Académique Documents

Professionnel Documents

Culture Documents

Process For Preparing Rhodium Nitrate Solution.

Transféré par

Richard.nl0 évaluation0% ont trouvé ce document utile (0 vote)

52 vues3 pagesProcess for Preparing Rhodium Nitrate Solution.

Titre original

Process for Preparing Rhodium Nitrate Solution.

Copyright

© © All Rights Reserved

Formats disponibles

PDF, TXT ou lisez en ligne sur Scribd

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentProcess for Preparing Rhodium Nitrate Solution.

Droits d'auteur :

© All Rights Reserved

Formats disponibles

Téléchargez comme PDF, TXT ou lisez en ligne sur Scribd

0 évaluation0% ont trouvé ce document utile (0 vote)

52 vues3 pagesProcess For Preparing Rhodium Nitrate Solution.

Transféré par

Richard.nlProcess for Preparing Rhodium Nitrate Solution.

Droits d'auteur :

© All Rights Reserved

Formats disponibles

Téléchargez comme PDF, TXT ou lisez en ligne sur Scribd

Vous êtes sur la page 1sur 3

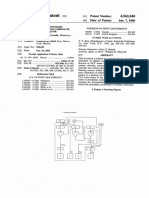

United States Patent [19] [11] Patent Number: 4,844,879

Yamazaki [45] Date of Patent: Jul. 4, 1989

[54] PROCESS FOR PREPARING RHODIUM Primary Examiner-John Doll

NITRATE SOLUTION Assistant Examiner-Wayne A. Langel

Attorney, Agent, or Firm—Klauber & Jackson

[75] Inventor: Hiroshi Yamazaki, Urayasu, Japan

[57] ABSTRACT

[73] Assignee: Tanaka Kikinzoku Kogyo K.K., Japan

A process of the present invention comprises dissolving

[21] Appl. No.: 216,125 rhodium black in sulfuric acid under heating, making

[22] Filed: Jul. 7, 1988 the pH of the said sulfuric acid solution neutral or basic

by adding an alkaline solution to the said sulfuric acid

[30] Foreign Application Priority Data solution to precipitate rhodium as rhodium hydroxide,

Jan. 12, 1988 [JP] Japan .................................. .. 62-4252 separating the rhodium hydroxide and dissolving it in

nitric acid.

[51] Int. Cl.4 ..................... .. C01F 11/14; COlG 55/00

[52] US. Cl. .................................. .. 423/395; 423/544; The process is useful for preparing the rhodium nitrate

423/592 solution which is not decomposed by heating or con

[58] Field of Search ...................... .. 423/395, 544, 592 centration to produce turbidity, and produces almost no

changes when it is allowed to stand at room tempera

[56] References Cited ture for a long period of time. Since the rhodium nitrate

U.S. PATENT DOCUMENTS solution has the excellent heat-stability and endurance

1,135,785 4/1915 Frasch ............................... .. 423/592

for long term storage, the said solution can be employed

3,425,801 2/1969 Stowe ................................ .. 423/544 as a useful rhodium source which does not decompose

for a variety of applications.

FOREIGN PATENT DOCUMENTS

744776 10/1966 Canada .............................. .. 423/592 3 Claims, No Drawings

4,844,879

1 2

prepared from such a rhodium source may be used in

PROCESS FOR PREPARING RHODIUM NITRATE the procedures of the invention after separation and

SOLUTION drying, the wet rhodium black is preferably employed

as it is without separation procedure for reducing the

BACKGROUND OF INVENTION number of steps.

This invention relates to a process for preparing a Then the rhodium black is dissolved in sulfuric acid

rhodium nitrate solution employed for producing a which is preferably concentrated sulfuric acid of 98% in

catalyst having the excellent stability and the like. such a heat stable vessel as a crucible made of quartz.

conventionally, in order to prepare a rhodium nitrate The amount of the rhodium black employed is prefera

solution, a caustic soda aqueous solution, aqueous am bly the one which is dissolved in the sulfuric acid to lead

monia or the like is added to a rhodium chloride solu it to saturation.

tion to form rhodium hydroxide therein, and the result Then the sulfuric acid solution in which the rhodium

ing precipitate is dissolved in nitric acid to prepare black has been dissolved is strongly heated at a rela

rhodium nitrate. tively high temperature, for example, at 260° to 330° C.

