Académique Documents

Professionnel Documents

Culture Documents

9) Tutorial Problem PDF

Transféré par

Ajitsingh JagtapDescription originale:

Titre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

9) Tutorial Problem PDF

Transféré par

Ajitsingh JagtapDroits d'auteur :

Formats disponibles

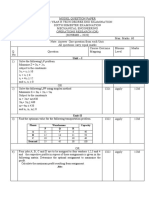

MEE1024 Operations Research / Module-3 Tutorial Problems / Darla / SMEC / WS2017-18

3.1. Four different jobs can be done on four different machines. The set up and take down time costs

are assumed to be prohibitively high for changeovers. The matrix below gives the cost in rupees

of producing job i on machine j.

Machine

M1 M2 M3 M4

J1 18 26 17 11

J2 13 28 14 26

Job

J3 38 19 18 15

J4 19 26 24 10

How should the jobs be assigned to the various machines so that the total cost is minimized?

3.2. A machine tool company decides to make four subassemblies through four contractors. Each

contactor is to receive only one subassembly. The cost of each subassembly is determined by the

bids submitted by each contractor and is shown in table in hundreds of rupees. Assign the

different subassemblies to contactors so as minimize the total cost.

Contractor

C1 C2 C3 C4

S1 15 13 14 17

S2 11 12 15 13

Subassembly

S3 13 12 10 11

S4 15 17 14 16

3.3. A company has one surplus truck in each of the cities A, B, C, D and E and one deficit truck in

each of the cities 1, 2, 3, 4, 5 and 6. The distance between the cities in kilometers is shown in the

matrix below. Find the assignment of trucks from cities in surplus to cities in deficit so that the

total distance covered by vehicles is minimum.

1 2 3 4 5 6

A 12 10 15 22 18 8

B 10 18 25 15 16 12

C 11 10 3 8 5 9

D 6 14 10 13 13 12

E 8 12 11 7 13 10

3.4.A company has a team of four salesmen and there are four districts where the company wants to

start its business. After taking into account the capabilities of salesman and the nature of districts,

the company estimates that the profit per day in rupees for each salesman in each district is as

below.

Darla / SMBS / VIT Page 1 of 4

1 2 3 4

A 16 10 14 11

B 14 11 15 15

Sales man C 15 15 13 12

D 13 12 14 15

E 8 12 11 7

3.5. Four new machines M1, M2, M3, M4 and are to be installed in a machine shop. There are five

vacant places A, B, C, D and E available. Because of limited space, machine M2 cannot be placed

at C and M3 cannot be placed at A. Cij, the assignment cost of machine i to place j in rupees is

shown below.

A B C D E

M1 4 6 10 5 6

M2 7 4 - 5 4

M3 - 6 9 6 2

M4 9 3 7 2 3

Find the optimal assignment schedule.

3.6. The job shop company has purchased three new machines of different type. There are four

available locations in the shop where machine could be installed. Some of these locations are

more desirable that others for particular machines because of their proximity to work centers that

will have a heavy work flow to and from these machines. (There will be no work flow between

the new machines.) Therefore, the objective is to assign the new machines to the available

locations to minimize the total cost of materials handling. The estimated cost in rupees per hour

of material handling involving each of the machines is given in table for the respective locations.

Location 2 is not considered suitable for machine 2, so no cost is given for this case.

Location Location 2 Location Location 4

1 3

1 13 16 12 11

2 15 - 13 20

Machine

3 5 7 10 6

Formulate the problem as an assignment model and determine the optimal assignment.

3.7.Klyne’s four children, John, Karen, Joseph and Terri, want to earn some money to take care of

personal expenses during a school trip. Mr. Klyne has chosen four chores for his children:

mowing the lawn, painting the garage door, cleaning the living hall and whasing the family cars.

He asks them to submit secret bids for these chores. All four children will abide by their father’s

decision as to who get which chore. The received bids (Rs.’100) are summarised below:

Darla / SMBS / VIT Page 2 of 4

Chore

C1 C2 C3 C4

John 1 4 6 3

Karen 9 7 10 9

Joseph 4 5 11 7

Terri 8 7 8 5

Based on this information, how should Mr.Klyne assign the chores in order to minimize his

money?

3.8.There are seven jobs, each of which has to go through the machine A and B in the order AB.

Processing times in hours are given as

Job: 1 2 3 4 5 6 7

Machine A: 3 12 15 6 10 11 9

Machine B: 8 10 10 6 12 1 3

Determine a sequence of these jobs that will minimize the total elapsed time.

3.9. A factory has five jobs, each of which should go through two machines A and B, in the order

AB. Processing time in hours for the jobs are given below.

