Académique Documents

Professionnel Documents

Culture Documents

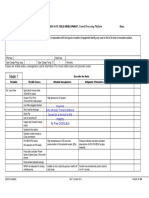

Attachment B - HAZID Worksheet

Transféré par

wibowo wibowo100%(1)100% ont trouvé ce document utile (1 vote)

211 vues9 pagescf

Copyright

© © All Rights Reserved

Formats disponibles

PDF, TXT ou lisez en ligne sur Scribd

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentcf

Droits d'auteur :

© All Rights Reserved

Formats disponibles

Téléchargez comme PDF, TXT ou lisez en ligne sur Scribd

100%(1)100% ont trouvé ce document utile (1 vote)

211 vues9 pagesAttachment B - HAZID Worksheet

Transféré par

wibowo wibowocf

Droits d'auteur :

© All Rights Reserved

Formats disponibles

Téléchargez comme PDF, TXT ou lisez en ligne sur Scribd

Vous êtes sur la page 1sur 9

Node: 1.

Duri Facility Drawings:

Risk

Category

Parameter Deviation Causes Consequences Safeguards Matrix Recommendations Responsibility Status Remarks

F R H L M S P RR

1.1. Loss of 1.1.1. Leaks / 1.1.1.1. Leak or rupture 1. Potential B BBB F F B F 1. Consider to install one KPE & KSO

Containment Rupture at TGI metering hydrocarbon pair OPGD between

facility release to metering shelter and

atmosphere leading office area

to fire / explosion

impinged to office 2. Consider to install gas KPE & KSO

area detector at control

room door

2. Potential B BBB F F B F

hydrocarbon 3. Consider to use KPE & KSO

release to electrical and

atmosphere leading instrument equipment

to fire / explosion based on specification

impinged to EDG & of HAC

IA package 4. Consider to install KPE & KSO

HVAC or move control

room door to plant

north side with panic

door and gas tight type

5. Consider to install KPE & KSO

flame detector with fire

& gas mapping study

to avoid blind spot area

1.1.1.2. Leak or rupture 1. Potential B BBB F F B F 9. Consider to install one KPE & KSO

at Duri regulator hydrocarbon pair OPGD between

area release to regulator and EDG &

atmosphere leading IA package

to fire / explosion

impinged to EDG &

IA package

1.2. Non- 1.2.1. Electrical 1.2.1.1. Electrical short 1. Electrical fire 1. Smoke detector B BBB F F B F 6. Consider to provide fire KPE & KSO

Hydrocarbon Fires circuit at control leading to suppression system

Fires room / Panel equipment damage 2. Portable fire electrical cabinet

room and plant shutdown extinguisher (general)

3. Heat detector

1.2.1.2. Battery room 1. Electrical fire 1. Smoke detector B BBB F F B F 8. Consider to provide KPE & KSO

electrical fire leading to explosion sufficient portable fire

causing to 2. Heat detector extinguisher (general)

equipment damage 3. Portable fire

and plant shutdown extinguisher

1.2.2. Combustible 1.2.2.1. Combustible 1. Fire at office area 1. Smoke detector B BBB B B B B 7. Consider to install fire KPE & KSO

Material material from alarm control panel for

office work 2. Heat detector building (general)

3. Portable fire

extinguisher

Node: 1. Duri Facility Drawings:

Risk

Category

Parameter Deviation Causes Consequences Safeguards Matrix Recommendations Responsibility Status Remarks

F R H L M S P RR

4. Manual call point

1.2.3. Static 1.2.3.1. Spark 1. Differential current 1. Grounding of

Electricity leading to fire equipment to

prevent static

electrical

discharges

1.2.4. Lightning 1.2.4.1. Lightning strike 1. No adverse 1. Lightning

Fires consequence protection

1.3. Transport 1.3.1. Vehicle crash 1.3.1.1. No issue of

Accidents / collision to concern

installation identified

1.3.2. Vehicle 1.3.2.1. No issue of

accidents concern

identified

1.4. Personnel 1.4.1. Falls 1.4.1.1. No issue of

Accidents concern

identified

1.4.2. Burn 1.4.2.1. No issue of

concern

identified

1.4.3. Working at 1.4.3.1. No issue of

Height concern

identified

1.4.4. Radiation 1.4.4.1. Radiation 1. Personnel ilness in 1. Proper PPE

exposure exposure during prolonged time

construction 2. Warning Sign

(NDT) 3. PTW

4. JSA

1.4.5. Confined 1.4.5.1. No issue of

space works concern

identified

1.4.6. Ergonomics 1.4.6.1. No issue of

concern

identified

1.5. Constructability 1.5.1. Drop Objects 1.5.1.1. Lifting devices 1. Personnel injury / 1. Warning Sign

failure fatality

2. Barricades

3. PTW

4. Rigger

Node: 1. Duri Facility Drawings:

