Académique Documents

Professionnel Documents

Culture Documents

Metalshield Clarity MC - 707: Conformances Key Features

Transféré par

Rumman Ul AhsanTitre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Metalshield Clarity MC - 707: Conformances Key Features

Transféré par

Rumman Ul AhsanDroits d'auteur :

Formats disponibles

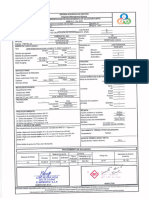

METAL-CORED WIRE

METALSHIELD® CLARITY™ MC®-707

Mild Steel • AWS E70C-6M H4

KEY FEATURES CONFORMANCES

• Over 40% reduction in Manganese Generation Rate AWS A5.18/A5.18M: E70C-6M-H4

when compared to a conventional E70C-6M electrode AWS A5.36/A5.36M: E70T15-M20A4-CS1-H4

• Assists efforts to reduce exposure to Manganese CWB/CSA W48-06: E492C-6M-H4

• H4 diffusible hydrogen levels

TYPICAL APPLICATIONS

• High deposition rates and fast travel speeds

• Robotics/hard automation

• Superior arc wetting and bead appearance

• Structural fabrication

• General fabrication

WELDING POSITIONS

Flat & Horizontal SHIELDING GAS

90% Ar, 10% CO2

Flow rate: 40-60 CFH

DIAMETERS / PACKAGING

Diameter 33 lb (15 kg) 500 lb (227 kg)

in (mm) Fiber Spool Accu-Trak® Drum (20 in dia.)

0.045 (1.1) ED036370 ED036491

0.052 (1.3) ED036371 ED036492

1/16 (1.6) ED036372 ED036493

MECHANICAL PROPERTIES (1) – As Required per AWS A5.18/A5.18M

Charpy V-Notch

Yield Strength(2) Tensile Strength Elongation J (ft•lbf)

MPa (ksi) MPa (ksi) % @ -29°C (-20°F) @ -40°C (-40°F)

Requirements -

400 (58) min 480 (70) min 22 min 27 (20) min -

AWS A5.18: E70C-6M-H4

AWS A5.36: E70T15-M20A4-CS1-H4 400 (58) min 490-660 (70-95) 22 min - 27 (20) min

Typical Results(3)

As-Welded with 75% Ar / 25% CO2(4) 440-480 (64-70) 520-565 (75-82) 24-31 30-74 (22-55) -

As-Welded with 90% Ar / 10% CO2 440-500 (64-72) 525-570 (76-83) 28-32 84-149 (62-110) 39-146 (23-108)

DEPOSIT COMPOSITION(1) – As Required per AWS A5.18/A5.18M

%C %Mn %Si %S %P %Cu

Requirements -

AWS A5.18: E70C-6M-H4 0.03 max 0.03 max

0.12 max 1.75 max 0.90 max 0.50 max

AWS A5.36: E70T15-M20A4-CS1-H4 0.030 max 0.030 max

Typical Results(3)

As-Welded with 75% Ar / 25% CO2 (4) 0.03-0.05 0.60-0.67 0.57-0.65 0.011-0.014 0.005-0.007 0.04-0.05

As-Welded with 90% Ar / 10% CO2 0.04-0.06 0.61-0.70 0.61-0.64 0.011- 0.013 0.005-0.006 0.04-0.06

Diffusible Hydrogen

%Ni %Cr %Mo %V %B

(mL/100g weld deposit)

Requirements -

4.0 max

AWS A5.18: E70C-6M-H4 0.50 max 0.20 max 0.30 max 0.08 max Not Specified

AWS A5.36: E70T15-M20A4-CS1-H4 4 max

Typical Results(3)

As-Welded with 75% Ar / 25% CO2 (4) 0.02-0.03 0.03-0.04 0.02 <0.01 0.002-0.003 1-2

As-Welded with 90% Ar / 10% CO2 0.02 0.03-0.04 0.02 <0.01 0.003 1

Typical all weld metal.

(1)

Measured with 0.2% offset.

(2)

See test results disclaimer

(3)

Required gas mixture 75-80% Argon/Balance CO2 for AWS testing.

(4)

METAL-CORED WIRE

TYPICAL OPERATING PROCEDURES

Approx.

