Académique Documents

Professionnel Documents

Culture Documents

Oee 3

Transféré par

AngelikaTitre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Oee 3

Transféré par

AngelikaDroits d'auteur :

Formats disponibles

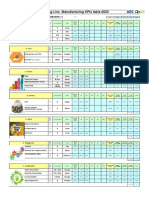

OVERALL EQUIPMENT EFFECTIVENESS

Equipment ID: Date:

Part ID: Supplier

EQUIPMENT AVAILABILITY

A. Total Available Time 60 min

B. Planned Downtime 0 min

C. Net Available Time (Total Available Time - Planned Downtime ) ( A - B) 60 min

D. Unplanned Downtime (from downtime reports)

# of breakdowns 0 Total Minutes 0.00 +

# of setups & adjustments 1 Total Minutes 30.00 +

# of minor breakdowns 0 Total Minutes 0.00 = 30.00 min

E. Operating Time (Net Available Time - Unplanned Downtime) (C - D) 30.00 min

F. Equipment Availability

F = (E / C x 100) 50.0%

(Operating Time / Net Available Time x 100)

PERFORMANCE EFFICIENCY

G. Total Parts Run (good and bad) 30 parts

H. Ideal Cycle Time Proc Cap Plan Est 1.000 min/part

I. Performance Efficiency

I = ((H x G) / E x 100) 100.0%

((Ideal Cycle Time x Total Parts Run) / Operating Time x 100)

QUALITY RATE

J. Total Defects (Rework + Scrap) 5 parts

K. Quality Rate

K = ((G - J) / G x 100) 83.3%

((Total Parts Run - Total Defects) / Total Parts Run x 100)

Overall Equipment Effectiveness O.E.E. = (F x I x K x 100) 41.7%

( Equipment Availability x Performance Efficiency x Quality Rate x 100 )

The OEE measurable is meant to be used as a tool to track machine improvement progress.

Total Available Time = The time that the equipment could run during a shift given that there was no

downtime either planned or unplanned.

Planned downtime = The time that the equipment is down due to planned activites such as lunch,

breaks, meetings, etc.

Unplanned Downtime = The time that the equipment is down due to breakdowns, setups,

adjustments, etc.

Ideal Cycle Time = Can be the best cycle time achieved, the design cycle time, or estimation.

Note = Enter data in yellow boxes only

O.E.E.Target Pass Rate = 80%

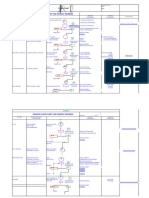

Planned Run Start Time: Planned Run Finish Time: Planned Down Time During Run: Planned Process Up Time:

Actual Run Start Time: Actual Run Finish Time: Planned Down Time During Run: Actual Process Up Times:

Cycle Time Confirmation

Press 2 Press 5 Press 7 Press 8 Press 11 Press 23 Press 1 Press 9 Press 10 Spot W 1

Planned Cycle Time

1

2

Actual Cycle Time

3

Observations

4

5

6

7

8

9 Average Total

10 Cycle Time

Average Cycle Time

Unplanned Down Time

Duration Reason Action Taken Preventative Action Require Owner Due Date

1

Breakdowns

2

3

4

5

1

Adjustments

Set-ups &

2

3

4

5

1

Breakdowns

2

Minor

3

4

5

Total Time Lost

Total Parts Run:

Qty Defective

Reworked:

Scrapped:

Total Defects:

Process OK Yield:

Vous aimerez peut-être aussi

- OEE CalculationDocument2 pagesOEE CalculationSudhaPas encore d'évaluation

- Kaga Components (M) SDN BHD: Operator Training ProceduresDocument2 pagesKaga Components (M) SDN BHD: Operator Training Proceduresrajesh sharmaPas encore d'évaluation

- Total Productive Maintenance WorksheetDocument2 pagesTotal Productive Maintenance WorksheetSeda De Drasnia100% (1)