Job: J1 J2 J3 J4 J5

Machine A: 5 1 9 3 10

Machine B: 2 6 7 8 4

Determine the sequence for performing the jobs that would minimize the total elapsed time.

3.10. Find the sequence that minimizes the total elapsed time required to complete the following

jobs on two machines in the order AB.

Job: 1 2 3 4 5 6

Machine A: 1 3 8 5 6 3

Machine B: 5 6 3 2 2 10

3.11. Find the sequence that minimizes the total elapsed time required to complete the following

tasks on two machines:

Task: A B C D E F G H I

Machine A: 2 5 4 9 6 8 7 5 4

Machine B: 6 8 7 4 3 9 3 8 11

3.12. We have five jobs, each of which must go through machines A, B and C in the order ABC.

Processing times in hours are given below.

Jobs: 1 2 3 4 5

Machine A: 5 7 6 9 5

Machine B: 2 1 4 5 3

Machine C: 3 7 5 6 7

Determine the sequence of the jobs that minimize the total elapsed time.

Darla / SMBS / VIT Page 3 of 4

3.13. Solve the following sequencing problem, giving an optimal solution when passing is not

allowed.

Jobs: A B C D E

Machine M1: 10 12 8 15 16

Machine M2: 3 2 4 1 5

Machine M3: 5 6 4 7 3

Machine M4:14 7 12 8 10

3.14. Determine the optimal sequence of performing 5 jobs on 4 machines. The machining of each

job is required in the order of A - B – C - D and the process timing are as follows.

Machines

A B C D

1 8 3 4 7

2 9 2 5 5

Jobs 3 6 4 5 8

4 12 5 1 9

5 7 1 2 3

3.15. A firm works 40 hours a week and has a capacity of overtime work to the extent of 20 hours

in a week. It has received seven orders to be processed on three machines A, B and C, in the

order A-B-C to be delivered in a week’s time from now. The processing times (in hours) are

recorded in the following table:

Job: 1 2 3 4 5 6 7

Machine A: 7 8 6 6 7 8 5

Machine B: 2 2 1 3 3 2 4

Machine C: 6 5 4 4 2 1 5

The manager, who in fairness insists on performing the jobs in the sequence in which they are

received, is refusing to accept an eighth order, which requires 7, 2 and 5 hours respectively on

A, B and C machines, because according to him the eight jobs would require a total of 61

hours for processing, which exceeds the firm’s capacity. What is your advice to him? Justify

your answer.

3.16. Find the sequence that minimizes the total elapsed time required to complet the following

tasks (in hrs) on series of Machine-I and Machine-II:

Task: A B C D E F G H

Machine-I: 6 2 8 9 9 6 7 6

Machine-II:8 7 3 6 4 10 4 8

Calculate the minimum elapsed time and idle times of machine-I and machine-II. Identify the

task which has to wait more time for machine-II.

3.17. A factory has five jobs, each of which should go through two machine A and B, in the order AB. Processing

time in hours for the jobs are given below.

Job: J1 J2 J3 J4 J5

Machine A: 15 11 19 13 30

Machine B: 12 16 17 18 15

Use Johnson’s rule to determine the optimal sequence for performing the jobs and its elapsed

time. Find the idle time of resources.

Darla / SMBS / VIT Page 4 of 4

Vous aimerez peut-être aussi

- ORT Questions 2Document6 pagesORT Questions 2Bob34wPas encore d'évaluation

- Assignment Problem TFJTDocument5 pagesAssignment Problem TFJTHrutik DeshmukhPas encore d'évaluation

- CMA Final Paper-9 Study Note 4 & 6: Operations ResearchDocument35 pagesCMA Final Paper-9 Study Note 4 & 6: Operations ResearchSaksham KhuranaPas encore d'évaluation

- Assignment Problem ExercisesDocument21 pagesAssignment Problem ExercisesOMM GOPAL EXIMPas encore d'évaluation

- Assignment 4Document3 pagesAssignment 4Varun PatidarPas encore d'évaluation

- Assignment 3: Job Man 1 2 3 4 5 I II III IV VDocument3 pagesAssignment 3: Job Man 1 2 3 4 5 I II III IV Vswatiraj05Pas encore d'évaluation

- Final Assessment Test - November 2016: Course: - Class NBR(S) : Slot: Time: Three Hours Max. Marks: 100Document3 pagesFinal Assessment Test - November 2016: Course: - Class NBR(S) : Slot: Time: Three Hours Max. Marks: 100ak164746Pas encore d'évaluation

- Operations ResearchDocument4 pagesOperations ResearchRishiPas encore d'évaluation