Diameter, Polarity CTWD(5) Wire Feed Speed Voltage(6) Current Melt-Off Rate Deposition Rate Efficiency

Shielding Gas mm (in) m/min (in/min) (volts) (amps) kg/hr (lb/hr) kg/hr (lb/hr) (%)

5.1 (200) 21-23 150 2.3 (5.1) 2.1 (4.7)

6.4 (250) 22-24 175 2.9 (6.4) 2.7 (6.0)

7.6 (300) 22-25 190 3.4 (7.6) 3.3 (7.3)

8.9 (350) 23-26 215 4.0 (8.9) 3.9 (8.5)

10.2 (400) 24-27 235 4.6 (10.2) 4.5 (9.8)

0.045 in (1.1 mm), DC+ 19-25 11.4 (450) 24-28 260 5.2 (11.5) 5.0 (11.1) 94-99

90% Argon / 10% CO2 (3/4-1) 12.7 (500) 24-28 270 5.8 (12.7) 5.6 (12.4)

14.0 (550) 25-28 290 6.4 (14.0) 6.2 (13.6)

15.2 (600) 25-30 300 6.9 (15.3) 6.8 (14.9)

16.5 (650) 26-30 320 7.5 (16.6) 7.3 (16.2)

17.8 (700) 26-31 325 8.1 (17.8) 7.9 (17.5)

5.1 (200) 22-25 200 3.1 (6.8) 2.9 (6.4)

6.4 (250) 22-25 230 3.9 (8.5) 3.7 (8.2)

7.6 (300) 23-26 255 4.6 (10.2) 4.5 (9.9)

0.052 in (1.3 mm), DC+ 19-25 8.9 (350) 24-27 285 5.4 (11.9) 5.3 (11.6)

90% Argon / 10% CO2 (3/4-1) 10.2 (400) 24-28 310 6.2 (13.6) 6.1 (13.4) 94-99

11.4 (450) 25-28 340 6.9 (15.3) 6.8 (15.1)

12.7 (500) 27-29 365 7.7 (17.0) 7.6 (16.8)

14.0 (550) 28-30 390 8.4 (18.6) 18.5 (18.6)

3.8 (150) 22-24 215 3.1 (6.9) 2.9 (6.3)

5.1 (200) 22-25 260 4.2 (9.2) 4.0 (8.7)

1/16 in (1.6 mm), DC+ 25-32 6.4 (250) 23-27 295 5.2 (11.5) 5.0 (11.1)

90% Argon / 10% CO2 (1-1 1/4) 7.6 (300) 24-28 350 6.2 (13.7) 6.1 (13.5) 94-99

8.9 (350) 26-30 375 7.3 (16.0) 7.2 (15.9)

10.2 (400) 26-30 425 8.3 (18.3) 8.3 (18.3)

11.4 (450) 27-31 460 9.3 (20.6) 9.4 (20.7)

Typical all weld metal. (2)Measured with 0.2% offset. (3)See test results disclaimer (4)Required gas mixture 75-80% Argon/Balance CO2 for AWS testing. (5)To estimate ESO, subtract 3/16 in (4.8 mm) from CTWD.

(1)

For greater percentage of CO2 shielding gas, increase voltage by 1-2 volts. NOTE: This product contains micro-alloying elements. Additional information available upon request.

(6)

Material Safety Data Sheets (MSDS) and Certificates of Conformance are available on our website at www.lincolnelectric.com

T E S T RE S U LT S

Test results for mechanical properties, deposit or electrode composition and diffusible hydrogen levels were obtained from a weld produced and tested according to prescribed stan-

dards, and should not be assumed to be the expected results in a particular application or weldment. Actual results will vary depending on many factors, including, but not limited to, weld

procedure, plate chemistry and temperature, weldment design and fabrication methods. Users are cautioned to confirm by qualification testing, or other appropriate means, the suitability of any welding

consumable and procedure before use in the intended application.

CU S TO ME R AS S I S TA N CE P O LI CY

The Lincoln Electric Company is manufacturing and selling high quality welding equipment, consumables, and cutting equipment. Our challenge is to meet the needs of our customers and to exceed their

expectations. On occasion, purchasers may ask Lincoln Electric for information or advice about their use of our products. Our employees respond to inquiries to the best of their ability based on informa-

tion provided to them by the customers and the knowledge they may have concerning the application. Our employees, however, are not in a position to verify the information provided or to evaluate the

engineering requirements for the particular weldment. Accordingly, Lincoln Electric does not warrant or guarantee or assume any liability with respect to such information or advice. Moreover, the provision

of such information or advice does not create, expand, or alter any warranty on our products. Any express or implied warranty that might arise from the information or advice, including any implied warranty

of merchantability or any warranty of fitness for any customers’ particular purpose is specifically disclaimed.