- Preventive CHK List Mig PDFDocument1 pagePreventive CHK List Mig PDFSandeep KumarPas encore d'évaluation

- Quality Manual: Foreword From Top ManagementDocument2 pagesQuality Manual: Foreword From Top ManagementmuthuselvanPas encore d'évaluation

- Simple Oee SpreadsheetDocument2 pagesSimple Oee SpreadsheetadePas encore d'évaluation

- OEE CalculatorDocument11 pagesOEE CalculatorosbertodiazPas encore d'évaluation

- Standard Work Chart: (NVA) (NVA) (NVA)Document2 pagesStandard Work Chart: (NVA) (NVA) (NVA)Carlos Manuel ParionaPas encore d'évaluation

- QM1 Quality Manual R9 (ISO 9001 - 2015)Document27 pagesQM1 Quality Manual R9 (ISO 9001 - 2015)paulPas encore d'évaluation

- 16 Major Losses in ProductionDocument18 pages16 Major Losses in ProductionAgung Chilmy FirdanaPas encore d'évaluation

- 5 Why AnalysisDocument8 pages5 Why AnalysisNirmal VashisthaPas encore d'évaluation

- Improve Operation Scrap Ratio at Sachet LineDocument47 pagesImprove Operation Scrap Ratio at Sachet Lineeka_526079427Pas encore d'évaluation

- 5S Audit - Task Force TeamDocument7 pages5S Audit - Task Force TeamRajaVeluPas encore d'évaluation

- Primary Member Process Flow ChartDocument3 pagesPrimary Member Process Flow Chartmadhu krishnaPas encore d'évaluation

- GSQT 004 Husqvarna Full Run Test Report Template Revision 0Document3 pagesGSQT 004 Husqvarna Full Run Test Report Template Revision 0Tien Dung Phan100% (1)

- New Prod-DB and KPI 22Document5 pagesNew Prod-DB and KPI 22Senthilmani MuthuswamyPas encore d'évaluation

- Process Sheet: DescriptionDocument9 pagesProcess Sheet: Descriptionmohamed abdullahPas encore d'évaluation

- Work Instructions Work Instructions: Display Standard-Assembly & FirewallDocument7 pagesWork Instructions Work Instructions: Display Standard-Assembly & Firewallshobha shelarPas encore d'évaluation

- Module 51. Improve TollgateDocument45 pagesModule 51. Improve Tollgatetaghavi1347Pas encore d'évaluation

- Process: Process Control Chart Chart No'Document1 pageProcess: Process Control Chart Chart No'AngelikaPas encore d'évaluation

- Nabtesco - Annual Appraisal Sheet (For Manager & Above) 2021Document10 pagesNabtesco - Annual Appraisal Sheet (For Manager & Above) 2021Kiran AmborePas encore d'évaluation

- NP Chart RBD Engineers, Ahmedabad: Machine Capability Study For Milling Surface Finish With Decided Attribute MethodDocument3 pagesNP Chart RBD Engineers, Ahmedabad: Machine Capability Study For Milling Surface Finish With Decided Attribute MethodDisha ShahPas encore d'évaluation

- A3 Toyota 8 Step TemplatesDocument11 pagesA3 Toyota 8 Step TemplatesBharathPas encore d'évaluation

- Skill MatrixxDocument11 pagesSkill MatrixxNikhil SirPas encore d'évaluation

- Standard Operating ProcedureDocument4 pagesStandard Operating ProcedureJana VinayaPas encore d'évaluation

- Capacity Verification Run at Rate IpaDocument4 pagesCapacity Verification Run at Rate IpaAnonymous VRspXsmPas encore d'évaluation

- APS-WP-15 Process Validation ProcedureDocument24 pagesAPS-WP-15 Process Validation Procedureshobha shelarPas encore d'évaluation

- 01.SOP - Center BezelDocument2 pages01.SOP - Center BezelRS MANIKANDANPas encore d'évaluation

- Plan de Surveillance Pièce PlastiqueDocument2 pagesPlan de Surveillance Pièce PlastiqueFida GhanmiPas encore d'évaluation

