Académique Documents

Professionnel Documents

Culture Documents

Stacker Cum Reclaimer - Operation & Maintenance

Transféré par

Durjoy Chakraborty75%(4)75% ont trouvé ce document utile (4 votes)

4K vues7 pagesStaker

Titre original

Stacker Cum Reclaimer_ Operation & Maintenance

Copyright

© © All Rights Reserved

Formats disponibles

PDF, TXT ou lisez en ligne sur Scribd

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentStaker

Droits d'auteur :

© All Rights Reserved

Formats disponibles

Téléchargez comme PDF, TXT ou lisez en ligne sur Scribd

75%(4)75% ont trouvé ce document utile (4 votes)

4K vues7 pagesStacker Cum Reclaimer - Operation & Maintenance

Transféré par

Durjoy ChakrabortyStaker

Droits d'auteur :

© All Rights Reserved

Formats disponibles

Téléchargez comme PDF, TXT ou lisez en ligne sur Scribd

Vous êtes sur la page 1sur 7

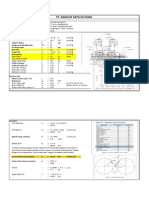

IJESS Volume3, Issue6 ISSN: 2249- 9482

OPERATION AND MAINTENANCE OF STACKER CUM RELAIMER IN

COAL HANDLING PLANT IN THERMAL POWER PLANT

Shilpa Sharma*

ABSTRACT

Compared with the actual situation of the current thermal power plant, this paper studies the

operation process of stacker cum reclaimer in coal handling plant in thermal power plant.

Analyzes the technical and operating characteristics of the equipment. The study is made to

reveal the safe operation and proper method of maintenance for ensuring the longer life of the

equipment with minimum possible failure.

Keywords: Thermal power plant, Coal Handling System, Stacker Cum Reclaimer.

*Department of Mechanical Engineering , MITS College Gwalior(MP),

International Journal of Engineering and Social Science

www.gjmr.org 15

IJESS Volume3, Issue6 ISSN: 2249- 9482

INTRODUCTION

At present, coal is the prominent fuel of thermal power plant. Continuing up the large unit, and

large capacity, the demand of coal is very large. Coal need to process from loading and

unloading to stockpile, this procedure can finish by stacker cum reclaimer.

The research has been carried out so as to ensure that failure does not impact on the material

handling rate of coal in coal handling plant.

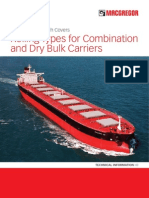

STACKER CUM RECLAIMER

The rail mounted stacker cum reclaimer is suitable for building stockpiles on either side of the

track rails and subsequently reclaiming these materials from the piles and feeding them for

working with a reversible yard conveyor with provision for feeding at one end for stacking and

discharging at the same end during reclaiming.

COMPONENTS

STRUCTURAL STEEL WORK

All parts are conveniently arranged for ease of access with special attention being paid to the

requirements for maintenance of the various machinery.

To facilitate the maintenance of the various parts, it is full of web construction and adequate

walkways, ladders etc are provided for convenient operation.

BUCKET WHEEL AND DRIVE

The bucket wheel drive consisting of motor, fluid coupling, thrustor brake and gear box,

mounted on a drive frame, is supported from the boom head by means of a torque arm with plain

spherical bearings. The hollow output shaft of the gear box is clamped onto the bucket wheel

shaft by a shrink disc element. The shaft assembly with bearings in housings is supported on the

boom head structure. The drive unit and the bearing housings are adequately protected by sheet

steel covers.

BOOM CONVEYOR

The reversible boom conveyor drive is mounted on a drive frame and is supported on the

revolving frame by a torque arm with plain spherical rod ends. The bearing housings supporting

the discharge pulley assembly on either side are supported on sliding blocks at boom head. The

movement of the bearing blocks for the purpose of adjustment of belt tension and belt changing

is achieved through screwed spindles.

International Journal of Engineering and Social Science

www.gjmr.org 16

IJESS Volume3, Issue6 ISSN: 2249- 9482

Belt sway, pull cord and belt slip monitor switches are included for protection of the conveyor.