Risk

Category

Parameter Deviation Causes Consequences Safeguards Matrix Recommendations Responsibility Status Remarks

F R H L M S P RR

5. JSA

2. Equipment damage 1. Warning Sign

2. Barricades

3. PTW

4. Rigger

5. JSA

1.5.2. Heavy duty 1.5.2.1. Heavy duty 1. Personnel injury / 1. Warning Sign

vehicle vehicle swing fatality

movement impact accident 2. Barricades

3. PTW

4. Rigger

5. JSA

2. Equipment damage 1. Warning Sign

2. Barricades

3. PTW

4. Rigger

5. JSA

1.5.3. Hot Work 1.5.3.1. Electric shock 1. Personnel Injury 1. PPE

2. PTW

3. JSA

1.5.4. High pressure 1.5.4.1. High pressure 1. Personnel Injury / 1. Barricades

hazards impact during fatality

pressure test 2. PTW

3. JSA

1.6. Evacuations 1.6.1. Mustering 1.6.1.1. No issue of

concern

identified

1.7. Design 1.7.1. Design 1.7.1.1. No issue of

Consideration Consideration concern

identified

1.8. Structural 1.8.1. Structural 1.8.1.1. No issue of

failure (i.e. concern

Structural/sup identified

port faitgue)

Node: 1. Duri Facility Drawings:

Risk

Category

Parameter Deviation Causes Consequences Safeguards Matrix Recommendations Responsibility Status Remarks

F R H L M S P RR

1.8.2. Earthquake 1.8.2.1. No issue of

concern

identified

1.9. Miscellaneous 1.9.1. Sabotage 1.9.1.1. No issue of

concern

identified

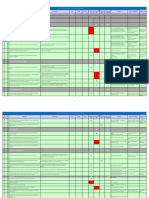

Node: 2. Pipeline Duri - Dumai Drawings: PGDD-KPE-1472-00-EPL-DG-004

Risk

Category

Parameter Deviation Causes Consequences Safeguards Matrix Recommendations Responsibility Status Remarks

F R H L M S P RR

2.1. Loss of 2.1.1. Leaks / 2.1.1.1. Leak or rupture 1. Potential 1. Fusible plug B BBB F F K M 10. Consider to conduct KPE

Containment Rupture at LBCV facility hydrocarbon interlock to close Quantitative Risk

release to LBCV Assessment complete

atmosphere leading with risk contour

to fire (potential 2. Preventive &

ignition from vehicle Periodic

and community maintenace

activity) causing during turn

community injury around

and fatality

2.2. Non- 2.2.1. Electrical 2.2.1.1. No issue of

Hydrocarbon Fires concern

Fires identified

2.2.2. Combustible 2.2.2.1. No issue of

Material concern

identified

2.2.3. Static 2.2.3.1. No issue of

Electricity concern

identified

2.2.4. Lightning 2.2.4.1. No issue of

Fires concern

identified

2.3. Transport 2.3.1. Vehicle crash 2.3.1.1. Vehicle crash to 1. Potential

Accidents / collision to LBCV hydrocarbon

installation release to

atmosphere leading

to fire (potential

ignition from vehicle

and community

activity) causing

community injury

and fatality

2.3.2. Vehicle 2.3.2.1. No issue of

accidents concern

Node: 2. Pipeline Duri - Dumai Drawings: PGDD-KPE-1472-00-EPL-DG-004

Risk

Category

Parameter Deviation Causes Consequences Safeguards Matrix Recommendations Responsibility Status Remarks

