Académique Documents

Professionnel Documents

Culture Documents

Lsis XBC Dr10e, Dr14e, Dr20e, Dr30e PDF

Transféré par

S M NaveedTitre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Lsis XBC Dr10e, Dr14e, Dr20e, Dr30e PDF

Transféré par

S M NaveedDroits d'auteur :

Formats disponibles

2.

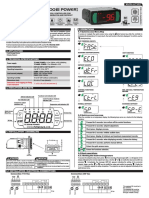

Performance Specifications

Safety Precautions

DATA SHEET ► Safety Precautions is for using the product safely and correctly in order to prevent

Related Manual

Read this data sheet carefully prior to any operation, mounting, installation or start-up of the

Specification

the accidents and danger, so please go by them. product. Item XBC- XBC- XBC- XBC- Ref.

LS Programmable Logic Controller ► The precautions explained here only apply to this module. For safety precautions Name Code DR10E DR14E DR20E DR30E

on the PLC system, refer to User’s manual. XG5000 User’s Manual(Programming software) 10310000512 Reiterative operation, fixed cycle operation

Operation method

XGB Compact Economy Type XGK/XGB Instruction & Programming User’s manual 10310000510 Interrupt operation, constant period scan

► The precautions are divided into 2 sections, ‘Warning’ and ‘Caution’. Each of the

XGB Cnet I/F User’s Manual 10310000816 Scan synchronous batch processing

meanings is represented as follows. XGB Standard/Economic Hardware User’s manual 10310001091 I/O control method (refresh method)

Direct method by instruction

If you violate instructions, it can cause death, fatal injury or a Ladder Diagram

Program language

XGB XBC-DR10E Warning considerable loss of property Revision History Instruction List

Date Version Updated Information No. of Basic 28

2010.2 V1.0 First Edition instruction Application 677

XBC-DR14E If you violate instructions, it can cause a slight injury or a slight 2010.3 V1.1 Error in performance specifications is fixed Operation speed

Caution loss of products KOREAN/ENGLISH data sheet integrated (Basic instruction)

0.24㎲/Step

XBC-DR20E 2011.5 V3.0

CI Changed Program memory 4ksteps

► The symbols which are indicated in the PLC and User’s Manual mean as follows. 14 18 28 38

XBC-DR30E This symbol means paying attention because of danger of injury, fire, Applicable version

I/O points (main +1 option) (main +1 option) (main+2 options) (main+2 options)

or malfunction For system configuration, the following version is necessary. P P0000 ~ P127F (2,048 points)

M M0000 ~ M255F (4,096 points)

► This symbol means paying attention because of danger of electric shock. Item Applicable version

K00000 ~ K2559F(Special area : K2600~2559F)

Store this datasheet in a safe place so that you can take it out and read XG5000 V3.4 or above K

(40,960 points)

it whenever necessary. Always forward it to the end user L L00000 ~ L1279F (20,480 points)

1. General Specifications F F000 ~ F255F (4,096 points)

Handling Precautions Data 100ms, 10ms, 1ms : T000 ~ T255 (256 points)

T

► Don’t drop or make impact. area (Variable by parameter setting)

No Item Specification Standard C C000 ~ C255 (256)

► Don’t detach PCB from case. It may cause problem. Operating

1 0 ~ 55℃ - S S00.00 ~ S127.99

► When wiring, let no foreign material go into the module. If it goes into the module, temperature D D0000 ~ D5119 (5120 words) Word

remove it. Storage U00.00 ~ U0A.31

2 temperature

-25 ~ 70℃ - U Word

► Don’t detach the module from slot while power is on (256 words, analog data refresh area)

Operating Z Z000~Z127 (128 words) Word

3 5 ~ 95%RH, non-condensing -

humidity No. of programs Max. 128

Storage

- When using LSIS equipment, thoroughly read this Warning 4

humidity

5 ~ 95%RH, non-condensing - Initialization 1

Fixed

datasheet and associated manuals introduced in this For discontinuous vibration - - cycle

Max. 8

► Do not contact the terminals while the power is applied. Frequency Acceleration Amplitude times

datasheet. Also pay careful attention to safety and handle Risk of electric shock and malfunction. Tack External