- VL2019201001189 DaDocument1 pageVL2019201001189 DaAniket LunkerPas encore d'évaluation

- Sheet 7 PDFDocument4 pagesSheet 7 PDFIniyan I TPas encore d'évaluation

- Assignment Mba-Ii Semester 51207: Operations ResearchDocument3 pagesAssignment Mba-Ii Semester 51207: Operations Researchanandilal dhabaiPas encore d'évaluation

- Transportation & Assignment Problem (LPP Approach)Document2 pagesTransportation & Assignment Problem (LPP Approach)Rohan PatilPas encore d'évaluation

- Gujarat Technological University: InstructionsDocument4 pagesGujarat Technological University: Instructionssiddharth devnaniPas encore d'évaluation

- BMS 401 CatDocument1 pageBMS 401 CatAbel BejaPas encore d'évaluation

- Transportation & Assignment Model Problems2007-09Document12 pagesTransportation & Assignment Model Problems2007-09Ketaki SomanPas encore d'évaluation

- Operational Research Assignment: The Information Is Reproduced in Table 1Document11 pagesOperational Research Assignment: The Information Is Reproduced in Table 1Sakshi GuptaPas encore d'évaluation

- Gujarat Technological UniversityDocument3 pagesGujarat Technological Universitysiddharth devnaniPas encore d'évaluation

- Assignment ProblemsDocument5 pagesAssignment ProblemsManoj ka Manoj kaPas encore d'évaluation

- ORDocument26 pagesORVarun Markandeya50% (2)

- Assignment ProblemsDocument5 pagesAssignment ProblemsSudip Thakur100% (1)

- Final Assessment Test - November 2016: Course: - Class NBR(S) : Slot: Time: Three Hours Max. Marks: 100Document3 pagesFinal Assessment Test - November 2016: Course: - Class NBR(S) : Slot: Time: Three Hours Max. Marks: 100ak164746Pas encore d'évaluation

- 24 - Sheet 4Document2 pages24 - Sheet 4Mahmoud EldesoukiPas encore d'évaluation

- OR TutorialsDocument8 pagesOR TutorialsFa CaPas encore d'évaluation

- Sapthagiri College of Engineering, Bangalore. Department of Computer Science and EngineeringDocument3 pagesSapthagiri College of Engineering, Bangalore. Department of Computer Science and EngineeringAasim InamdarPas encore d'évaluation

- 4 AssignmentDocument10 pages4 AssignmentSuraj ManikPas encore d'évaluation

- VR14 14ME3603: Siddhartha Engineering CollegeDocument2 pagesVR14 14ME3603: Siddhartha Engineering CollegeVenkateshPas encore d'évaluation

- Marketing ManagementDocument4 pagesMarketing ManagementAnonymous WtjVcZCgPas encore d'évaluation

- Transportation Problem ExercisesDocument26 pagesTransportation Problem ExercisesVenkatesh m50% (2)

- BMS College of Engineering, Bangalore-560019: January 2017 Semester End Make Up ExaminationsDocument4 pagesBMS College of Engineering, Bangalore-560019: January 2017 Semester End Make Up ExaminationsSanketh SPas encore d'évaluation

- Tybms - orDocument6 pagesTybms - orSahil ChaudhariPas encore d'évaluation

- Advanced Operations Research: Last Date of Submission: 25 Feb 2011Document17 pagesAdvanced Operations Research: Last Date of Submission: 25 Feb 2011praveendhariwalPas encore d'évaluation

- PDF DocumentDocument12 pagesPDF DocumentAchievers ClubPas encore d'évaluation

- Operations Research-ORDocument3 pagesOperations Research-ORSuthari AmbikaPas encore d'évaluation

- 4 Assignment ProblemDocument29 pages4 Assignment ProblembalajiPas encore d'évaluation

- Operations Research - 2013Document106 pagesOperations Research - 2013vinit557% (7)

- University of Tunis Tunis Business School Spring 2023Document2 pagesUniversity of Tunis Tunis Business School Spring 2023Rahma ZarroukPas encore d'évaluation

- Chapter 13 Managerial AccountingDocument168 pagesChapter 13 Managerial AccountingChandler Schleifs100% (4)

- Buss 206 Operations ResearchDocument4 pagesBuss 206 Operations ResearchDan OnsongoPas encore d'évaluation

- Operations Research Techniques: Assignment No. 2Document19 pagesOperations Research Techniques: Assignment No. 2indu296Pas encore d'évaluation

- PDF Operations Research 2013 CompressDocument106 pagesPDF Operations Research 2013 CompressDelrioPas encore d'évaluation

