Académique Documents

Professionnel Documents

Culture Documents

Process Control in Textile Manufacturing

Transféré par

rakibCopyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Process Control in Textile Manufacturing

Transféré par

rakibDroits d'auteur :

Formats disponibles

See

discussions, stats, and author profiles for this publication at:

https://www.researchgate.net/publication/272892472

Process control in textile

manufacturing

Book · November 2012

CITATIONS READS

0 7,800

1 author:

Abhijit Majumdar

Indian Institute of Technology Delhi

75 PUBLICATIONS 801 CITATIONS

SEE PROFILE

All content following this page was uploaded by Abhijit Majumdar on 01 March 2015.

The user has requested enhancement of the downloaded file.

Process control in textile manufacturing

© Woodhead Publishing Limited, 2013

The Textile Institute and Woodhead Publishing

The Textile Institute is a unique organisation in textiles, clothing and foot-

wear. Incorporated in England by a Royal Charter granted in 1925, the

Institute has individual and corporate members in over 90 countries. The

aim of the Institute is to facilitate learning, recognise achievement, reward

excellence and disseminate information within the global textiles, clothing

and footwear industries.

Historically, The Textile Institute has published books of interest to its

members and the textile industry. To maintain this policy, the Institute has

entered into partnership with Woodhead Publishing Limited to ensure that

Institute members and the textile industry continue to have access to high

calibre titles on textile science and technology.

Most Woodhead titles on textiles are now published in collaboration

with The Textile Institute. Through this arrangement, the Institute provides

an Editorial Board which advises Woodhead on appropriate titles for future

publication and suggests possible editors and authors for these books. Each

book published under this arrangement carries the Institute’s logo.

Woodhead books published in collaboration with The Textile Institute

are offered to Textile Institute members at a substantial discount. These

books, together with those published by The Textile Institute that are still in

print, are offered on the Woodhead web site at: www.woodheadpublishing.

com. Textile Institute books still in print are also available directly from the

Institute’s web site at: www.textileinstitutebooks.com

A list of Woodhead books on textiles science and technology, most of

which have been published in collaboration with the Textile Institute, can

be found towards the end of the contents pages.

© Woodhead Publishing Limited, 2013

Woodhead Publishing Series in Textiles: Number 131

Process control in

textile manufacturing

Edited by

Abhijit Majumdar, Apurba Das, R. Alagirusamy

and V. K. Kothari

Oxford Cambridge Philadelphia New Delhi

© Woodhead Publishing Limited, 2013

Published by Woodhead Publishing Limited in association with The Textile Institute

Woodhead Publishing Limited, 80 High Street, Sawston, Cambridge CB22 3HJ, UK

www.woodheadpublishing.com

www.woodheadpublishingonline.com

Woodhead Publishing, 1518 Walnut Street, Suite 1100, Philadelphia,

PA 19102-3406, USA

Woodhead Publishing India Private Limited, G-2, Vardaan House, 7/28 Ansari Road,

Daryaganj, New Delhi – 110002, India

www.woodheadpublishingindia.com

First published 2013, Woodhead Publishing Limited

© Woodhead Publishing Limited, 2013. Note: The publishers have made every effort

to ensure that permission for copyright material has been obtained by authors wishing

to use such material. The authors and the publishers will be glad to hear from any

copyright holder it has not been possible to contact.

The authors have asserted their moral rights.

This book contains information obtained from authentic and highly regarded sources.

Reprinted material is quoted with permission, and sources are indicated. Reasonable

efforts have been made to publish reliable data and information, but the authors and

the publishers cannot assume responsibility for the validity of all materials. Neither

the authors nor the publishers, nor anyone else associated with this publication, shall

be liable for any loss, damage or liability directly or indirectly caused or alleged to be

caused by this book.

Neither this book nor any part may be reproduced or transmitted in any form or

by any means, electronic or mechanical, including photocopying, microfilming and

recording, or by any information storage or retrieval system, without permission in

writing from Woodhead Publishing Limited.

The consent of Woodhead Publishing Limited does not extend to copying for general

distribution, for promotion, for creating new works, or for resale. Specific permission

must be obtained in writing from Woodhead Publishing Limited for such copying.

Trademark notice: Product or corporate names may be trademarks or registered

trademarks, and are used only for identification and explanation, without intent to

infringe.

British Library Cataloguing in Publication Data

A catalogue record for this book is available from the British Library.

Library of Congress Control Number: 2012949006

ISBN 978-0-85709-027-0 (print)

ISBN 978-0-85709-563-3 (online)

ISSN 2042-0803 Woodhead Publishing Series in Textiles (print)

ISSN 2042-0811 Woodhead Publishing Series in Textiles (online)

The publisher’s policy is to use permanent paper from mills that operate a

sustainable forestry policy, and which has been manufactured from pulp

which is processed using acid-free and elemental chlorine-free practices.

Furthermore, the publisher ensures that the text paper and cover board used

have met acceptable environmental accreditation standards.

