Académique Documents

Professionnel Documents

Culture Documents

IMG Scheda ISOLATION-JOINTS Web PDF

Transféré par

devpal78Description originale:

Titre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

IMG Scheda ISOLATION-JOINTS Web PDF

Transféré par

devpal78Droits d'auteur :

Formats disponibles

SALES OFFICE & FORGING/

M AN UFAC T UR I N G PL A N T OFFI C E

PIPELINE INSULATING JOINT

IMG International srl is the sales office of Officine Binda & Galperti srl, flanges and insulating joints manufacturer.

Off. Binda & Galperti is a leader company which has an exclusive management system. In this way they can design

and produce insulating joints completely: from forged body, welding, painting, assembly and testing of the finished

item. Pipeline insulating joints are used both for onshore and offshore projects. Saving in the overall cost of corrosion

system is just one of the benefits of using this kind of joint.

PIPELINE INSULATING JOINT are used worldwide for

permanently controlling the flow of electrical currents or

electrically isolating pipe sections in pipes and piping systems.

Effective management of cathodic protection programs

results from the use of these highly reliable substitutes for

flanged insulating systems.

Other benefits include protection against earthing currents

at domestic and industrial premises, isolation of pipeline

cathodic protection system, and to ensure that cathodic

protection or stray currents do not cause increased corrosion.

The PIPELINE INSULATING JOINT are

designed to meet and satisfy very high

pressure services up to 20,000 psi. Upon

request, we can supply MONO-BLOCK

INSULATING JOINTS according to your

specification.

WC

THE PIPELINE INSULATING JOINT

WB

• eliminates short circuits

• eliminates field assembly WA

DFTi

ØD ±1%

+15%

ØO ±5%

• eliminates maintenance

t -12%

• is less expensive

• is coated both internally and externally

• is 100% electrically tested

DFTe

• is completely weld inspected

B ±5%

• is manufactured in accordance with =

±50

=

L

ISO 9001:2000 specifications

STANDARD DESIGN CONSTRUCTION CUSTOMER SPECIFICATION

Class 150 Class 300 Class 600 DESIGN

DN Wtk Length DN Wtk Length DN Wtk Length

2 3.9 350 2 3.9 350 2 3.9 350 • Size

3 4.8 350 3 5.5 350 3 5.5 350 • Materials

4 4.8 350 4 6.0 400 4 6.0 400 • Wall Thickness

6 5.6 400 6 7.1 500 6 7.1 500 • Fluid

8 6.4 400 8 8.2 500 8 8.2 500 • Type of installation

10 6.4 400 10 9.3 600 10 9.3 600 • Design Pressure

12 6.4 450 12 10.3 600 12 10.3 600 • Design Temperature

14 7.9 450 14 12.7 600 14 12.7 600 • Corrosion Allowance

16 9.5 500 16 12.7 700 16 12.7 700 • Dielectric Resistance

18 9.5 500 18 12.7 700 18 12.7 700 • Electric Insulation

20 9.5 600 20 12.7 800 20 12.7 800 • Design Loads

24 12.7 600 24 14.3 800 24 14.3 800 • Design Life

30 12.7 800 30 15.9 1000 30 15.9 1000 • Testing

36 14.3 900 36 19.1 1100 36 19.1 1100 • Coating

48 15.9 1000 48 20.6 1200 48 20.6 1200

ALLOWABLE LOADS

Standard Total Design Load 50 % Pipe SMYS

(Special Total Design Load 75 % Pipe SMYS)

(Special Total Design Load 95 % Pipe SMYS)

(Special Total Design Load 100 % Pipe SMYS)

INSTALLATION ABOVEGROUND / UNDERGROUND

HYDROSTATIC TEST 1.5 Times the Design Pressure PIPELINE INSULATING

1.5 to 5 KV @ 1 minute AC 50÷60 Hz

DIELECTRIC TEST

(Special 20 KV @ 1 minute AC 50÷60 Hz)

JOINT SPECIFICATION

> 100 MΩ @ 1000 Volt DC PIPELINE INSULATING JOINTS shall

ELECTRIC INSULATION TEST

( Special > 100 GΩ @ 5000 Volt DC ) be boltless and completely factory

NDE TEST

WA-WB-WC: MT & UT, Bevel Ends MT assembled in accordance with the

According to ASME V appropriate requirements of ASME,

WELDS WA-WB-WC: According To ASME IX ASTM, API, DIN and BS codes.