10≤f∠57 Hz - 0.075 mm point

Max. 4

the module properly. 57 ≤f≤150 Hz 9.8㎨ (1G) 10 times in

► Protect the product from being gone into by foreign metallic matter. 5

Vibration - Internal

resistance For continuous vibration each IEC61131-2 Max. 8

- Store this datasheet in a safe place so that you can take it Risk of fire, electric shock and malfunction. direction device

Frequency Acceleration Amplitude Operating mode RUN, STOP

out and read it whenever necessary. ► Risk of fire, electric shock and malfunction. for

10≤f∠57 Hz - 0.035 mm X, Y, Z Self-diagnosis Delay of operation, abnormal memory, abnormal I/O

Risk of injury and fire by explosion and ignition. 57≤f≤150 Hz 4.9㎨(0.5G) - Program port RS-232C(Loader)

Max. impact acceleration : 147 ㎨ (15G) Data keeping

6

Shocks Authorized time : 11㎳ IEC61131-2 method at power Setting latch area at basic parameter

resistance Pulse wave : Sign half-wave pulse failure

(Each 3 times in X,Y,Z directions)

Dedicated protocol

Square wave AC: ±1,500V LSIS

Modbus protocol

impulse noise DC: ±900V standard Cnet I/F

User defined protocol

HEAD OFFICE Caution Electrostatic

Voltage: 4kV (Contact discharge)

IEC61131-2 function

discharge IEC 000-4-2 Selects one port between RS-232C 1 port and

LS Tower, 127, LS-ro, Dongan-gu, Anyang-si,Gyeonggi-do, 431-848, Korea RS-485 1 port by parameter

► Be sure to check the rated voltage and terminal arrangement for the Radiated

Tel: 82-2-2034-4870 Fax: (82-2)2034-4648 e-mail: cshwang@lsis.biz IEC61131-2

Noise electromagnetic 80 ~ 1,000 MHz, 10 V/m Performa- 1-phase : 4㎑ 4 channels

module before wiring work. 7 IEC61000-4-3

nce 2-phase : 2㎑ 2 channels

resistance field noise

Risk of electric shock, fire and malfunction.

LSIS(ME) FZE _ Dubai, U.A.E. Power

Digital/analog 4 counter modes are supported based on input

► Tighten the screw of terminal block with the specified torque range.

High Speed Counter

Tel: 971-4-886-5360 Fax: 971-4-886-5361 e-mail: jungyongl@lsis.biz input/output pulse and INC/DEC method

Fast transient Segment supply IEC61131-2

Built-in Function

If the terminal screw is loose, it can cause fire and electric shock. communication 1 pulse operation Mode : INC/DEC count by program

/burst noise module IEC61000-4-4

interface Counter 1 pulse operation Mode : INC/DEC count by phase B

.

LSIS Tokyo Office _ Tokyo, Japan ► Use the PLC in an environment that meets the general Voltage 2 kV 1 kV mode pulse input

Tel: 81-3-3582-9128 Fax: 81-3-3582-2667 e-mail: jschuna@lsis.biz specifications contained in this datasheet. Ambient 2 pulse operation Mode : INC/DEC count by input pulse

Risk of electrical shock, fire, erroneous operation and deterioration of the 8 No corrosive gas or dust - 2 pulse operation Mode : INC/DEC count by difference

conditions

PLC. Operating of phase

LSIS Shanghai Office _ Shanghai, China 9 2000m or less -

height Internal/External preset function

Tel: 86-21-5237-9977(609) Fax: 89-21-5237-7189 e-mail: liyong@lsis.com.cn ► Be sure that external load does not exceed the rating of output

Pollution Latch counter function

module. 10 2 or less - Function

degree Comparison output function

LSIS Beijing Office _ Beijing, China Risk of fire and erroneous operation. Cooling Revolution number per unit time function

11 Natural air cooling -

Tel: 86-10-5825-6027(666) Fax: 86-10-5825-6028 e-mail: xunmj@lsis.com.cn ► Do not use the PLC in the environment of direct vibration type Pulse catch 50㎲ 4 points (P0000 ~ P0003)

Risk of electrical shock, fire and erroneous operation. External point

4 points: 50㎲ (P0000 ~ P0003)

LSIS Guangzhou Office _ Guangzhou, China ► Do not disassemble, repair or modify the PLC. interrupt