F R H L M S P RR

identified

2.4. Personnel 2.4.1. Falls 2.4.1.1. Personnel 1. Personnel injury 1. Barricades

Accidents falldown to

trench 2. PTW

3. JSA

2.4.2. Burn 2.4.2.1. FJC application 1. Personnel injury 1. PPE

2. PTW

3. JSA

2.4.3. Working at 2.4.3.1. No issue of

Height concern

identified

2.4.4. Radiation 2.4.4.1. Radiation 1. Personnel ilness in 1. Proper PPE

exposure exposure during prolonged time

construction 2. Warning Sign

(NDT) 3. PTW

4. JSA

2.4.5. Confined 2.4.5.1. No issue of

space works concern

identified

2.4.6. Ergonomics 2.4.6.1. No issue of

concern

identified

2.5. Constructability 2.5.1. Drop Objects 2.5.1.1. Lifting devices 1. Personnel injury / 1. Warning Sign

failure fatality

2. Barricades

3. PTW

4. Rigger

5. JSA

2. Equipment damage 1. Warning Sign

2. Barricades

3. PTW

4. Rigger

5. JSA

2.5.2. Heavy duty 2.5.2.1. Heavy duty 1. Personnel injury / 1. Warning Sign

vehicle vehicle swing fatality

movement impact accident 2. Barricades

Node: 2. Pipeline Duri - Dumai Drawings: PGDD-KPE-1472-00-EPL-DG-004

Risk

Category

Parameter Deviation Causes Consequences Safeguards Matrix Recommendations Responsibility Status Remarks

F R H L M S P RR

3. PTW

4. Rigger

5. JSA

2. Equipment damage 1. Warning Sign

2. Barricades

3. PTW

4. Rigger

5. JSA

2.5.3. Hot Work 2.5.3.1. Electric shock 1. Personnel Injury 1. PPE

2. PTW

3. JSA

2.5.4. High pressure 2.5.4.1. High pressure 1. Personnel Injury / 1. Barricades

hazards impact during fatality

pressure test 2. PTW

3. JSA

2.6. Evacuations 2.6.1. Mustering 2.6.1.1. No issue of

concern

identified

2.7. Design 2.7.1. Design 2.7.1.1. No issue of

Consideration Consideration concern

identified

2.8. Structural 2.8.1. Structural 2.8.1.1. No issue of

failure (i.e. concern

Structural/sup identified

port faitgue)

2.8.2. Earthquake 2.8.2.1. No issue of

concern

identified

2.9. Miscellaneous 2.9.1. Sabotage 2.9.1.1. Burglary, theft 1. Equipment loss or 1. Fence

or sabotage damage

2. Security patrol

Node: 3. Dumai Facility Drawings: PGDD-KPE-1472-00-EPG-DG-004

Risk

Category

Parameter Deviation Causes Consequences Safeguards Matrix Recommendations Responsibility Status Remarks

F R H L M S P RR

3.1. Loss of 3.1.1. Leaks / 3.1.1.1. Leak or rupture 1. Potential 1. F&G detection

Containment Rupture at Dumai facility hydrocarbon system

release to

Node: 3. Dumai Facility Drawings: PGDD-KPE-1472-00-EPG-DG-004

Risk

Category

Parameter Deviation Causes Consequences Safeguards Matrix Recommendations Responsibility Status Remarks

F R H L M S P RR

atmosphere leading 2. Fire Water

to fire impinged to system

surrounding

equipment 3. Portable fire

extinguisher

4. Blowdown system

3.2. Non- 3.2.1. Electrical 3.2.1.1. No issue of

Hydrocarbon Fires concern

Fires identified

3.2.2. Combustible 3.2.2.1. No issue of

Material concern

identified

3.2.3. Static 3.2.3.1. Spark 1. Differential current 1. Grounding of

Electricity leading to fire equipment to

prevent static

electrical

discharges

3.2.4. Lightning 3.2.4.1. Lightning strike 1. No adverse 1. Lightning

Fires consequence protection

3.3. Transport 3.3.1. Vehicle crash 3.3.1.1. No issue of

Accidents / collision to concern

installation identified

3.3.2. Vehicle 3.3.2.1. No issue of

accidents concern

identified

3.4. Personnel 3.4.1. Falls 3.4.1.1. No issue of

Accidents concern

identified

3.4.2. Burn 3.4.2.1. No issue of

concern

identified

3.4.3. Working at 3.4.3.1. No issue of

Height concern

identified

3.4.4. Radiation 3.4.4.1. Radiation 1. Personnel ilness in 1. Proper PPE

exposure exposure during prolonged time

construction 2. Warning Sign

(NDT) 3. PTW

4. JSA

3.4.5. Confined 3.4.5.1. No issue of

space works concern

Node: 3. Dumai Facility Drawings: PGDD-KPE-1472-00-EPG-DG-004

Risk

Category

Parameter Deviation Causes Consequences Safeguards Matrix Recommendations Responsibility Status Remarks