Typeset by Newgen Knowledge Works Pvt Ltd, India

Printed and bound in the UK by the MPG Books Group

© Woodhead Publishing Limited, 2013

Contents

Contributor contact details xi

Woodhead Publishing Series in Textiles xiv

Foreword xix

Part I General issues 1

1 Basics of process control in textile manufacturing 3

VEDPAL and V. JAIN, Indian Institute of Technology Delhi, India

1.1 Introduction 3

1.2 Process mapping, analysis and control 5

1.3 Statistical process control (SPC) and improving processes 9

1.4 Future trends 11

1.5 References 13

2 Basic principles of control systems in textile

manufacturing 14

S. S. SAHA, Government College of Engineering & Textile

Technology, Berhampore, India

2.1 Introduction 14

2.2 Components of control systems 18

2.3 The control system design process 28

2.4 Digital control systems 34

2.5 Intelligent control systems using soft computing 36

2.6 Application of control systems in textile processing 39

2.7 References 39

3 Testing and statistical quality control in textile

manufacturing 41

A. DAS, Indian Institute of Technology Delhi, India

3.1 Introduction: statistical quality control 41

3.2 Basic measurement concepts in statistical quality control 42

© Woodhead Publishing Limited, 2013

vi Contents

3.3 Interpretations: critical difference 48

3.4 Interpretations: ‘t’ tests, ‘F ’ tests and the chi-square method 53

3.5 Decision-making using control charts 57

3.6 Decision-making: hypothesis testing 59

3.7 Decision-making: significance testing 61

3.8 Testing fibre and yarn properties 72

3.9 Testing fabric properties 75

3.10 References 78

Part II Process control in fibre production and

yarn manufacture 79

4 Process and quality control in cultivating

natural textile fibres 81

M. ZIMNIEWSKA, Institute of Natural Fibres and Medicinal Plants,

Poland, I. FRYDRYCH, Technical University of Lodz, Poland,

J. MANKOWSKI, Institute of Natural Fibres and Medicinal Plants,

Poland, and W. TRYWIANSKA, Gdynia Cotton Association, Poland

4.1 Introduction 81

4.2 Control of cotton fibre quality 81

4.3 Indexes for cotton fibre quality 85

4.4 Process control in harvesting 89

4.5 Control of natural lignocellulosic/bast fibre quality: climatic

conditions 96

4.6 Process control in production 100

4.7 Evaluating fibre quality 105

4.8 Future trends 107

4.9 References 107

5 Process control in the manufacturing of synthetic

textile fibres 109

B. L. DEOPURA, Indian Institute of Technology Delhi,

India, A. CHATTERJEE, Dr B R Ambedkar National Institute of

Technology Jalandhar, India and N. V. PADAKI, CSTRI Central

Silk Board, India

5.1 Introduction 109

5.2 Process control in polymerisation and fibre spinning 111

5.3 Post-spinning process control: drawing and heat setting 122

5.4 Key control points in synthetic fibre manufacture 127

5.5 Future trends 130

5.6 References 131

© Woodhead Publishing Limited, 2013

Contents vii

6 Process control in blowroom and carding operations 132

R. ALAGIRUSAMY, Indian Institute of Technology Delhi, India

6.1 Introduction to blowroom operations 132

6.2 General process control in the blowroom 135

6.3 Process control in blowroom processes 137

6.4 Process control in carding: control of process parameters 142

6.5 Process control in carding: control of card clothing, wire

maintenance and card waste 147

6.6 Yarn count issues and other common process control

problems for blowroom and carding operations 153

6.7 Bibliography 157

7 Process control in drawing, combing and speed frame

operations 158

A. GHOSH, Government College of Engineering & Textile

Technology, Berhampore, India, and A. MAJUMDAR, Indian Institute

of Technology Delhi, India

7.1 Introduction 158

7.2 Process control in drawing: key elements 159

7.3 The impact of drawing on yarn quality 164

7.4 Process control in drawing: common problems 166

7.5 Process control in combing: key elements 171

7.6 Process control in combing: the impact of combing

on yarn quality and common problems arising from

the process 178

7.7 Process control in speed frame operations:

key elements 181

7.8 Process control in speed frame operations: the impact

of speed frame operations on yarn quality and common

defects related to the process 185

7.9 Conclusions and future trends 189

7.10 Acknowledgement 189

7.11 References 189

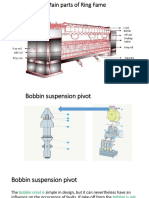

8 Process control in ring and rotor spinning 191

P. K. MAJUMDAR, Government College of Engineering & Textile

Technology, Serampore, India

8.1 Introduction 191

8.2 Factors affecting spinning tension in ring spinning 195

8.3 Control of end breakage rate in ring spinning 202

© Woodhead Publishing Limited, 2013

viii Contents

8.4 Factors affecting end breakage rates in ring spinning 205

8.5 Control of fly generation and twist variations

in ring spinning 208

8.6 Process control in rotor spinning 213

8.7 Control of end breakage rate and twist loss in rotor spinning 217

8.8 Future trends 220

8.9 References 221

9 Maintenance of yarn spinning machines 225

A. BASU, Central Silk Board, India

9.1 Introduction 225

9.2 Maintenance of spinning preparatory machines 231

9.3 Maintenance of ring and rotor spinning machines 235

9.4 Future trends 236

9.5 Sources for further information and advice 239

9.6 References 240

Part III Process control in fabric manufacture, coloration

and finishing 241

10 Process control in knitting 243

S. C. RAY, University of Calcutta, India

10.1 Introduction 243

10.2 Key control points in knitting 244

10.3 Quality control of knitted fabrics 248

10.4 Control of knitted loop length 251

10.5 Common faults in knitted fabrics 253

10.6 Other process control factors in knitting 259

10.7 Future trends: online quality control 262

10.8 References 264

11 Process control in weaving 265

V. K. KOTHARI, Indian Institute of Technology Delhi, India

11.1 Introduction 265

11.2 Controlling loom productivity, efficiency and

fabric quality 267

11.3 Online process control, quality control and monitoring

in weaving 269

11.4 Cost control in weaving 276

11.5 References 278

© Woodhead Publishing Limited, 2013

Contents ix

12 Process control in nonwovens production 279

