Académique Documents

Professionnel Documents

Culture Documents

Design & Development of Parkinson Gear Tester For Spur Gear To Check The Flank Surface

Transféré par

Maharajan McsTitre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Design & Development of Parkinson Gear Tester For Spur Gear To Check The Flank Surface

Transféré par

Maharajan McsDroits d'auteur :

Formats disponibles

International Journal of Advanced Research in ISSN : 2454-4736 (Online)

Mechanical Engineering & Technology (IJARMET) Vol. 1, Issue 1 (Apr. - Jun. 2015) ISSN : 2454-8723 (Print)

Design & Development of Parkinson Gear Tester for

Spur Gear to Check the Flank Surface

I

ShindeTushar B., IIShitalD.Tarawade, IIIMayuri G. Kurhe, IVVinod D Shinde, VReshma V. kurkute

I

S.V.C.E.T.RAJURI, Pune, India

II,III,IV,V

G.P.Awasarkd

Abstract

In order to check the combined tooth error different types of gear testing machines are used. Various machines have its ability to

check specified parameters only. Highly precise machine required special installation and space. For the purpose of checking gear

in machine shop while performing machine required such an arrangement which is robust and quick one. This purpose can be solved

using gear test rig. This type of gear test rig can be used for mass production of gears of a particular gear box.

Gear test rig is such arrangement which simplifies the measurement and saves the labourtime and labour cost with greater accuracy.

In gear test rig all the gears will be mounted on a plate which may be fixed or stationary as per the requirement of the measurement.

While measuring the one gear remaining will act as a master gear. This will help in finding the composite error. This test rig can

be used in shop floor as it requires less space and operator can use it as per need without wasting much time. The test rig can be

developed for different parameter as per measurement requirement. There are various test rigs which can be used for that particular

designed condition.

Keywords

Gear,flank surface.

Introduction space and operatorcan use it as per need without wasting much

Today world requires speed on each and every field. Hence time. The test rig can be developed for different parameter as per

rapidness and quick working is the most important. Now a day measurement requirement. There are various test rigs which can

for achieving rapidness, man manufactures various machines be used for that particular designed condition.

and equipments. The engineer being constantly conformed to From the above study it can be concluded that there are various

the challenges of bringing ideas and new design in to reality. New test rig which are used formeasurement of particular parameters.

machines, equipments and the techniques are being developed Design of test rig differs as per the requirement of application and

continuously to manufacture various products at cheaper rates as per requirement of parameter to be tested.

and high quality.

This paper“Design & Development of Parkinson gear tester for Development of testrig

spur gear to Check the Flank Surface” being compact and Portable To operate the testing machine, electric motor (prime mover),

equipment, which is skillful and is having some thing precise which is torque motor having 20 N-m torque capacity, is used to

in testing the gears being manufactured. Most of the material rotate the master gear against the gear to be tested. Also an another

is made available by our college. The parts can be easily made motor of the same capacity is used to rotate the paper rolling drum

in our college work-shop. It’s price is also considerable. This to pass the recording paper against the vibrating pen and stylus

project gives us knowledge, experience , skill and new ideas of due to the improper tooth geometry provided.

manufacturing. It is a working project and having guarantee of The gear to be tested is installed on the trolley gear shaft using the

success. This project is the equipment useful to improve the quality fasteners as the nut and bolts. The trolley being spring loaded is

of the gear being manufactured and can be made in less time, in continuous close contact with the master gear. The master gear

hence we have selected this paper. shaft is extended and is coupled with the driving torque motor

using a coupling.

History When the pair of master gear and the gear to be tested is rotating

Gears have been in use for hundreds of years and it will be continue and if there is any mis-run of the gear to be tested then the stylus

for few more years.Sometime these gears are manufactured in mass and pen arrangement will deflect and the appropriate amount of

production like manufacturing the gears of a specific machine’s variation in the graph which is recorded on the moving paper is

gear box. Gear performance depends on various parameters such being recorded. Thus the operation of gear testing machine is

as material, design, manufacturing, operation and environment. done.