Tel: 86-20-8328-6754 Fax: 86-20-8326-6287 e-mail: chenxs@lsis.com.cn Risk of electrical shock, fire and erroneous operation Selects among 1,3,5,10,20,70,100㎳

Input filter

(For each module)

► When disposing of PLC and battery, treat it as industrial waste. Current consumption

LSIS Chengdu Office _ Chengdu, China Risk of poisonous pollution or explosion. (mA)

250 315 355 485

Tel: 86-20-8328-6754 Fax: 86-20-8326-6287 e-mail: comysb@lsis.biz Weight(g) 330 340 450 465

LSIS Qingdao Office _ Qingdao, China

Precautions for use

► Do not Install other places except PLC controlled place.

Tel: 86-532-8501-6068 Fax: 86-532-8501-6057 e-mail: wangzy@lsis.com.cn

► Make sure that the FG terminal is grounded with class 3 grounding which is

dedicated to the PLC. Otherwise, it can cause disorder or malfunction of PLC

LSIS Europe B.V., Netherlands

Tel: +31 (0)20 654 1420 Fax: +31(0)20 654 1429 e-mail: junshickp@lsis.biz PLC Others PLC Others PLC Others

Homepage: http://eng.lsis.biz

A) Best B) Good C) Bad

► Connect expansion connector correctly when expansion module is needed.

► Do not detach PCB from the case of the module and do not modify the module.

LS constantly endeavors to improve our products so that information in this ► Turn off power when attaching or detaching module.

datasheet is subject to change without notice. ► Cellular phone or walkie-talkie should be farther than 30cm from the PLC.

The date of issue: 2011. 5 ► Input signal and communication line should be farther than 10cm from a high-

10310001095 Ver 3.0 tension and a power line in order not to be affected by noise and magnetic field.

(2) Input Filter Function

3. Parts Name and Descriptions 5. Built-in High Speed Counter Function The input filter function can be used to reject noises. The input filter constant from the 8. Dimension (㎜)

(1) Summary range of 1-100㎳ can be designated.

The high-speed counter can count high frequency pulse which can not be processed (1) XBC-DR10/14E

with the input unit. It can count pulse which occurs from encoder or pulse generator. (a) Usage

(2) Performance Specification Input signal status affects the credibility of system where noise occurs frequently or

Item Specification pulse width of input signal affects as a crucial factor. In this case the user sets up

Signal A Phase, B Phase the proper input on/off delay time, the trouble by miss operation of input signal may

Signal be prevented because the signal which is shorter than set up value is not adopted.

Input DC24V

level

Signal

Signal (b) Operation Explanation

Voltage Input (Open collector)

Type

Counting range Signed 32 Bit (-2,147,483,648 ~ 2,147,483,647)

Input filter constant (Filter time)

Counting speed 1-phase: 4kpps 4 channels 2-phase: 2kpps 2 channels

Counter format Linear counter / Ring counter

1 pulse operation Mode : INC/DEC count by program

1 pulse operation Mode : INC/DEC count by phase B pulse input Input signal

Counter mode 2 pulse operation Mode : INC/DEC count by input pulse

2 pulse operation Mode : INC/DEC count by difference of phase

(4 multiplication) Input image data

Time

Internal/External preset function / Latch counter function

Function

Compare output function / no. of rotation per unit time

Input signal

(2) XBC-DR20/30E

6. PID Control Function Input image data

(1) Dedicated communication

No Name Description

XGB Compact Type has built-in Cnet communication function, and can communicate

① Input status LED ■ Indicates input status. with various external devices without expansion Cnet I/F module.

■ Connector to connect with XG5000 Narrower width pulse than input filter constant is not considered as input

② PADT Connector (XGB Compact Type Main Unit has built-in RS-232C and RS-485.) signal.