However, the rhodium nitrate solution prepared ac for 0.2 to 2.0 hours, preferably for 0.5 to 1.0 hour, to

cording to the above process produces a colloidal pre convert the rhodium black into rhodium sulfate. In this

cipitate to make itself turbid when the solution is conversion, it is expected that the sulfuric acid which is

heated. The solution also produces a similar colloidal strongly heated completely converts the rhodium black

precipitate even at room temperature when it is allowed into the rhodium sulfate by its strong oxidative effect as

to stand for one week or more. Although the reason the fuming sulfuric acid can do. Even if, in this stage, part

precipitate is formed is not necessarily apparent, the of an insoluble substance such as unreacted rhodium

following ones are considered to be acceptable. That is, black remains, it may be harmless.

(i) part of the rhodium nitrate is converted into rhodium After this conversion, it is preferable to remove the

hydroxide through hydrolysis; (ii) since the rhodium precipitates such as the unreacted rhodium black and

hydroxide is not completely converted into the rhodium impurities by ?ltering the heat-treated solution. How

nitrate by simply dissolving the rhodium hydroxide in ever, the ?ltration can be omitted if these precipitates

the nitric acid, the rhodium hydroxide which easily do not exist.

precipitates remains in the solution so that the hydrox Subsequently, the rhodium is made to be precipitated

ide deposits with the elapse of time; and (iii) the conver as rhodium hydroxide by adding an alkaline solution to

sion of the rhodium chloride to the rhodium hydroxide the above rhodium sulfate solution so that the sulfuric

is insuf?cient so that the rhodium hydroxide contains

acid is neutralized and further the solution is made neu

impurities which promote the deposition of the rhodium tral or basic. The alkaline solution employed may not be

nitrate. The said decomposition and the like lower such

a characteristic of rhodium as catalyst efficiency. especially limited. It is sufficient to employ an ordinar

Heating or concentration of a rhodium nitrate solu ily used solution such as an caustic sodaaqueous solu

tion may be necessary depending on a purpose of use, tion and aqueous ammonia. The amount of the alkaline

and further the longer term storage may be required. solution to be added is preferably the minimum amount

The conventionally prepared rhodium nitrate solution which is sufficient to precipitate the rhodium hydroxide

can not keep its characteristic in such conditions. almost completely, and the absolute amount changes

with the amount of the dissolved rhodium. The alkaline

SUMMARY OF INVENTION solution may be added until the pH of the solution is

It is an object of the present invention to provide a made to be 7 to 9.

process for preparing a rhodium nitrate solution which The precipitated rhodium hydroxide is then sepa

is stable and produces substantially no precipitates upon rated from the solution by an appropriate means such as

heating or concentration. 45 filtration, and if necessary the rhodium hydroxide is

It is another object of the invention to provide a washed with pure water so that the above alkaline solu

process for preparing a rhodium nitrate solution which tion and the impurities are removed.

produces substantially no precipitates when it is al Nitric acid is then added to the separated rhodium

lowed to stand at room temperature for a long period of hydroxide to dissolve the hydroxide to form a rhodium

time. 50 nitrate solution.

The present invention is a process for preparing a The rhodium nitrate solution prepared according to

rhodium‘nitrate solution which comprises dissolving the present invention produces substantially no turbid

rhodium black in sulfuric acid under heating, making ity by producing the precipitates upon heating up to

the pH of the said sulfuric acid solution neutral or basic 110° C., and similarly produces no turbidity when it is

by adding an alkaline solution to the said sulfuric acid allowed to stand at room temperature for about 15

solution to precipitate rhodium as rhodium hydroxide, weeks.

separating the rhodium hydroxide and dissolving it in Although the accurate reason the rhodium nitrate

nitric acid. solution prepared according to the invention produces

no precipitates upon heating or standing of a long per

DETAILED DESCRIPTION iod of time remains uncertain, it may be conjectured

The starting material for preparing a rhodium nitrate that, when the process of this invention is compared

solution according to the present invention is rhodium with the conventional process, the rhodium hydroxide

black. Commercially available rhodium black may be prepared through the series of steps which comprises

employed as the starting rhodium black, or the rhodium the step of adding the rhodium black to the sulfuric acid

black may be prepared from other rhodium sources. 65 under heating and the step of converting the resulting

The rhodium black can be made by adding a reductant rhodium sulfate into the rhodium hydroxide with the

to a rhodium chloride solution, an example of one of the alkaline solution, in each step of which the reaction

other rhodium sources. Although the rhodium black suf?ciently proceeds, contains substantially no impuri

