Académique Documents

Professionnel Documents

Culture Documents

Historical Development of Copper Vapor Laser: ISPIE Vol. 1859 Laser Isotope Separation (1993)

Transféré par

Sutanwi LahiriTitre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Historical Development of Copper Vapor Laser: ISPIE Vol. 1859 Laser Isotope Separation (1993)

Transféré par

Sutanwi LahiriDroits d'auteur :

Formats disponibles

New Japanese AVLIS Program

N. Monoka

Laser Atomic Separation Engineering Research Association of Japan (Laser-J)

2-76, Aza Shirane, Oaza Shirakata, Tokaimura, Nakagun, Ibaraki, Japan

ABSTRACT

The historical descriptions on developing AVLIS laser systems for the last six years in Japan are given, and such items

as some development issues, operational expenences and those further to be developed in the next step of R and D program

are bnefly explained.

Laser-J completed its first term of R and D program at the end of June, 1992 and received a check and review procedure

by its sponsors and Japanese AEC on its consequences. Laser-J has got a GO' signal to implement the next step of develop-

ing full scale of AVLIS hardwares, the outcome of which will be subjected to another check and review to be made by them.

If Laser-J could clear the process, it would go to the the last step of building a set of Demo Facility and making Enrich-

ing Demonstration Test thereof. The total span will amount to 10 years.

1. HISTORICAL DEVELOPMENT OF COPPER VAPOR LASER

The first term or step of R and D of laser systems concentrated itself on increasing power outputs of Copper Vapor Laser

(CVL) and consequently Dye Laser (DL) as quickly as possible. We therefore postponed studying some of more advanced

topics. I will summarize here how we have been developing a CVL system.

1.1 CVL DEVELOPMENT

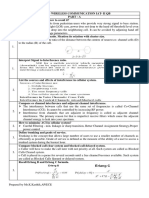

CVL is usually operated in a chain which consists of an oscillator and some amplifiers (MOPA). To make the story

simpler, 1 will mainly explain the historical development of CVL unit. Fig. 1 shows how the unit power output level grew

up in time where I attached LLNLs corresponding record up to 1990, just for reference.

I classify our CVLs into the first and second generation, the first generation of which were developed from 1987 to 1989

and brought to the Tokai Test Facility to be re-used. I will later describe their operational data collected in 1991 and 1992.

(Fig.2)

Our contractors voluntanlv exerted their efforts further to increase CVL power output by enlarging the ceramic tube dia-

meter from 6 cm of the first generation to 8 cm of the second generation. As shown in Fig. 1 ,they attainted the maximum

unit power output of 430 W (average 415 W plus minus 3% for 3 hours) on 10/22/92.

From our economical evaluation and optimization on 1500 TSWU/yr AVLIS plant, it would be sufficient for us to pro-

duce about 500 W of CVL unit power output. Therefore, there seems to be no serious problem for us to produce a commer-

cial scale of CVL MOPA in terms of power output level.

1.2 HIGH FREQUENCY SWITCHING DEVICE

The thyratron is usually used for a high frequency switching device for CVL which is not a continuous wave but pulsed

laser. In the earlier days of R and D, we thought that the thyratron's lifetime was rather short for its usage. One of contrac-

tors did chaillenge this problem and developed a semi-conductor type of switch which constitutes multiple MOS-FET transis-

tors. They manufactured a few switches which were actually housed in the enclosures of CVL at Tokai Test Facility. (Fig.3)

During a series of irradiation tests, the' worked at a high level of reliability with less jittering and their lifetime is clearly

beyond the accumulated operational hours so far achieved. (Fig.4)

2 ISPIE Vol. 1859 Laser Isotope Separation (1993) O-8194-1086-l/93/$4.OO

Downloaded From: http://proceedings.spiedigitallibrary.org/ on 04/26/2017 Terms of Use: http://spiedigitallibrary.org/ss/termsofuse.aspx

However, the thvratron is also fairly improved on its performance, especially with an assoicated electrical circuit which

has magnetic assisting and compressing elements. Therefore, we must carefully compare both types economically for their

final selection. The semi-conductor type would exceed the thyratron in engineering performances as a high frequency switch

but might be more expensive in its manufacturing cost. (dependent on the mass production scale)

1.3 FEEDING COPPER PARTICLES INTO CERAMIC TUBE BORE

As a weak point of metallic vapor laser, copper particles must be fed from time to time into the ceramic tube bore of

CVL. We can maintain the normal copper vapor pressure longer to some extent, if we

( 1) suppress the buffer gas flow rate as low as possible

(2) load copper particles as many as possible

(3) take the aspect ratio ( diameter I length of the ceramic tube) as small as possible

(4) install the "wick" inside the tube

Our expenences on the copper consumption rate are shown in Fig. 5.

We have developed a sort of wick which was tested for its effectiveness with a small CVL. We will possibly improve it

further in the future. Whether we adopt for the wick or not will again depend upon the result of economical assessment on

what would be the influence of the cost of continuously operating CVL MOPAs (including spares) with or without the wick

on the enriching cost. Anyhow, we will aim at developing the simpler and cheaper version of CVL MOPA in the next step

of R and D program.

2. DEVELOPMENT ON DL SYSTEM

The DL MOPA power output will increase if pumping CVL MOPA power output increases. I think the supports for

glass made DL cells should be carefully designed for seismic attacks in Japan. We delayed studying such advanced topics as

the DL beam quality and its degradation due to a long distance of DL beam propagation through the uranium vapor streams.

Here, I rather address myself to these scientific problems related.