Manufacturing of the gear is avery important step which decides

the accuracy of the gear. This requires the inspection at various Principle

steps. Also this inspection should not consume too much money It works on the principle of measurement of the mis-run of the

in terms of labourand time. That’s why it should be easy to inspect smooth running of the precisely meshing gears (when rotated

and operate. Gear test rig is such arrangement which simplifies with respect to each other) with any variation in the geometry of

the measurement and saves the labourtime and labour cost with the gear tooth profile due to the wear and tear by the periodic use

greater accuracy. In gear test rig all the gears will be mounted on or the faulty manufacturing.

a plate which may be fixed or stationary as per the requirement

of the measurement. While measuring the one gear remaining Special Features

will act as a master gear. This will help in finding the composite It is having the precisely measuring capacity and the reproducibility

error. This test rig can be used in shop floor as it requires less of Parkinson gear testing machine due to stylus and pen and spring

© 2015, IJARMET All Rights Reserved 30 www.ijarmet.com

International Journal of Advanced Research in

ISSN : 2454-4736 (Online)

Mechanical Engineering & Technology (IJARMET)

ISSN : 2454-8723 (Print) Vol. 1, Issue 1 (Apr. - Jun. 2015)

arrangement is high. So however, a small variation in the flank of

the gear tooth will deflect the stylus along with the pen. We get

the consistent force on job. Previously the operations, which this

machine does, were done individually in different comparing-

machines such as optical profile protector or by testing manually,

using gear tooth varniercalliper.

Its special features are:

• It applies the accuracy up to 1 micron.

• It is light in weight and hence it is portable.

• Weight of machine is 30 kg.(approx.)

• It requires very low maintenance.

• Its setting time is less.

• It requires very low floor space area.

• Its manufacturing cost is also very low.

• No separate arrangement of drawing sketch is required.

• It requires low power for its operations hence it can be excited

using d.c.

• Power and d.c. motor (also to be used in remote areas

also).

• It is compact. Total length of machine is 1200 mm.

Fig. 1 : Testrig of parkinson Gear tester

Design Parameters &Dimentions

Design of Shaft :

The shaft may be designed on the basis of :

1) Strength 2) Rigidity

The following cases may be considered when shaft designing is

on the strength basis:-

a.

Shaft subjected

to twisting movement

or torque only.

b.

Shaft subjected to bending moment only.

c. to

Shaft subjected combined

twisting

& bending

moment.

d.

Shaft subjected to axial loading in addition to combined

torsional & bending load.

Shaft

Subjected To Twisting

Combined

Moment

&Bending

Moment

When

the shaft is subjected to combined twisting and bending

moment then

the shaft must be

designed

on the

basis of the two

moments.

The following two theories are important from design point of

view

: 1) Max.Shear

stress theory. It is

used for

ductile

material

such

as M.S.

2)

Max. Normal stress theory or Rankine’s theory, it is used

for brittle material such as C.I.

A. Twisting moment (T) may obtained by using the following

relation.

www.ijarmet.com

© All Rights Reserved, IJARMET 2015

31

International Journal of Advanced Research in

ISSN : 2454-4736 (Online)

Vol. 1, Issue 1 (Apr. - Jun. 2015)

Mechanical Engineering & Technology (IJARMET) ISSN : 2454-8723 (Print)

© 2015, IJARMET All Rights Reserved 32 www.ijarmet.com

of Advanced Research in

ISSN : 2454-4736 (Online) International

Journal

ISSN : 2454-8723 (Print) Vol. 1, Issue 1 (Apr. - Jun. 2015) Mechanical Engineering & Technology (IJARMET)

Result Analysis

Fig. 2

: Variation In Flank Surface For Model 1

www.ijarmet.com

© All Rights Reserved, IJARMET 2015

33

International Journal of Advanced Research in ISSN : 2454-4736 (Online)

Mechanical Engineering & Technology (IJARMET) Vol. 1, Issue 1 (Apr. - Jun. 2015) ISSN : 2454-8723 (Print)

of our batch colleague in bringing out a resourceful fulfillment of

our assignment described by the university.

The design criterion imposed challenging problems which however

were welcome by us due to availability of good reference books.

The selection of choice of raw materials helped us in machining

of the various components to very close tolerances and thereby

minimizing the level of wear and tear.

In this paper, we developed a branch and bound approach which is

coupled with quick, gear testing in mass production requirement

within a manufacturing cell.

The design of control architecture was an important aspect of

study because a strong interaction between the many different

parts was needed. We are testing gear with low running cost.. So

Fig. 3 : Variation In Flank Surface For Model 2 we are satisfied with our project.

References

[1]. R. K. JAIN, “Engineering Metrology” KhannaPublishers,

twentieth edition , 2007.