Lincoln Electric is a responsive manufacturer, but the selection and use of specific products sold by Lincoln Electric is solely within the control of, and remains the sole responsibility of the customer. Many

variables beyond the control of Lincoln Electric affect the results obtained in applying these types of fabrication methods and service requirements.

Subject to Change – This information is accurate to the best of our knowledge at the time of printing. Please refer to www.lincolnelectric.com for any updated information.

THE LINCOLN ELECTRIC COMPANY

Publication C3.11.10 | Issue Date 06/16 22801 St. Clair Avenue • Cleveland, OH • 44117-1199 • U.S.A.

© Lincoln Global, Inc. All Rights Reserved. Phone: +1.216.481.8100 • www.lincolnelectric.com

Vous aimerez peut-être aussi

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsD'EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsPas encore d'évaluation

- Metalshield MC - 706: Conformances Key FeaturesDocument3 pagesMetalshield MC - 706: Conformances Key FeaturesGerson HenriquesPas encore d'évaluation

- Metalshield MC-710XL: Conformances Key FeaturesDocument3 pagesMetalshield MC-710XL: Conformances Key FeaturesRumman Ul AhsanPas encore d'évaluation

- Ultracore 360 C71: Conformances Key FeaturesDocument3 pagesUltracore 360 C71: Conformances Key FeaturesYousab CreatorPas encore d'évaluation

- E9018 M Specifications PDFDocument2 pagesE9018 M Specifications PDFMohamed MostafaPas encore d'évaluation

- Superarc L-59: Conformances Key FeaturesDocument2 pagesSuperarc L-59: Conformances Key FeaturesjustinPas encore d'évaluation

- Ultracore 360 M81: Conformances Key FeaturesDocument3 pagesUltracore 360 M81: Conformances Key FeaturesDaniel Lvqve GarciaPas encore d'évaluation

- Pipeliner 7P+: Conformances Key FeaturesDocument2 pagesPipeliner 7P+: Conformances Key FeaturesAnand GPas encore d'évaluation

- Innershield NS-3M: Welding Positions Key FeaturesDocument2 pagesInnershield NS-3M: Welding Positions Key FeaturesGiancarlo BlandinoPas encore d'évaluation

- Pipeliner 70S-G: Conformances Key FeaturesDocument2 pagesPipeliner 70S-G: Conformances Key FeaturesZanuardi YahyaPas encore d'évaluation

- Outershield MC - 409: Conformances Key FeaturesDocument2 pagesOutershield MC - 409: Conformances Key FeaturesNurPurnamaSariPas encore d'évaluation

- Adobe Scan 06 Jun. 2023Document1 pageAdobe Scan 06 Jun. 2023BayardoPas encore d'évaluation

- Superarc LA-75: Conformances Key FeaturesDocument2 pagesSuperarc LA-75: Conformances Key Featuressattar12345Pas encore d'évaluation

- FICHADocument2 pagesFICHAadmisecoinperuPas encore d'évaluation

- Lincoln, TECHALLOY® 606 (c14107)Document2 pagesLincoln, TECHALLOY® 606 (c14107)RodrigoPas encore d'évaluation

- Techalloy 276 ERNiCrMo-4Document2 pagesTechalloy 276 ERNiCrMo-4wiPas encore d'évaluation

- Atom Arc 8018Document2 pagesAtom Arc 8018Jagan TnPas encore d'évaluation

- 320LR StainlessSteel 73Document1 page320LR StainlessSteel 73Cristóbal cardenasPas encore d'évaluation

- Pamphlet MG-51T PDFDocument2 pagesPamphlet MG-51T PDFImmalatulhusnaPas encore d'évaluation

- 11018M Low Hydrogen RodsDocument1 page11018M Low Hydrogen Rodsjhax90Pas encore d'évaluation