D. MOYO, A. PATANAIK and R. D. ANANDJIWALA, CSIR Materials

Science and Manufacturing, South Africa, and Department of Textile

Science, Nelson Mandela Metropolitan University, South Africa

12.1 Introduction 279

12.2 Needle punching: process variables and process control 280

12.3 Hydroentanglement: process variables and process control 285

12.4 Melt blowing: process variables and process control 288

12.5 Spunbonding: process variables and process control 292

12.6 Future trends 295

12.7 Sources of further information 296

12.8 Acknowledgement 296

12.9 References 296

13 Process control in dyeing of textiles 300

S. M. SHANG, The Hong Kong Polytechnic University, China

13.1 Introduction 300

13.2 Dyeing of cotton 302

13.3 Dyeing of synthetic materials 315

13.4 Dyeing of blends 322

13.5 Process control in batchwise dyeing machines 326

13.6 Process control in continuous dyeing machines 334

13.7 References 338

14 Process control in printing of textiles 339

S. M. SHANG, The Hong Kong Polytechnic University, China

14.1 Introduction 339

14.2 Direct printing 339

14.3 Discharge, resist and heat transfer printing 345

14.4 Process control in roller and screen printing machines 348

14.5 Inkjet printing and its process control 353

14.6 Product safety and low-carbon production 360

14.7 Sources of further information 361

14.8 References 362

15 Process control in finishing of textiles 363

A. K. ROY CHOUDHURY, Government College of Engineering

and Textile Technology, Serampore, India

15.1 Introduction 363

15.2 Instrumental process control 365

© Woodhead Publishing Limited, 2013

x Contents

15.3 Textile finishing processes and process

control in finishing 369

15.4 Process control in basic finishing machines 373

15.5 Process control in stenter machines 376

15.6 Calendering process 380

15.7 Surface raising and pre-shrinking finishes 385

15.8 Finishing with alkali 389

15.9 Softeners 393

15.10 Resin finishes 396

15.11 Protection from fire damage and water penetration 401

15.12 Anti-pilling finish 405

15.13 Other types of finishing: antistatic, soil release,

antimicrobial and UV protection 407

15.14 Wool treatment and enzyme finishes 413

15.15 Low-liquor finishing 417

15.16 Plasma treatments 421

15.17 Future trends 425

15.18 References 425

16 Process control in apparel manufacturing 428

G.THILAGAVATHI and S.VIJU, PSG College of Technology, India

16.1 Introduction 428

16.2 Process control in spreading, pattern making and cutting 428

16.3 Process control in sewing 432

16.4 Causes of damage to the fabric during sewing 441

16.5 Control of fusing and pressing operations, storage

and packaging 449

16.6 Quality evaluation of apparel: testing for tailorability 454

16.7 Quality evaluation of apparel: testing for sewability 463

16.8 Quality evaluation of accessories 465

16.9 References 471

Index 475

© Woodhead Publishing Limited, 2013

Contributor contact details

(* main contact) Chapter 2

Editors Dr S. S. Saha

Department of Electrical

Dr Abhijit Majumdar,* Dr Apurba Engineering

Das, Prof. R. Alagirusamy and Government College of

Prof. Vijay Kumar Kothari Engineering & Textile

Department of Textile Technology Technology

Indian Institute of Technology Berhampore

Delhi West Bengal – 742101

Hauz Khas India

New Delhi - 110016

India Email: sahashib@hotmail.com

Email: majumdar@textile.iitd.ac.in;

Chapter 3

apurba@textile.iitd.ernet.in;

alagiru@gmail.com; Dr Apurba Das

kothari@textile.iitd.ernet.in; Department of Textile Technology

Indian Institute of Technology

Delhi

Chapter 1 Hauz Khas

New Delhi - 110016

Vedpal and Dr Vipul Jain*

India

Department of Mechanical

Engineering Email: apurba@textile.iitd.ernet.in

Indian Institute of Technology

Delhi Chapter 4

Hauz Khas

Dr M. Zimniewska* I. Frydrych and

New Delhi - 110016

J. Mankowski

India

Department of Innovative Textile

Email: vjain@mech.iitd.ac.in Technologies

xi

© Woodhead Publishing Limited, 2013

xii Contributor contact details

Institute of Natural Fibres and Dr Abhijit Majumdar

Medicinal Plants Department of Textile Technology

Wojska Plskiego 71b Indian Institute of Technology

60-630 Poznan Delhi

Poland Hauz Khas

New Delhi - 110016

Email: gosiaz@inf.poznan.pl

India

Chapter 5 Email: majumdar@textile.iitd.ac.in

Prof. B. L. Deopura, A. Chatterjee Chapter 8

and N. V. Padaki

Prof. Prabal Kumar Majumdar

Department of Textile Technology

Department of Textile Technology

Indian Institute of Technology

Government College of

Delhi

Engineering and Textile

Hauz Khas

Technology

New Delhi - 110016

Serampore - 712201 Dt. Hooghly

India

(W.B.)

Email: bdeopura@yahoo.com India

Email: pkm5@rediffmail.com

Chapter 6

Prof. R. Alagirusamy Chapter 9

Department of Textile Technology Dr Arindam Basu

Indian Institute of Technology Central Silk Technological

Delhi Research Institute

Hauz Khas Central Silk Board

New Delhi - 110016 Madivala, BTM Layout

India Bangalore - 560068

Email: alagiru@gmail.com India

Email: arindambasu_dr@yahoo.co.in

Chapter 7

Chapter 10

Dr Anindya Ghosh*

Government College of Prof. Sadhan Chandra Ray

Engineering and Textile Professor in Fabric Manufacture

Technology Department of Jute and Fibre

Berhampore Technology

West Bengal – 742101 University of Calcutta

India 35 Ballygunge Circular Road

Kolkata - 700019

Email: anindya.textile@gmail.com India

and Email: sadhan53@yahoo.co.in

© Woodhead Publishing Limited, 2013

Contributor contact details xiii

Chapter 11 Chapter 13 and 14

Prof. Vijay Kumar Kothari Dr Songmin Shang

Department of Textile Technology Institute of Textiles and Clothing

Indian Institute of Technology The Hong Kong Polytechnic

Delhi University

Hauz Khas Hung Hom

New Delhi - 110016 Kowloon

India Hong Kong

China

Email: kothari@textile.iitd.ernet.in;

iitkothari@gmail.com Email: tcshang@inet.polyu.edu.hk

Chapter 12 Chapter 15

Doice Moyo, Dr Asis Patanaik* and Prof. Asim Kumar Roy Choudhury

Dr Rajesh D. Anandjiwala Department of Textile Technology

CSIR Materials Science and Government College of

Manufacturing Engineering and Textile

Polymers and Composites Technology

Competence Area Serampore - 712201 Dt. Hooghly

P.O. Box 1124 (W.B.)