[2]. V. Manoj , “ Development of A Power Re-circulating Gear

Test Rig” M. Tech Thesis, IIT Madras,1999.

[3]. N.A.Wright,S.N. Kukureka, “Wear testing and measurement

techniques for polymer composite gears” Wear

251(2001)1567-1578.

[4]. Mats Akerblom, “gear test rig for noise and vibration Testing

of cylinder gears” Volvo Construction Equipment Component

AB SE-631 85 Eskilstuna, Sweden.

a) [5]. Shuting Li, “Experimental investigation and FEM analysis

of resonance frequency behavior of three-dimentional,

thin walled spur gears with a power circulating test rig”

Mechanism and Machine Theory 43 (2008) 934-963

Author Profiles

Mr.ShindeTushar B., S.V.C.E.T.RAJURI,

PUNE, tusharshinde33@gmail.com

b)

Ms.ShitalD.Tarawade, G.P.Awasarkd

shitaltarawade96@gmail.com

c)

Fig. 4 : Variation In flank Surface for different models

Conclusion

While concluding this part, we fill quite contended in having

completed the project assignment well on time. We had enormous

practical experience on the manufacturing schedules of the

working project model. We are therefore, happy to state that the

inculcation of mechanical aptitude proved to be a very useful

purpose. We are as such overwhelmingly elated in the arriving at

the targeted mission.

Undoubtedly the joint venture has had all the merits of interest and

zeal shown by all of us the credit goes to the healthy co-ordination

© 2015, IJARMET All Rights Reserved 34 www.ijarmet.com

ISSN : 2454-4736 (Online) International Journal of Advanced Research in

ISSN : 2454-8723 (Print) Vol. 1, Issue 1 (Apr. - Jun. 2015) Mechanical Engineering & Technology (IJARMET)

Ms.Mayuri G. Kurhe, G.P.Awasarkd,

mayurikurhe@gmail.com

Vinod D Shinde, G.P. Awsarikdvinodshinde.90@gmail.com

Reshma V. kurkute, G.P.Awsari Kd,

reshmakurkute94@gmail.com

www.ijarmet.com 35 © All Rights Reserved, IJARMET 2015

Vous aimerez peut-être aussi

- Advanced Gear Manufacturing and Finishing: Classical and Modern ProcessesD'EverandAdvanced Gear Manufacturing and Finishing: Classical and Modern ProcessesÉvaluation : 3.5 sur 5 étoiles3.5/5 (2)

- Vibration Basics and Machine Reliability Simplified : A Practical Guide to Vibration AnalysisD'EverandVibration Basics and Machine Reliability Simplified : A Practical Guide to Vibration AnalysisÉvaluation : 4 sur 5 étoiles4/5 (2)

- Design, Fabrication and Analysis of Fault Diagnosis in Spur GearDocument4 pagesDesign, Fabrication and Analysis of Fault Diagnosis in Spur GearIJRASETPublicationsPas encore d'évaluation

- Modified Parkinson's Gear Tester: Prof. Dattatraya K. NannawareDocument6 pagesModified Parkinson's Gear Tester: Prof. Dattatraya K. NannawareNaveen PrabhuPas encore d'évaluation

- Test Rig On Parkinson Gear Tester: ISSN: 2454-132X Impact Factor: 4.295Document6 pagesTest Rig On Parkinson Gear Tester: ISSN: 2454-132X Impact Factor: 4.295Gabriel SoaresPas encore d'évaluation

- Parkison Gear TesterDocument4 pagesParkison Gear TesterManoj SinghPas encore d'évaluation

- PD ReportDocument6 pagesPD Reportbitish commectPas encore d'évaluation

- Semi Automatic Ceramic Sleeve Surface Finishing MachineDocument2 pagesSemi Automatic Ceramic Sleeve Surface Finishing MachineInternational Journal of Innovative Science and Research TechnologyPas encore d'évaluation

- Optimization of Cutting Parameters in Hard Turning of AISI 4340 SteelDocument6 pagesOptimization of Cutting Parameters in Hard Turning of AISI 4340 SteelIJIRAE- International Journal of Innovative Research in Advanced EngineeringPas encore d'évaluation

- Fabrication of Dual Side Shaper Machine Using Scotch Yoke Mechanism IJERTV8IS070088Document4 pagesFabrication of Dual Side Shaper Machine Using Scotch Yoke Mechanism IJERTV8IS070088Mikyas BelayPas encore d'évaluation