BOOM LUFFING ARRANGEMENT

The raising and lowering of the hinged bascule

system and controlling it in operation, is achieved

by a hydraulic system with two hydraulic

cylinders. The cabin is also maintained level

automatically by a hydraulic cylinder fed

simultaneously from this system. The power pack

also includes an independent system for actuation

of the chutes etc. and is mounted on at the rear of

the revolving platform.

SLEWING ARRANGEMENT

The revolving superstructure of the machine is supported on a large diameter slewing bearing.

An external ring gear, bolted to the revolving frame, is driven by two meshing pinions powered

by two independent drive units each comprising a sq. cage motor, slip clutch, brake and

planetary with bevel helical gear reducer.

The slew angles are monitored by limit switches. Additional contacts in the limit switch ensure

that the boom can only be slewed over the yard conveyor after it has been raised clear of it.

TRIPPER CONVEYOR

The tripper raises the belt of the yard conveyor and supports it over a concave curve and

discharge through guide chute onto intermediate conveyor. After passing over the discharge

pulley, the belt is guided back to the yard level over a bend pulleys

INTERMEDIATE CONVEYOR

The intermediate conveyor shall travel on the same rails as those of machine. After receiving

from tripper, discharge pulley material on the boom conveyor by a chute.

The intermediate conveyor drive comprising motor, fluid coupling, brake and gear box, mounted

on a drive frame, is supported by a bracket. The hollow output shaft of the gear box is clamped

on the drive pulley shaft through a key-less shrink disc element.

IMPACT TABLE

It carries a number of idler assemblies for supporting the yard belt to take the impact of

reclaimed material.

International Journal of Engineering and Social Science

www.gjmr.org 17

IJESS Volume3, Issue6 ISSN: 2249- 9482

LONG TRAVEL MECHANISM

The gantry portal essentially consists of a ring

girder of box construction, supported at 3 points.

Two pier legs project from it on both rails side

and a third leg construction at the centre of two

rails.

An automatic rail clamp is provided on each rail

to secure the machine against drifting in storm.

PRINCIPLES OF OPERATION

The rail mounted stacker cum reclaimer is suitable for serving two parallel stockpiles, one on

either side of the track rails. The machine is designed to operate with a yard conveyor for

stacking and discharging at the same end during reclaiming i.e. a reversible one.

The following modes of operation are possible:

STACKING

The material on the forward moving yard conveyor is raised by the tripper and discharged

through a discharge guide chute onto an intermediate inclined conveyor which lift the material

and ultimately discharges on to the boom conveyor by a chute. The boom conveyor carries the

material up to its end and allows it to fall from a stockpile.

The stacking operation starts at one end of the stockpile with the boom kept low. The travel

motion operates simultaneously and at the other end of the stockpile, the motor reverse. After a

number of such cycles the boom is luffed up and the cycles repeated.

RECLAIMING

The machine reclaimes the material from the stockpile in layers by the rotating bucket wheel

swing across the pile. The material picked up by the bucket is retained and guided by the ring

chute as the buckets move up.

When the bucket is about 45 deg above horizontal, the material starts discharging it to the

bucket wheel chute, which guides it to the boom conveyor. On reaching the end of the conveyor,

the material passes through the central chute and portal chute on to the yard conveyor belt,

supported on the impact table.

The reclamation of the entire stockpile can be carried out either by bench-type and modular

methods.

International Journal of Engineering and Social Science

www.gjmr.org 18

IJESS Volume3, Issue6 ISSN: 2249- 9482

1. In the bench-type method the reclaimer starts at one end on the top bench or layer and

reclaims that bench for the full length of the pile. On reaching the end of the pile the machine

returns to the other end, the boom is lowered and reclaiming commences on the next lower

bench.

2. The modular method is accomplished by

starting at the top of the pile at one end and taking

a series of cuts one bench deep and then returning

to the end of the pile, lowering the boom and

taking the same number of cuts on the lower

bench. This process is repeated upto the lowest

bench, thereby completing one reclaim module.

MAINTENANCE AND INSPECTION

1. Conveyor components

The belt should be inspected regularly both in

standstill condition for any wear or damage and

when running to ensure straightness and that there

is no slip. All idlers should be inspected that they

rotate freely in operation.

2. Slew bearing

The slew bearing should be checked carefully and at regular intervals, every 3 months, to

determine the amount of wear in the races and thereby foresee the need for replacement.