CERTIFICATION EN 10204 - 3.1 ( EN 10204 - 3.2 if request ) Insulation material is a thermosetting

Suitable for flow media such as natural gas, fibreglass epoxy material. NEMA

crude oil, kerosene, gasoline, propane, G10/11. Sealing system shall be by

butane, coal gas, ethylene, nitrogen and

two Standard “O” ring seals. Interior

drinking water - Media such as sour gas and

APPLICATION and exterior coating by epoxy with a

oxygen require special material and design.

Standard versions up to maximum + 80°C thickness of 150 microns.

constant temperature - Special versions for - Dielectric Resistance @ 5 KV

district heating pipelines up to +150°C.

- Isolation Resistance > 50 MOhm

- Design According

to ANSI/ASME

B31.3/4/8

- Dimens. ASME VIII

Div.I

IMG INTERNATIONAL srl OFFICINE BINDA & GALPERTI Srl

SALES OFFICE FORGING - MANUFACTURING PLANT

Via Masero, 57 Via Roma, 43

10010 SCARMAGNO (TO) - ITALY 23813 CORTENOVA (LC) - ITALY

Phone +39 0125.639289 Phone +39 0341.901333

Fax +39 0125.712640 Fax +39 0341.901300

info@imginternational.it obg@officinebindaegalperti.com www.imginternational.it

Vous aimerez peut-être aussi

- (Catalog) Durus SealsDocument159 pages(Catalog) Durus Sealssmart holyboyPas encore d'évaluation

- Saej 10 V 003Document4 pagesSaej 10 V 003neojfbPas encore d'évaluation

- Man FXM FKM Motors PDFDocument166 pagesMan FXM FKM Motors PDFPaun AlPas encore d'évaluation

- In-Service Inspection For Coal Handling Plant of Thermal Power Stations Using NDTDocument4 pagesIn-Service Inspection For Coal Handling Plant of Thermal Power Stations Using NDTPravivVivpraPas encore d'évaluation

- 4 Foundation For Static EquipmentDocument30 pages4 Foundation For Static Equipmentdevpal78100% (1)

- HLX5 Drifter Failure Guide (Rev3)Document57 pagesHLX5 Drifter Failure Guide (Rev3)Leo67% (3)

- Low Voltage ABC FittingsDocument22 pagesLow Voltage ABC FittingskingoglobalPas encore d'évaluation

- Trench Wall Design SheetDocument7 pagesTrench Wall Design SheetramyaPas encore d'évaluation

- Equipment Definition: Operation and Maintenance ManualDocument17 pagesEquipment Definition: Operation and Maintenance ManualgodwinPas encore d'évaluation

- DEP 31.10.00.10 Material Control and Verification (PMI)Document25 pagesDEP 31.10.00.10 Material Control and Verification (PMI)MN VenkatesanPas encore d'évaluation

- T Panda 47Document78 pagesT Panda 47Nijam NihmathPas encore d'évaluation

- Draka CatalogDocument50 pagesDraka Catalogbodiemcd100% (1)

- Specification of RCC: Submitted To:-Prof R.J.Shah Submitted By: - Madhav Purohit 000RDMTCE1920007Document39 pagesSpecification of RCC: Submitted To:-Prof R.J.Shah Submitted By: - Madhav Purohit 000RDMTCE1920007Madhav PurohitPas encore d'évaluation

- ECISGROUP - Cooling Tower Water Treatment - Rev1Document31 pagesECISGROUP - Cooling Tower Water Treatment - Rev1Ecisgroup100% (2)

- Piling HandbookDocument390 pagesPiling HandbooksuvraPas encore d'évaluation

- Prezentare CIBSE PT EN806Document56 pagesPrezentare CIBSE PT EN806danateoPas encore d'évaluation

- API 570 Exam June 1Document24 pagesAPI 570 Exam June 1Sudarshan79% (14)

