltage EquipmentmohammedtofiqahmedPas encore d'évaluation

- SAUDI ARAMCO SEAL WELD INSPECTIONDocument1 pageSAUDI ARAMCO SEAL WELD INSPECTIONkartik_harwani4387Pas encore d'évaluation

- Checklist For Rebar and Concrete WorkDocument4 pagesChecklist For Rebar and Concrete WorkDwinto RachmadPas encore d'évaluation

- LOCO - SOP - E - 0004 Lubrication of LocoDocument16 pagesLOCO - SOP - E - 0004 Lubrication of LocoFiron Kumar RanaPas encore d'évaluation

- General Corrosion Survey of Tr 1A Glycol PipingDocument11 pagesGeneral Corrosion Survey of Tr 1A Glycol PipingShamsul AffendiPas encore d'évaluation

- RFI 891 - 18 MarDocument1 pageRFI 891 - 18 MarSAIF JAFFERPas encore d'évaluation

- Welder Qualification Test RFIDocument1 pageWelder Qualification Test RFISAIF JAFFERPas encore d'évaluation

- Installation of Earthing, Lightning Protection System JSADocument2 pagesInstallation of Earthing, Lightning Protection System JSAAsif Hussain100% (1)

- Daswin Project MEP 2nd Fix InspectionDocument30 pagesDaswin Project MEP 2nd Fix InspectionKristofel SinagaPas encore d'évaluation

- Mitsubishi Heavy Industries, LTD.: Plan RecordDocument2 pagesMitsubishi Heavy Industries, LTD.: Plan RecordJin HernPas encore d'évaluation

- Level Switch Data SheetDocument3 pagesLevel Switch Data SheetNikhil KarkeraPas encore d'évaluation

- Apartemen Tugu Tani - JakartaDocument14 pagesApartemen Tugu Tani - Jakartaiwd_smPas encore d'évaluation

- Drawing Tracking List Mep (Electrical) : STC - Multikon J.O. Nama Proyek: G3TV Gedung: Global TVDocument19 pagesDrawing Tracking List Mep (Electrical) : STC - Multikon J.O. Nama Proyek: G3TV Gedung: Global TViwd_smPas encore d'évaluation

- Tanggal: 21 Oktober 2013: Rangkuman Pekerjaan M.E.P & Hvac Proyek G3Tv - Kebon Jeruk - Jakarta Barat Stc-Multikon JoDocument16 pagesTanggal: 21 Oktober 2013: Rangkuman Pekerjaan M.E.P & Hvac Proyek G3Tv - Kebon Jeruk - Jakarta Barat Stc-Multikon Joiwd_smPas encore d'évaluation

- Hotel Park - MedanDocument13 pagesHotel Park - Medaniwd_smPas encore d'évaluation

- Office Voza Tower - SurabayaDocument33 pagesOffice Voza Tower - Surabayaiwd_smPas encore d'évaluation

- OPTIMALKAN PLUMBINGDocument8 pagesOPTIMALKAN PLUMBINGAditya AmklPas encore d'évaluation

- Xin Tian Di (Mix Used) Pluit City - JakartaDocument37 pagesXin Tian Di (Mix Used) Pluit City - Jakartaiwd_smPas encore d'évaluation

- Jadwal Service Ahu & Fcu Tower 2 MNC GroupDocument8 pagesJadwal Service Ahu & Fcu Tower 2 MNC Groupiwd_smPas encore d'évaluation

- Shop House Pluit City - JakartaDocument4 pagesShop House Pluit City - Jakartaiwd_smPas encore d'évaluation

- MNC Broadcast EntrancesDocument3 pagesMNC Broadcast Entrancesiwd_smPas encore d'évaluation

- Detail ModelDocument1 pageDetail Modeliwd_smPas encore d'évaluation

- Site Defect Inspection Report: Lt. 17 Area Office Utara, Kondensasi Dari Aksesoris AHU Dan Pipa ChillerDocument1 pageSite Defect Inspection Report: Lt. 17 Area Office Utara, Kondensasi Dari Aksesoris AHU Dan Pipa Chilleriwd_smPas encore d'évaluation