2.1 MATCHING DL FREQUENCY CHARACTERISTICS WITH HYPERFINE STRUCTURE OF

U235 ABSORPTION SPECTRA

DL is suitable for tuning its output freqeuncy with a particular transition or step from an energy level to another of an

atom. Such an atom as U238 (even mass number) has a single absorption line at a particular frequency with degenerate mag-

netic sublevels, for which U235 (odd mass number) has multiple absorption lines with a range of a few GHz spread around

that frequency due to its intrinsic nuclear spin. (Hyperfine structure of absorption spectra)

Therefore, in case of exciting U235 atom from an energy level to another, the band of a DLs frequency is too narrow to

match such widely spread absorption lines. ( How to let U235 atom absorb the energy of sharply tuned light effectively

We gave it a try on a few candidates of DL matching method in vain. There seems to be two outstanding candidates:

( 1) static DL matching, that is, let DL output a beam with multiple frequency or axial modes, for example, 10 modes,

the band of whose frequencies as a whole will cover the range of a hyperfine structure for a particular transition

(2) dynamic DL matching, that is, let DL output a beam with a single frequency mode whose frequency will quickly be

chirped or swept over the range of the hyperfine structure within its beam pulse duration of 4O ns or so (Fig. 6)

We have developed a comprehensive quantum mechanical code for the light-atom interaction which cancompute the ion-

ization rate for a separation scheme (a combination of transitions) with such input as absorption cross section, magnectic sub-

levels specification, laser intensity, laser polarization, chirping and so on.

With this code, we made extensive computations for a particular separation scheme on the ionization rate in case of a sin-

SPIE Vol. 1859 Laser Isotope Separation (1993)! 3

Downloaded From: http://proceedings.spiedigitallibrary.org/ on 04/26/2017 Terms of Use: http://spiedigitallibrary.org/ss/termsofuse.aspx

gle or multiple frequency mode of laser beam with or without chirping, resulting in almost the same ionization rate bcah for

the static and best opitmized dynamic DL matching methods.

Although most of laser specialists were in for the static matching, Laser-J decided to develop hardwares for the dynamic

matching in spring, 1990 with an additional budget given by some of its sponsors, and its contractors finished developing

and fabricating hardwares in 1991 which they brought to Tokai to be installed. We tested them in a second series of Funda-

mental Test in that year to confirm that it worked well.

The comparison of measured ionization rates at the chirping tests with the computed, showed a reasonable level of coin-

cidence. However, I think it necessary still to improve them to a practical level and test them more extensively to conclude

that the method is really effective. I have to say that how to chirp or not is closely connected with the separation scheme se-

lected. Therefore, there is no general rule to determine the way of chirping but it must be decided after lots of simulation ana-

lyses thereof.

2.2 DL BEAM PROFILE AND QUALITY

DL MOPA would have been conceived to produce a good beam quality by adopting a top oscillator which is of small

power output but can produce a good quality of beam that will further be amplified. We adopted a separation scheme of four

frequencies (or wavelengths) and three steps. This means we must prepare four independent DL beams of different frequencies

%%'ith the same dimensional shape of beam section to be uniformly mixed or combined into a beam bundle.

We, as engineer's instinct, thought it natural to select the shape of beam section as circular. Unfortunately, the circular

shape of beam section is most susceptible to the diffraction effect. If we opt for the circular shape, it means to opt for a circu-

las shaped hard edged aperture which will greatly cause the peak value of the on-axis ripple in the near field diffraction pattern

due to its high symmetry. (For example, refer to p. 905 of "LASERS" by A.E.Siegman)

Also our DL beam quality was so poor that we must have frequently cut and modified deformed sectional shapes by aper-

ture in order to make each shape of beam section circular with the same diameter. ( It can be done but with lots of laserpower

losses ! ) In the next step of R and D program, we will select a rectangular shape of beam section which is not only less

susceptible to the diffraction effect but also good for irradiating DL beam effectively on uranium vapor stream between extrac-

tion plates.

In order to improve the DL beam quality to a level of 1.0 Times Diffraction Limited (TDL), we must do lots of things,

such as improving DL oscillator design, the quality of inbetween optical systems, the way of pumping and so on. We have

already been using the "image relaying " in a DL MOPA which is effective in keeping the good beam quality on transmitting

beam from a place to another.

As to the DL oscillator, Laser-J encouraged contractors to renew the current designs and gave them the generic instruction

on how to improve the oscillator to conform with the specification of 1.0 TDL of output beam quality, in January, 1992.

This is closely related with the resonator theory which says the "unstable resonator" would be more suitable for this design

purposes. However, it is the contractors' option which they opt for, stable or unstable resonator, because I would like to give

them a design freedom and their own feature of the oscillator.

Of course, we need to develop a set of diagnostic apparatus to measure and check the beam quality at each location of DL

systems and inbetween optical systems.

2.3 EFFECT OF LONG DISTANCE OF DL PROPAGATION THROUGH URANIUM VAPOR

ON ITS BEAM QUALITY

As to the DL beam quality, there will be a more difficult problem for us to solve. When I refer to it, I mean that the beam

quality would be the best if it resembled a plane wave coming from the infinity so that its wavefront is flat and on which laser

intensity is as uniform as possible.

Even if we can produce the best beam quality of rectangular section at the exit of DL MOPA, its beam must propagate

through the uranium vapor medium of a few hundred meter depth in the commercial plant. There will be miscellaneous causes

4 ISP1E Vol. 1859 Laser Isotope Separation (1993)

Downloaded From: http://proceedings.spiedigitallibrary.org/ on 04/26/2017 Terms of Use: http://spiedigitallibrary.org/ss/termsofuse.aspx

to degrade its beam quality, such as U238 near resonance effect, diffraction effect, U235 absorption and notably vapor density

variation across the space between a pair of extraction plates. If DL beam quality is deteriorated, the ionization rate averaged

over the toi1 distance of DL propagation will soon drop, for example, below 80 %.