- Dual Shield 710X: Gas-Shielded Flux-Cored Wires (Fcaw) Mild Steel WiresDocument3 pagesDual Shield 710X: Gas-Shielded Flux-Cored Wires (Fcaw) Mild Steel WiresPhilippe TrudelPas encore d'évaluation

- UltracoreDocument3 pagesUltracorerpcampbellPas encore d'évaluation

- Techalloy 625: Conformances Key FeaturesDocument2 pagesTechalloy 625: Conformances Key FeaturesJulian AdaraquePas encore d'évaluation

- Coreweld 70: Metal-Cored Wires (Mcaw) Mild Steel WiresDocument2 pagesCoreweld 70: Metal-Cored Wires (Mcaw) Mild Steel WiresJerald GuevarraPas encore d'évaluation

- Dual Shield T-115: Gas-Shielded Flux-Cored Wires (Fcaw) Low Alloy WiresDocument2 pagesDual Shield T-115: Gas-Shielded Flux-Cored Wires (Fcaw) Low Alloy WiresPEPITO GRILLO2Pas encore d'évaluation

- Magmotor S23 FeaturesDocument2 pagesMagmotor S23 FeaturesKevin Peña RománPas encore d'évaluation

- 01f Hyundai Supercored 71H Data Sheet 2022Document2 pages01f Hyundai Supercored 71H Data Sheet 2022DHANEESH VELLILAPULLIPas encore d'évaluation

- Data - Sheet 2H Grade 50Document3 pagesData - Sheet 2H Grade 50sagitrosePas encore d'évaluation

- Lincoln6011 AS ES-MX PDFDocument2 pagesLincoln6011 AS ES-MX PDFJuan Novillo RamosPas encore d'évaluation

- Techalloy 718: Conformances Key FeaturesDocument2 pagesTechalloy 718: Conformances Key FeaturesvishuPas encore d'évaluation

- ESB 321M116700 SpecSheetDocument2 pagesESB 321M116700 SpecSheetCitra Adelina SitorusPas encore d'évaluation

- SF-71 en EngDocument2 pagesSF-71 en EngbvbarcPas encore d'évaluation

- ESB 321M116700 SpecSheetDocument2 pagesESB 321M116700 SpecSheetArthanari VaidyanathanPas encore d'évaluation

- Product Specifications: Specifications For Continuous Cast ProductsDocument4 pagesProduct Specifications: Specifications For Continuous Cast ProductsvejanidbPas encore d'évaluation

- Key Features Conformances: Low Alloy Steel - AWS E9018-D1Document2 pagesKey Features Conformances: Low Alloy Steel - AWS E9018-D1Aliakbar GhaderiPas encore d'évaluation

- CSF-71T Technical Report EN - V2Document7 pagesCSF-71T Technical Report EN - V2Miroslav ThôngPas encore d'évaluation

- Lincolnweld LA-93, AWS EB3RDocument2 pagesLincolnweld LA-93, AWS EB3Rpratik charkhawalaPas encore d'évaluation

- Q1 DisplayDocument1 pageQ1 DisplayOscar BasantesPas encore d'évaluation

- Covered (Stick) Electrodes (Smaw) Mild Steel Electrodes: Typical Tensile PropertiesDocument1 pageCovered (Stick) Electrodes (Smaw) Mild Steel Electrodes: Typical Tensile PropertiesKannan MurugesanPas encore d'évaluation

- Midalloy ER80S B6 EB6Document1 pageMidalloy ER80S B6 EB6joel cisnerosPas encore d'évaluation

- Dual Shield 7100 Ultra: Gas-Shielded Flux-Cored Wires (Fcaw) Mild Steel WiresDocument3 pagesDual Shield 7100 Ultra: Gas-Shielded Flux-Cored Wires (Fcaw) Mild Steel Wiresadanmeneses1Pas encore d'évaluation

- Shield Bright 309L-1Document1 pageShield Bright 309L-1adanmeneses1Pas encore d'évaluation

- Coremax 71Document2 pagesCoremax 71Branko FerenčakPas encore d'évaluation

- Outershield 71M: Conformances Key FeaturesDocument3 pagesOutershield 71M: Conformances Key FeatureswilmercristianPas encore d'évaluation

- KV 2Document3 pagesKV 2Branko FerenčakPas encore d'évaluation

- Covered (Stick) Electrodes (Smaw) Low Hydrogen ElectrodesDocument2 pagesCovered (Stick) Electrodes (Smaw) Low Hydrogen Electrodesdarmawan listyonoPas encore d'évaluation