4,844,879

3 4

ties so that the ?nal product, the rhodium nitrate solu 62% nitric acid to obtain 3.5 mol/l of a rhodium nitrate

tion, contains substantially no substances which are solution. The yield was about 70%.

likely to precipitate. When the rhodium nitrate solution was heated to 110°

The process of the invention, in preparation of the C. for 60 minutes, no turbidity was produced. When the

rhodium nitrate solution from the rhodium black, com temperature was further raised to 120° C. and the solu

prises dissolving the rhodium black in the concentrated tion was heated for 120 minutes, slight turbidity was

sulfuric acid under heating, making the pH of the said observed.

sulfuric acid solution neutral or basic by adding the When the rh'odium nitrate solution was allowed to

alkaline solution to the said sulfuric acid solution to stand at room temperature for 15 weeks, no turbidity

precipitate rhodium as rhodium hydroxide, separating was observed, and slight turbidity was observed after 25

the rhodium hydroxide and dissolving it in nitric acid. weeks.

The thus prepared rhodium nitrate solution is not de

composed upon heating or concentration to produce COMPARATIVE EXAMPLE

turbidity, and produces almost no changes when it is After rhodium hydroxide was precipitated by adding

allowed to stand at room temperature for a long period a caustic soda aqueous solution to a rhodium chloride

of time. Since the rhodium nitrate solution has the ex solution, the precipitate was separated by ?ltration. To

cellent heat-stability and endurance for long term stor~ 100 g of this wet rhodium hydroxide was added 40 ml of

age, the said solution can be employed as a useful rho 62% nitric acid to form a rhodium nitrate solution.

dium source which does not decompose for a variety of When the solution was heated to 105° C., brown turbid

applications. 20 ity was formed. Further when the solution was allowed

The present invention will now be described in detail to stand at room temperature of 20° to 25° C. for two

in connection with the following Example and the weeks, the formation of black-brownish turbidity was

Comparative Example which are intended to be illustra observed.

tive of the invention but not limitative. What is claimed is:

25 1. A process for preparing a rhodium nitrate solution

EXAMPLE which comprises dissolving rhodium black in sulfuric

About 250 g of wet rhodium black which had been acid under heating, making the pH of the said sulfuric

prepared by reducing a rhodium chloride solution by acid solution neutral or basic by adding an alkaline

means of a caustic soda aqueous solution and hydrazine solution to the said sulfuric acid solution to precipitate

was put into a crucible made of quartz, and was dis 30 rhodium as rhodium hydroxide, separating the rhodium

solved in 300 ml of concentrated sulfuric acid (guaran hydroxide and dissolving it in nitric acid.

teed reagent, 98%) and was strongly heated for one and 2. The process as claimed in claim 1, wherein the

half hours. Subsequently, the solution was ?ltered, and heating of the sulfuric acid solution is carried out at 260°

aqueous ammonia (guaranteed reagent, 28%) was to 330° C. for 0.2 to 2.0 hours.

added to the solution until the pH thereof became 8 to 3. The process as claimed in claim 1, wherein the

9 to produce a yellow precipitate. After the solution alkaline solution is a caustic soda aqueous solution and

was ?ltered, the resultant precipitate was washed with /or aqueous ammonia.

* * * * *

pure water. The precipitate was dissolved in 150 ml of

40

45

55

60

65

Vous aimerez peut-être aussi

- Modern Carbonylation MethodsD'EverandModern Carbonylation MethodsLászló KollárPas encore d'évaluation

- Production of Sodium DithioniteDocument10 pagesProduction of Sodium DithioniteDhaval PadaliaPas encore d'évaluation

- Natural Gas Processing: Technology and Engineering DesignD'EverandNatural Gas Processing: Technology and Engineering DesignÉvaluation : 5 sur 5 étoiles5/5 (8)

- United States Patent: ABSTRACT: A Free-Flowing Crystalline Noncaking TrisodiumDocument3 pagesUnited States Patent: ABSTRACT: A Free-Flowing Crystalline Noncaking Trisodiumkamil_vidPas encore d'évaluation

- Deactivation of Heavy Oil Hydroprocessing Catalysts: Fundamentals and ModelingD'EverandDeactivation of Heavy Oil Hydroprocessing Catalysts: Fundamentals and ModelingPas encore d'évaluation