Port Elizabeth 6000 India

South Africa Email: akrc2008@yahoo.in

and

Chapter 16

Faculty of Science

Department of Textile Science G.Thilagavathi* and S.Viju

Nelson Mandela Metropolitan Department of Fashion Technology

University PSG College of Technology

Port Elizabeth 6031 Peelamedu

South Africa Coimbatore - 641004

Tamilnadu

Email: patnaik_asis@yahoo.com; India

APatnaik@csir.co.za

Email: thilagapsg@gmail.com

© Woodhead Publishing Limited, 2013

Woodhead Publishing Series in Textiles

1 Watson’s textile design and colour Seventh edition

Edited by Z. Grosicki

2 Watson’s advanced textile design

Edited by Z. Grosicki

3 Weaving Second edition

P. R. Lord and M. H. Mohamed

4 Handbook of textile fibres Vol 1: Natural fibres

J. Gordon Cook

5 Handbook of textile fibres Vol 2: Man-made fibres

J. Gordon Cook

6 Recycling textile and plastic waste

Edited by A. R. Horrocks

7 New fibers Second edition

T. Hongu and G. O. Phillips

8 Atlas of fibre fracture and damage to textiles Second edition

J. W. S. Hearle, B. Lomas and W. D. Cooke

9 Ecotextile ’98

Edited by A. R. Horrocks

10 Physical testing of textiles

B. P. Saville

11 Geometric symmetry in patterns and tilings

C. E. Horne

12 Handbook of technical textiles

Edited by A. R. Horrocks and S. C. Anand

13 Textiles in automotive engineering

W. Fung and J. M. Hardcastle

14 Handbook of textile design

J. Wilson

15 High-performance fibres

Edited by J. W. S. Hearle

16 Knitting technology Third edition

D. J. Spencer

17 Medical textiles

Edited by S. C. Anand

18 Regenerated cellulose fibres

Edited by C. Woodings

19 Silk, mohair, cashmere and other luxury fibres

Edited by R. R. Franck

20 Smart fibres, fabrics and clothing

Edited by X. M. Tao

21 Yarn texturing technology

J. W. S. Hearle, L. Hollick and D. K. Wilson

22 Encyclopedia of textile finishing

H-K. Rouette

xiv

© Woodhead Publishing Limited, 2013

Woodhead Publishing Series in Textiles xv

23 Coated and laminated textiles

W. Fung

24 Fancy yarns

R. H. Gong and R. M. Wright

25 Wool: Science and technology

Edited by W. S. Simpson and G. Crawshaw

26 Dictionary of textile finishing

H-K. Rouette

27 Environmental impact of textiles

K. Slater

28 Handbook of yarn production

P. R. Lord

29 Textile processing with enzymes

Edited by A. Cavaco-Paulo and G. Gübitz

30 The China and Hong Kong denim industry

Y. Li, L. Yao and K. W. Yeung

31 The World Trade Organization and international denim trading

Y. Li, Y. Shen, L. Yao and E. Newton

32 Chemical finishing of textiles

W. D. Schindler and P. J. Hauser

33 Clothing appearance and fit

J. Fan, W. Yu and L. Hunter

34 Handbook of fibre rope technology

H. A. McKenna, J. W. S. Hearle and N. O’Hear

35 Structure and mechanics of woven fabrics

J. Hu

36 Synthetic fibres: nylon, polyester, acrylic, polyolefin

Edited by J. E. McIntyre

37 Woollen and worsted woven fabric design

E. G. Gilligan

38 Analytical electrochemistry in textiles

P. Westbroek, G. Priniotakis and P. Kiekens

39 Bast and other plant fibres

R. R. Franck

40 Chemical testing of textiles

Edited by Q. Fan

41 Design and manufacture of textile composites

Edited by A. C. Long

42 Effect of mechanical and physical properties on fabric hand

Edited by H. M. Behery

43 New millennium fibers

T. Hongu, M. Takigami and G. O. Phillips

44 Textiles for protection

Edited by R. A. Scott

45 Textiles in sport

Edited by R. Shishoo

46 Wearable electronics and photonics

Edited by X. M. Tao

47 Biodegradable and sustainable fibres

Edited by R. S. Blackburn

48 Medical textiles and biomaterials for healthcare

Edited by S. C. Anand, M. Miraftab, S. Rajendran and J. F. Kennedy

49 Total colour management in textiles

Edited by J. Xin

50 Recycling in textiles

Edited by Y. Wang

51 Clothing biosensory engineering

Y. Li and A. S. W. Wong

© Woodhead Publishing Limited, 2013

xvi Woodhead Publishing Series in Textiles

52 Biomechanical engineering of textiles and clothing

Edited by Y. Li and D. X-Q. Dai

53 Digital printing of textiles

Edited by H. Ujiie

54 Intelligent textiles and clothing

Edited by H. R. Mattila

55 Innovation and technology of women’s intimate apparel

W. Yu, J. Fan, S. C. Harlock and S. P. Ng

56 Thermal and moisture transport in fibrous materials

Edited by N. Pan and P. Gibson

57 Geosynthetics in civil engineering

Edited by R. W. Sarsby

58 Handbook of nonwovens

Edited by S. Russell

59 Cotton: Science and technology

Edited by S. Gordon and Y-L. Hsieh

60 Ecotextiles

Edited by M. Miraftab and A. R. Horrocks

61 Composite forming technologies

Edited by A. C. Long

62 Plasma technology for textiles

Edited by R. Shishoo

63 Smart textiles for medicine and healthcare

Edited by L. Van Langenhove

64 Sizing in clothing

Edited by S. Ashdown

65 Shape memory polymers and textiles

J. Hu

66 Environmental aspects of textile dyeing

Edited by R. Christie

67 Nanofibers and nanotechnology in textiles

Edited by P. Brown and K. Stevens

68 Physical properties of textile fibres Fourth edition

W. E. Morton and J. W. S. Hearle

69 Advances in apparel production

Edited by C. Fairhurst

70 Advances in fire retardant materials

Edited by A. R. Horrocks and D. Price

71 Polyesters and polyamides

Edited by B. L. Deopura, R. Alagirusamy, M. Joshi and B. Gupta

72 Advances in wool technology

Edited by N. A. G. Johnson and I. Russell

73 Military textiles

Edited by E. Wilusz

74 3D fibrous assemblies: Properties, applications and modelling of three-dimensional textile