By the way, we calculated the effect of utilization factor of DL photon on the enriching cost, resulting in that less the fac-

tor is, more quickly the cost becomes expensive, based on the design concept of 1500 TSWU/yr commercial plant. (Fig. 7)

It means that we must increase the factor. They say it will be in the range of 5 to 10 %. Why is it of so low percentages,

although it is a vital parameter in the economical optimization ? I believe it is because DL beam so quickly degrades its

quality on propagating through the medium that it must get out of the light-atom interacting process before the ionization rate

decreases considerably.

If we could restore the original good beam quality that we can enjoy at the inlet of a separator optical cell, after some dis-

tance of beam propagation, we might be able to utilize DL beam energy more in order to improve the AVLIS economy.

In May, 1991, Laser-J determined to study and develop the hardware of so called "adaptive control mirror" or "phase con-

Jugate mirror" for that purpose in the next step of R and D program.

One of our contractors is engaged in a project to make a sort of adaptive control mirror that should compensate the atmos-

pheric turbulence which will reduce the resolving power of a gigantic astronomical telescope to be built in Hawaiian Islands.

I think they could apply the technology to our case of correcting any wavefront distortion within a specified precision, for ex-

ample, DL wavelength /10. The concept of the adaptive control mirror system is illustrated in Fig. 8.

Laser-J once asked an university to compute the effect of long distance of DL propagation through uranium vapor on its

beam quality based on Maxwell-Bloch equations by NEC's supercomputer to produce an imformative result on at what extent

of every specified propagation distance we should install such a mirror . This simulation model assumed that the popagating

beam is of a single frequency mode. If it is of multi-frequency mode, I think it very hard to build the simulation model by

which we can compute the average ionization rate by the supercomputer.

The beam quality improvement and the adaptive control mirror system development will be items of top priority in the

next step of R and D program in the field of laser technology.

3. OPERATIONAL EXPERIENCES ON LASER AND OPTICAL SYSTEMS

I only briefly touch with the operational experiences from 1990 to 1992 of laser systems which constitute CVL and DL

MOPAs at Tokai Test Facility, as shown by attached tables.

I also took an example of day to day operational chart for each CVL and DL MOPAs illustrated by attached graphs in the

Fig. 9 and 10. Please be sure that those lasers were developed, fabricated and tested at contractors' works from 1987 to 1989,

belonging to the first generation of lasers which were brought to Tokai Test Facility later to be re-used due to a budget const-

raint, as stated earlier.

It might be rather a rare case that once assembled lasers at manufacturer's works were disassembled and transported to ano-

ther place and assembled again. Pnor to starting their actual operation, it took manufacturers almost the same efforts to in-

stall and adjust them properly as new ones.

From Laser-J's points of view, it took a considerable manpower of laser technicians for maintaining laser systems bet-

ween continued operations. We think alignment jobs thereof should be automated in order to reduce manpower and time

required. In this relation, adopting the optical fiber for CVL to pump up DL is very useful for easier alignment and we will

try to increase the maximum power transmitting capability of the optical fiber to the extent that we may apply it up to the

last stage of DL amplifier in the next step of R and D.

We had a queer experience that we needed a cooling capability for CVL room even in winter season against ourexpecta-

tion, because CVL system dissipates a considerable amount of heat during its operation.

We can say in general that the laser systems could be operated more reliably than the separator system throughout series

SPIE Vol. 1859 Laser isotope Separation (1993) / 5

Downloaded From: http://proceedings.spiedigitallibrary.org/ on 04/26/2017 Terms of Use: http://spiedigitallibrary.org/ss/termsofuse.aspx

of miscellaneous tests at Tokai.

By using these laser systems, we could irradiate uranium vapor to ionize, that is, conduct a senes of enriching test with

separators installed at Tokai Test Facility from 1990 to 1992 which I like to explain at a separate occasion. In June, 1992, at

the end of series of all tests, we could make continuous uranium recirculation tests for a few tens of hours without any serious

operational troubles with a larger separator.

However, we had a bitter and careless mistake in building the larger separator. Our time schedule was so short that we dis-

carded a possibility that one of four stages of the vacuum pumps would be a hazardous vibration source to the rigidly install-

ed, high precision of reflecting mirror sytem inside the separator. We tried to eliminate the induced vibration effect on the

minor in vain which will tell us that we should have a separate concrete foundation for installing the pump and take a vibra-

tion absorbing measure on the mirror system.

4. NEXT STEP OF AVLIS R AND D PROGRAM

In mid- 1992, our sponsors, Japanese utility industry have decided to let Laser-J go to the next step of full scale of

AVLIS hardwares development program, where the performance targets for main components are set and will be compared

with the actual achievements that Laser-J will attain (possibly in 1998).

They will make another check and review on the technical reliability and economy based on these achievements further

to decide if Laser-J should go to the final step of building a Demo Facility and making the Enriching Demonstration thereof.

(Another 5 years) Based on the operational data to be collected, Laser-J will then submit the detailed cost estimate on the

commercial plant of 1500 TSWU I yr capacity to its sponsors who will decide the commercial deployment plan, if the' want.

I will show just the overall shematic of the program in Fig. I 1 and R and D targets for laser systems in Fig. 12 and 13.

The logics by which we have made these targets are as follows:

( 1 ) Evaluate the current technical level we have reached so far

(2) Set a bit "conservative" targets for the commercial plant of 1500 TSWU / yr capcity and make its design concepts

br economical assessment on the enriching cost thereof

(3) Plan the R and D program that can fill the gap between (1) and (2) performances

"Conservative" in the above (2) means that we will be able to meet the targets with due efforts within 5or 6 years to come,

based upon our last 6 years' experience on AVLIS R and D activity.

In Japan, they are now building a commercial enriching plant by centrifuge technology and sometime in the next century,

they plan to replace old centrifuges with the improved ones. Japanese AVLIS must compete with the improved centrifuges

in its enriching cost at that time.