- MTTR & MTBF TrendDocument2 pagesMTTR & MTBF TrendMASU BRAKE PADS QAPas encore d'évaluation

- Main KPI JV 2023Document70 pagesMain KPI JV 2023kumaravPas encore d'évaluation

- Control Plan For Lighting ProductDocument6 pagesControl Plan For Lighting ProductpapplionPas encore d'évaluation

- Internal Process Perspective - KPI LibraryDocument4 pagesInternal Process Perspective - KPI Librarytaghavi1347Pas encore d'évaluation

- Total Productive Maintenance WorksheetDocument2 pagesTotal Productive Maintenance Worksheethasan_waqar2004Pas encore d'évaluation

- BudgetingDocument4 pagesBudgetingSapaPas encore d'évaluation

- Internal Rejection LevelDocument1 pageInternal Rejection LevelISO CERTIFICATION-ROHSPas encore d'évaluation

- Daily Machine Production ReportDocument1 pageDaily Machine Production ReportimtiazPas encore d'évaluation

- OEE: Overall Equipment Efficiency: OrganizerDocument5 pagesOEE: Overall Equipment Efficiency: OrganizerSachin RamdurgPas encore d'évaluation

- IMS-MRM-DC-SC-NO. MRM FormatDocument1 pageIMS-MRM-DC-SC-NO. MRM FormatRohit SoniPas encore d'évaluation

- 6W2H For Side Wrinkles MY17 - RearDocument4 pages6W2H For Side Wrinkles MY17 - RearVishvendra Pratap SinghPas encore d'évaluation

- QAF-160 Supplier Quality Survey 3-5-18Document9 pagesQAF-160 Supplier Quality Survey 3-5-18Gábor MonokPas encore d'évaluation

- 5S Implementation Audit: 5S To-Do Items Observed Condition Improvement ActionDocument2 pages5S Implementation Audit: 5S To-Do Items Observed Condition Improvement ActionJavier GutierrezPas encore d'évaluation

- Delphi Supplier Quality Fmea Severity RankingsDocument3 pagesDelphi Supplier Quality Fmea Severity Rankingsmani317Pas encore d'évaluation

- Skill Matrix - Honeywell Project, Production Dept.: Indo Schottle Auto PartsDocument4 pagesSkill Matrix - Honeywell Project, Production Dept.: Indo Schottle Auto PartsmaxvaigPas encore d'évaluation

- In House PPM MonitoringDocument2 pagesIn House PPM MonitoringSrinath NavadaPas encore d'évaluation

- A3Document1 pageA3chavesierra20081 SierraPas encore d'évaluation

- HR-03 - Skill - Matrix NEWDocument7 pagesHR-03 - Skill - Matrix NEWVikin JainPas encore d'évaluation

- Improvement KaizenDocument11 pagesImprovement KaizenAnkur DhirPas encore d'évaluation

- Cost Weighted OEE TemplateDocument10 pagesCost Weighted OEE TemplateSAMGPROPas encore d'évaluation

- Six Sigma: DMAIC Y F (X)Document37 pagesSix Sigma: DMAIC Y F (X)mohannadsinjabPas encore d'évaluation

- Continual Improvement Using Jishu Hozen Pillar of Total Productive Maintenance in Manufacturing OrganizationDocument7 pagesContinual Improvement Using Jishu Hozen Pillar of Total Productive Maintenance in Manufacturing OrganizationPE QAPas encore d'évaluation

- Unawareness: (Inadequate Attention To Detail)Document1 pageUnawareness: (Inadequate Attention To Detail)Jorge FracaroPas encore d'évaluation

- 8.19 Poster Unusual SituationsDocument1 page8.19 Poster Unusual Situationsedumm001Pas encore d'évaluation

- Setup & Inprocess Inspection Report CaseDocument19 pagesSetup & Inprocess Inspection Report CaseMURALIDHRAPas encore d'évaluation