•RS-232C 1 channel

③ Input terminal block ■ Input Terminal Block Built-in Cnet of XGB Main Unit supports the following functions;

④ Output terminal block ■ Output terminal block (a) Read single/continuous device

■ Sets the operation mode of main unit. (3) External interrupts function

(b) Write single/continuous device XGB PLC can perform max 4 external contact tasks by using input of main unit

• STOP → RUN : Operation execution of (c) Register monitoring device

RUN/STOP mode program without special interrupt module

⑤ (d) Execute monitoring

switch • RUN → STOP : Operation stop of program (e) 1:1 connection system (LS link) (a) Usage

(In case of STOP, it can be changed to remote

mode) This function is useful when you need to process operation related to external

(2) User defined communication

⑥ Output status LED ■ Indicates output status

User can define a user-defined protocol to communicate with other manufacturer’s input signal fast without scan time.

■ Indicates the operation status of the main unit devices. By supporting user-defined protocol, XGB PLC can communicate with various

• PWR(RED ON) : Indicates power status. (b) Operation Explanation

⑦ Operation status LED devices which have their own protocol. 9. Warranty

• RUN(GREEN ON) : RUN mode

• ERR(RED blink) : indicates error External input signal (1) Warranty period

(3) Modbus protocol LSIS provides an 18-month-warranty from the date of the production.

Built-in

■ Terminal block for built-in RS-232C/485 XGB PLC includes Modbus protocol, and it is easy to connect to Modbus devices.

⑧ Communication (2) Warranty conditions

communication (It is not necessary to write Modbus protocol as user-defined protocol.) Scan

Terminal block Scan For troubles within the warranty period, LSIS will replace the entire PLC or repair

⑨ Power terminal block ■ Terminal block for power (AC 100~240V) program program

(4) P2P communication support the troubled parts free of charge except the following cases.

■ Dip switch for selecting Operation or O/S

download mode XGB PLC supports client function service with P2P form to above item. Interrupt (a) The troubles caused by improper condition, environment or treatment except

⑩ O/S mode dip switch •On: BOOT mode. Downloading O/S is available In case of occurrence Program the instructions of LSIS.

•Off: User mode. Downloading program by PADT Remarks of external interrupt (b) The troubles caused by external devices.

is available Ends the interrupt

1) Please refer to XGB Cnet I/F User’s Manual for the details of built-in Cnet I/F signal pauses being (c) The troubles caused by remodeling or repairing based on the user’s own

⑪ Option board holder ■ For connecting option board program process

function. executed scan program discretion.

then resumes to

and processes interrupt

execute (d) The troubles caused by improper usage of the product.

program

4. I/O No. Allocation Method 7. Other Built-in Function scan program. (e) The troubles caused by the reason which exceeded the expectation from

(1) I/O No. Allocation grants address to unit & module for input/output data (1) Pulse Catch Function science and technology level when LSIS manufactured the product.

In the main unit, 4 pulse catch input contact points (P000~P003) are included. Through (f) The troubles caused by natural disaster.

using this contact point short pulse signal (min. 50㎲) which cannot be executed by (3) This warranty is limited to the PLC itself only. It is not valid for the whole system

general digital input can be taken.

(c) Function which the PLC is attached to.

(a) Usage 1) It can be use the max. 4 point input (P000 ~ P003).

When narrow pulse signal is input which can not be executed by general digital input, 2) Input 4 points (P000 ~ P003) of XGB Compact Type Main Unit are shared for

the operation can not performed as user's intention. But in this case through pulse several functions as following table.

catch function even narrow pulse signal (min. 10㎲) can be executed. 3) Each of the functions can be disabled according to whether other functions

(b) Operation Explanation are enabled.

High Speed External

Main unit Option module #1~2 Input Point Pulse Catch Input Filter

Counter Interrupt

P000 Ch0 Input Unavailable Unavailable Available

Input signal

No. of module can P001 Ch1 Input Unavailable Unavailable Available

Mounting module Ref.

be mounted P002 Ch2 Input Unavailable Unavailable Available

1 10/14 points unit Input image data P003 Ch3 Input Unavailable Unavailable Available

Option module

2 20/30 points unit

scan1 scan2 scan3

(2) The following is method of I/O number allocation

Area

Item Ref.

Input Output

Main unit P0000 ~ P003F P0040 ~ P007F Fixed Step Execution contents

Option #1 P0400~P043F 64point fixed CPU senses input when pulse signal of min. 50㎲ is input, then saves the

Scan1

Option #2 P0440~P047F 64point fixed status.

-. I/O allocation for all expansion modules is fixed at 64points Scan2 Turns on the region of input image.