F R H L M S P RR

identified

3.4.6. Ergonomics 3.4.6.1. No issue of

concern

identified

3.5. Constructability 3.5.1. Drop Objects 3.5.1.1. Lifting devices 1. Personnel injury / 1. Warning Sign

failure fatality

2. Barricades

3. PTW

4. Rigger

5. JSA

2. Equipment damage 1. Warning Sign

2. Barricades

3. PTW

4. Rigger

5. JSA

3.5.2. Heavy duty 3.5.2.1. Heavy duty 1. Personnel injury / 1. Warning Sign

vehicle vehicle swing fatality

movement impact accident 2. Barricades

3. PTW

4. Rigger

5. JSA

2. Equipment damage 1. Warning Sign

2. Barricades

3. PTW

4. Rigger

5. JSA

3.5.3. Hot Work 3.5.3.1. Electric shock 1. Personnel Injury 1. PPE

2. PTW

3. JSA

3.5.4. High pressure 3.5.4.1. High pressure 1. Personnel Injury / 1. Barricades

hazards impact during fatality

pressure test 2. PTW

3. JSA

Node: 3. Dumai Facility Drawings: PGDD-KPE-1472-00-EPG-DG-004

Risk

Category

Parameter Deviation Causes Consequences Safeguards Matrix Recommendations Responsibility Status Remarks

F R H L M S P RR

3.6. Evacuations 3.6.1. Mustering 3.6.1.1. No issue of

concern

identified

3.7. Design 3.7.1. Design 3.7.1.1. No issue of

Consideration Consideration concern

identified

3.8. Structural 3.8.1. Structural 3.8.1.1. No issue of

failure (i.e. concern

Structural/sup identified

port faitgue)

3.8.2. Earthquake 3.8.2.1. No issue of

concern

identified

3.9. Miscellaneous 3.9.1. Sabotage 3.9.1.1. No issue of

concern

identified

Vous aimerez peut-être aussi

- Review Formalities HAZID ReportDocument3 pagesReview Formalities HAZID ReportNaresh Nutakki50% (2)

- HSE Parts Count Guide PDFDocument19 pagesHSE Parts Count Guide PDFBanjoPas encore d'évaluation

- Hazid Report Form: Project: Drawing Nos Date: Sheet No: Area or System: AttendeesDocument13 pagesHazid Report Form: Project: Drawing Nos Date: Sheet No: Area or System: AttendeesElias EliasPas encore d'évaluation

- GM Saf 006a (Hazid)Document27 pagesGM Saf 006a (Hazid)Edwin Nuñez FlorezPas encore d'évaluation

- HAZID Report FormDocument12 pagesHAZID Report FormElias EliasPas encore d'évaluation

- Project Safety StudiesDocument74 pagesProject Safety StudiesBaba Johneh100% (1)

- Chapter 5 - Hazard IdentificationDocument53 pagesChapter 5 - Hazard IdentificationChieng Tiew Hing100% (1)

- HAZID Terms of Reference for Garraf Field Surface Facilities Modification ProjectDocument27 pagesHAZID Terms of Reference for Garraf Field Surface Facilities Modification ProjectXiang Jintao100% (1)

- Hazid RecordDocument21 pagesHazid Recordavanish.vPas encore d'évaluation

- Template Hazid ReportDocument17 pagesTemplate Hazid ReportJagan Bose75% (4)

- HAZID Report for North Bahariya DevelopmentDocument16 pagesHAZID Report for North Bahariya Developmentkokykarkar100% (2)

- I. HAZID Attendance Sheet 17 II. HAZID WORKSHEET 17 III. TOR FOR HAZID WORKSHOP 17Document15 pagesI. HAZID Attendance Sheet 17 II. HAZID WORKSHEET 17 III. TOR FOR HAZID WORKSHOP 17KehindePas encore d'évaluation

- Shell Shepherd v3.1.0Document3 pagesShell Shepherd v3.1.0Mochamad SafarudinPas encore d'évaluation