6 / SPIE Vol. 1859 Laser Isotope Separation (1993)

Downloaded From: http://proceedings.spiedigitallibrary.org/ on 04/26/2017 Terms of Use: http://spiedigitallibrary.org/ss/termsofuse.aspx

>

0

0

U-

E

0

G)

cc

[Ml 1OMOd lAO

Power Scaling-up of CVL

500 4-PLANT-SCALE CVL

400 - B (ç58Ornrn CVL)

o Expeririient

300 — A Calculation

a)

0 (560mm CVL)

3-

-J 200 - • Experiment

>

0 Ca Ic Lila tio n

100-

A ; Conventional Circuit

B MPC Circuit

I . I

Oo 100 200 300 400

Laser Tube Length (cm)

Fig.2

SPIE Vol. 1859 Laser Isotope Separation (1993)! 7

Downloaded From: http://proceedings.spiedigitallibrary.org/ on 04/26/2017 Terms of Use: http://spiedigitallibrary.org/ss/termsofuse.aspx

Fig.3 Semi—Conductor Type of Switching Device

C,)

I0

C

0

00

C)

D

C)

E

0

0

4-'91 5 6 7 8 9 10 11 12 1-'922 3 4 5 6

month

Fig.4 Accumulated Operational Hours

8 ISPIE Vol. 1859 Laser Isotope Separation (1993)

Downloaded From: http://proceedings.spiedigitallibrary.org/ on 04/26/2017 Terms of Use: http://spiedigitallibrary.org/ss/termsofuse.aspx

C)

uu

0

C) 'Buffer gas flow rate - a few cdmn

18O

00 160—

•

.. •

.

.

C.) • ,—......

• :• •••• . .

0C)

0 140- -•-•-••---• .

:...

. —•• • • -

0 120-• .. .

'I-

0 100 -•

•• •

.

65 qSCV [ •

...- . -. - ----- ——-4 - —.

4-'

8O :• . •.

12Og/9OOh O.14g/h

:

•

:3

0 6O • . .

(56bg/4,000h)

E

.. CVL 'Ti

4O->,,

• . .

//' • •• •

4g/92OhO.OO5g/h

f .

a)

4-' ..

20- i . ..

•k' .

(26g/4,000h)

:3

0

•I r .

E 0 200 400 600 800 1000 1200h

:3

0

0 Accumulated Operational Hours

Fig.5 Copper Consumption Rate

L Without Chirpij] iith Chirpi]

Laser Spectrum Laser Spectrum

Frequency V (t)

(GHz)

E/O Crystal

I— —i

A Laser Beam

B CD A B

C DE

I

Absorption Lines of 235U

I

GF

liii

Absorption Lines of 235U

Fig.6 DL Matching with U235 Hyperfine Structure

SPIE Vol. 1859 Laser Isotope Separation (1993)19

Downloaded From: http://proceedings.spiedigitallibrary.org/ on 04/26/2017 Terms of Use: http://spiedigitallibrary.org/ss/termsofuse.aspx

(/)

Wave Front

CD

Measurement Relative Enriching Cost

cD cJ cD

0 Incident Beam

0 (precision A/1O

CD

respons speed O.lsec)

CD

A)

A)

0 Adaptive Shack - Hartmann Sensor

Control

Mirror

.1 0

0

Reflective ( c-fl

Mirror .J 3•

T1

0

0

speed 3sec)

Downloaded From: http://proceedings.spiedigitallibrary.org/ on 04/26/2017 Terms of Use: http://spiedigitallibrary.org/ss/termsofuse.aspx

Fig.8 Concept of Adaptive Mirror System

CVL MOPA Line Al A2 B2 Bi C Dl D2 E

Accumulated 2080 1970 2061 1852 2303 2155 1074 1099

Operational Hours

Output Maximum 97 91 98 94 130 95 203 196

Power [W] Average 84 77 84 84 114 86 165 174

Conversion 0.49 0.55 0.53 0.57 0.84 0.46 0.67 0.70

Efficiency [%]

Beam alignment & Instrument cal ibrat ion

250 . Instrument calibration

200

150

0

100

50

0

8:00 9:00 10:00 11:00 12:00 13:00 14:00 15:00 16:00 17:00

Time (1 2/1 2/ 91)

Fig.9 Output Power Trends of CVL MOPAs

SPIE Vol. 1859 Laser Isotope Separation (1993) / 11

Downloaded From: http://proceedings.spiedigitallibrary.org/ on 04/26/2017 Terms of Use: http://spiedigitallibrary.org/ss/termsofuse.aspx

I ypKdl JperiwurkII IJdLU UI IJL. IV1J1MS

DL MOPA Line A B C D Comment

Dye DCM R6G R6G KRS

Accumulated 1183 1184 1735 1(5 MayP90-Junei92

Operational Hours

Output Maximum 87 34 15 during the service—time for a separation run

13

Power [W] Average 59 11 24 10 during the service—time for a separation run

Conversion 16.2 186 23.8 12.2 at the end of the service—time for a separa—

Efficiency [%] tion run

90

80

78

60

G)

o 48

0

30

20

10

0

8:00 9:00 10:00 11:00 12:00 13:00 14:00 15:00 16:00 17:00

Time (12/12/91)

Fig.1O Output Power Trends of DL MOPAs

12 / SPIE Vol. 1859 Laser Isotope Separation (1993)

Downloaded From: http://proceedings.spiedigitallibrary.org/ on 04/26/2017 Terms of Use: http://spiedigitallibrary.org/ss/termsofuse.aspx