Scan3 Turns off the region of input image

(The unused area can be used as internal relay)

Vous aimerez peut-être aussi

- Data Sheet: LS Programmable Logic Controller XGB Module TypeDocument1 pageData Sheet: LS Programmable Logic Controller XGB Module TypeRizonaldo Lucineide RibeiroPas encore d'évaluation

- Smart IoDocument2 pagesSmart Iotranhuutri1987quangngaiPas encore d'évaluation

- Xbo Ad02aDocument1 pageXbo Ad02aJeferson FigueiredoPas encore d'évaluation

- Ds 2mlf Ad4s Ai 200 v10 PDFDocument2 pagesDs 2mlf Ad4s Ai 200 v10 PDFsamim_khPas encore d'évaluation

- Ib63581j eDocument1 pageIb63581j eLucas PaulaPas encore d'évaluation

- NJ - NX-series CPU Unit Motion Control User's ManualDocument462 pagesNJ - NX-series CPU Unit Motion Control User's Manualthiago.prata.mrvPas encore d'évaluation

- w503 NJ Nx-Series Troubleshooting Manual Users Manual enDocument1 118 pagesw503 NJ Nx-Series Troubleshooting Manual Users Manual enDiki DikiPas encore d'évaluation

- TOEC8431331BDocument411 pagesTOEC8431331BAtthapol YuyaPas encore d'évaluation

- CNC ManualDocument411 pagesCNC ManualHarvey Haw ChangPas encore d'évaluation

- G7F-ADHB Eng0403Document2 pagesG7F-ADHB Eng0403atakan kurtcaPas encore d'évaluation

- NJ - NX-series CPU Unit Built-In EtherCAT Port User's ManualDocument276 pagesNJ - NX-series CPU Unit Built-In EtherCAT Port User's Manualthiago.prata.mrvPas encore d'évaluation

- Melsec QnPHCPU - User's - Manual - (Hardware - Design, - Maintenance - and - Inspection) - SH (NA) - 080314-B - (10.02)Document220 pagesMelsec QnPHCPU - User's - Manual - (Hardware - Design, - Maintenance - and - Inspection) - SH (NA) - 080314-B - (10.02)Leader OnePas encore d'évaluation

- Ds 2mlr Cpu Power Base 200 v10Document2 pagesDs 2mlr Cpu Power Base 200 v10samim_khPas encore d'évaluation

- Mitsubishi Maintenence ManualDocument212 pagesMitsubishi Maintenence ManualFERNSPas encore d'évaluation

- k3p 07AS SheetDocument2 pagesk3p 07AS SheetsoniPas encore d'évaluation

- Om 20131001Document232 pagesOm 20131001Christian ChavezPas encore d'évaluation

- W503-E1-12 Nj-Series Troubleshooting ManualDocument284 pagesW503-E1-12 Nj-Series Troubleshooting ManualasasdasddasPas encore d'évaluation

- Easygen 1000 SeriesDocument4 pagesEasygen 1000 SeriesLahir Untuk MenangPas encore d'évaluation

- DM6100/DM6300 Digital Meter: Quick Start Guide English Safety Precautions Digital Meter Physical DescriptionDocument4 pagesDM6100/DM6300 Digital Meter: Quick Start Guide English Safety Precautions Digital Meter Physical DescriptionOo Pen DraPas encore d'évaluation

- TC-900 Power: 6. Operations 1. DescriptionDocument5 pagesTC-900 Power: 6. Operations 1. DescriptionReinel Damian Orrego Quintero100% (1)

- UM33A Digital Indicator With Alarms Operation Guide - IM05P03D21-11EN - 020Document8 pagesUM33A Digital Indicator With Alarms Operation Guide - IM05P03D21-11EN - 020Albert KristianPas encore d'évaluation

- RXF IM Ed04Document66 pagesRXF IM Ed04Marius ClavacPas encore d'évaluation

- Us30 Manual EngDocument2 pagesUs30 Manual Engkakachy100% (1)

- Safeball™: One-And Two-Hand DevicesDocument4 pagesSafeball™: One-And Two-Hand DevicesluisPas encore d'évaluation

- Instruction Manual: Digital Clamp MeterDocument2 pagesInstruction Manual: Digital Clamp Meterferdinand hutapeaPas encore d'évaluation