- QRA scope for liquid fuel storageDocument3 pagesQRA scope for liquid fuel storagevarunkumar415100% (1)

- Philosophy: 1. Loss PreventionDocument3 pagesPhilosophy: 1. Loss PreventionDheeraj ShuklaPas encore d'évaluation

- Hazard Identification (Hazid) Study Diesel Engine Generator (Deg) 3 River Water IntakeDocument18 pagesHazard Identification (Hazid) Study Diesel Engine Generator (Deg) 3 River Water IntakeXiang JintaoPas encore d'évaluation

- SIL Rated Fire & Gas Functions - PaperDocument19 pagesSIL Rated Fire & Gas Functions - PaperTan100% (4)

- To-HQ-02-075-00 Philosophy Escape Evacuation Rescue OnshoreDocument13 pagesTo-HQ-02-075-00 Philosophy Escape Evacuation Rescue Onshoreagaricus100% (1)

- Ep 95-0313 HazopDocument88 pagesEp 95-0313 HazopManjunathBVenkatesh100% (4)

- Guidance on Identifying Major Incident HazardsDocument26 pagesGuidance on Identifying Major Incident HazardsPopa Marian100% (2)

- IZOMBE FLOWSTATION FIRE AND GAS SYSTEM ASSESSMENTDocument26 pagesIZOMBE FLOWSTATION FIRE AND GAS SYSTEM ASSESSMENTLawrence Osuvwe OfuokuPas encore d'évaluation

- 6.63 Pipeline Hazid Envid ReportDocument17 pages6.63 Pipeline Hazid Envid ReportGaluh Pramudipto100% (7)

- EGPC PSM GL 001 Hazard Identfication HAZID GuidelineDocument56 pagesEGPC PSM GL 001 Hazard Identfication HAZID Guidelinekhaled farag100% (2)

- Container Securing HAZID Report Identifies HazardsDocument54 pagesContainer Securing HAZID Report Identifies Hazardsirfankaushar100% (2)

- PHAST Models ExplainedDocument8 pagesPHAST Models ExplainedHimanshu ChichraPas encore d'évaluation

- Comparison of Pha Methods PDFDocument10 pagesComparison of Pha Methods PDFQayyum KhanPas encore d'évaluation

- Simops Risk AssessmentDocument3 pagesSimops Risk Assessmentzineddinmakram100% (1)

- PHADocument19 pagesPHAJacekPas encore d'évaluation

- Simultaneous Operations (SIMOPS) TERM OF REFERANCE (TORDocument25 pagesSimultaneous Operations (SIMOPS) TERM OF REFERANCE (TORkokykarkar80% (5)

- HAZID - IntroductionDocument9 pagesHAZID - IntroductionAmin ZoharPas encore d'évaluation

- Mitigation Performance Standards GuideDocument117 pagesMitigation Performance Standards GuideAzeemPas encore d'évaluation

- HAZID TemplateDocument38 pagesHAZID TemplateMd AfzanPas encore d'évaluation

- HSE Manual: Overview Hazards and Effects Management ProcessDocument84 pagesHSE Manual: Overview Hazards and Effects Management ProcessHmahPas encore d'évaluation

- HazopDocument5 pagesHazopMohammed KhatibPas encore d'évaluation

- Module 9 - ALARP 20150305Document32 pagesModule 9 - ALARP 20150305Muhammad.SaimPas encore d'évaluation

- QP-GDL-S-040 - HazidDocument28 pagesQP-GDL-S-040 - HazidMarcus HartfelderPas encore d'évaluation

- MhdpIssue 6.1Document137 pagesMhdpIssue 6.1billPas encore d'évaluation

- Hazop Worksheet Suggested ScenariosDocument16 pagesHazop Worksheet Suggested ScenariosJagan BosePas encore d'évaluation

- HAZOp Report - BFI PDFDocument62 pagesHAZOp Report - BFI PDFJoseph Samir EshakPas encore d'évaluation

- Hazard Identification Risk Assessment and Control Measures For MHFDocument49 pagesHazard Identification Risk Assessment and Control Measures For MHFprav.sarada100% (1)

- 8 - RJN NAD HSE Management PlanDocument45 pages8 - RJN NAD HSE Management PlanMartahanManurung100% (1)

- RAS MARKAZ CRUDE OIL PARK PSSR PROCEDUREDocument57 pagesRAS MARKAZ CRUDE OIL PARK PSSR PROCEDUREKhan Wasim100% (1)