FUTURE PROJECT SCHEDULE

1993 94 95 96 97 98 99 01 Q

A A

o_ ••bó•• Q$LR ç&•.•.•

Test Facility ——————

A & D on Hardwares

Demo.Plant ... uoee Ope

Fig. 11

Copper Vapor Laser

R&D Targets How to Demonstrate

Single Unit Output : 500W • Continuous operation test

For lasertubes, switches etc., life

Single Unit Efficiency : 2%

time is confirmed by accumulative

MOPA Output : 2000W time under operation of target out-

Output Stability : 2% put level

Repetition Rate :46kHz

Beam Delivery Efficiency :95%

Maintenance Time : 6 hr s . Independent maintenance test

Fig.1 2

Dye Laser —

R&D Targets

L How to Demonstrate

Output (MOPA) : 700W •Continuous operation test

OutputStability : 5%

Conversion Efficiency :40%

Beam Profile : Rectangular

Homogeneous

Wave Front Quality : , /4

Repetition Rate : 12kHz

Beam Shaping Efficiency : 80%

Beam Conbination " :85%

Maintenance Time : 6hrs Independent maintenance test

Fig.13

SPIE Vol. 1859 Laser Isotope Separation (1993) 1 13

Downloaded From: http://proceedings.spiedigitallibrary.org/ on 04/26/2017 Terms of Use: http://spiedigitallibrary.org/ss/termsofuse.aspx

Vous aimerez peut-être aussi

- Conceptual Design For A 1-Gev Ifel AcceleratorDocument7 pagesConceptual Design For A 1-Gev Ifel AcceleratorParticle Beam Physics LabPas encore d'évaluation

- Using Diode Lasers For Atomic Physics WiemanDocument20 pagesUsing Diode Lasers For Atomic Physics WiemanMario Ricardo Montero HurtadoPas encore d'évaluation

- The Quantum Cascade Laser: A Versatile High-Power Semiconductor Laser For Mid-Infrared ApplicationsDocument16 pagesThe Quantum Cascade Laser: A Versatile High-Power Semiconductor Laser For Mid-Infrared ApplicationsAndreiPas encore d'évaluation

- Carl WeimanDocument20 pagesCarl WeimanTushar GuptaPas encore d'évaluation

- Ring Amplifiers For Switched Capacitor CircuitsDocument15 pagesRing Amplifiers For Switched Capacitor CircuitsJack KangPas encore d'évaluation

- Ring Amplifiers For Switched Capacitor CircuitsDocument15 pagesRing Amplifiers For Switched Capacitor CircuitsheqiPas encore d'évaluation

- THPMS027Document3 pagesTHPMS027Michael FairchildPas encore d'évaluation

- Aik'F - ?G0 Ss7 - G": Ucrl-92160 PreprintDocument6 pagesAik'F - ?G0 Ss7 - G": Ucrl-92160 Preprintskr2010Pas encore d'évaluation

- EUV Lithography - State of The ArtDocument14 pagesEUV Lithography - State of The ArtGabriel DonovanPas encore d'évaluation

- 2013 - Cheng, Lin, Lin - Single - and Double-Walled Carbon Nanotube Based Saturable Absorbers For Passive Mode-Locking of An Erbium-DopedDocument11 pages2013 - Cheng, Lin, Lin - Single - and Double-Walled Carbon Nanotube Based Saturable Absorbers For Passive Mode-Locking of An Erbium-DopedClaudio BiaginiPas encore d'évaluation

- Dielectric Wakefield Accelerator Experiments at The Saber FacilityDocument3 pagesDielectric Wakefield Accelerator Experiments at The Saber FacilityParticle Beam Physics LabPas encore d'évaluation

- Design-Time Reliability Enhancement Using Hotspot Identification For RF CircuitsDocument5 pagesDesign-Time Reliability Enhancement Using Hotspot Identification For RF CircuitsNguyen Van ToanPas encore d'évaluation

- Eye-Safe Microchip Laser For LRF ApplicationDocument3 pagesEye-Safe Microchip Laser For LRF ApplicationsobagsPas encore d'évaluation

- Radio Interference Voltage Measurement System For The Measurement of Corona1Document13 pagesRadio Interference Voltage Measurement System For The Measurement of Corona1Siphesihle NkosiPas encore d'évaluation

- EUV Sources of LithographyDocument2 pagesEUV Sources of Lithographychirag sharmaPas encore d'évaluation

- Sekutowicz 2005 617Document12 pagesSekutowicz 2005 617Particle Beam Physics LabPas encore d'évaluation

- ModulatorreliabilityDocument17 pagesModulatorreliabilityRahul ChatterjeePas encore d'évaluation

- Resonant Clock Latch Based DesignDocument10 pagesResonant Clock Latch Based DesignDebarshee BhattacharjeePas encore d'évaluation

- Universidad Tecnólogica de Panamá: 1. Commissioning Practical Aspects of Relays With IECDocument20 pagesUniversidad Tecnólogica de Panamá: 1. Commissioning Practical Aspects of Relays With IECIsaac JustinPas encore d'évaluation

- Machine Learner Optimization of Optical Nanofiber-Based Dipole Traps - R K Gupta - A D Tranter - P K Lam - S Nic-Chormaic - AVS Quant SciDocument9 pagesMachine Learner Optimization of Optical Nanofiber-Based Dipole Traps - R K Gupta - A D Tranter - P K Lam - S Nic-Chormaic - AVS Quant SciArijit SharmaPas encore d'évaluation

- Modeling of Metal Oxide Surge Arresters 1992Document8 pagesModeling of Metal Oxide Surge Arresters 1992Marcelo VillarPas encore d'évaluation

- Design of A Terahertz Cascade Backward Wave AmplifierDocument6 pagesDesign of A Terahertz Cascade Backward Wave AmplifierRupaShawPas encore d'évaluation

- 2017 - Light Sources For High-Volume EUV Technology, Performance, and Power ScalingDocument14 pages2017 - Light Sources For High-Volume EUV Technology, Performance, and Power Scalingsg909909Pas encore d'évaluation