- Leptis MagnaDocument25 pagesLeptis Magnadevpal78Pas encore d'évaluation

- Mos3200 Bs 2000m FP Product DataDocument4 pagesMos3200 Bs 2000m FP Product DataJeromePas encore d'évaluation

- Vishay g200Document7 pagesVishay g200rogerPas encore d'évaluation

- O-Rings Static SealsDocument50 pagesO-Rings Static Sealskamal arabPas encore d'évaluation

- Maskell GRP Pipe Rev1Document5 pagesMaskell GRP Pipe Rev1Satria fajarPas encore d'évaluation

- PDF Version!: Flowtite GRP Pipe SystemsDocument12 pagesPDF Version!: Flowtite GRP Pipe Systemsshrikant tilekarPas encore d'évaluation

- Des Case Spin On Filter Element Data Sheet 2020Document2 pagesDes Case Spin On Filter Element Data Sheet 2020Alaa saidPas encore d'évaluation

- FLOWTITE Pipe Systems - For Hydropower and Penstock Applications - enDocument12 pagesFLOWTITE Pipe Systems - For Hydropower and Penstock Applications - enNolo ReenPas encore d'évaluation

- KAT-A 5022 Klamflex VARIplus-DC Dedicated Coupling 16-01-2014 ENDocument3 pagesKAT-A 5022 Klamflex VARIplus-DC Dedicated Coupling 16-01-2014 ENSonny LuuPas encore d'évaluation

- Hydrostop AWDocument2 pagesHydrostop AWosama mohPas encore d'évaluation

- Sika Waterbar o VNDocument3 pagesSika Waterbar o VNSlamet Tri UsadhaPas encore d'évaluation

- GTOI Non-Capacitive Type Bushings, 12 - 36kV: Your Independent Bushing and Busbar SupplierDocument4 pagesGTOI Non-Capacitive Type Bushings, 12 - 36kV: Your Independent Bushing and Busbar SupplierKhalid AzmyPas encore d'évaluation

- Instructions: For Installation, Commissioning, Operation & MaintenanceDocument32 pagesInstructions: For Installation, Commissioning, Operation & Maintenanceseil iexPas encore d'évaluation

- DEL Assembly InstructionsDocument8 pagesDEL Assembly InstructionsKarl Ove BlindheimPas encore d'évaluation

- PVC Cable TrayDocument24 pagesPVC Cable TrayDavidPas encore d'évaluation

- Bending PVC ASTM D3034Document4 pagesBending PVC ASTM D3034Oscar PachecoPas encore d'évaluation

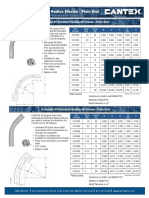

- CANTEX Schedule 80 ElbowDocument2 pagesCANTEX Schedule 80 Elboweng laythPas encore d'évaluation

- GRS Installation ManualDocument38 pagesGRS Installation Manualkevan.perumalPas encore d'évaluation

- Taco Brazed Plate HX Install ManualDocument11 pagesTaco Brazed Plate HX Install ManualTEMPPas encore d'évaluation

- NSPB e 1212Document12 pagesNSPB e 1212mazzoffaPas encore d'évaluation

- Sika Waterbars Pds enDocument4 pagesSika Waterbars Pds enYutthakorn Ngo-charitPas encore d'évaluation

- Sika Waterbars Pds enDocument4 pagesSika Waterbars Pds enerhansinattraPas encore d'évaluation

- Sika Waterbar V VNDocument3 pagesSika Waterbar V VNSlamet Tri UsadhaPas encore d'évaluation

- DV Range: Waste Water Volute PumpsDocument8 pagesDV Range: Waste Water Volute PumpsHamza HariatePas encore d'évaluation

- Hyundai Heavy Industries - Gas Insulated SwitchgearDocument25 pagesHyundai Heavy Industries - Gas Insulated SwitchgearbadbenzationPas encore d'évaluation

- Sika Waterbar o VNDocument3 pagesSika Waterbar o VNIpraPas encore d'évaluation

- Stay Cable Specifications SummaryDocument21 pagesStay Cable Specifications SummaryManukantShrotriyaPas encore d'évaluation