structures

J. Hu

75 Medical and healthcare textiles

Edited by S. C. Anand, J. F. Kennedy, M. Miraftab and S. Rajendran

76 Fabric testing

Edited by J. Hu

77 Biologically inspired textiles

Edited by A. Abbott and M. Ellison

78 Friction in textile materials

Edited by B. S. Gupta

79 Textile advances in the automotive industry

Edited by R. Shishoo

80 Structure and mechanics of textile fibre assemblies

Ediited by P. Schwartz

© Woodhead Publishing Limited, 2013

Woodhead Publishing Series in Textiles xvii

81 Engineering textiles: Integrating the design and manufacture of textile products

Edited by Y. E. El-Mogahzy

82 Polyolefin fibres: Industrial and medical applications

Edited by S. C. O. Ugbolue

83 Smart clothes and wearable technology

Edited by J. McCann and D. Bryson

84 Identification of textile fibres

Edited by M. Houck

85 Advanced textiles for wound care

Edited by S. Rajendran

86 Fatigue failure of textile fibres

Edited by M. Miraftab

87 Advances in carpet technology

Edited by K. Goswami

88 Handbook of textile fibre structure Volume 1 and Volume 2

Edited by S. J. Eichhorn, J. W. S. Hearle, M. Jaffe and T. Kikutani

89 Advances in knitting technology

Edited by K-F. Au

90 Smart textile coatings and laminates

Edited by W. C. Smith

91 Handbook of tensile properties of textile and technical fibres

Edited by A. R. Bunsell

92 Interior textiles: Design and developments

Edited by T. Rowe

93 Textiles for cold weather apparel

Edited by J. T. Williams

94 Modelling and predicting textile behaviour

Edited by X. Chen

95 Textiles, polymers and composites for buildings

Edited by G. Pohl

96 Engineering apparel fabrics and garments

J. Fan and L. Hunter

97 Surface modification of textiles

Edited by Q. Wei

98 Sustainable textiles

Edited by R. S. Blackburn

99 Advances in yarn spinning technology

Edited by C. A. Lawrence

100 Handbook of medical textiles

Edited by V. T. Bartels

101 Technical textile yarns

Edited by R. Alagirusamy and A. Das

102 Applications of nonwovens in technical textiles

Edited by R. A. Chapman

103 Colour measurement: Principles, advances and industrial applications

Edited by M. L. Gulrajani

104 Fibrous and composite materials for civil engineering applications

Edited by R. Fangueiro

105 New product development in textiles: Innovation and production

Edited by L.Horne

106 Improving comfort in clothing

Edited by G. Song

107 Advances in textile biotechnology

Edited by V. A. Nierstrasz and A. Cavaco-Paulo

108 Textiles for hygiene and infection control

Edited by B. McCarthy

109 Nanofunctional textiles

Edited by Y. Li

110 Joining textiles: Principles and applications

Edited by I. Jones and G. Stylios

© Woodhead Publishing Limited, 2013

xviii Woodhead Publishing Series in Textiles

111 Soft computing in textile engineering

Edited by A. Majumdar

112 Textile design

Edited by A. Briggs-Goode and K. Townsend

113 Biotextiles as medical implants

Edited by M. King and B. Gupta

114 Textile thermal bioengineering

Edited by Y. Li

115 Woven textile structure

B. K. Behera and P. K. Hari

116 Handbook of textile and industrial dyeing. Volume 1: Principles, processes and types of

dyes

Edited by M. Clark

117 Handbook of textile and industrial dyeing. Volume 2: Applications of dyes

Edited by M. Clark

118 Handbook of natural fibres. Volume 1: Types, properties and factors affecting breeding

and cultivation

Edited by R. Kozłowski

119 Handbook of natural fibres. Volume 2: Processing and applications

Edited by R. Kozłowski

120 Functional textiles for improved performance, protection and health

Edited by N. Pan and G. Sun

121 Computer technology for textiles and apparel

Edited by J. Hu

122 Advances in military textiles and personal equipment

Edited by E. Sparks

123 Specialist yarn and fabric structures

Edited by R. H. Gong

124 Handbook of sustainable textile production

M. I. Tobler-Rohr

125 Woven textiles: Principles, developments and applications

Edited by K. Gandhi

126 Textiles and fashion: Materials design and technology

Edited by R. Sinclair

127 Industrial cutting of textile materials

I. Viļumsone-Nemes

128 Colour design: Theories and applications

Edited by J. Best

129 False twist textured yarns

C. Atkinson

130 Modelling, simulation and control of the dyeing process

R. Shamey and X. Zhao

131 Process control in textile manufacturing

Edited by A. Majumdar, A. Das, R. Alagirusamy and V. K. Kothari

132 Understanding and improving the durability of textiles

Edited by P. A. Annis

133 Smart textiles for protection

Edited by R. Chapman

134 Functional nanofibers and applications

Edited by Q. Wei

135 The global textile and clothing industry: Technological advances and future challenges

Edited by R. Shishoo

136 Simulation in textile technology: Theory and applications

Edited by D. Veit

137 Pattern cutting for clothing using CAD: How to use Lectra Modaris pattern cutting

software

M. Stott

© Woodhead Publishing Limited, 2013

Foreword

I am pleased to write a Foreword for this unique and comprehensive volume

on Process control in textile manufacturing edited by Abhijit Majumdar,