- +merge RemainingDocument17 pages+merge RemainingVISHALPas encore d'évaluation

- Fabrication of Portable Hammer Using Crank and Lever MechanismDocument14 pagesFabrication of Portable Hammer Using Crank and Lever MechanismMassive Minds100% (1)

- Optimization and Development of Pulverization MachineDocument7 pagesOptimization and Development of Pulverization MachineIJRASETPublicationsPas encore d'évaluation

- Minor Final - PPTDocument20 pagesMinor Final - PPTHRISHABH CHOPRAPas encore d'évaluation

- CAD Modelling of Automated Spring Load Testing MachineDocument6 pagesCAD Modelling of Automated Spring Load Testing MachineIJRASETPublicationsPas encore d'évaluation

- Jyme10088 (25) 12Document5 pagesJyme10088 (25) 12IJIRAE- International Journal of Innovative Research in Advanced EngineeringPas encore d'évaluation

- 10 1 1 1071 7012 PDFDocument7 pages10 1 1 1071 7012 PDFKombet 69Pas encore d'évaluation

- Design and Manufacturing of Special Purpose Machine For DrillingDocument4 pagesDesign and Manufacturing of Special Purpose Machine For DrillingInternational Journal of Innovative Science and Research Technology100% (1)

- Methodology of Special Purpose Spot Facing MachineDocument5 pagesMethodology of Special Purpose Spot Facing MachineInternational Journal of computational Engineering research (IJCER)Pas encore d'évaluation

- A Review Paper On Vibration Monitoring of Lathe Ijariie12185Document5 pagesA Review Paper On Vibration Monitoring of Lathe Ijariie12185ASHWIN JAWAHARPas encore d'évaluation

- IJIRAE:: A Study of Design Framework For Squareness Inspection FixtureDocument6 pagesIJIRAE:: A Study of Design Framework For Squareness Inspection FixtureIJIRAE- International Journal of Innovative Research in Advanced EngineeringPas encore d'évaluation

- Sciencedirect: Design & Development of Special Automobile Interior Testing MachineDocument9 pagesSciencedirect: Design & Development of Special Automobile Interior Testing MachineMuthu KumarPas encore d'évaluation

- Sub 1Document6 pagesSub 1Aye Chan AungPas encore d'évaluation

- IJREAMV04I1147055Document6 pagesIJREAMV04I1147055Dhruv SutharPas encore d'évaluation

- Term Work Machine GuardingDocument41 pagesTerm Work Machine GuardingSonika SinghPas encore d'évaluation

- Blade ArrangmentsDocument6 pagesBlade ArrangmentsRavi MirzaPas encore d'évaluation

- Irjet V5i4209 PDFDocument6 pagesIrjet V5i4209 PDFSinghs vip addaPas encore d'évaluation

- Re Munde Pagal Ne Sarey Research PaperDocument4 pagesRe Munde Pagal Ne Sarey Research PaperArman AhmedPas encore d'évaluation

- Content: SKF Spindle Assessment Quick Start User GuideDocument10 pagesContent: SKF Spindle Assessment Quick Start User GuideJom BonhayagPas encore d'évaluation

- 2019getting in SyncDocument2 pages2019getting in SyncAnonymous kHYFVEOPas encore d'évaluation

- ReportDocument8 pagesReportPejuangHatiPas encore d'évaluation

- Designing and Development of A Dynamic Vibration BDocument22 pagesDesigning and Development of A Dynamic Vibration Bmagiva873Pas encore d'évaluation

- Design and Analysis of Drill Jig For Head and Cover Part of The Actuator IJERTV3IS080184 PDFDocument9 pagesDesign and Analysis of Drill Jig For Head and Cover Part of The Actuator IJERTV3IS080184 PDFamolPas encore d'évaluation

- Design and Fabrication of Pneumatic Bar Bending MachineDocument4 pagesDesign and Fabrication of Pneumatic Bar Bending MachineAnonymous kw8Yrp0R5rPas encore d'évaluation

- Torque Testing Machine OMDocument18 pagesTorque Testing Machine OMChristopher VergaraPas encore d'évaluation

- Intern ProjectDocument23 pagesIntern ProjectNahom NahomPas encore d'évaluation

- Designing and Development of A Dynamic Vibration B PDFDocument22 pagesDesigning and Development of A Dynamic Vibration B PDFvalericaPas encore d'évaluation