- Sikla Pipe Support Catalogue 07Document98 pagesSikla Pipe Support Catalogue 07ShubiPas encore d'évaluation

- Sika Waterbars®Document4 pagesSika Waterbars®Abdulghani AsalaiPas encore d'évaluation

- Sikaflex ConstructionapDocument4 pagesSikaflex ConstructionapYe Min AungPas encore d'évaluation

- Sikaflex® Construction AP: Product Data SheetDocument4 pagesSikaflex® Construction AP: Product Data Sheetneo2jatiPas encore d'évaluation

- Sikaflex 140construction en ID 02 2023 1 1 PDFDocument4 pagesSikaflex 140construction en ID 02 2023 1 1 PDFcahyo hutomoPas encore d'évaluation

- 2035 XX SMDocument3 pages2035 XX SMDDAANNIIEELLPas encore d'évaluation

- Sikaflex ProDocument4 pagesSikaflex ProAmr Adel HameedPas encore d'évaluation

- Sikasil 715 WsDocument4 pagesSikasil 715 WskhalidPas encore d'évaluation

- 0361tq Bs 638 Orange Welding CableDocument3 pages0361tq Bs 638 Orange Welding CableAdnan KhanPas encore d'évaluation

- K SDB en 07 02Document6 pagesK SDB en 07 02victorPas encore d'évaluation

- Branch v06Document4 pagesBranch v06Kerr AgotPas encore d'évaluation

- Brochure Alfa 2019Document15 pagesBrochure Alfa 2019ClarkFedele27Pas encore d'évaluation

- Twinflex PVC Battery CableDocument2 pagesTwinflex PVC Battery Cablerahul_2005Pas encore d'évaluation

- Van Bư M Tay DN250-500Document8 pagesVan Bư M Tay DN250-500Minh nhut LưuPas encore d'évaluation

- 12 kV-BS-6622Document4 pages12 kV-BS-6622Fahad UsmanPas encore d'évaluation

- KAT-A 1030 EKOplusWater en 07-11Document20 pagesKAT-A 1030 EKOplusWater en 07-11Sonny LuuPas encore d'évaluation

- KAT-A 1030 EKOplusWater en 07-11Document20 pagesKAT-A 1030 EKOplusWater en 07-11Jeffrey Calinao ManaloPas encore d'évaluation

- Gate Valve VAGDocument5 pagesGate Valve VAGrosiPas encore d'évaluation

- Brochure - SIL PT BarDocument4 pagesBrochure - SIL PT Barprashant patilPas encore d'évaluation

- 02 Circular Duct SystemsDocument42 pages02 Circular Duct SystemsDiki PrayogoPas encore d'évaluation

- Sikaflex®-717 WS: Product Data SheetDocument4 pagesSikaflex®-717 WS: Product Data SheetbeerPas encore d'évaluation

- C44A, 400 - 1,500 VDC/250 - 630 VAC, For General Purpose & SnubbingDocument8 pagesC44A, 400 - 1,500 VDC/250 - 630 VAC, For General Purpose & SnubbingRaphael Santos do NascimentoPas encore d'évaluation

- Wilson Cables - FR.Document12 pagesWilson Cables - FR.ថុន មករាPas encore d'évaluation

- Vishay Bccomponents: FeaturesDocument18 pagesVishay Bccomponents: FeaturesJose cuelloPas encore d'évaluation

- S Series Gap-Kap: Vishay BccomponentsDocument4 pagesS Series Gap-Kap: Vishay BccomponentsShibu Kumar SPas encore d'évaluation

- PS1909 SpfeDocument2 pagesPS1909 SpfeCelular Oil Control 05Pas encore d'évaluation

- WaboElastoFlex Park 0408Document4 pagesWaboElastoFlex Park 0408Cristhian Alfonso Mandujano PérezPas encore d'évaluation

- PLP AEM Distribution SwitchgearDocument15 pagesPLP AEM Distribution SwitchgearturintoPas encore d'évaluation

- 2017 Series: Features ApplicationsDocument4 pages2017 Series: Features ApplicationsCarlos MoralesPas encore d'évaluation