Apurba Das, R. Alagirusamy and V. K. Kothari. The editors and authors

have compiled urgently needed information, reflecting the highest standard

of publication in this field, on a very important aspect of the conversion

of fibers into the ultimate textile structures employed in various end-use

applications. The subject matter discussed in this text is timely. The glob-

alization of trade now demands that products marketed around the world

meet certain basic quality and performance requirements. The current pro-

duction of all types of fibers such as natural, manmade, and synthetics now

exceeds 80 odd million tons annually. The use of suitable textile fibers in

such highly sophisticated applications as medical devices, civil and construc-

tion engineering, automotive industry, filtration and aircraft and aerospace

industries as well as for more mundane purposes, such as apparel, requires

the maintenance of high quality products. ‘Engineering With Fibers’, a term

that was coined and made popular by my mentor and professional col-

league, Subhash Batra, is quite appropriate in the current environment of

utilization of textiles in highly engineered textile structures. Consequently,

the engineers and technologists engaged in machine design and processing

of fibers must be knowledgeable regarding the availability and the perfor-

mance of process control devices used in the industry. It has become manda-

tory on the part of textile manufacturers that they certify and guarantee the

performance characteristics of highly engineered textile structures designed

for composite applications.

The authors have done an excellent and noteworthy job of introducing

the reader to the fundamentals of process and quality control in the culti-

vation of natural fibers and in the manufacture of synthetic fibers. Separate

chapters on the process and control in the main systems of yarn production,

nonwovens, knitting, weaving and subsequent handling of products in the

dyeing and finishing and apparel manufacturing of textiles are important

and extremely useful. In today’s highly competitive environment the manu-

facturers must be diligent as well as expert in placing products in the mar-

ket that are well-made and that meet the expectations of the industry and

xix

© Woodhead Publishing Limited, 2013

xx Foreword

the customer. This volume will be be an important resource in the hands of

textile engineers, technologists and managers engaged in the development

and manufacture of textile products.

Bhuvenesh C. Goswami, Emeritus Alumni

Distinguished Professor of Textiles,

Clemson University, USA

© Woodhead Publishing Limited, 2013

View publication stats

Vous aimerez peut-être aussi

- Nonwoven Market (Journal)Document11 pagesNonwoven Market (Journal)Nzfah MalikPas encore d'évaluation

- Organic Cotton Yarn QualityDocument87 pagesOrganic Cotton Yarn QualityMuhammad Qamar TusiefPas encore d'évaluation

- ENGLISH Use in Textile EngineeringDocument63 pagesENGLISH Use in Textile EngineeringDhrubo Adhikary100% (1)

- Study On Fleece Knit FabricDocument45 pagesStudy On Fleece Knit Fabrickhurshid100% (1)

- Knitting Production and Quality ControlDocument10 pagesKnitting Production and Quality ControlDr Muhammad Mushtaq Mangat0% (1)

- ATY Fabric PropertiesDocument5 pagesATY Fabric PropertiesHitesh ShahPas encore d'évaluation

- Naina ApparelsDocument11 pagesNaina ApparelsAman DeepPas encore d'évaluation

- Indian Textile IndustryDocument0 pageIndian Textile Industrydianty_marienkafergsPas encore d'évaluation

- Textile Fibre Yarn CountDocument30 pagesTextile Fibre Yarn CountSujit GulhanePas encore d'évaluation

- Nonwovens For Medical TextilesDocument11 pagesNonwovens For Medical TextilesaswinipranavPas encore d'évaluation

- NONWOVENDocument114 pagesNONWOVENSwati SharmaPas encore d'évaluation

- Fiber PropertiesDocument24 pagesFiber Propertiessatheeshpag12367% (3)

- Eco Friendly Garment Finishes The Need of Hour For FashionDocument12 pagesEco Friendly Garment Finishes The Need of Hour For FashionAntotexPas encore d'évaluation

- Filament Yarn Sizing Why We Need To Size Filament Yarn?Document3 pagesFilament Yarn Sizing Why We Need To Size Filament Yarn?RAHEEL JAVEDPas encore d'évaluation

- Cotton, Polyester & Cotton Polyester BlendDocument4 pagesCotton, Polyester & Cotton Polyester BlendTanaji Santra100% (1)

- Different Types of WeavesDocument6 pagesDifferent Types of WeavesShoaib ChaudhryPas encore d'évaluation

- Automotive Textiles by Anandkumar Ubhare and Avdhoot Jadhav From V.J.T.I.Document79 pagesAutomotive Textiles by Anandkumar Ubhare and Avdhoot Jadhav From V.J.T.I.avdhoot7Pas encore d'évaluation

- List of Spinning MachineDocument8 pagesList of Spinning MachinegunaPas encore d'évaluation

- AATCC 163-2002 Colorfastness - Dye Transfer in Storage-Fabric-to-FabricDocument2 pagesAATCC 163-2002 Colorfastness - Dye Transfer in Storage-Fabric-to-FabricMichael Chen50% (2)

- LinenDocument15 pagesLinenswarna swarna100% (1)

- TEXTILE Testing InstrumentsDocument236 pagesTEXTILE Testing Instrumentsselvapdm100% (2)