- CPU Unit Software: User's ManualDocument938 pagesCPU Unit Software: User's ManualWallie BillingsleyPas encore d'évaluation

- Ixmv 7 WDocument3 pagesIxmv 7 Wwandi rdPas encore d'évaluation

- OI-XC-XG 201904 English Spanish ArabicDocument24 pagesOI-XC-XG 201904 English Spanish ArabicteynxmPas encore d'évaluation

- GDS-1000B Quick Start Guide ADocument2 pagesGDS-1000B Quick Start Guide Aketab_doostPas encore d'évaluation

- w593 Nx102 Cpu Unit Technical Manual enDocument230 pagesw593 Nx102 Cpu Unit Technical Manual enMePas encore d'évaluation

- IS0259A00MMDocument2 pagesIS0259A00MMSupuran RichardoPas encore d'évaluation

- Climate Control Module (CCM)Document2 pagesClimate Control Module (CCM)ojopodoabePas encore d'évaluation

- Pt-Lb3E Pt-Lb2Ve Pt-Lb1Ve: Operating Instructions Basic ManualDocument59 pagesPt-Lb3E Pt-Lb2Ve Pt-Lb1Ve: Operating Instructions Basic ManualhectorPas encore d'évaluation

- w593 Nx102 Cpu Unit Technical Manual enDocument230 pagesw593 Nx102 Cpu Unit Technical Manual enCabe IsaiasPas encore d'évaluation

- X6 ManualDocument1 pageX6 ManualRizky Tantyo100% (1)

- Jy997d18801k PDFDocument8 pagesJy997d18801k PDFElang Fajar PutraPas encore d'évaluation

- Feeder Protection and Control REF611: Product GuideDocument56 pagesFeeder Protection and Control REF611: Product GuideBenjie CallantaPas encore d'évaluation

- Installation Guidelines: Programming of LevelsDocument4 pagesInstallation Guidelines: Programming of LevelsSudipto MajumderPas encore d'évaluation

- GT2103 PMBDSDocument3 pagesGT2103 PMBDSSawatsakorn SirisoPas encore d'évaluation

- CL 500 Manual Funciones de PantallaDocument24 pagesCL 500 Manual Funciones de Pantallajdelgadoag25Pas encore d'évaluation

- DDT Full Operating Manual-1901600540621502Document85 pagesDDT Full Operating Manual-1901600540621502Sreepriodas Roy0% (1)

- Installation Manual Sharp MX-B450PDocument28 pagesInstallation Manual Sharp MX-B450PMinh Khoa PhạmPas encore d'évaluation

- User Manual Test Surftest SJ - 210Document200 pagesUser Manual Test Surftest SJ - 210Bùi Đại CaPas encore d'évaluation

- Tea1552 DatasheetDocument26 pagesTea1552 DatasheetMarcelo Coronel CastromontePas encore d'évaluation

- AN12910Document13 pagesAN12910Balvir SinghPas encore d'évaluation

- Sl-Vtad1 eDocument1 pageSl-Vtad1 eAjay MayalPas encore d'évaluation

- Easygen Series Controls For Asynchronous Genset ApplicationsDocument4 pagesEasygen Series Controls For Asynchronous Genset ApplicationsXaoc KabataPas encore d'évaluation

- Hfe Pioneer pdr-555rw en de FR ItDocument117 pagesHfe Pioneer pdr-555rw en de FR ItRadim ŘezníčekPas encore d'évaluation

- Enclosure - CR 10-X CR 12-X CR 15-X - Quick Installation GuideDocument2 pagesEnclosure - CR 10-X CR 12-X CR 15-X - Quick Installation GuideTAIWO ISHOLAPas encore d'évaluation

- vr7000 Operators Guide PDFDocument2 pagesvr7000 Operators Guide PDFvangPas encore d'évaluation

- Ib63927c eDocument1 pageIb63927c eLucas PaulaPas encore d'évaluation

- Controller: Important: Retain These InstructionsDocument12 pagesController: Important: Retain These InstructionsAnonymous XYAPaxjbYPas encore d'évaluation

- Cato Edition: Anaesthetic WorkstationDocument148 pagesCato Edition: Anaesthetic WorkstationEcole Acharaf100% (1)