- Obsfbt LC Pbjf'lkar'qlo LMQF' I Jmifcfbo Epl F CRK'QFLK IfqfbpDocument12 pagesObsfbt LC Pbjf'lkar'qlo LMQF' I Jmifcfbo Epl F CRK'QFLK IfqfbpFahmi PranandaPas encore d'évaluation

- A Design Approach of Higher Oscillation VCO Made of CS Amplifier With Varying Active LoadDocument11 pagesA Design Approach of Higher Oscillation VCO Made of CS Amplifier With Varying Active LoadAzizur RahmanPas encore d'évaluation

- Quartz Pendulous Accelerometers For Navigation and Tactical Grade Systems - CompressedDocument20 pagesQuartz Pendulous Accelerometers For Navigation and Tactical Grade Systems - CompressedLê Đình TiếnPas encore d'évaluation

- Development of an amplified variable shaped long pulse system for Vulcan laserDocument4 pagesDevelopment of an amplified variable shaped long pulse system for Vulcan laserIbrahim AbdelfattahPas encore d'évaluation

- Winick 1993 0258Document3 pagesWinick 1993 0258Particle Beam Physics LabPas encore d'évaluation

- Frequency-Domain Analysis of Super-Regenerative Amplifiers: CitationDocument14 pagesFrequency-Domain Analysis of Super-Regenerative Amplifiers: CitationMauro MarafonPas encore d'évaluation

- Parametric Study of An X-Ray FELDocument5 pagesParametric Study of An X-Ray FELParticle Beam Physics LabPas encore d'évaluation

- IHCE Tripple Width PFL Electronics-11-00406-V2Document12 pagesIHCE Tripple Width PFL Electronics-11-00406-V2SriPas encore d'évaluation

- Chemical Physics LettersDocument18 pagesChemical Physics LettersAndreiPas encore d'évaluation

- Progress in The Next Linear Collider Design (JNL Article) - T. Raubenheimer WWDocument5 pagesProgress in The Next Linear Collider Design (JNL Article) - T. Raubenheimer WWljosidPas encore d'évaluation

- Travish 2000 0563Document3 pagesTravish 2000 0563Particle Beam Physics LabPas encore d'évaluation

- A Novel Periodic CPW UWB Low Pass Filter With Large Rejected BandDocument8 pagesA Novel Periodic CPW UWB Low Pass Filter With Large Rejected BandFa Mido ChemseddinePas encore d'évaluation

- Development of Semiconductor Laser For OpticalDocument8 pagesDevelopment of Semiconductor Laser For Opticalvinod kapatePas encore d'évaluation

- Gunawan - SunsVoc Characteristics of High Performance CZTSSe - 2014Document9 pagesGunawan - SunsVoc Characteristics of High Performance CZTSSe - 2014Prit ShahPas encore d'évaluation

- Fiber Optical Parametric Amplifiers in Optical Communication SystemsDocument25 pagesFiber Optical Parametric Amplifiers in Optical Communication SystemsHaojia SUNPas encore d'évaluation

- Effective Non-Reflective Boundary For Lamb Waves - TheoryDocument20 pagesEffective Non-Reflective Boundary For Lamb Waves - TheoryHiram RoblesPas encore d'évaluation

- The Ucla Helical Permanent-Magnet Inverse Free Electron LaserDocument3 pagesThe Ucla Helical Permanent-Magnet Inverse Free Electron LaserParticle Beam Physics LabPas encore d'évaluation

- PSP-based Scalable MOS Varactor Model: Proceedings of The Custom Integrated Circuits Conference October 2007Document9 pagesPSP-based Scalable MOS Varactor Model: Proceedings of The Custom Integrated Circuits Conference October 2007Thomas GeorgePas encore d'évaluation

- Rosenzweig 2000 0495Document3 pagesRosenzweig 2000 0495Particle Beam Physics LabPas encore d'évaluation

- Towards A PWFA Linear Collider - Opportunities and ChallengesDocument16 pagesTowards A PWFA Linear Collider - Opportunities and Challengesarohi9Pas encore d'évaluation

- ch1Document24 pagesch1Jean Jacques Monga KabokoPas encore d'évaluation

- Modeling Erbium-Doped Fiber Amplifiers: Randy Giles, and Emmanuel DesurvireDocument13 pagesModeling Erbium-Doped Fiber Amplifiers: Randy Giles, and Emmanuel DesurvireElbis Santos CardosoPas encore d'évaluation

- 10 - 2015 - FIO - Experimental Investigation of A Nanoplasmonic Air-Slot Coupler Toward Dense Optical Integrated CircuitsDocument2 pages10 - 2015 - FIO - Experimental Investigation of A Nanoplasmonic Air-Slot Coupler Toward Dense Optical Integrated CircuitsRami WahshehPas encore d'évaluation

- Experimental Study On Wavelength Tunability of All-Optical Flip-Flop Based On Multimode-Interference Bistable Laser DiodeDocument9 pagesExperimental Study On Wavelength Tunability of All-Optical Flip-Flop Based On Multimode-Interference Bistable Laser DiodeAlonso YapoPas encore d'évaluation

- 16-Article Text-89-1-10-20191202Document11 pages16-Article Text-89-1-10-20191202okonkwo innocentPas encore d'évaluation

- Emission Directionality of Semiconductor Ring Lasers: A Traveling-Wave DescriptionDocument8 pagesEmission Directionality of Semiconductor Ring Lasers: A Traveling-Wave DescriptionAnshuman SinhaPas encore d'évaluation

- Slac Pub 11792Document8 pagesSlac Pub 11792Particle Beam Physics LabPas encore d'évaluation

- Yu 1997 0177Document3 pagesYu 1997 0177Particle Beam Physics LabPas encore d'évaluation

- Wireless Communication IAT- II QB: Cell Dragging, Co-Channel Reuse Ratio & Signal InterferenceDocument12 pagesWireless Communication IAT- II QB: Cell Dragging, Co-Channel Reuse Ratio & Signal InterferencekkarthikecPas encore d'évaluation