- Lecture 20 Sodium Thiosulfate PDFDocument5 pagesLecture 20 Sodium Thiosulfate PDFPutri AzzahraPas encore d'évaluation

- Lecture 20 Sodium ThiosulfateDocument5 pagesLecture 20 Sodium ThiosulfateVarsha Kankani100% (1)

- Patente 2Document3 pagesPatente 2Saul MamaniPas encore d'évaluation

- Us5270023 PDFDocument8 pagesUs5270023 PDFYustinus Selis ToronPas encore d'évaluation

- 3 Sodium ThiosalphateDocument8 pages3 Sodium ThiosalphateRohan GohilPas encore d'évaluation

- United States Patent (19) : Assignee: Pennwalt Corporation, PhiladelphiaDocument3 pagesUnited States Patent (19) : Assignee: Pennwalt Corporation, PhiladelphiaPatricio CaboPas encore d'évaluation

- United States Patent Office: Patented Sept. 5, 1950Document2 pagesUnited States Patent Office: Patented Sept. 5, 1950ari factoryPas encore d'évaluation

- Us 3607021Document4 pagesUs 3607021haviedPas encore d'évaluation

- Patent On Peroxide Stablization AlkalineDocument5 pagesPatent On Peroxide Stablization AlkalineparagPas encore d'évaluation

- Sulfur and Sulfuric Acid-UpctDocument22 pagesSulfur and Sulfuric Acid-UpctRohan GohilPas encore d'évaluation

- Sodium HydroxideDocument9 pagesSodium HydroxideMuizz RasaniPas encore d'évaluation

- KOH From K2SO4 and NaOHDocument3 pagesKOH From K2SO4 and NaOHamirPas encore d'évaluation

- Lecture 23 Sodium SulfiteDocument5 pagesLecture 23 Sodium Sulfiteselvaraj5natesanPas encore d'évaluation

- Production of Sulphuric AcidDocument3 pagesProduction of Sulphuric AcidShahid Mehmud100% (1)

- Group 01Document34 pagesGroup 01Muhammad MugheeraPas encore d'évaluation

- 10 Chemistry ABS 6Document2 pages10 Chemistry ABS 6Aryan GuptaPas encore d'évaluation

- Us 4319922Document7 pagesUs 4319922borgiamatricePas encore d'évaluation

- United States Patent 0: Patented Jan. 26, 1965 2Document5 pagesUnited States Patent 0: Patented Jan. 26, 1965 2Waheed ZebPas encore d'évaluation

- 1Document19 pages1Rayadi Sinaga100% (1)

- Preparation of Cupric HydroxideDocument5 pagesPreparation of Cupric HydroxideAnonymous PdsQnCAyPas encore d'évaluation

- Project Agd PDFDocument111 pagesProject Agd PDFNikhil PraneshPas encore d'évaluation

- 2015-02-17-Port CityDocument5 pages2015-02-17-Port CityprabathnilanPas encore d'évaluation

- United States Patent (19.: 54) - Stabilizer System For CommercialDocument4 pagesUnited States Patent (19.: 54) - Stabilizer System For CommercialcholoqfPas encore d'évaluation

- Sodium Hydride / Sodium Hydroxide 867Document3 pagesSodium Hydride / Sodium Hydroxide 867AHMEDPas encore d'évaluation

- ' Umted States Patent (19) (11) Patent Number: 4,954,330 Ziegenhain (45) Date of Patent: Sep. 4, 1990Document4 pages' Umted States Patent (19) (11) Patent Number: 4,954,330 Ziegenhain (45) Date of Patent: Sep. 4, 1990Waheed ZebPas encore d'évaluation

- AJCA - Volume 3 - Issue 2 - Pages 159-164Document6 pagesAJCA - Volume 3 - Issue 2 - Pages 159-164Abdulrahman JradiPas encore d'évaluation

- Sodium Hydroxide Production With A Calcium CarbonaDocument7 pagesSodium Hydroxide Production With A Calcium CarbonaFebri SandiPas encore d'évaluation

- Us 4772757Document8 pagesUs 4772757Naomi HerreraPas encore d'évaluation

- Chemistry Manufactured Substances in IndustryDocument81 pagesChemistry Manufactured Substances in Industrynabiellahuda88% (8)

- IntroductionDocument10 pagesIntroductionAmith Singh J100% (1)