- Dual Shield II 70T-12H4: Gas-Shielded Flux-Cored Wires (Fcaw) Mild Steel WiresDocument2 pagesDual Shield II 70T-12H4: Gas-Shielded Flux-Cored Wires (Fcaw) Mild Steel WiresPhilippe TrudelPas encore d'évaluation

- Blue Max Mig 309L N: Key Features Typical ApplicationsDocument2 pagesBlue Max Mig 309L N: Key Features Typical ApplicationsJhonatan SantosPas encore d'évaluation

- ESAB Filler Metal GuideDocument1 pageESAB Filler Metal GuidekapsarcPas encore d'évaluation

- SC-71MSR: Hyundai Welding Co., LTDDocument7 pagesSC-71MSR: Hyundai Welding Co., LTDRaviTeja BhamidiPas encore d'évaluation

- Merit RM-56: Lincoln Electric China Gmaw Solid WireDocument2 pagesMerit RM-56: Lincoln Electric China Gmaw Solid WirejuanchepeinPas encore d'évaluation

- Chromet 92: Mma All-Positional Electrode For Joining P92 Creep Resisting SteelDocument2 pagesChromet 92: Mma All-Positional Electrode For Joining P92 Creep Resisting SteelVVan TanPas encore d'évaluation

- Pinnacle Alloys E7018 E7018 1Document2 pagesPinnacle Alloys E7018 E7018 1BerniIrlePas encore d'évaluation

- F-Cem-021 - Cptch-012-19a-Fcaw - Aws D1.1 - Plana-HorizontalDocument7 pagesF-Cem-021 - Cptch-012-19a-Fcaw - Aws D1.1 - Plana-Horizontalenrique.chavezPas encore d'évaluation

- Esab, Ok 309L (29.12.16)Document1 pageEsab, Ok 309L (29.12.16)RodrigoPas encore d'évaluation

- FabCO 811N1Document2 pagesFabCO 811N1Sleyda MunozPas encore d'évaluation

- Data Sheet API 2W Grade 50Document3 pagesData Sheet API 2W Grade 50sagitrosePas encore d'évaluation

- Ficha Tecnica Esab Electrodos EspecialesDocument1 pageFicha Tecnica Esab Electrodos EspecialesStanley RamirezPas encore d'évaluation

- 42crmo6 : Steel GradeDocument2 pages42crmo6 : Steel GradeYonas Dwiananta YuwonoPas encore d'évaluation

- Computational Materials ScienceDocument94 pagesComputational Materials ScienceRumman Ul AhsanPas encore d'évaluation

- Introduction To GMAWDocument63 pagesIntroduction To GMAWRumman Ul AhsanPas encore d'évaluation

- 8 Metrology of Screw ThreadDocument24 pages8 Metrology of Screw ThreadRumman Ul AhsanPas encore d'évaluation

- Gear Drawing TutorialDocument16 pagesGear Drawing TutorialRumman Ul AhsanPas encore d'évaluation

- 1.introduction To SMAWDocument74 pages1.introduction To SMAWRumman Ul AhsanPas encore d'évaluation

- 1 Introduction To MetrologyDocument9 pages1 Introduction To MetrologyRumman Ul AhsanPas encore d'évaluation

- Teach Yourself KoreanDocument139 pagesTeach Yourself KoreanJay Mar Isorena100% (18)

- Objective: MD Rumman Ul AhsanDocument1 pageObjective: MD Rumman Ul AhsanRumman Ul AhsanPas encore d'évaluation

- Resume MD Imrul Reza Shishir RummanDocument2 pagesResume MD Imrul Reza Shishir RummanRumman Ul AhsanPas encore d'évaluation

- Arc Length and Dynamic Correction in CMTDocument4 pagesArc Length and Dynamic Correction in CMTRumman Ul AhsanPas encore d'évaluation

- Korean Word List-ToPIKDocument23 pagesKorean Word List-ToPIKRumman Ul AhsanPas encore d'évaluation

- KorDocument262 pagesKorZizou ZeinoubaPas encore d'évaluation

- Dunia Kapano 10 DinDocument476 pagesDunia Kapano 10 DinRumman Ul AhsanPas encore d'évaluation