- Analytical Gear Inspection - The Shape of Things To ComeDocument4 pagesAnalytical Gear Inspection - The Shape of Things To ComesurawutwijarnPas encore d'évaluation

- Design and Fabrication of Multi Operational Material Removal MachineDocument3 pagesDesign and Fabrication of Multi Operational Material Removal MachineDHAMOTHARAKUMARPas encore d'évaluation

- Modelling and Analysis of CNC Milling Machine Bed With UHM CFRP Composite MaterialDocument11 pagesModelling and Analysis of CNC Milling Machine Bed With UHM CFRP Composite MaterialIJRASETPublicationsPas encore d'évaluation

- ProjectDocument15 pagesProjectpravdivPas encore d'évaluation

- Application of Taguchi Method For Optimizing Turning Process by The Effects of Machining ParametersDocument12 pagesApplication of Taguchi Method For Optimizing Turning Process by The Effects of Machining ParameterscevherimPas encore d'évaluation

- Study & Analysis of Multi-Function Drill PressDocument2 pagesStudy & Analysis of Multi-Function Drill PressDhruvPas encore d'évaluation

- Modelling and Analysis of Drilling Jig For MountinDocument5 pagesModelling and Analysis of Drilling Jig For MountinHarsha MetiPas encore d'évaluation

- Research Paper On Milling MachineDocument6 pagesResearch Paper On Milling Machineafnhemzabfueaa100% (1)

- IJCRT2306900Document7 pagesIJCRT2306900Shanu KumarPas encore d'évaluation

- Productivity Improvement of Gear Hobbing Process by Analysing Process Parameters IJERTCONV5IS02008Document4 pagesProductivity Improvement of Gear Hobbing Process by Analysing Process Parameters IJERTCONV5IS02008Dhruv SutharPas encore d'évaluation

- 360 Degree Flexible Drilling Machine ReportDocument26 pages360 Degree Flexible Drilling Machine ReportSapna KumariPas encore d'évaluation

- A Review Paper On Design, Optimization and Testing of Special Purpose Worm and Worm Wheel Gearbox For Butterfly Valve OperationDocument3 pagesA Review Paper On Design, Optimization and Testing of Special Purpose Worm and Worm Wheel Gearbox For Butterfly Valve Operationess_mnsPas encore d'évaluation

- A Project Progress Report On " ".: Design and Development of Multi-Tasking Cutting MachineDocument13 pagesA Project Progress Report On " ".: Design and Development of Multi-Tasking Cutting Machineprabhat kumarPas encore d'évaluation

- A Project Progress Report On " ".: Design and Development of Multi-Tasking Cutting MachineDocument13 pagesA Project Progress Report On " ".: Design and Development of Multi-Tasking Cutting Machineprabhat kumarPas encore d'évaluation

- Ijetae 0415 85Document4 pagesIjetae 0415 85ifyPas encore d'évaluation

- Design of Gears For Drilling MachineDocument10 pagesDesign of Gears For Drilling MachineRohan Julian FrancisPas encore d'évaluation

- Gear Error Final 2024Document47 pagesGear Error Final 2024ronybhau2050Pas encore d'évaluation

- DesignofAutomatedOutriggersforSelf PropelledHydraulicScissorLift ACaseStudyAtAirIndia PDFDocument5 pagesDesignofAutomatedOutriggersforSelf PropelledHydraulicScissorLift ACaseStudyAtAirIndia PDFmohamed mostafaPas encore d'évaluation

- Rubber Hardness: Gibitre Developments and Technical Market TendenciesDocument35 pagesRubber Hardness: Gibitre Developments and Technical Market TendenciesErisell CastilloPas encore d'évaluation

- Design and Manufacturing of Lathe Tool Post Grinding AttachmentDocument3 pagesDesign and Manufacturing of Lathe Tool Post Grinding AttachmentAnonymous kw8Yrp0R5rPas encore d'évaluation

- 1023 GearsolutionsDocument76 pages1023 GearsolutionsPepe CruzPas encore d'évaluation

- Super Finishing of Gear Tooth Profile Using Profile GrindingDocument8 pagesSuper Finishing of Gear Tooth Profile Using Profile GrindingTJPRC PublicationsPas encore d'évaluation

- Design and Fabrication of Automatic Multidimensional Spring Rolling MachineDocument4 pagesDesign and Fabrication of Automatic Multidimensional Spring Rolling MachineNandha KumarPas encore d'évaluation