- United States Patent (191 (11) Patent Number: 5,270,023: May Et A1. (45) Date of Patent: Dec. 14, 1993Document8 pagesUnited States Patent (191 (11) Patent Number: 5,270,023: May Et A1. (45) Date of Patent: Dec. 14, 1993Yustinus Selis ToronPas encore d'évaluation

- Methods of Sulphuric AcidDocument18 pagesMethods of Sulphuric AcidKrushit PatelPas encore d'évaluation

- US5364986Document4 pagesUS5364986Alam IlhamPas encore d'évaluation

- Sodium CarbonateDocument6 pagesSodium CarbonateLihini NimsaraPas encore d'évaluation

- DCDADocument23 pagesDCDARushikesh Dhapse80% (5)

- Us 2427642Document2 pagesUs 2427642SatyamSahuPas encore d'évaluation

- Us4643848 Fumaric RosinDocument5 pagesUs4643848 Fumaric RosinPudien MuhamadPas encore d'évaluation

- 2023-12-Jurnal - Internasional - Donda DKKDocument10 pages2023-12-Jurnal - Internasional - Donda DKKDimas FranantaPas encore d'évaluation

- Sodium Percarbonate PDFDocument16 pagesSodium Percarbonate PDFillpraydo2Pas encore d'évaluation

- Manufactured Substances in IndustryDocument18 pagesManufactured Substances in IndustryjhlkpPas encore d'évaluation

- Daligdig & Dibartun - Salt and Miscellaneous Compounds PDFDocument66 pagesDaligdig & Dibartun - Salt and Miscellaneous Compounds PDFsidick dibaratunPas encore d'évaluation

- US5352424Document5 pagesUS5352424Ipalma 3Pas encore d'évaluation

- Chemistry Project: Name: Azad Abdullahi Class: Ss3S Teacher: Mr. AdekunleDocument14 pagesChemistry Project: Name: Azad Abdullahi Class: Ss3S Teacher: Mr. Adekunleapi-383198550% (2)

- Us 4501724Document7 pagesUs 4501724DARWIN STALIN ALCACIEGA PILCOPas encore d'évaluation

- SemicarbazideDocument3 pagesSemicarbazideshenn0Pas encore d'évaluation

- Acids Bases and SaltsDocument4 pagesAcids Bases and SaltsMandeep SinghPas encore d'évaluation

- United States Patent (19) : Rodriguez-LeonDocument5 pagesUnited States Patent (19) : Rodriguez-LeonAshir ShahbazPas encore d'évaluation

- JPSTDocument16 pagesJPSTYarisa Villar BonilloPas encore d'évaluation

- Us 2375054Document3 pagesUs 2375054haviedPas encore d'évaluation

- LTBFP NaOH Etch PDFDocument4 pagesLTBFP NaOH Etch PDFsayyadmannanPas encore d'évaluation

- 16 - Impurities Removal From Liqued FuelsDocument21 pages16 - Impurities Removal From Liqued FuelsSHREEPas encore d'évaluation

- NaOH UllmanDocument12 pagesNaOH UllmanelhamPas encore d'évaluation

- 10.1.polendo (Additional Patent)Document11 pages10.1.polendo (Additional Patent)Rima AmaliaPas encore d'évaluation

- Sodium Hydroxide: 1 PropertiesDocument9 pagesSodium Hydroxide: 1 PropertiesApolloMPPas encore d'évaluation

- Small Chemical Laboratory 1920.Document146 pagesSmall Chemical Laboratory 1920.Richard.nlPas encore d'évaluation

- Platinum Silver Alloys.Document28 pagesPlatinum Silver Alloys.Richard.nlPas encore d'évaluation

- Hoke, A Young Woman.Document1 pageHoke, A Young Woman.Richard.nlPas encore d'évaluation

- Compressed Air Magazine, Page 26Document56 pagesCompressed Air Magazine, Page 26Richard.nlPas encore d'évaluation

- Qualitative Chemical Analysis 1904.Document512 pagesQualitative Chemical Analysis 1904.Richard.nlPas encore d'évaluation

- Calm M. Hoke, Page 5.Document5 pagesCalm M. Hoke, Page 5.Richard.nlPas encore d'évaluation

- Ansell 8thEditionChemicalResistanceGuideDocument8 pagesAnsell 8thEditionChemicalResistanceGuideAndry De Jesus GraulauPas encore d'évaluation

- Chemical Etching and Ion Milling of Uranium Dioxide-Tungsten Unidirectional Composites.Document95 pagesChemical Etching and Ion Milling of Uranium Dioxide-Tungsten Unidirectional Composites.Richard.nlPas encore d'évaluation