- Monitoring Penyelesaian Defect G3Tv Project - Global TV: NO UraianDocument4 pagesMonitoring Penyelesaian Defect G3Tv Project - Global TV: NO Uraianiwd_smPas encore d'évaluation

- Construction Photograph: Project Name Owner Location Title of Work DateDocument4 pagesConstruction Photograph: Project Name Owner Location Title of Work Dateiwd_smPas encore d'évaluation

- Insulation Test Busduct PLBN Badau PJT: 1. Serial A (Trafo - LVMDP)Document1 pageInsulation Test Busduct PLBN Badau PJT: 1. Serial A (Trafo - LVMDP)iwd_smPas encore d'évaluation

- Chiller G3TVDocument1 pageChiller G3TViwd_smPas encore d'évaluation

- Fire Compartement Penetration ProcessDocument12 pagesFire Compartement Penetration Processiwd_smPas encore d'évaluation

- Schedule Service AC MNC Land KB - JRKDocument43 pagesSchedule Service AC MNC Land KB - JRKiwd_smPas encore d'évaluation

- Measuring Continuity Test ReportDocument1 pageMeasuring Continuity Test Reportiwd_smPas encore d'évaluation

- Rab MNCDocument2 pagesRab MNCiwd_smPas encore d'évaluation

- Iksan 29 MaretDocument22 pagesIksan 29 Maretiwd_smPas encore d'évaluation

- Ilmudrafter - Shortcut Autocad v1.001Document4 pagesIlmudrafter - Shortcut Autocad v1.001iwd_smPas encore d'évaluation

- System Ro Pak Rus-AbDocument1 pageSystem Ro Pak Rus-Abiwd_smPas encore d'évaluation

- Solid State, Enclosed & Reed RelaysDocument1 pageSolid State, Enclosed & Reed RelayskartikaPas encore d'évaluation

- PIC Supplier 1Document6 pagesPIC Supplier 1iwd_smPas encore d'évaluation

- ABPS Product BS476 PT 67 ASTM Assessment ABPS 2011 07Document10 pagesABPS Product BS476 PT 67 ASTM Assessment ABPS 2011 07iwd_smPas encore d'évaluation

- NRC-3651B Dune RH99-52238 - 1Document2 pagesNRC-3651B Dune RH99-52238 - 1iwd_smPas encore d'évaluation

- Menteng Residence: Progress Klaim Ke Iii Bulan DesemberDocument4 pagesMenteng Residence: Progress Klaim Ke Iii Bulan Desemberiwd_smPas encore d'évaluation

- Solid State, Enclosed & Reed RelaysDocument1 pageSolid State, Enclosed & Reed RelayskartikaPas encore d'évaluation

- AKIRA 14THS3-CE (Chassis UOC-OM8370) PDFDocument65 pagesAKIRA 14THS3-CE (Chassis UOC-OM8370) PDFRed Biokid TotingsPas encore d'évaluation

- Science 2004Document5 pagesScience 2004yilongwei.comPas encore d'évaluation

- 00-KX02A (XX) DS 3-0-1Document1 page00-KX02A (XX) DS 3-0-1jacunaPas encore d'évaluation

- 3 ELECTROCHEMISTRY Document - 2Document15 pages3 ELECTROCHEMISTRY Document - 2abdimoh7522Pas encore d'évaluation

- Data Sheet: Integrated FM Tuner For Radio ReceiversDocument11 pagesData Sheet: Integrated FM Tuner For Radio ReceiversahmedPas encore d'évaluation

- MS-SB250-12 12V250A: Specifications Product PictureDocument2 pagesMS-SB250-12 12V250A: Specifications Product PictureRui SvenssonPas encore d'évaluation