- Notification NLC India Limited Graduate Executive Trainee Advt No PDFDocument5 pagesNotification NLC India Limited Graduate Executive Trainee Advt No PDFsrinivas reddyPas encore d'évaluation

- Renacon Brochure 1 PDFDocument9 pagesRenacon Brochure 1 PDFMaharajan McsPas encore d'évaluation

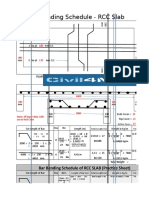

- Bar Bending Schedule RCC SlabDocument6 pagesBar Bending Schedule RCC SlabAnupam SahuPas encore d'évaluation

- NotificationDocument14 pagesNotificationRoever Director officePas encore d'évaluation

- Drawing1 Layout1Document1 pageDrawing1 Layout1Maharajan McsPas encore d'évaluation

- FHJFDocument5 pagesFHJFMaharajan McsPas encore d'évaluation

- India Situation Report 8 PDFDocument6 pagesIndia Situation Report 8 PDFOm paraka kumar KumarPas encore d'évaluation

- 3238-Article Text-5879-1-10-20180104Document140 pages3238-Article Text-5879-1-10-20180104Maharajan McsPas encore d'évaluation

- Irjet V4i6628 PDFDocument14 pagesIrjet V4i6628 PDFBMSF khaliqePas encore d'évaluation

- Steel Framed Multi Storey Residential Building Analysis and DesignDocument2 pagesSteel Framed Multi Storey Residential Building Analysis and DesignMaharajan McsPas encore d'évaluation

- Price List of Textbooks For Standards 1st To 12thDocument5 pagesPrice List of Textbooks For Standards 1st To 12thaishuPas encore d'évaluation

- Suresh Academy Police One Liner 1 PDFDocument80 pagesSuresh Academy Police One Liner 1 PDFtamilan tech 007 - தமிழன் டெக் 007Pas encore d'évaluation

- House Construction Cost CalculatorDocument2 pagesHouse Construction Cost CalculatorklevinPas encore d'évaluation

- TNPSCDocument54 pagesTNPSCLogesh KumarPas encore d'évaluation

- MT1 PDFDocument4 pagesMT1 PDFMaharajan McsPas encore d'évaluation

- Residential Building With EtabsDocument27 pagesResidential Building With EtabsMaharajan McsPas encore d'évaluation

- General Input:-: Moment & Shear Strength Design of Rectangular RC According ACI318M-08Document14 pagesGeneral Input:-: Moment & Shear Strength Design of Rectangular RC According ACI318M-08Maharajan McsPas encore d'évaluation

- Cost EstimateDocument27 pagesCost EstimateRRCDC JEEFRY100% (1)

- Irjet V4i6628Document25 pagesIrjet V4i6628Maharajan McsPas encore d'évaluation

- Slab Design Cantilever One Way Two Way ContinuousDocument11 pagesSlab Design Cantilever One Way Two Way ContinuousMaharajan McsPas encore d'évaluation

- Department of Civil EngineeringDocument4 pagesDepartment of Civil EngineeringMaharajan McsPas encore d'évaluation

- Slab Design by ShubhamBabarDocument7 pagesSlab Design by ShubhamBabarMaharajan McsPas encore d'évaluation

- Load CalculationDocument3 pagesLoad CalculationMaharajan McsPas encore d'évaluation

- Load Calculation From Slab To Beam: M by KN/M KN/M KN/M KN/M KN/M KN/MDocument3 pagesLoad Calculation From Slab To Beam: M by KN/M KN/M KN/M KN/M KN/M KN/MMaharajan McsPas encore d'évaluation

- PSN College of Engineering and Technology (Autonomous) PSN College of Engineering and Technology (Autonomous)Document5 pagesPSN College of Engineering and Technology (Autonomous) PSN College of Engineering and Technology (Autonomous)Maharajan McsPas encore d'évaluation

- General Input:-: Moment & Shear Strength Design of Rectangular RC According ACI318M-08Document14 pagesGeneral Input:-: Moment & Shear Strength Design of Rectangular RC According ACI318M-08Maharajan McsPas encore d'évaluation

- Slab Design by ShubhamBabarDocument7 pagesSlab Design by ShubhamBabarMaharajan McsPas encore d'évaluation

- 05-08-17 10.00Document33 pages05-08-17 10.00Maharajan McsPas encore d'évaluation