- Conversion of Fibre Into A YarnDocument32 pagesConversion of Fibre Into A YarnMohammed Atiqul Hoque ChowdhuryPas encore d'évaluation

- Textile CalculationDocument6 pagesTextile CalculationKhandaker Sakib FarhadPas encore d'évaluation

- Fabric CDocument11 pagesFabric CgeethikaPas encore d'évaluation

- GTN Industries BrochureDocument8 pagesGTN Industries Brochureahelios79Pas encore d'évaluation

- Quality Assessment System For TextilesDocument93 pagesQuality Assessment System For TextilesSahil SharmaPas encore d'évaluation

- FinishesDocument75 pagesFinishesShubham TilaraPas encore d'évaluation

- Industrialattachmentofnazbangladeshltd 140515042508 Phpapp02Document198 pagesIndustrialattachmentofnazbangladeshltd 140515042508 Phpapp02Ripon SayanPas encore d'évaluation

- Terry Towel CalculationsDocument1 pageTerry Towel CalculationsSENTHIL KUMAR86% (7)

- Textile Ebook FreeDocument10 pagesTextile Ebook FreeMazharul IslamPas encore d'évaluation

- Yarn Manufacturing ProcessDocument92 pagesYarn Manufacturing ProcessUjjwal Anand50% (2)

- Textile FinishesDocument12 pagesTextile FinishesFakrul Hasan KhanPas encore d'évaluation

- Introduction To TextileDocument30 pagesIntroduction To Textileumar.niift3049100% (1)

- Textile Internship Report: Ocm Private Limited Textile Unit, AmritsarDocument49 pagesTextile Internship Report: Ocm Private Limited Textile Unit, AmritsarJyoti Rawal100% (1)

- Tesco Textile Performance StandardsDocument21 pagesTesco Textile Performance StandardsRezoanul Haque100% (1)

- Textile DocumentDocument28 pagesTextile DocumentKhandaker Sakib FarhadPas encore d'évaluation

- Basic Structure of Knitted FabricDocument9 pagesBasic Structure of Knitted FabricFarhan AriyanPas encore d'évaluation

- Woven Garments MerchandisingDocument79 pagesWoven Garments MerchandisingShahin Mahmud100% (1)

- Conventional Bundle SytemDocument14 pagesConventional Bundle SytemAnshu Raj100% (3)

- Yarn Price List 01.12.2014Document2 pagesYarn Price List 01.12.2014navinvijay2Pas encore d'évaluation

- Viyellatex Group Internship ReportDocument184 pagesViyellatex Group Internship ReportAlauddin Ahmed Jahan95% (20)

- Complete - Short Course - Textile Design and Weaving - DR Kashif Bangash - 7-4-2019Document98 pagesComplete - Short Course - Textile Design and Weaving - DR Kashif Bangash - 7-4-2019Muhammad IlyasPas encore d'évaluation

- Fabric and Testing Manual EU Own Buy Apparel: Version 1, February 16Document25 pagesFabric and Testing Manual EU Own Buy Apparel: Version 1, February 16Tahir NizamPas encore d'évaluation

- Finishing (Textiles) : OriginalDocument11 pagesFinishing (Textiles) : OriginalChandru TG100% (1)

- Internship Report ON Marketing Merchandising in Garments IndustryDocument78 pagesInternship Report ON Marketing Merchandising in Garments IndustrySharif IftekharPas encore d'évaluation

- Best Practice For Fabric InspectionDocument3 pagesBest Practice For Fabric InspectionvinayakasisPas encore d'évaluation

- Presentation of Shrinkage of KnitsDocument21 pagesPresentation of Shrinkage of KnitsRajesh KasettyPas encore d'évaluation

- Sadia Alam, Lecturer (FDT), Chittagong BGMEA Institute of Fashion & TechnologyDocument23 pagesSadia Alam, Lecturer (FDT), Chittagong BGMEA Institute of Fashion & TechnologyJubayer Uddin100% (1)

- Textile Yarns PDFDocument35 pagesTextile Yarns PDFVu Ngo Tuan100% (1)

- Fabric Weight For KnitDocument36 pagesFabric Weight For KnitMohammad Zahirul IslamPas encore d'évaluation

- sss2 BookDocument56 pagessss2 BookrakibPas encore d'évaluation

- Modern Yarn SolutionDocument43 pagesModern Yarn SolutionrakibPas encore d'évaluation

- Simplex MathDocument6 pagesSimplex MathrakibPas encore d'évaluation

- Textile Spinning PDFDocument297 pagesTextile Spinning PDFzubair100% (1)

- Main Parts of Ring FameDocument11 pagesMain Parts of Ring FamerakibPas encore d'évaluation

- Ring and TravellerDocument26 pagesRing and TravellerrakibPas encore d'évaluation

- Fabric Manufturing II: WeavingDocument33 pagesFabric Manufturing II: WeavingrakibPas encore d'évaluation

- Electricalengineeringstudentsnotes 151107185649 Lva1 App6891Document157 pagesElectricalengineeringstudentsnotes 151107185649 Lva1 App6891rakibPas encore d'évaluation

- Fabric StractureDocument152 pagesFabric Stracturearivaazhi90% (10)

- Scanned by CamscannerDocument6 pagesScanned by CamscannerrakibPas encore d'évaluation

- Short Note On ShedDocument21 pagesShort Note On ShedrakibPas encore d'évaluation

- KnittingDocument13 pagesKnittingrakibPas encore d'évaluation

- CV Formate For Students of FreshersDocument2 pagesCV Formate For Students of FreshersrakibPas encore d'évaluation

- Mechanics of Materials: Analysis and Design of Beams For BendingDocument22 pagesMechanics of Materials: Analysis and Design of Beams For BendingrakibPas encore d'évaluation