- C 015 Arch Shade B مظلة سيارات قوسDocument4 pagesC 015 Arch Shade B مظلة سيارات قوسGameTasticPas encore d'évaluation

- Kuch Bhi On EMI - KBE 3 Months Offer Terms and ConditionsDocument1 pageKuch Bhi On EMI - KBE 3 Months Offer Terms and Conditionsdevpal78Pas encore d'évaluation

- Flexpip4 PDFDocument16 pagesFlexpip4 PDFdevpal78Pas encore d'évaluation

- Optic Nerve AtrophyDocument1 pageOptic Nerve Atrophydevpal78Pas encore d'évaluation

- Tax VAHAN 4 01 PDFDocument1 pageTax VAHAN 4 01 PDFdevpal78Pas encore d'évaluation

- Tax VAHAN 4 01Document1 pageTax VAHAN 4 01devpal78Pas encore d'évaluation

- OptiPlex 330 (Late 2007) DriversDocument2 pagesOptiPlex 330 (Late 2007) Driversdevpal78Pas encore d'évaluation

- Premise Consumer BrochureDocument10 pagesPremise Consumer Brochuredevpal78Pas encore d'évaluation

- Premise Delivers Termite EliminationDocument4 pagesPremise Delivers Termite Eliminationdevpal78Pas encore d'évaluation

- Terms and Conditions For SavingsDocument10 pagesTerms and Conditions For Savingsdevpal78Pas encore d'évaluation

- Hydrogen Probe InsertsDocument2 pagesHydrogen Probe Insertsumarkhalid321Pas encore d'évaluation

- Tube Catalogue AnitaDocument64 pagesTube Catalogue AnitaChinnaraja GandhiPas encore d'évaluation

- Workshop ManualDocument26 pagesWorkshop Manuallucy.morrisPas encore d'évaluation

- 354215-Aug 2014Document121 pages354215-Aug 2014Alemgilg100% (1)

- Arcelormittal Dofasco Scrap Specifications and Requirements: Revision Date: January 2017Document37 pagesArcelormittal Dofasco Scrap Specifications and Requirements: Revision Date: January 2017Tanveer us zamanPas encore d'évaluation

- Power Point Presentation - Template For Review - M.Tech RevisedDocument16 pagesPower Point Presentation - Template For Review - M.Tech RevisedajjuPas encore d'évaluation

- (Doi 10.4043/7730-MS) Lane, M. McNamara, J.F. Gibson, R. Tyrer, A.Document10 pages(Doi 10.4043/7730-MS) Lane, M. McNamara, J.F. Gibson, R. Tyrer, A.thlim19078656Pas encore d'évaluation

- Drum Scrubber 100: Product BulletinDocument8 pagesDrum Scrubber 100: Product Bulletinفاعل الخيرPas encore d'évaluation

- Catalogo DTH SandvikDocument49 pagesCatalogo DTH SandvikStevenPas encore d'évaluation

- AURA Gas-Controls Brochure 9461Document4 pagesAURA Gas-Controls Brochure 9461XavierPas encore d'évaluation

- Polytechnic First Year Syllabus: Semester IDocument25 pagesPolytechnic First Year Syllabus: Semester IPremchand PremchandPas encore d'évaluation

- Astm C547Document7 pagesAstm C547DilaFirizqinaPas encore d'évaluation

- Unit 13 (E)Document34 pagesUnit 13 (E)Kurtis LEEPas encore d'évaluation

- 62bf83AA 98169Document56 pages62bf83AA 98169fercomandoPas encore d'évaluation

- Brochure PREDICTDocument6 pagesBrochure PREDICTAlex ArmendarizPas encore d'évaluation

- 5 Ddcet Syllabus Engineering1702910382 - 231218 - 203535Document9 pages5 Ddcet Syllabus Engineering1702910382 - 231218 - 203535alonewarrior2004Pas encore d'évaluation

- Venus Magma PlusDocument2 pagesVenus Magma Plusdeepakshi.inPas encore d'évaluation

- DELLON GX Series Videoscope ManualDocument38 pagesDELLON GX Series Videoscope ManualvictorPas encore d'évaluation