- Periodic Hazard Studies GuideDocument9 pagesPeriodic Hazard Studies GuideFaisal TariqPas encore d'évaluation

- OMAR Fire Safety AssessmentDocument19 pagesOMAR Fire Safety AssessmentasdasdPas encore d'évaluation

- Input Documents and Deliverables Quantitative Risk Assessment (QRA) Study: Study Input Documents DeliverablesDocument9 pagesInput Documents and Deliverables Quantitative Risk Assessment (QRA) Study: Study Input Documents Deliverablessandhyakasturi123Pas encore d'évaluation

- PSG-001A - Part 5, Hazard Study 5Document4 pagesPSG-001A - Part 5, Hazard Study 5Faisal TariqPas encore d'évaluation

- H E M P: Azards and Ffects Anagement RocessDocument28 pagesH E M P: Azards and Ffects Anagement RocessNid Piks100% (1)

- Hazard Effect Register For Mode 2 Contracts EngDocument1 pageHazard Effect Register For Mode 2 Contracts EngamizanPas encore d'évaluation

- RLOC Equipment Integrity PolicyDocument10 pagesRLOC Equipment Integrity PolicyMohammed ZubairPas encore d'évaluation

- PTTP ProcessSafetyFundamentalsDocument12 pagesPTTP ProcessSafetyFundamentalsAnonymous q2iHVfPas encore d'évaluation

- Hazid WorksheetDocument2 pagesHazid WorksheetHarry SiswajiPas encore d'évaluation

- HAZID Workshop PDFDocument45 pagesHAZID Workshop PDFNora Afzam Abd Wahab100% (1)

- 6419RJ510-10006 Blinds Management ProcedureDocument14 pages6419RJ510-10006 Blinds Management ProcedureLuqman Osman100% (1)

- F&G MappingDocument1 pageF&G MappingRuban RkPas encore d'évaluation

- TSE FrameworkDocument3 pagesTSE FrameworkyePas encore d'évaluation

- PSSR Checksheet - Offshore Asset - DraftDocument6 pagesPSSR Checksheet - Offshore Asset - Draftjai kumar100% (1)

- Guidelines for Defining Process Safety Competency RequirementsD'EverandGuidelines for Defining Process Safety Competency RequirementsÉvaluation : 3 sur 5 étoiles3/5 (1)

- Hazard And Risk Analysis A Complete Guide - 2020 EditionD'EverandHazard And Risk Analysis A Complete Guide - 2020 EditionPas encore d'évaluation

- JSA For Various WorkDocument11 pagesJSA For Various WorkGopakumar KPas encore d'évaluation

- Engineering Kinetics (PVT) LTD: Task Risk AssessmentDocument3 pagesEngineering Kinetics (PVT) LTD: Task Risk AssessmentandrePas encore d'évaluation

- Calculation Cathodic Protection ICCP Duri Dumai PGDDDocument48 pagesCalculation Cathodic Protection ICCP Duri Dumai PGDDwibowo wibowo100% (1)

- Contoh Data Sheet For Electrical Cable Tray Rev - BDocument12 pagesContoh Data Sheet For Electrical Cable Tray Rev - Bwibowo wibowo100% (1)

- ReadmeDocument1 pageReadmeJihadLe-PunkPas encore d'évaluation

- Apgreid Training 2Document2 pagesApgreid Training 2wibowo wibowo100% (1)

- SLS-70-CIV-DB-001 Civil Design Basis, Rev. D - AFD PDFDocument36 pagesSLS-70-CIV-DB-001 Civil Design Basis, Rev. D - AFD PDFwibowo wibowo100% (1)

- SLS-70-CIV-DB-001 Civil Design Basis, Rev. 0 - AFCDocument36 pagesSLS-70-CIV-DB-001 Civil Design Basis, Rev. 0 - AFCwibowo wibowo100% (1)

- Chek Lsit Interlock BoilerDocument6 pagesChek Lsit Interlock BoilerDwi Mulyanti DwimulyantishopPas encore d'évaluation

- Apgreid TrainingDocument1 pageApgreid Trainingwibowo wibowo100% (1)

- TOP Instrument Air Review 2Document1 pageTOP Instrument Air Review 2wibowo wibowoPas encore d'évaluation