- What Is LoomDocument64 pagesWhat Is LoomrakibPas encore d'évaluation

- SubstationDocument18 pagesSubstationrakib100% (1)

- Job, Viva, Interview Questions For Textile EngineersDocument86 pagesJob, Viva, Interview Questions For Textile EngineersMazedul Hasan Shishir100% (8)

- Khushboo PriyambadaDocument121 pagesKhushboo PriyambadarakibPas encore d'évaluation

- Fabric StractureDocument152 pagesFabric Stracturearivaazhi90% (10)

- Truss 150303044746 Conversion Gate01Document10 pagesTruss 150303044746 Conversion Gate01rakibPas encore d'évaluation

- SubstationDocument18 pagesSubstationrakib100% (1)

- Textile Institute of Pakistan: Zargham ShafiDocument7 pagesTextile Institute of Pakistan: Zargham ShafirakibPas encore d'évaluation

- Electronic EngineeringDocument58 pagesElectronic EngineeringrakibPas encore d'évaluation

- Engineering MaterialsDocument72 pagesEngineering MaterialsrakibPas encore d'évaluation

- Đề Ôn Thi Vào 10 2Document7 pagesĐề Ôn Thi Vào 10 2Quỳnh PhạmPas encore d'évaluation

- African Polyphony and PolyrhythmDocument742 pagesAfrican Polyphony and Polyrhythmepartheni100% (5)

- APA Reference Review Sheet: APA Format MLA FormatDocument1 pageAPA Reference Review Sheet: APA Format MLA Formatedward_sheed28Pas encore d'évaluation

- School WebsiteDocument12 pagesSchool WebsiteMohamed RiyasPas encore d'évaluation

- What Really MattersDocument320 pagesWhat Really MatterspitydoulosPas encore d'évaluation

- Oxford Progressive English Teaching Guide 1Document184 pagesOxford Progressive English Teaching Guide 1Muhammad Adnan50% (12)

- A Dictionary of Greek and Roman Antiquities (Smith Et Al.) (1890) 01Document545 pagesA Dictionary of Greek and Roman Antiquities (Smith Et Al.) (1890) 01Dedpul 79Pas encore d'évaluation

- Book Scanner User Manual - EN - V1.6Document50 pagesBook Scanner User Manual - EN - V1.6JohnnyPas encore d'évaluation

- O Filisteu e o GênioDocument125 pagesO Filisteu e o GênioLeonardo AmaralPas encore d'évaluation

- DocuCentre-II 3005 - 2055 - 2005Document44 pagesDocuCentre-II 3005 - 2055 - 2005Huỳnh Ngọc LânPas encore d'évaluation

- Hack Literature ReviewDocument6 pagesHack Literature Reviewfeiaozukg100% (1)

- Reading and WritingDocument18 pagesReading and WritingMichelle Anne PanganPas encore d'évaluation

- The Adventures of Lawsuit and T Boy 1 by Jacob Mott 1897102836 PDFDocument5 pagesThe Adventures of Lawsuit and T Boy 1 by Jacob Mott 1897102836 PDFMohd AimanPas encore d'évaluation

- Annette Keen: PDF Processed With Cutepdf Evaluation EditionDocument21 pagesAnnette Keen: PDF Processed With Cutepdf Evaluation EditionAgustin SuarezPas encore d'évaluation

- Reading Practices in Early Christianity and The Individualization Process - Guy Stroumsa PDFDocument18 pagesReading Practices in Early Christianity and The Individualization Process - Guy Stroumsa PDFPricopi Victor100% (1)

- 8 Figure Funnel BlueprintDocument25 pages8 Figure Funnel Blueprintoscar thano100% (2)

- Teaching Writing To Young LearnersDocument27 pagesTeaching Writing To Young LearnersRanya Farraj100% (1)

- Chinas Twentieth Century Revolution Retreat and The Road To EqualityDocument2 pagesChinas Twentieth Century Revolution Retreat and The Road To Equalityrabia basriPas encore d'évaluation

- Contamination Control in Healthcare Product Manufacturing Volume 5 - ContenidoDocument11 pagesContamination Control in Healthcare Product Manufacturing Volume 5 - Contenidocargscrib100% (1)

- Cy7 201710 QST Ms STQ Nonotes FinalDocument83 pagesCy7 201710 QST Ms STQ Nonotes FinalRuby Joy ClaroPas encore d'évaluation

- Crescent Moons and Pointed Minarets Teacher GuideDocument12 pagesCrescent Moons and Pointed Minarets Teacher GuideChronicleBooksPas encore d'évaluation

- Grid TemplatesDocument21 pagesGrid Templateshershey barroga100% (15)

- Blackwell Publishing, Incorporated Et Al v. Miller - Document No. 10Document12 pagesBlackwell Publishing, Incorporated Et Al v. Miller - Document No. 10Justia.comPas encore d'évaluation

- Middle School Outline Template For Book ReportDocument4 pagesMiddle School Outline Template For Book Reportapi-461005186Pas encore d'évaluation

- API CalculationDocument8 pagesAPI Calculationgirish ranaPas encore d'évaluation

- The Protocols of The Learned Elders of Zion Book 1 PDFDocument104 pagesThe Protocols of The Learned Elders of Zion Book 1 PDFpatsy price100% (2)

- 427 NegokuwywocajDocument4 pages427 Negokuwywocajrobin dagarPas encore d'évaluation

- The Essential Friends of Libraries Fast Facts, Forms, and TipsDocument118 pagesThe Essential Friends of Libraries Fast Facts, Forms, and Tipsantonius0990100% (1)

- Guide Book Complete - Version 01 - ReducedDocument40 pagesGuide Book Complete - Version 01 - ReducedHaytham BafoPas encore d'évaluation

- 006 Chris-Haroun-Networking-Book PDFDocument214 pages006 Chris-Haroun-Networking-Book PDFRares Nastai100% (2)