- How To Do Focuses ImprovementDocument39 pagesHow To Do Focuses Improvementashutoshpal21Pas encore d'évaluation

- 43.8D - 20456 - Cyl Bottom - Thread Perpendicular IssueDocument4 pages43.8D - 20456 - Cyl Bottom - Thread Perpendicular IssueVasanth KumarPas encore d'évaluation

- Oee 3Document2 pagesOee 3Lowell HarperPas encore d'évaluation

- Overall Equipment EffectivenessDocument19 pagesOverall Equipment EffectivenessKopral JonoPas encore d'évaluation

- Overall Equipment Effectiveness (OEE)Document16 pagesOverall Equipment Effectiveness (OEE)Arif Abu FarhanaPas encore d'évaluation

- OEE MethodDocument2 pagesOEE MethodPhan Van SinhPas encore d'évaluation

- CP 230058 enDocument2 pagesCP 230058 enAngelikaPas encore d'évaluation

- OEE Calculation: Process 1 Operating Pattern and Machine DataDocument2 pagesOEE Calculation: Process 1 Operating Pattern and Machine DataAngelikaPas encore d'évaluation

- Process: Process Control Chart Chart No'Document1 pageProcess: Process Control Chart Chart No'AngelikaPas encore d'évaluation

- System Safety BookDocument101 pagesSystem Safety BookAngelikaPas encore d'évaluation

- Bibliografia PDFDocument13 pagesBibliografia PDFAngelikaPas encore d'évaluation

- Apresentaçôes ArDocument2 pagesApresentaçôes ArAngelikaPas encore d'évaluation

- Apresentação Matriz Falhas PDFDocument30 pagesApresentação Matriz Falhas PDFAngelikaPas encore d'évaluation

- Ifa Audit Oee Action PDFDocument1 pageIfa Audit Oee Action PDFAngelikaPas encore d'évaluation

- 07423.cos - Qua.std - Inspection and Tests For Package SuppliesDocument6 pages07423.cos - Qua.std - Inspection and Tests For Package SuppliesMatteoPas encore d'évaluation

- Synopsis For Online Hotel Management For LUCKNOW UNIVERSITYDocument35 pagesSynopsis For Online Hotel Management For LUCKNOW UNIVERSITYSumit Waitforit Rana100% (1)

- Com - Cherisher.beauty - Camera.videocall LogcatDocument14 pagesCom - Cherisher.beauty - Camera.videocall Logcatbossteju80Pas encore d'évaluation

- Systems Development Life CycleDocument3 pagesSystems Development Life CycleBianca Jane MaaliwPas encore d'évaluation

- CV Resume RedactedDocument2 pagesCV Resume RedactedraondmPas encore d'évaluation

- Literature Review of PID Controller Based On Various Soft Computing TechniquesDocument4 pagesLiterature Review of PID Controller Based On Various Soft Computing TechniquesEditor IJRITCCPas encore d'évaluation

- Key Features of Oracle Apps Inventory Release 12: Madhu BabuDocument30 pagesKey Features of Oracle Apps Inventory Release 12: Madhu BabubirudukotaPas encore d'évaluation

- MBIST Verification Best Practices ChallengesDocument5 pagesMBIST Verification Best Practices ChallengespkashyPas encore d'évaluation

- Lesson Plan - Introduction To Programming and C++Document5 pagesLesson Plan - Introduction To Programming and C++Abhishek Singh0% (1)

- BAg - FDD - Integrasi Odoo Dan PMSDocument21 pagesBAg - FDD - Integrasi Odoo Dan PMSEry Noer WibowoPas encore d'évaluation

- Dcit 201-Programming I: Session 4 - Introduction To PHPDocument18 pagesDcit 201-Programming I: Session 4 - Introduction To PHPPrincess Naomi AkinboboyePas encore d'évaluation

- C++ SIMP - Simp QB (1) PDFDocument2 pagesC++ SIMP - Simp QB (1) PDFMohammed owaisPas encore d'évaluation