- REB611 PG 757467 ENfDocument40 pagesREB611 PG 757467 ENfMohamed ELnadyPas encore d'évaluation

- MKD g7f AdhaDocument2 pagesMKD g7f AdhaJan Richardo GultomPas encore d'évaluation

- IPC Machine Controller Industrial Panel PC / Industrial Box PCDocument460 pagesIPC Machine Controller Industrial Panel PC / Industrial Box PCJosé Luis Camargo OlivaresPas encore d'évaluation

- Linde EN Ds 131 p50 0206 ADocument6 pagesLinde EN Ds 131 p50 0206 ANadeem AhmedPas encore d'évaluation

- Enclosure - CR 10-X CR 12-X CR 15-X - Quick Installation GuideDocument2 pagesEnclosure - CR 10-X CR 12-X CR 15-X - Quick Installation Guideleo clPas encore d'évaluation

- Users Manual Remote Controller Kobe SmartDocument15 pagesUsers Manual Remote Controller Kobe Smart4ward arrowPas encore d'évaluation

- 01b EasyIO FS20 Installation v1Document13 pages01b EasyIO FS20 Installation v1S M NaveedPas encore d'évaluation

- Installation and Operation Manual: 701 Digital Speed Control For Reciprocating EnginesDocument70 pagesInstallation and Operation Manual: 701 Digital Speed Control For Reciprocating EnginesS M NaveedPas encore d'évaluation

- FW SeriesDocument12 pagesFW SeriesS M NaveedPas encore d'évaluation

- 2301A Speed Control: ApplicationsDocument4 pages2301A Speed Control: ApplicationsS M NaveedPas encore d'évaluation

- Installation and Operation Manual: 701A Digital Speed Control For Reciprocating EnginesDocument64 pagesInstallation and Operation Manual: 701A Digital Speed Control For Reciprocating EnginesS M NaveedPas encore d'évaluation

- Alternator: From Wikipedia, The Free EncyclopediaDocument7 pagesAlternator: From Wikipedia, The Free EncyclopediaS M NaveedPas encore d'évaluation

- Basler InstallationDocument22 pagesBasler InstallationS M NaveedPas encore d'évaluation

- Autotransformer: From Wikipedia, The Free EncyclopediaDocument5 pagesAutotransformer: From Wikipedia, The Free EncyclopediaS M NaveedPas encore d'évaluation

- AC Motor: From Wikipedia, The Free EncyclopediaDocument12 pagesAC Motor: From Wikipedia, The Free EncyclopediaS M NaveedPas encore d'évaluation

- Diesel Engine - Wikipedia PDFDocument32 pagesDiesel Engine - Wikipedia PDFS M NaveedPas encore d'évaluation

- Permanent Magnet Synchronous GeneratorDocument3 pagesPermanent Magnet Synchronous GeneratorS M NaveedPas encore d'évaluation

- Current TransformerDocument6 pagesCurrent TransformerS M NaveedPas encore d'évaluation

- HM ManualDocument48 pagesHM ManualS M NaveedPas encore d'évaluation

- ECU ListDocument4 pagesECU ListS M NaveedPas encore d'évaluation

- Ntertp2c PDFDocument92 pagesNtertp2c PDFS M NaveedPas encore d'évaluation

- GET6600G Section 6 Rev 1 BookmarksDocument28 pagesGET6600G Section 6 Rev 1 BookmarksS M NaveedPas encore d'évaluation

- Abb (Avs) Price ListDocument24 pagesAbb (Avs) Price ListS M Naveed0% (1)

- Tixi Data HE400+600 EN 090222Document5 pagesTixi Data HE400+600 EN 090222S M NaveedPas encore d'évaluation

- Dief AGC Multi Line 2 SeriesDocument12 pagesDief AGC Multi Line 2 SeriesS M NaveedPas encore d'évaluation

- SGSM 3000, SGCM 3000, SGCO 3000 53414-4-MM, Rev 4 09-08-1Document2 pagesSGSM 3000, SGCM 3000, SGCO 3000 53414-4-MM, Rev 4 09-08-1Adam SamyPas encore d'évaluation