- 3-D Finite Element Modeling of Nanostructure Enhanced SAW SensorDocument6 pages3-D Finite Element Modeling of Nanostructure Enhanced SAW SensornitinsriniwasPas encore d'évaluation

- Circular Polarized Antenna Feed: (For Eme On 10Ghz and 5.7Ghz)Document9 pagesCircular Polarized Antenna Feed: (For Eme On 10Ghz and 5.7Ghz)ROmanPas encore d'évaluation

- Apparatus and Demonstration Notes: Hsu, Dhingra, D'UrsoDocument8 pagesApparatus and Demonstration Notes: Hsu, Dhingra, D'UrsokkhykkPas encore d'évaluation

- A 6-UW Chip-Area-Efficient Output-Capacitorless LDO in 90-Nm CMOS TechnologyDocument10 pagesA 6-UW Chip-Area-Efficient Output-Capacitorless LDO in 90-Nm CMOS Technology孙士祯Pas encore d'évaluation

- 20110013317Document11 pages20110013317Gautam GadgilPas encore d'évaluation

- Performance Study of Optical ModulatorDocument10 pagesPerformance Study of Optical ModulatorAbu SalmanPas encore d'évaluation

- An Introduction To Quantum Cascade Lasers (QCLS) : What Is A QCL?Document3 pagesAn Introduction To Quantum Cascade Lasers (QCLS) : What Is A QCL?Manish KumarPas encore d'évaluation

- 5 Step PENCIL Shape InfographicDocument1 page5 Step PENCIL Shape InfographicSutanwi LahiriPas encore d'évaluation

- 14.create GLASS FLASK InfographicDocument1 page14.create GLASS FLASK InfographicSutanwi LahiriPas encore d'évaluation

- 5 Step 3D Pyramid Infographic GuideDocument1 page5 Step 3D Pyramid Infographic GuideSutanwi LahiriPas encore d'évaluation

- 9.create HONEY BEE InfographicDocument1 page9.create HONEY BEE InfographicSutanwi LahiriPas encore d'évaluation

- 14.create 3 Step CIRCULAR InforgraphicDocument1 page14.create 3 Step CIRCULAR InforgraphicSutanwi LahiriPas encore d'évaluation

- 14.create 4 Step Circular Gear InfographicDocument1 page14.create 4 Step Circular Gear Infographicascom asPas encore d'évaluation

- 13.create 7 Step BULB InfographicDocument1 page13.create 7 Step BULB InfographicSutanwi LahiriPas encore d'évaluation

- 8 Step Custom Shape Infographic PowerPoint TemplateDocument1 page8 Step Custom Shape Infographic PowerPoint TemplateSutanwi LahiriPas encore d'évaluation

- Mathematical Models for Sonochemical Effects of Hydrodynamic CavitationDocument49 pagesMathematical Models for Sonochemical Effects of Hydrodynamic CavitationSutanwi LahiriPas encore d'évaluation

- 7.create TRANSPARENT GLASS InfographicDocument1 page7.create TRANSPARENT GLASS InfographicSutanwi LahiriPas encore d'évaluation

- 13.create 5 Step CONE SHAPE InfographicDocument1 page13.create 5 Step CONE SHAPE InfographicSutanwi LahiriPas encore d'évaluation

- (Radiochimica Acta) Sonochemical Dissolution of Metallic Plutonium in A Mixture of Nitric and Formic Acid PDFDocument8 pages(Radiochimica Acta) Sonochemical Dissolution of Metallic Plutonium in A Mixture of Nitric and Formic Acid PDFSutanwi LahiriPas encore d'évaluation

- Solubility of Pu Surrogates in Nuc GlassesDocument5 pagesSolubility of Pu Surrogates in Nuc GlassesSutanwi LahiriPas encore d'évaluation

- 5.create 7 Step CIRCULAR InfographicDocument1 page5.create 7 Step CIRCULAR InfographicSutanwi LahiriPas encore d'évaluation

- Energies 05 02724 PDFDocument21 pagesEnergies 05 02724 PDFSutanwi LahiriPas encore d'évaluation

- 1997 Cu-X Graphite PDFDocument9 pages1997 Cu-X Graphite PDFSutanwi LahiriPas encore d'évaluation

- Indian Institute of Chemical Engineers: DR H L Roy Building, Raja Subodh Mullick Road, KOLKATA - 700 032Document3 pagesIndian Institute of Chemical Engineers: DR H L Roy Building, Raja Subodh Mullick Road, KOLKATA - 700 032Sutanwi LahiriPas encore d'évaluation

- Research Article: Numerical Simulation and Investigation of System Parameters of Sonochemical ProcessDocument15 pagesResearch Article: Numerical Simulation and Investigation of System Parameters of Sonochemical ProcessSutanwi LahiriPas encore d'évaluation

- Letters: Biasing Reaction Pathways With Mechanical ForceDocument5 pagesLetters: Biasing Reaction Pathways With Mechanical ForceSutanwi LahiriPas encore d'évaluation

- Andaman Fact SheetDocument9 pagesAndaman Fact SheetSutanwi LahiriPas encore d'évaluation

- Research ArticleDocument8 pagesResearch ArticleSutanwi LahiriPas encore d'évaluation

- Synthesis of Thermal Spray Grade Yttrium Oxide Powder and Its Application For Plasma Spray DepositionDocument6 pagesSynthesis of Thermal Spray Grade Yttrium Oxide Powder and Its Application For Plasma Spray DepositionSutanwi LahiriPas encore d'évaluation

- K B Thakur 2002 J. Phys. D Appl. Phys. 35 324Document10 pagesK B Thakur 2002 J. Phys. D Appl. Phys. 35 324PostPas encore d'évaluation