- Documentation: DescriptionDocument5 pagesDocumentation: DescriptionSandesh PokhrelPas encore d'évaluation

- High Authority Backlinks List SitesDocument5 pagesHigh Authority Backlinks List Sitesitap linkPas encore d'évaluation

- Final Year Internship Report CybersecuriyDocument64 pagesFinal Year Internship Report CybersecuriySaurabhPas encore d'évaluation

- Digital Twin - Mitigating Unpredictable, Undesirable Emergent Behavior in Complex SystemsDocument29 pagesDigital Twin - Mitigating Unpredictable, Undesirable Emergent Behavior in Complex Systemsjwpaprk1100% (1)

- Lesson 11 RoutingDocument44 pagesLesson 11 RoutingreshmaitagiPas encore d'évaluation

- Loader and Linker Lec5 6 7 8 9Document58 pagesLoader and Linker Lec5 6 7 8 9akbisoi1Pas encore d'évaluation

- Gowtham ResumeDocument3 pagesGowtham Resumeragupathi.arumugaPas encore d'évaluation

- RNAV Feedback Austro SpainDocument10 pagesRNAV Feedback Austro SpainChristian AnayaPas encore d'évaluation

- Intro To OOPDocument24 pagesIntro To OOPskill coursePas encore d'évaluation

- Problem Solving ProcessDocument13 pagesProblem Solving Processmatthewivan100% (1)

- 2 Swapnil DravyakarDocument3 pages2 Swapnil DravyakarmajkatiPas encore d'évaluation

- Introductiontoscala 161222153627Document83 pagesIntroductiontoscala 161222153627loda lasunPas encore d'évaluation

- Gi Catalogue 2015Document88 pagesGi Catalogue 2015Khairudin Ahmad MIPas encore d'évaluation

- Project Charter and Scope StatementDocument36 pagesProject Charter and Scope StatementsaikumarPas encore d'évaluation

- Diesel Engine Crankshaft DisassemblyDocument15 pagesDiesel Engine Crankshaft DisassemblyAnshar NaraPas encore d'évaluation

- Testing Roles ResponsibilitiesDocument3 pagesTesting Roles Responsibilitiesapi-3698888100% (1)

- Chaos Monkeys: Obscene Fortune and Random Failure in Silicon ValleyD'EverandChaos Monkeys: Obscene Fortune and Random Failure in Silicon ValleyÉvaluation : 3.5 sur 5 étoiles3.5/5 (111)

- Scary Smart: The Future of Artificial Intelligence and How You Can Save Our WorldD'EverandScary Smart: The Future of Artificial Intelligence and How You Can Save Our WorldÉvaluation : 4.5 sur 5 étoiles4.5/5 (55)

- Cyber War: The Next Threat to National Security and What to Do About ItD'EverandCyber War: The Next Threat to National Security and What to Do About ItÉvaluation : 3.5 sur 5 étoiles3.5/5 (66)

- Digital Gold: Bitcoin and the Inside Story of the Misfits and Millionaires Trying to Reinvent MoneyD'EverandDigital Gold: Bitcoin and the Inside Story of the Misfits and Millionaires Trying to Reinvent MoneyÉvaluation : 4 sur 5 étoiles4/5 (51)

- Algorithms to Live By: The Computer Science of Human DecisionsD'EverandAlgorithms to Live By: The Computer Science of Human DecisionsÉvaluation : 4.5 sur 5 étoiles4.5/5 (722)

- The Future of Geography: How the Competition in Space Will Change Our WorldD'EverandThe Future of Geography: How the Competition in Space Will Change Our WorldÉvaluation : 4 sur 5 étoiles4/5 (6)

- Generative AI: The Insights You Need from Harvard Business ReviewD'EverandGenerative AI: The Insights You Need from Harvard Business ReviewÉvaluation : 4.5 sur 5 étoiles4.5/5 (2)

- System Error: Where Big Tech Went Wrong and How We Can RebootD'EverandSystem Error: Where Big Tech Went Wrong and How We Can RebootPas encore d'évaluation