- PGDD-KPE-1403-09-EEL-MT-002 MTO For Electrical Bulk Material Duri1 PDFDocument1 pagePGDD-KPE-1403-09-EEL-MT-002 MTO For Electrical Bulk Material Duri1 PDFwibowo wibowoPas encore d'évaluation

- N2XY 1 x (1.5 - 500) mm2 0.6/1 kV cable specsDocument1 pageN2XY 1 x (1.5 - 500) mm2 0.6/1 kV cable specswibowo wibowoPas encore d'évaluation

- TOP Instrument Air Review 1 PDFDocument1 pageTOP Instrument Air Review 1 PDFwibowo wibowoPas encore d'évaluation

- Parameter Boiler Drum HRSGDocument7 pagesParameter Boiler Drum HRSGDwi Mulyanti DwimulyantishopPas encore d'évaluation

- Mixed Metal Oxide Mixed Metal Oxide: Tubular AnodesDocument2 pagesMixed Metal Oxide Mixed Metal Oxide: Tubular Anodeswibowo wibowoPas encore d'évaluation

- Hazop Hazid Action SheetDocument4 pagesHazop Hazid Action Sheetwibowo wibowoPas encore d'évaluation

- Attachment C - HAZOP WorksheetDocument18 pagesAttachment C - HAZOP Worksheetwibowo wibowo50% (2)

- PGDD KPE 1403 09 EEL MT 002 MTO For Electrical Bulk Material Duri9Document1 pagePGDD KPE 1403 09 EEL MT 002 MTO For Electrical Bulk Material Duri9wibowo wibowoPas encore d'évaluation

- Table Torque Tabel Torsi Baut Flange PDFDocument1 pageTable Torque Tabel Torsi Baut Flange PDFwibowo wibowoPas encore d'évaluation

- PGDD KPE 1403 09 EEL MT 002 MTO For Electrical Bulk Material Duri2Document1 pagePGDD KPE 1403 09 EEL MT 002 MTO For Electrical Bulk Material Duri2wibowo wibowoPas encore d'évaluation

- PGDD KPE 1403 09 EEL MT 002 MTO For Electrical Bulk Material Duri4Document1 pagePGDD KPE 1403 09 EEL MT 002 MTO For Electrical Bulk Material Duri4wibowo wibowoPas encore d'évaluation

- Mechanical Completion (Mechanical) : 22033-730-01 r0 Erection ManualDocument1 pageMechanical Completion (Mechanical) : 22033-730-01 r0 Erection ManualDwi Mulyanti DwimulyantishopPas encore d'évaluation

- PGDD KPE 1403 09 EEL MT 002 MTO For Electrical Bulk Material Duri6Document2 pagesPGDD KPE 1403 09 EEL MT 002 MTO For Electrical Bulk Material Duri6wibowo wibowoPas encore d'évaluation

- PGDD KPE 1403 09 EEL MT 002 MTO For Electrical Bulk Material Duri7Document1 pagePGDD KPE 1403 09 EEL MT 002 MTO For Electrical Bulk Material Duri7wibowo wibowoPas encore d'évaluation

- PGDD-KPE-1403-09-EEL-MT-002 MTO For Electrical Bulk Material Duri1 PDFDocument1 pagePGDD-KPE-1403-09-EEL-MT-002 MTO For Electrical Bulk Material Duri1 PDFwibowo wibowoPas encore d'évaluation

- PGDD KPE 1403 09 EEL MT 002 MTO For Electrical Bulk Material Duri5Document1 pagePGDD KPE 1403 09 EEL MT 002 MTO For Electrical Bulk Material Duri5wibowo wibowoPas encore d'évaluation

- PGDD KPE 1403 09 EEL MT 002 MTO For Electrical Bulk Material Duri8Document1 pagePGDD KPE 1403 09 EEL MT 002 MTO For Electrical Bulk Material Duri8wibowo wibowoPas encore d'évaluation

- Quick StartDocument4 pagesQuick Startwibowo wibowoPas encore d'évaluation

- Set Point System Plant46Document15 pagesSet Point System Plant46Dwi Mulyanti DwimulyantishopPas encore d'évaluation

- PGDD KPE 1403 09 EEL MT 002 MTO For Electrical Bulk Material Duri7Document1 pagePGDD KPE 1403 09 EEL MT 002 MTO For Electrical Bulk Material Duri7wibowo wibowoPas encore d'évaluation