- 2022 1 Bba 313 A2Document7 pages2022 1 Bba 313 A2MASMO SHIYALAPas encore d'évaluation

- Operations ResearchDocument104 pagesOperations Researchparikshitdesh0% (2)

- Operational Reasearch Question Bank (Mba)Document9 pagesOperational Reasearch Question Bank (Mba)Vikas NarwalPas encore d'évaluation

- Unit-3 Assignement Model Notes & Practice QuestionsDocument19 pagesUnit-3 Assignement Model Notes & Practice QuestionsIsha NatuPas encore d'évaluation

- Assignment Sheet PGDM, SIBMDocument3 pagesAssignment Sheet PGDM, SIBMDovena CarePas encore d'évaluation

- Final Assessment Test (FAT) - May 2017: Course: - Class NBR(S) : Slot: Time: Three Hours Max. Marks: 100Document4 pagesFinal Assessment Test (FAT) - May 2017: Course: - Class NBR(S) : Slot: Time: Three Hours Max. Marks: 100ak164746Pas encore d'évaluation

- Bba 313 Assignment 2Document4 pagesBba 313 Assignment 2Stanley KasusuPas encore d'évaluation

- Worksheet Assignment 26772566Document4 pagesWorksheet Assignment 26772566SRISHTI SHARMAPas encore d'évaluation

- Tutorial 3Document2 pagesTutorial 3gasmiirouaPas encore d'évaluation

- Amity University HaryanaDocument3 pagesAmity University Haryananidhi malikPas encore d'évaluation

- Gujarat Technological UniversityDocument4 pagesGujarat Technological UniversityTPas encore d'évaluation

- Q T Bank1kDocument12 pagesQ T Bank1kJigar ShahPas encore d'évaluation

- Assignment NotesDocument9 pagesAssignment NotesVikram MulikPas encore d'évaluation

- Xavier University Mba-Rm Operations Management 2020-21, TERM-III End Term Examination-April 2021 Name .......... Roll Number InstructionsDocument2 pagesXavier University Mba-Rm Operations Management 2020-21, TERM-III End Term Examination-April 2021 Name .......... Roll Number InstructionsPriyam MrigPas encore d'évaluation

- Amity University HaryanaDocument2 pagesAmity University Haryananidhi malikPas encore d'évaluation

- P/id 6011/MBLDocument4 pagesP/id 6011/MBLbogal02Pas encore d'évaluation

- Production and Maintenance Optimization Problems: Logistic Constraints and Leasing Warranty ServicesD'EverandProduction and Maintenance Optimization Problems: Logistic Constraints and Leasing Warranty ServicesPas encore d'évaluation

- Base ExcitationDocument51 pagesBase ExcitationAjitsingh JagtapPas encore d'évaluation

- Professional Synopsis:: Kunal AnarseDocument2 pagesProfessional Synopsis:: Kunal AnarseAjitsingh JagtapPas encore d'évaluation

- Kunal Anarse: Professional SynopsisDocument3 pagesKunal Anarse: Professional SynopsisAjitsingh JagtapPas encore d'évaluation

- Response To Harmonic ExcitationDocument51 pagesResponse To Harmonic ExcitationAjitsingh JagtapPas encore d'évaluation

- Gaseous FuelsDocument24 pagesGaseous FuelsAjitsingh JagtapPas encore d'évaluation

- Solid FuelsDocument46 pagesSolid FuelsAjitsingh JagtapPas encore d'évaluation

- Water Softening MethodsDocument34 pagesWater Softening MethodsAjitsingh Jagtap100% (1)

- Job Safety AnalysisDocument22 pagesJob Safety AnalysisAjitsingh JagtapPas encore d'évaluation

- Operations Research Tutorial ProblemDocument4 pagesOperations Research Tutorial ProblemAjitsingh JagtapPas encore d'évaluation

- Safe/Happy/ Stress Free: Make A Work EnvironmentDocument19 pagesSafe/Happy/ Stress Free: Make A Work EnvironmentAjitsingh JagtapPas encore d'évaluation

- Chemical EngineeringDocument44 pagesChemical EngineeringAjitsingh JagtapPas encore d'évaluation

- Consolidated Question Bank 4Document3 pagesConsolidated Question Bank 4Ajitsingh JagtapPas encore d'évaluation

- Dispersion ModelsDocument36 pagesDispersion ModelsAjitsingh Jagtap100% (1)

- Experiment 7: InputDocument6 pagesExperiment 7: InputAjitsingh JagtapPas encore d'évaluation

- Secant MethodDocument49 pagesSecant MethodAjitsingh JagtapPas encore d'évaluation