- Heating Ventilation and Air ConditioningDocument68 pagesHeating Ventilation and Air ConditioningchinnuPas encore d'évaluation

- Determination of The Efficiency Level of The Camouflage NetDocument5 pagesDetermination of The Efficiency Level of The Camouflage NetLatwPIATPas encore d'évaluation

- Exercise 1 PDFDocument12 pagesExercise 1 PDFAnjali GuptaPas encore d'évaluation

- 350502main Optics Building A MicroscopeDocument4 pages350502main Optics Building A MicroscopeAzraeliusPas encore d'évaluation

- Laws of Motion MCQs Sheet 1Document6 pagesLaws of Motion MCQs Sheet 1eka123100% (1)

- E0-190-2008 (2) Chapter 1 PDFDocument41 pagesE0-190-2008 (2) Chapter 1 PDFWendy CohenPas encore d'évaluation

- Quantitative Application of UV-Visible SpectrosDocument7 pagesQuantitative Application of UV-Visible SpectrosRoshan Mohammad100% (1)

- 3D ExerciseDocument1 page3D ExerciseRashiqah RazlanPas encore d'évaluation

- Session 11 Physical Vapour DepositionDocument26 pagesSession 11 Physical Vapour DepositionMurali DontuPas encore d'évaluation

- Pumps and Hydraulic CheckDocument67 pagesPumps and Hydraulic CheckNivas SadhasivamPas encore d'évaluation

- PracticeTest1 SolutionsDocument10 pagesPracticeTest1 SolutionsMar Lorenz Robles LingaoPas encore d'évaluation

- Origin of Modern AstronomyDocument41 pagesOrigin of Modern AstronomyNordianaPas encore d'évaluation

- An Introduction To Dynamics of Colloids - Jan K. G. DhontDocument661 pagesAn Introduction To Dynamics of Colloids - Jan K. G. DhontSaul Diaz Infante50% (2)

- Solving Equilibrium Problems FDocument16 pagesSolving Equilibrium Problems FAntonyPas encore d'évaluation

- Fast Numerical Methods For Mixed-Integer Nonlinear Model-Predictive ControlDocument380 pagesFast Numerical Methods For Mixed-Integer Nonlinear Model-Predictive ControlDaniel Suarez ReyesPas encore d'évaluation

- SM Lab (Tension Test)Document15 pagesSM Lab (Tension Test)sushilkumar100% (1)

- Point Group PDFDocument46 pagesPoint Group PDFDharamsingh WaskalePas encore d'évaluation

- Muffle FurnaceDocument7 pagesMuffle FurnaceRonPas encore d'évaluation

- DiffractionDocument45 pagesDiffractionDEVYANI AGGARWALPas encore d'évaluation

- Active Force on Retaining Wall Supporting Φ Backfill Considering Curvilinear Rupture SurfaceDocument10 pagesActive Force on Retaining Wall Supporting Φ Backfill Considering Curvilinear Rupture SurfaceLawrence CainPas encore d'évaluation

- D2789Document7 pagesD2789rimi7alPas encore d'évaluation

- Laminar and Turbulent Flow, Experimental Vs Theoretical Profile in A Wind TurbineDocument12 pagesLaminar and Turbulent Flow, Experimental Vs Theoretical Profile in A Wind Turbinehamza shazibPas encore d'évaluation

- Makalah Perkerasan LanjutDocument22 pagesMakalah Perkerasan LanjutHana M'wf CiieManroePas encore d'évaluation

- Repair and Strengthening of Reinforced Concrete Beam-Column Joints StateDocument15 pagesRepair and Strengthening of Reinforced Concrete Beam-Column Joints StateJorge Enrique Diaz Durier100% (2)

- Hipparchus and Ptolomy PDFDocument35 pagesHipparchus and Ptolomy PDFavisanPas encore d'évaluation

- Producer TheoryDocument8 pagesProducer TheoryOmer KhayyamPas encore d'évaluation

- Traffic Flow Simulation by Using A Mathematical Model Based OnDocument4 pagesTraffic Flow Simulation by Using A Mathematical Model Based Onhkabir_juPas encore d'évaluation

- HartfordDocument7 pagesHartfordapi-443631703Pas encore d'évaluation

- ES 442 Homework #8: SolutionsDocument5 pagesES 442 Homework #8: SolutionslovePas encore d'évaluation

- Ch09 TestbankDocument61 pagesCh09 Testbanklimpaj35Pas encore d'évaluation