- 252931791-The-Metallurgy-of-Gold of Eissler PDFDocument775 pages252931791-The-Metallurgy-of-Gold of Eissler PDFAnonymous FfIxH2o9100% (1)

- Laboratory Waste Management Guide.Document66 pagesLaboratory Waste Management Guide.Richard.nlPas encore d'évaluation

- Electro-Metallurgy (1910)Document522 pagesElectro-Metallurgy (1910)Richard.nlPas encore d'évaluation

- A Manual On Dental Metallurgy.Document334 pagesA Manual On Dental Metallurgy.Richard.nlPas encore d'évaluation

- Escrap Refiners Gold Mining Guide - Rev 0.7.1Document0 pageEscrap Refiners Gold Mining Guide - Rev 0.7.1dorutzu67% (3)

- Lab Safety Inspection Checklist GuideDocument5 pagesLab Safety Inspection Checklist GuideRichard.nlPas encore d'évaluation

- Acid Worksheet Silver Cell.Document1 pageAcid Worksheet Silver Cell.Richard.nlPas encore d'évaluation

- Whatman Filter Paper Guide en VWR PDFDocument4 pagesWhatman Filter Paper Guide en VWR PDFjeneveuxpasPas encore d'évaluation

- Metallurgyofgold00roserich PDFDocument616 pagesMetallurgyofgold00roserich PDFRocha-85Pas encore d'évaluation

- Kinetics of Silver Dissolution in Nitric Acid.Document5 pagesKinetics of Silver Dissolution in Nitric Acid.Richard.nlPas encore d'évaluation

- All About Silver Button BatteriesDocument7 pagesAll About Silver Button BatteriesAFLAC ............Pas encore d'évaluation

- Button Cell Collection.Document5 pagesButton Cell Collection.Richard.nlPas encore d'évaluation

- Fire Assay Sheppard y Dietricht PDFDocument296 pagesFire Assay Sheppard y Dietricht PDFAnonymous FfIxH2o9Pas encore d'évaluation

- Ensayes Al FuegoDocument274 pagesEnsayes Al FuegoFer Garcia VelaPas encore d'évaluation

- Furnace Temperature Colors.Document1 pageFurnace Temperature Colors.Richard.nlPas encore d'évaluation

- Critical Review Six Platinum Metals.Document35 pagesCritical Review Six Platinum Metals.Richard.nl100% (1)

- FnoxdocDocument57 pagesFnoxdocSanchit Pravin ChitrePas encore d'évaluation

- Applications of Electrolysis in Chemical Industry.Document176 pagesApplications of Electrolysis in Chemical Industry.Richard.nlPas encore d'évaluation

- Catalytic Converter Rhodium Leach.Document7 pagesCatalytic Converter Rhodium Leach.Richard.nlPas encore d'évaluation

- The Art of Electrolytic Separation of Metals.Document328 pagesThe Art of Electrolytic Separation of Metals.Richard.nlPas encore d'évaluation

- The Metallurgy of The Common Metals.Document650 pagesThe Metallurgy of The Common Metals.Richard.nlPas encore d'évaluation

- Copper Refining.Document232 pagesCopper Refining.Richard.nlPas encore d'évaluation

- Food-Chemistry 2011 128 773Document5 pagesFood-Chemistry 2011 128 773Brenda C RoldánPas encore d'évaluation

- Cape Chemistry Unit 1 Labs 2022Document22 pagesCape Chemistry Unit 1 Labs 2022Akeisha King50% (2)

- Chem ProjectDocument10 pagesChem ProjectUrfa SaleemPas encore d'évaluation

- Environmental Chemistry and Microbiology: NptelDocument57 pagesEnvironmental Chemistry and Microbiology: NptelAbhijit NathPas encore d'évaluation

- Expt.4 Isolation of Casein From Milk and Analysis of Amino AcidsDocument10 pagesExpt.4 Isolation of Casein From Milk and Analysis of Amino Acidsbenina biancaPas encore d'évaluation

- Gold Refining Forum Hanbook Vol 1Document128 pagesGold Refining Forum Hanbook Vol 1AFLAC ............96% (52)

- Qualitative Tests For Preliminary Phytochemical Screening: An OverviewDocument6 pagesQualitative Tests For Preliminary Phytochemical Screening: An OverviewJaved KhanPas encore d'évaluation