- CourseAllotted - Report - 26 12 2016 - 17 17 04Document448 pagesCourseAllotted - Report - 26 12 2016 - 17 17 04Ajitsingh Jagtap100% (1)

- Cat-I QPDocument2 pagesCat-I QPAjitsingh JagtapPas encore d'évaluation

- Nano MaterialsDocument44 pagesNano MaterialsAjitsingh Jagtap100% (1)

- Chemical EngineeringDocument44 pagesChemical EngineeringAjitsingh JagtapPas encore d'évaluation

- Form 20B: (Refer Section 159 of The Companies Act, 1956)Document6 pagesForm 20B: (Refer Section 159 of The Companies Act, 1956)Surendra DevadigaPas encore d'évaluation

- Sepm Question BankDocument1 pageSepm Question BankRahul ThoratPas encore d'évaluation

- Omde 606 Excel A2Document8 pagesOmde 606 Excel A2api-237484773Pas encore d'évaluation

- Chapter 02 - Rosenbloom 8edDocument28 pagesChapter 02 - Rosenbloom 8edheize resentePas encore d'évaluation

- NLCDocument10 pagesNLCPujaMishraPas encore d'évaluation

- Lec 1 Introduction To Industrial Management - MM112Document24 pagesLec 1 Introduction To Industrial Management - MM112Asad KhokharPas encore d'évaluation

- Economics Chapter 6-7 Guided NotesDocument2 pagesEconomics Chapter 6-7 Guided NotesTookiePas encore d'évaluation

- CH 2 Audit IIDocument9 pagesCH 2 Audit IIsamuel debebePas encore d'évaluation

- Tanishq JRM 090729172938 Phpapp01Document25 pagesTanishq JRM 090729172938 Phpapp01Pragya AgrawalPas encore d'évaluation

- Presentation Assignment: Inventory Control Inventory ManagementDocument14 pagesPresentation Assignment: Inventory Control Inventory Managementiftikhar AhmedPas encore d'évaluation

- 1027 02 Swot Analysis PowerpointDocument6 pages1027 02 Swot Analysis PowerpointTohed JomaPas encore d'évaluation

- Royal EnfieldDocument2 pagesRoyal EnfieldGopinath GovindarajPas encore d'évaluation

- Income Generating ProjectDocument5 pagesIncome Generating ProjectZwei Gonzaga FernandezPas encore d'évaluation

- Chapter 13 Entrepreneurship by Zubair A Khan.Document29 pagesChapter 13 Entrepreneurship by Zubair A Khan.Zubair A Khan100% (1)

- Tutorial Chapter 1Document2 pagesTutorial Chapter 1Tan Su SuanPas encore d'évaluation

- CV QC Form M Shahid Iqbal With PicDocument3 pagesCV QC Form M Shahid Iqbal With PicSheikhPas encore d'évaluation

- Module 5 - Fundamental Principles of ValuationDocument55 pagesModule 5 - Fundamental Principles of ValuationTricia Angela Nicolas100% (1)

- Letter of CancellationDocument2 pagesLetter of CancellationJoekoid KoidPas encore d'évaluation

- Neerja Modi School Entrepreneurship Market Survey ReportDocument31 pagesNeerja Modi School Entrepreneurship Market Survey Reportshilpi goelPas encore d'évaluation

- 1PPM PPS Course Outline 22Document4 pages1PPM PPS Course Outline 22YusufPas encore d'évaluation

- T3 Case. Coda Coffee & Bext360 Case SolutionDocument10 pagesT3 Case. Coda Coffee & Bext360 Case SolutionMarcel Lasselsberger67% (6)

- Basic Accounting ExamDocument8 pagesBasic Accounting ExamMikaela SalvadorPas encore d'évaluation

- PMBOK Guide 7th Edition (12 Principles)Document24 pagesPMBOK Guide 7th Edition (12 Principles)TanveerAhmed Niazi0% (2)

- Case Study Currency SwapsDocument2 pagesCase Study Currency SwapsSourav Maity100% (2)

- FAR16 Share Capital Transactions - For PrintDocument9 pagesFAR16 Share Capital Transactions - For PrintAJ CresmundoPas encore d'évaluation

- SM Chapter 07Document57 pagesSM Chapter 07mas aziz100% (1)

- Project SynopsisDocument4 pagesProject SynopsisPrithvi kumar YadavPas encore d'évaluation

- Mod Iv - IprDocument29 pagesMod Iv - IprSoumya Shefali ChandrakarPas encore d'évaluation

- IAS 32 - NotesDocument30 pagesIAS 32 - NotesJyPas encore d'évaluation

- Accounting BasicsDocument68 pagesAccounting BasicsEd Caty100% (1)