3. Structural steel work

The entire structural steel work should be thoroughly inspected every year. The attention should

be paid to welds and loose bolts or rivets which should be immediately replaced. The paint work

should be inspected at least every six months.

4. Chutes and skirts

The chutes and skirts should be inspected for wear and clogging. The wear plates in the skirts

have to be checked at short intervals.

International Journal of Engineering and Social Science

www.gjmr.org 19

IJESS Volume3, Issue6 ISSN: 2249- 9482

5. Limit switches

All limit switches should be closely checked for free movement and satisfactory condition of the

contacts.

A similar inspection should be made for other electrical equipment inside and outside of E-

house, operator`s cabin and at other location of the machine.

ELECTRICAL MAINTENANCE

1. Motor maintenance

All electrical connections must be kept tight and clean. The motor should be stopped and isolated

from all supply points. Greasing of motor bearing is needed every 3 months. Motor vibration,

sound level, current has to be monitored regularly.

2. Variable frequency drive

a. Tightness check

b. Loop check

c. Voltage check of control transformer.

3. Air circuit breaker maintenance

a. Visual inspection of opened circuit breaker.

b. Arc chute checking is required in case of heavy wear and tear.

c. Check tripping circuit and its indication.

d. Breaker operation is to be checked.

4. Power transformer

a. Cleaning and tightness checking.

b. Winding resistance checking.

c. Satisfactory neutral grounding system.

WEEKLY MAINTENANCE

1. The oil level of all gear boxes should be checked.

2. All brakes should be inspected and adjusted if required.

3. The slew ring gear is to be checked for greasing.

4. All limit switches should be inspected.

6-MONTHLY MAINTENANCE

1. A general inspection should take place at half yearly intervals.

International Journal of Engineering and Social Science

www.gjmr.org 20

IJESS Volume3, Issue6 ISSN: 2249- 9482

2. All load carrying parts of the steel structure should be examined for possible cracks and

rusting.

3. The brakes should be checked for obtaining the braking torques.

4. A careful inspection of all the bearings should also be done.

DAILY INSPECTION

1. The operator should inspect daily the general condition of the machine, including lubrication.

2. All pins and bush bearings should be checked, especially those of the brakes.

3. It is to be seen whether used grease leaks out of all the bearings. If too much grease leaks out

of one bearing, it should be checked if there is too much wear. It may be necessary to adjust the

flow of grease.

4. All the fasteners should be checked for tightness.

CONCLUSION

This is the study made for improving the life of the equipment , to keep the equipment running in

good working condition and to improve the quality of operation. It describes the working

principle of stacker cum reclaimer in thermal power plant and also analyzes the proposed method

of equipment maintenance so as to reduce the failure of the equipment.

ACKNOWLEDGEMENT

I express my gratitude to the management of Parichha thermal power Jhansi and to the faculty of

MITS for their valuable support and help in my work.

REFERENCES

1. Lihua Zhao (2001),”The Adjustment Method of Conveyor Belt Deviation[J]”, Colliery

Machine, No.5.

2. Lihua Zhao and Yin Lin (2011),”Operation and Maintenance of Coal Handling System in

Thermal Power Plant [J]”, Colliery Machine, No. 2.

3. Mazurkiewicz D (2005), “Monitoring the Condition of Adhesive-Sealed Belt Conveyors in

Operation”, Maintenance and Reliablity, No. 3, pp. 41-49a.

4. Raghuvendra Singh Gurjar(20120,”Failure Analysis of Belt Conveyor System[J]”, I.J.E.S.S.,

Vol. 2, No. 10.