- Lead Acid BatteryDocument6 pagesLead Acid BatterysafariPas encore d'évaluation

- User Manual Ly IR 9000Document6 pagesUser Manual Ly IR 9000mariabaccaroPas encore d'évaluation

- Kohler 750ROZD4 Spec SheetDocument4 pagesKohler 750ROZD4 Spec SheetrodizianoPas encore d'évaluation

- SBO Product Selection Guide PDFDocument58 pagesSBO Product Selection Guide PDFGicuPas encore d'évaluation

- Testing & Commissioning Procedure For Earthing System - Method StatementDocument3 pagesTesting & Commissioning Procedure For Earthing System - Method Statementvin ssPas encore d'évaluation

- PB5600 Series Spec Sheet EngDocument2 pagesPB5600 Series Spec Sheet EngmehralsmenschPas encore d'évaluation

- Hong Lam International Vocational CollegeDocument17 pagesHong Lam International Vocational CollegelsahoangPas encore d'évaluation

- Position Control of A DC Servo Using A PID PDFDocument28 pagesPosition Control of A DC Servo Using A PID PDFBrasoveanu Gheorghita0% (1)

- Introduction To VHDL: Dr. Adnan ShaoutDocument32 pagesIntroduction To VHDL: Dr. Adnan ShaoutBhargav ShahPas encore d'évaluation

- SP50 30 ManualDocument1 pageSP50 30 ManualwoqpPas encore d'évaluation

- Microprocessor 8085 - Two Mark QuestionsDocument23 pagesMicroprocessor 8085 - Two Mark Questionssaravanamoorthy81% (16)

- SS ZG656Document13 pagesSS ZG656Mahesh H MPas encore d'évaluation

- Image Tamper Detection Based On JPEG ArtifactsDocument6 pagesImage Tamper Detection Based On JPEG ArtifactsInternational Journal of Application or Innovation in Engineering & ManagementPas encore d'évaluation

- Ani C Bus Analyser To Let You Satisfy Your Curiosity: The Secrets of I CDocument7 pagesAni C Bus Analyser To Let You Satisfy Your Curiosity: The Secrets of I CChico SouzaPas encore d'évaluation

- Atoll NB IoTDocument3 pagesAtoll NB IoTDenmark Wilson100% (1)

- Nokia Industrial 4G Fieldrouter FRRO401aDocument4 pagesNokia Industrial 4G Fieldrouter FRRO401aAlejandro RojasPas encore d'évaluation

- G120 CU250S2 Op Instr 0917 en-USDocument538 pagesG120 CU250S2 Op Instr 0917 en-USJovica ČukuranovićPas encore d'évaluation

- Design of Nano-Satellite Communication SubsystemDocument90 pagesDesign of Nano-Satellite Communication SubsystemPramath Keny100% (1)

- Durag Dust MonitorDocument13 pagesDurag Dust MonitorVivek KumarPas encore d'évaluation

- 6000 Tech ManualDocument42 pages6000 Tech Manualaung minhtet67% (3)

- Bosch KAD Spare Parts ManualDocument14 pagesBosch KAD Spare Parts ManualYan Naing HtwePas encore d'évaluation

- Function Expansions For ET 200SP Interface and I - O ModuleDocument3 pagesFunction Expansions For ET 200SP Interface and I - O ModuletrueavatharPas encore d'évaluation

- Scatalo Duo Station Datasheet A4Document2 pagesScatalo Duo Station Datasheet A4wmcPas encore d'évaluation

- Ee6502 Microprocessors and MicrocontrollersDocument2 pagesEe6502 Microprocessors and MicrocontrollersgokulchandruPas encore d'évaluation

- Stamford DM110 Voltage RegulatorDocument71 pagesStamford DM110 Voltage RegulatorThomas Pendergrass100% (2)

- Juniper MX960 Hardware GuideDocument590 pagesJuniper MX960 Hardware Guideiqbal apriansyahPas encore d'évaluation

- HD Multimedia Price List 2011 HRDocument1 pageHD Multimedia Price List 2011 HRbasmitrebatoPas encore d'évaluation

- Microwave Journal-March 2021Document168 pagesMicrowave Journal-March 2021Petros TsenesPas encore d'évaluation

- Marconi 6970 OpsDocument48 pagesMarconi 6970 OpsarsenaldoPas encore d'évaluation