- Improve GMAW and GTAW With Alternating Shield GasesDocument3 pagesImprove GMAW and GTAW With Alternating Shield GasesRumman Ul AhsanPas encore d'évaluation

- Inspection ReportDocument4 pagesInspection ReportgeorgiadisgPas encore d'évaluation

- Green House Gas Emission - Reporting StandardsDocument3 pagesGreen House Gas Emission - Reporting StandardsBeroe Inc.Pas encore d'évaluation

- GEASDocument11 pagesGEASRobert E XanaduPas encore d'évaluation

- Shiploader Pilbara EngDocument2 pagesShiploader Pilbara EngMohamed ElfawalPas encore d'évaluation

- MZ 2019Document315 pagesMZ 2019muskan singlaPas encore d'évaluation

- BRIDGE TO INDIA India RE Map 1 PDFDocument2 pagesBRIDGE TO INDIA India RE Map 1 PDFAkash JanaPas encore d'évaluation

- Amitchaudhary (7,8) UnavailableDocument7 pagesAmitchaudhary (7,8) UnavailableTapaswi ChandraPas encore d'évaluation

- TCLT100. Series: Vishay SemiconductorsDocument6 pagesTCLT100. Series: Vishay Semiconductorsmarcos aragaoPas encore d'évaluation

- Plant Performance Assessment QuestionnaireDocument27 pagesPlant Performance Assessment QuestionnairesoumitrabanPas encore d'évaluation

- 0001Document9 pages0001Mohamed AdelPas encore d'évaluation

- R V Vessel Jacket TypesDocument2 pagesR V Vessel Jacket TypesJohan ConradiePas encore d'évaluation

- Investment Fiscal IncentivesDocument28 pagesInvestment Fiscal Incentivesjeanvaljean999Pas encore d'évaluation

- Intro To MaintenanceDocument31 pagesIntro To Maintenancesharif339Pas encore d'évaluation

- Ahu 01 (STD)Document5 pagesAhu 01 (STD)onspsnonsPas encore d'évaluation

- Hrsi Manual C Part 1 GB FRDocument2 pagesHrsi Manual C Part 1 GB FRtapas naoPas encore d'évaluation

- Circulating Current Relay Cag14&34Document6 pagesCirculating Current Relay Cag14&34sivaguruk2Pas encore d'évaluation

- Carrier chiller-30XADocument12 pagesCarrier chiller-30XAamitbslpawar100% (1)

- 05 Lwali LukuluDocument1 page05 Lwali LukuluNatasha Wyne100% (1)

- Training Report 2Document33 pagesTraining Report 2Nishant BahugunaPas encore d'évaluation

- Bombas de Doble Diafragma (00000002)Document99 pagesBombas de Doble Diafragma (00000002)gonzalotecsupplantaPas encore d'évaluation

- Strategic Marketing Plan For Philips HueDocument50 pagesStrategic Marketing Plan For Philips HueAminPas encore d'évaluation

- Delta Opti Instruction K 636Document4 pagesDelta Opti Instruction K 636Maikl HimkPas encore d'évaluation

- Bill Sample OHDocument1 pageBill Sample OHJOANNEPas encore d'évaluation

- Manual de Calibracion FLUKE 1555Document32 pagesManual de Calibracion FLUKE 1555Mario CanazaPas encore d'évaluation

- Cs-00171 Precision Cooling Preventive Maintenance Data SheetDocument2 pagesCs-00171 Precision Cooling Preventive Maintenance Data SheetMarco MenaPas encore d'évaluation

- AN Overview of The Petroleum Industry Reforms: Dr. Adeoye AdefuluDocument27 pagesAN Overview of The Petroleum Industry Reforms: Dr. Adeoye AdefuluAdeoye AdefuluPas encore d'évaluation

- Raychem TerminalesDocument26 pagesRaychem TerminalesAcuario Chable Gomez100% (1)

- LaminateDocument68 pagesLaminatedesignPas encore d'évaluation

- 2018 EE6285 PPT Lecture1 20180109 v02Document61 pages2018 EE6285 PPT Lecture1 20180109 v02Ratik MittalPas encore d'évaluation

- E-Maintenance: Trends, Challenges and Opportunities For Modern IndustryDocument6 pagesE-Maintenance: Trends, Challenges and Opportunities For Modern IndustryJai PandeyPas encore d'évaluation