5. Parichha Thermal Power Plant, Jhansi.

International Journal of Engineering and Social Science

www.gjmr.org 21

Vous aimerez peut-être aussi

- Calculating Overall Equipment EffectivenessDocument2 pagesCalculating Overall Equipment Effectivenessbhavesh_balasPas encore d'évaluation

- Pushover Analysis ExplainedDocument62 pagesPushover Analysis ExplainedRakesh7770100% (2)

- Stability ChecksDocument5 pagesStability Checksshobhit mohtaPas encore d'évaluation

- Erection Procedure SCRDocument23 pagesErection Procedure SCRvskreddy90% (10)

- Shop Manual Komatsu WA250-1lcDocument648 pagesShop Manual Komatsu WA250-1lcElmer Lagua Malpaso100% (7)

- Network Rail Asset Protection Handbook High Speed Rail PDFDocument58 pagesNetwork Rail Asset Protection Handbook High Speed Rail PDFhugojameswoodPas encore d'évaluation

- Operational Writup of Stacker and ReclaimerDocument10 pagesOperational Writup of Stacker and ReclaimerZahoor AhmedPas encore d'évaluation

- Reclaim Material StockpileDocument8 pagesReclaim Material Stockpileprashant mishraPas encore d'évaluation

- 1workover OnshoreDocument100 pages1workover OnshoreLOVE SABBARWAL100% (1)

- Workover OpertionsDocument365 pagesWorkover Opertionsjayant89% (9)

- Write Up Apron FeederDocument11 pagesWrite Up Apron FeederParmeshwar Nath Tripathi0% (1)

- Corrosion and Material Selection in Desalination PlantsDocument32 pagesCorrosion and Material Selection in Desalination PlantsCharlie Chong100% (6)

- Stacker Reclaimers: Equipment Division of The HALL GroupDocument2 pagesStacker Reclaimers: Equipment Division of The HALL GroupJavier TorresPas encore d'évaluation

- Iw-02 Lime Stucco Waterproof Finish Rev 02 Final PDFDocument115 pagesIw-02 Lime Stucco Waterproof Finish Rev 02 Final PDFlinga2014Pas encore d'évaluation

- Types of Shipboard CranesDocument5 pagesTypes of Shipboard Cranesegyinspectoryahoo100% (1)

- Stacker Reclaimer 1Document14 pagesStacker Reclaimer 1Avinash GocherPas encore d'évaluation

- Design Aspects ForDocument11 pagesDesign Aspects ForNirajkumar NairPas encore d'évaluation

- Wagon TipplerDocument429 pagesWagon Tipplerparuchurivenkat52720% (1)

- Mechanised stacking and reclaiming systemsDocument31 pagesMechanised stacking and reclaiming systemsADITYA_PATHAK100% (2)

- An/arc-102 Parts Catalogue TM11-5821-248-34P - 1981Document222 pagesAn/arc-102 Parts Catalogue TM11-5821-248-34P - 1981ΒΕΗΣ ΣΤΕΛΙΟΣ Veis SteliosPas encore d'évaluation

- Stacker and Reclaimer Inspection ReportDocument8 pagesStacker and Reclaimer Inspection Reportriysall100% (1)

- Spare Parts List of Stacker SL. NODocument22 pagesSpare Parts List of Stacker SL. NOanil100% (1)

- Vibrating FeederDocument7 pagesVibrating FeederRk Upadhyay100% (1)

- Maximize crusher capacity with optimal roll speedDocument2 pagesMaximize crusher capacity with optimal roll speedWaris La Joi Wakatobi100% (1)

- Heating Belt Conveyor Design ReportDocument20 pagesHeating Belt Conveyor Design ReportamardeepsinghseeraPas encore d'évaluation

- P&ID Process Measurement DiagramDocument19 pagesP&ID Process Measurement Diagramian ridz100% (1)

- AA - SPEC - 254001 Stacker Reclaimer SpecDocument28 pagesAA - SPEC - 254001 Stacker Reclaimer SpecJD75% (4)

- Barrel Reclaimers TRFDocument4 pagesBarrel Reclaimers TRFkaustavPas encore d'évaluation

- Stacker ReclaimerDocument2 pagesStacker ReclaimerAvinash GocherPas encore d'évaluation

- Conveyor Belt StandardsDocument7 pagesConveyor Belt Standardssuraia100% (1)

- Deck MachineryDocument10 pagesDeck Machineryaman kumarPas encore d'évaluation

- Wagon Tippler Specification As Per Latest RDSO GuidelinesDocument29 pagesWagon Tippler Specification As Per Latest RDSO GuidelinesShantanu Dutta100% (2)

- HOMOGENIZATION OF BULK MATERIAL IN Chevron PileDocument7 pagesHOMOGENIZATION OF BULK MATERIAL IN Chevron Pilesupendra phuyal100% (1)