- A Long Flashover ArresterDocument10 pagesA Long Flashover ArresterNAMEER999100% (1)

- Design and test sheet metal rolling machine with steel rollersDocument4 pagesDesign and test sheet metal rolling machine with steel rollersAbinash BajgainPas encore d'évaluation

- Clamps Buying GuideDocument8 pagesClamps Buying GuidegauravPas encore d'évaluation

- Ground Grid Design in Large Industrial PlantsDocument5 pagesGround Grid Design in Large Industrial PlantsAshley100% (1)

- PEP LV UL 1558 Switchgear Specification R0Document10 pagesPEP LV UL 1558 Switchgear Specification R0Alex0% (1)

- manHIDRIVE GBDocument233 pagesmanHIDRIVE GBLeandro FreitasPas encore d'évaluation

- 2012 NAPTIN DocumentDocument48 pages2012 NAPTIN DocumentbenaikodonPas encore d'évaluation

- 70E A2011 ROPDraftDocument101 pages70E A2011 ROPDraftMUTHU krishnanPas encore d'évaluation

- LCD Sharp LC-60E77 - LC-65E77 PDFDocument118 pagesLCD Sharp LC-60E77 - LC-65E77 PDFYeison Izquierdo MontenegroPas encore d'évaluation

- PEC Reviewer 4Document5 pagesPEC Reviewer 4JmPas encore d'évaluation

- S1892R211M Service Manual GuideDocument23 pagesS1892R211M Service Manual GuideRicardo Cinjiro Conte100% (1)

- Manual de Servicio Harman KardonDocument130 pagesManual de Servicio Harman KardonschaiPas encore d'évaluation

- DeltaDocument152 pagesDeltasampathPas encore d'évaluation

- Estaquick Aemd-600 Automatic Applicator: Service ManualDocument39 pagesEstaquick Aemd-600 Automatic Applicator: Service ManualVarun YadavPas encore d'évaluation

- Guía de Usuario UPS HP R3000Document64 pagesGuía de Usuario UPS HP R3000scoutperPas encore d'évaluation

- Central PBXDocument540 pagesCentral PBXHernan SaprodPas encore d'évaluation

- C15 and C18 Generator SetDocument4 pagesC15 and C18 Generator Setspider blackPas encore d'évaluation

- Volume II Technical Specifications-CompressedDocument409 pagesVolume II Technical Specifications-Compressedkajale.shrikantPas encore d'évaluation

- 1756-In005 - En-P ControlLogix Chassis and Power SupplyDocument58 pages1756-In005 - En-P ControlLogix Chassis and Power SupplyLuevandresPas encore d'évaluation

- Effects of Harmonic Distortion on Distribution TransformersDocument7 pagesEffects of Harmonic Distortion on Distribution TransformersAdonis CuevasPas encore d'évaluation

- Sony kdl-22l4000 Chassis cz1r PDFDocument58 pagesSony kdl-22l4000 Chassis cz1r PDFFernando DelvastoPas encore d'évaluation

- Haier Le40b8000 Chassis v59Document55 pagesHaier Le40b8000 Chassis v59Miguelina RossiPas encore d'évaluation

- M20 ManualDocument108 pagesM20 ManualHarold Hernan Muñoz100% (1)

- Alfa Standard. IPB Catalogue PDFDocument8 pagesAlfa Standard. IPB Catalogue PDFabes1234Pas encore d'évaluation

- Lenovo Ideapad S100 Hardware Maintenance Manual (English)Document79 pagesLenovo Ideapad S100 Hardware Maintenance Manual (English)isa'Pas encore d'évaluation

- Cqm1h Series Programming ManualDocument602 pagesCqm1h Series Programming ManualDaniel CallePas encore d'évaluation

- AnyScan-S PreinstallationGuide v2Document23 pagesAnyScan-S PreinstallationGuide v2Abraham Antonio HidalgoPas encore d'évaluation

- CCJ Issue 53 PDFDocument108 pagesCCJ Issue 53 PDFsleepanon4362Pas encore d'évaluation

- Troubleshooting Guide: HP t630 Thin ClientDocument58 pagesTroubleshooting Guide: HP t630 Thin ClientBinh Thai HYPas encore d'évaluation

- BS 200eDocument195 pagesBS 200eAnonymous GhWU5YK8100% (2)