- Xa00152120 Welding Defects February 2011Document1 pageXa00152120 Welding Defects February 2011Mehmet Soysal100% (1)

- Non Ideal Reactors - Dispersion Model PDFDocument23 pagesNon Ideal Reactors - Dispersion Model PDFSutanwi LahiriPas encore d'évaluation

- Rhodamine B Doped Silica Encapsulation Matrices PDFDocument6 pagesRhodamine B Doped Silica Encapsulation Matrices PDFSutanwi LahiriPas encore d'évaluation

- Kinetics of Dissolution of UO 2 in Nitric Acid Solutions: A Multiparametric Study of The Non-Catalysed ReactionDocument15 pagesKinetics of Dissolution of UO 2 in Nitric Acid Solutions: A Multiparametric Study of The Non-Catalysed ReactionSutanwi LahiriPas encore d'évaluation

- Laser in Chem ProcessingDocument25 pagesLaser in Chem ProcessingSutanwi LahiriPas encore d'évaluation

- Colloids and Surfaces B: Biointerfaces: SciencedirectDocument9 pagesColloids and Surfaces B: Biointerfaces: SciencedirectSutanwi LahiriPas encore d'évaluation

- Comsol Pressure Distribution LeachingDocument10 pagesComsol Pressure Distribution LeachingSutanwi LahiriPas encore d'évaluation

- National Achievement Test 2 2022 2023Document67 pagesNational Achievement Test 2 2022 2023Jessie CentillasPas encore d'évaluation

- SPM Chemistry Definitions GuideDocument3 pagesSPM Chemistry Definitions GuideLooiPas encore d'évaluation

- Strand 7 - Atomic Physics (Yr 12)Document11 pagesStrand 7 - Atomic Physics (Yr 12)Sumeet KumarPas encore d'évaluation

- Syllabus TrackerDocument9 pagesSyllabus Trackersondhiyaabhi196Pas encore d'évaluation

- L5 Percentage Yield and Atom EconomyDocument58 pagesL5 Percentage Yield and Atom EconomylolPas encore d'évaluation

- GRADE-8 Most Essential Learning Competencies Budget of Work School Year 2020-2021Document2 pagesGRADE-8 Most Essential Learning Competencies Budget of Work School Year 2020-2021Rosita CayananPas encore d'évaluation

- Threshold 1 Big BangDocument18 pagesThreshold 1 Big Bangnelle de leonPas encore d'évaluation

- 2.2. Electromagnetic Radiation and Quantum Phenomena QPDocument33 pages2.2. Electromagnetic Radiation and Quantum Phenomena QPHector KennerleyPas encore d'évaluation

- On Nuclear MicrobatteriesDocument20 pagesOn Nuclear MicrobatteriesVikasmatrey50% (2)

- Periodic Classification of ElementsDocument33 pagesPeriodic Classification of ElementsHarsh GuptaPas encore d'évaluation

- SerwayCh12 Superconductivity PDFDocument52 pagesSerwayCh12 Superconductivity PDFNeenu JollyPas encore d'évaluation

- Lesson PlanDocument1 pageLesson Planapi-267920911100% (1)

- Diffusion in SolidsDocument7 pagesDiffusion in SolidsBSMK60Pas encore d'évaluation

- Electrostatics Assignment 1Document8 pagesElectrostatics Assignment 1Manoj GuptaPas encore d'évaluation

- Session-09-Periodocity and PracticeDocument43 pagesSession-09-Periodocity and PracticeMojdeh AnbarfamPas encore d'évaluation

- PNPA Admission Test CoverageDocument7 pagesPNPA Admission Test Coveragecarol indangan100% (3)

- Lesson Exemplar For VolcanoDocument7 pagesLesson Exemplar For VolcanoAngelita MenesesPas encore d'évaluation

- Structure of The Atom - Exam - Part1Document1 pageStructure of The Atom - Exam - Part1zehra giyoriPas encore d'évaluation

- Atomic Structure Notes Ohis State UniversityDocument4 pagesAtomic Structure Notes Ohis State Universityapi-246187169Pas encore d'évaluation

- Wilson 1934Document9 pagesWilson 1934Vigneshwaran KannanPas encore d'évaluation

- Atomic Structure and Periodic TableDocument51 pagesAtomic Structure and Periodic TableSoumyaa KumarPas encore d'évaluation

- Constructing Diabatic States From Adiabatic States: Extending Generalized Mulliken-Hush To Multiple Charge Centers With Boys LocalizationDocument10 pagesConstructing Diabatic States From Adiabatic States: Extending Generalized Mulliken-Hush To Multiple Charge Centers With Boys LocalizationGomsajPas encore d'évaluation

- Chemistry 5070 Class 9Document9 pagesChemistry 5070 Class 9WaqarPas encore d'évaluation

- IIT Jam Modern PhysicsDocument12 pagesIIT Jam Modern Physicsshreya debnath100% (1)

- ECE5018 Module 1n PDFDocument55 pagesECE5018 Module 1n PDFHerbert AnisionPas encore d'évaluation

- Pauli-Jung Letters - Atom and ArchetypeDocument313 pagesPauli-Jung Letters - Atom and ArchetypeMiguelAngelBroc100% (17)

- Three Main Types of Chemical BondingDocument49 pagesThree Main Types of Chemical Bondingjasumin91Pas encore d'évaluation

- Introduction - Chemistry: Released Test QuestionsDocument24 pagesIntroduction - Chemistry: Released Test QuestionsJo CesPas encore d'évaluation

- Matriculation Physics (Nucleus)Document39 pagesMatriculation Physics (Nucleus)ridwan67% (3)

- Physical Science 12 Reviewer 3RD Periodical ExamDocument12 pagesPhysical Science 12 Reviewer 3RD Periodical ExamJoshkorro GeronimoPas encore d'évaluation