- Research Article: Synthesis of New Benzofuran-2-Carboxylic Acid DerivativesDocument8 pagesResearch Article: Synthesis of New Benzofuran-2-Carboxylic Acid Derivativesfatriani smakPas encore d'évaluation

- Solutions Book: 2016 Chemistry Written ExaminationDocument43 pagesSolutions Book: 2016 Chemistry Written Examinationfullname isPas encore d'évaluation

- Systematic Analysis of Simple Salt-3Document7 pagesSystematic Analysis of Simple Salt-3Bala Murugan.VPas encore d'évaluation

- Handling Silica in Cooling WaterDocument17 pagesHandling Silica in Cooling WaterLekhamani YadavPas encore d'évaluation

- Chemistry Viva QuestionsDocument3 pagesChemistry Viva QuestionsWill The WisePas encore d'évaluation

- June 2019 MS - Paper 2 (F) Edexcel Chemistry GCSEDocument34 pagesJune 2019 MS - Paper 2 (F) Edexcel Chemistry GCSETariq JacksonPas encore d'évaluation

- CHEM 3L Group 4 Cation 1Document6 pagesCHEM 3L Group 4 Cation 1Beatrice AlejePas encore d'évaluation

- 9701 s03 Ms 1+2+3+4+5+6Document39 pages9701 s03 Ms 1+2+3+4+5+6Bismaht60% (5)

- WGC 2010 Paper On Amorphous SilicaDocument6 pagesWGC 2010 Paper On Amorphous Silicaangcoy.ecPas encore d'évaluation

- Protein Precipitation ProceduresDocument2 pagesProtein Precipitation ProceduresPrakash BalakrishnanPas encore d'évaluation

- Solubility Rules Solubility of Common Ionic Compounds - PrinterviewDocument2 pagesSolubility Rules Solubility of Common Ionic Compounds - PrinterviewHesham AlsoghierPas encore d'évaluation

- Synthesis of Cesium Octacyanomolybdate (V) - and Cesium Cyanotungstate (V) Dihydrate: A More Successful Method OctaDocument3 pagesSynthesis of Cesium Octacyanomolybdate (V) - and Cesium Cyanotungstate (V) Dihydrate: A More Successful Method OctaDabasish DekaPas encore d'évaluation

- Pdfjoiner-111 OrganizedDocument69 pagesPdfjoiner-111 OrganizedshabanaPas encore d'évaluation

- Techno-Economic Assessment About Precipitated SilicaDocument3 pagesTechno-Economic Assessment About Precipitated SilicaIntratec SolutionsPas encore d'évaluation

- Salt AnalysisDocument6 pagesSalt Analysisashraf_mphilPas encore d'évaluation

- Smak 8 Penabur International Tanjung Duren: Detention From Practical ChemistryDocument10 pagesSmak 8 Penabur International Tanjung Duren: Detention From Practical ChemistryJodhi GushastokoPas encore d'évaluation

- Author's Accepted Manuscript: TalantaDocument29 pagesAuthor's Accepted Manuscript: TalantaPutri Zahra ArdiyanitaPas encore d'évaluation

- Chemistry Lab Report 06 (Long)Document12 pagesChemistry Lab Report 06 (Long)Michael LauPas encore d'évaluation

- Berkala. Huruf-Huruf Yang Digunakan Bukan Simbol Sebenar Unsur-Unsur TersebutDocument13 pagesBerkala. Huruf-Huruf Yang Digunakan Bukan Simbol Sebenar Unsur-Unsur TersebutDania DesaPas encore d'évaluation

- Preparation of Salts: Suitable For FORM 2,3, AND 4Document44 pagesPreparation of Salts: Suitable For FORM 2,3, AND 4Richard NestorPas encore d'évaluation

- Waste Water TreatmentDocument43 pagesWaste Water TreatmentRahul Deka100% (1)

- Salt Analysis PDFDocument9 pagesSalt Analysis PDFNisheethPas encore d'évaluation

- Membrane Preparation Techniques AnisotropicDocument22 pagesMembrane Preparation Techniques AnisotropicAhammed Sherief Kizhakkethil YousephPas encore d'évaluation

- Water-Based Paint Formulations, Vol. 3D'EverandWater-Based Paint Formulations, Vol. 3Évaluation : 4.5 sur 5 étoiles4.5/5 (6)