- Learn Python Programming for Beginners: Best Step-by-Step Guide for Coding with Python, Great for Kids and Adults. Includes Practical Exercises on Data Analysis, Machine Learning and More.D'EverandLearn Python Programming for Beginners: Best Step-by-Step Guide for Coding with Python, Great for Kids and Adults. Includes Practical Exercises on Data Analysis, Machine Learning and More.Évaluation : 5 sur 5 étoiles5/5 (34)

- Four Battlegrounds: Power in the Age of Artificial IntelligenceD'EverandFour Battlegrounds: Power in the Age of Artificial IntelligenceÉvaluation : 5 sur 5 étoiles5/5 (5)

- ChatGPT Side Hustles 2024 - Unlock the Digital Goldmine and Get AI Working for You Fast with More Than 85 Side Hustle Ideas to Boost Passive Income, Create New Cash Flow, and Get Ahead of the CurveD'EverandChatGPT Side Hustles 2024 - Unlock the Digital Goldmine and Get AI Working for You Fast with More Than 85 Side Hustle Ideas to Boost Passive Income, Create New Cash Flow, and Get Ahead of the CurvePas encore d'évaluation

- Chip War: The Quest to Dominate the World's Most Critical TechnologyD'EverandChip War: The Quest to Dominate the World's Most Critical TechnologyÉvaluation : 4.5 sur 5 étoiles4.5/5 (229)

- AI Superpowers: China, Silicon Valley, and the New World OrderD'EverandAI Superpowers: China, Silicon Valley, and the New World OrderÉvaluation : 4.5 sur 5 étoiles4.5/5 (399)

- The Intel Trinity: How Robert Noyce, Gordon Moore, and Andy Grove Built the World's Most Important CompanyD'EverandThe Intel Trinity: How Robert Noyce, Gordon Moore, and Andy Grove Built the World's Most Important CompanyPas encore d'évaluation

- The Bitcoin Standard: The Decentralized Alternative to Central BankingD'EverandThe Bitcoin Standard: The Decentralized Alternative to Central BankingÉvaluation : 4.5 sur 5 étoiles4.5/5 (41)

- The Manager's Path: A Guide for Tech Leaders Navigating Growth and ChangeD'EverandThe Manager's Path: A Guide for Tech Leaders Navigating Growth and ChangeÉvaluation : 4.5 sur 5 étoiles4.5/5 (99)

- Reality+: Virtual Worlds and the Problems of PhilosophyD'EverandReality+: Virtual Worlds and the Problems of PhilosophyÉvaluation : 4 sur 5 étoiles4/5 (24)

- The Infinite Machine: How an Army of Crypto-Hackers Is Building the Next Internet with EthereumD'EverandThe Infinite Machine: How an Army of Crypto-Hackers Is Building the Next Internet with EthereumÉvaluation : 3 sur 5 étoiles3/5 (12)

- Mini Farming: Self-Sufficiency on 1/4 AcreD'EverandMini Farming: Self-Sufficiency on 1/4 AcreÉvaluation : 4 sur 5 étoiles4/5 (76)

- The Master Algorithm: How the Quest for the Ultimate Learning Machine Will Remake Our WorldD'EverandThe Master Algorithm: How the Quest for the Ultimate Learning Machine Will Remake Our WorldÉvaluation : 4.5 sur 5 étoiles4.5/5 (107)

- Excel Essentials: A Step-by-Step Guide with Pictures for Absolute Beginners to Master the Basics and Start Using Excel with ConfidenceD'EverandExcel Essentials: A Step-by-Step Guide with Pictures for Absolute Beginners to Master the Basics and Start Using Excel with ConfidencePas encore d'évaluation

- The E-Myth Revisited: Why Most Small Businesses Don't Work andD'EverandThe E-Myth Revisited: Why Most Small Businesses Don't Work andÉvaluation : 4.5 sur 5 étoiles4.5/5 (709)