- Review of Analog Sensors/Transducers: Muhammad Zaigham Abbas ShahDocument16 pagesReview of Analog Sensors/Transducers: Muhammad Zaigham Abbas ShahAbdul Razaque MagsiPas encore d'évaluation

- HPD Low PowerDocument98 pagesHPD Low PowervcrichignoPas encore d'évaluation

- Physics 12 CH 4 SQs PDFDocument22 pagesPhysics 12 CH 4 SQs PDFLabiba TariqPas encore d'évaluation

- PBX-RF: RF-Isolated Parallel Port CNC Breakout BoardDocument3 pagesPBX-RF: RF-Isolated Parallel Port CNC Breakout BoardsjpsoaresPas encore d'évaluation

- TM 221Document124 pagesTM 221Carlos Gabriel EstergaardPas encore d'évaluation

- EU - Type Examination Certificate: II 2G Ex Ia IIC T5/T6 GB II 2D Ex Ia IIIC T100°C/T85°C DB IP6XDocument4 pagesEU - Type Examination Certificate: II 2G Ex Ia IIC T5/T6 GB II 2D Ex Ia IIIC T100°C/T85°C DB IP6XHabibulla BavajiPas encore d'évaluation

- 65 LBC 184Document21 pages65 LBC 184Feng TiejiPas encore d'évaluation

- Millennium Ycaj150Document116 pagesMillennium Ycaj150Hewa AkreyPas encore d'évaluation

- Hot Cathode Ionization Vacuum Gauge - The HornetDocument24 pagesHot Cathode Ionization Vacuum Gauge - The HornetInstruTech, Inc.Pas encore d'évaluation

- PR5597 Rev11 CPX Quick Start EngDocument2 pagesPR5597 Rev11 CPX Quick Start EngTony Brooke-TaylorPas encore d'évaluation

- Panel Solar 635WDocument2 pagesPanel Solar 635WVictor Manuel Levicoy OsorioPas encore d'évaluation

- Genset Controller HJ-103B, China Genset Controller HJ-103B Supplier, FactoryDocument2 pagesGenset Controller HJ-103B, China Genset Controller HJ-103B Supplier, FactoryARMFX67% (3)

- Irfd113, Sihfd113: Vishay SiliconixDocument8 pagesIrfd113, Sihfd113: Vishay SiliconixWellison RodriguesPas encore d'évaluation

- Nsap 12-150Document2 pagesNsap 12-150tobriPas encore d'évaluation

- Statement of Purpose For Admission in Masters in Power EngineeringDocument2 pagesStatement of Purpose For Admission in Masters in Power EngineeringDany 31Pas encore d'évaluation

- CCTV8 PDFDocument2 pagesCCTV8 PDFFelix John NuevaPas encore d'évaluation

- Ilaw Atbp 2020Document42 pagesIlaw Atbp 2020cheyanne guia oaferinaPas encore d'évaluation

- Machine Chap 1Document47 pagesMachine Chap 1Taha MohammedPas encore d'évaluation

- Observe Output Voltage of Buck & Boost ConvertersDocument7 pagesObserve Output Voltage of Buck & Boost ConvertersAnshuman DebataPas encore d'évaluation

- DoordarshanDocument57 pagesDoordarshanMegha OmshreePas encore d'évaluation

- PHYWE - Hall Effect - Experiments N and P Germanium - P2530116e PDFDocument11 pagesPHYWE - Hall Effect - Experiments N and P Germanium - P2530116e PDFMarco Antonio RH100% (1)

- TI Motor Control Compendium 2010Document221 pagesTI Motor Control Compendium 2010Junhui ZhaoPas encore d'évaluation

- Analysis and Damping Control of Power System Low-Frequency OscillationsDocument403 pagesAnalysis and Damping Control of Power System Low-Frequency OscillationsToni Alfian100% (1)

- Iqan-Xa2 Uk Ed0907 InstruçãoDocument37 pagesIqan-Xa2 Uk Ed0907 InstruçãoAxicelPas encore d'évaluation