- Process Steam Systems: A Practical Guide for Operators, Maintainers, and DesignersD'EverandProcess Steam Systems: A Practical Guide for Operators, Maintainers, and DesignersPas encore d'évaluation

- Nuclear Energy in the 21st Century: World Nuclear University PressD'EverandNuclear Energy in the 21st Century: World Nuclear University PressÉvaluation : 4.5 sur 5 étoiles4.5/5 (3)

- Process Plant Equipment: Operation, Control, and ReliabilityD'EverandProcess Plant Equipment: Operation, Control, and ReliabilityÉvaluation : 5 sur 5 étoiles5/5 (1)

- Sodium Bicarbonate: Nature's Unique First Aid RemedyD'EverandSodium Bicarbonate: Nature's Unique First Aid RemedyÉvaluation : 5 sur 5 étoiles5/5 (21)

- The Periodic Table of Elements - Post-Transition Metals, Metalloids and Nonmetals | Children's Chemistry BookD'EverandThe Periodic Table of Elements - Post-Transition Metals, Metalloids and Nonmetals | Children's Chemistry BookPas encore d'évaluation

- The Periodic Table of Elements - Alkali Metals, Alkaline Earth Metals and Transition Metals | Children's Chemistry BookD'EverandThe Periodic Table of Elements - Alkali Metals, Alkaline Earth Metals and Transition Metals | Children's Chemistry BookPas encore d'évaluation

- Guidelines for Chemical Process Quantitative Risk AnalysisD'EverandGuidelines for Chemical Process Quantitative Risk AnalysisÉvaluation : 5 sur 5 étoiles5/5 (1)

- Lees' Process Safety Essentials: Hazard Identification, Assessment and ControlD'EverandLees' Process Safety Essentials: Hazard Identification, Assessment and ControlÉvaluation : 4 sur 5 étoiles4/5 (4)

- Physical and Chemical Equilibrium for Chemical EngineersD'EverandPhysical and Chemical Equilibrium for Chemical EngineersÉvaluation : 5 sur 5 étoiles5/5 (1)

- Operational Excellence: Journey to Creating Sustainable ValueD'EverandOperational Excellence: Journey to Creating Sustainable ValuePas encore d'évaluation

- Phase Equilibria in Chemical EngineeringD'EverandPhase Equilibria in Chemical EngineeringÉvaluation : 4 sur 5 étoiles4/5 (11)

- Pharmaceutical Blending and MixingD'EverandPharmaceutical Blending and MixingP. J. CullenÉvaluation : 5 sur 5 étoiles5/5 (1)

- Guidelines for Engineering Design for Process SafetyD'EverandGuidelines for Engineering Design for Process SafetyPas encore d'évaluation

- Functional Safety from Scratch: A Practical Guide to Process Industry ApplicationsD'EverandFunctional Safety from Scratch: A Practical Guide to Process Industry ApplicationsPas encore d'évaluation

- Piping and Pipeline Calculations Manual: Construction, Design Fabrication and ExaminationD'EverandPiping and Pipeline Calculations Manual: Construction, Design Fabrication and ExaminationÉvaluation : 4 sur 5 étoiles4/5 (18)

- The HAZOP Leader's Handbook: How to Plan and Conduct Successful HAZOP StudiesD'EverandThe HAZOP Leader's Handbook: How to Plan and Conduct Successful HAZOP StudiesPas encore d'évaluation

- An Introduction to the Periodic Table of Elements : Chemistry Textbook Grade 8 | Children's Chemistry BooksD'EverandAn Introduction to the Periodic Table of Elements : Chemistry Textbook Grade 8 | Children's Chemistry BooksÉvaluation : 5 sur 5 étoiles5/5 (1)

- Guidelines for the Management of Change for Process SafetyD'EverandGuidelines for the Management of Change for Process SafetyPas encore d'évaluation

- Recognizing Catastrophic Incident Warning Signs in the Process IndustriesD'EverandRecognizing Catastrophic Incident Warning Signs in the Process IndustriesPas encore d'évaluation

- Chemical Process Safety: Learning from Case HistoriesD'EverandChemical Process Safety: Learning from Case HistoriesÉvaluation : 4 sur 5 étoiles4/5 (14)

- Pharmaceutical Excipients: Properties, Functionality, and Applications in Research and IndustryD'EverandPharmaceutical Excipients: Properties, Functionality, and Applications in Research and IndustryOtilia M. Y. KooPas encore d'évaluation