- Energy Efficiency GuidebookDocument55 pagesEnergy Efficiency Guidebookvinydv100% (1)

- Flange FacingDocument6 pagesFlange FacingDurjoy ChakrabortyPas encore d'évaluation

- Conveyor Belt Commissioning ProcedureDocument7 pagesConveyor Belt Commissioning Procedurevvijaybhan100% (6)

- IS Code For StackerDocument20 pagesIS Code For StackerManish VermaPas encore d'évaluation

- Enexco BrochureDocument35 pagesEnexco BrochureErin CraigPas encore d'évaluation

- Reclaimer Inspection ReportDocument51 pagesReclaimer Inspection ReportThiru Malpathi100% (1)

- Belt Conveyor Erection ManualDocument27 pagesBelt Conveyor Erection ManualIvonne BernatePas encore d'évaluation

- Hammer CrusherDocument2 pagesHammer Crusherdlodha5100% (1)

- ESP Operation ExplainedDocument162 pagesESP Operation ExplainedSekar CmPas encore d'évaluation

- Conveyor Chain Design GuideDocument64 pagesConveyor Chain Design GuideAtacomaPas encore d'évaluation

- Traveling Tripper Operation ProcedureDocument10 pagesTraveling Tripper Operation Procedureratan das75% (4)

- Stacker Reclaimer Improvements 2.09Document5 pagesStacker Reclaimer Improvements 2.09benduts100% (1)

- Elecon Scraper ReclaimerDocument8 pagesElecon Scraper ReclaimerADITYA_PATHAK100% (1)

- Shell White - VDU UpgradeDocument16 pagesShell White - VDU Upgradesachins1318Pas encore d'évaluation

- Pipe Conveyor SystemDocument6 pagesPipe Conveyor Systemsurajit81100% (2)

- Pipe Conveyors: Optimal Solutions For Specialised HandlingDocument6 pagesPipe Conveyors: Optimal Solutions For Specialised Handlingneeshakothari31Pas encore d'évaluation

- 04 Pipe ConveyorsDocument77 pages04 Pipe Conveyorsbetojulio100% (2)

- Stacker ReclaimerDocument16 pagesStacker ReclaimerThiru MalpathiPas encore d'évaluation

- Coal Conveyor Belt Fault DetectionDocument4 pagesCoal Conveyor Belt Fault Detectionc pawarPas encore d'évaluation

- Compressor FAD Calculation MethodsDocument2 pagesCompressor FAD Calculation MethodsDurjoy ChakrabortyPas encore d'évaluation

- QUESTION: STACKER RECLAIMER INSPECTIONDocument77 pagesQUESTION: STACKER RECLAIMER INSPECTIONAlif Rahmat Febrianto100% (1)

- 2.5.2.3 Inspection Task List - Circular Stacker ReclaimerDocument3 pages2.5.2.3 Inspection Task List - Circular Stacker Reclaimervikash kumar100% (2)

- Seminar Report On Hydrogen TrainDocument25 pagesSeminar Report On Hydrogen TrainYamuna100% (2)

- Methodology To Calculate The Effective Reclaiming Capacity of Rail Mounted Boom Type Bucket Wheel Reclaimer and Stacker ReclaimerDocument14 pagesMethodology To Calculate The Effective Reclaiming Capacity of Rail Mounted Boom Type Bucket Wheel Reclaimer and Stacker ReclaimerMatheus SimõesPas encore d'évaluation

- Wagons Modern Bulk Material HandlingDocument4 pagesWagons Modern Bulk Material Handlingparuchurivenkat5272Pas encore d'évaluation

- Stacker ReclaimerDocument4 pagesStacker ReclaimerVinoth Ravi100% (1)

- BIM 3D To 7D Implementation - Hani Elsafadi - Pulse - LinkedInDocument4 pagesBIM 3D To 7D Implementation - Hani Elsafadi - Pulse - LinkedInNurul Nabila SahriPas encore d'évaluation

- Obata - Grab Bucket Type Ship UnloaderDocument20 pagesObata - Grab Bucket Type Ship Unloadertrungnq_ktd97Pas encore d'évaluation

- 2.5.4. Combined Stacker/Reclaimers and Their LimitationsDocument19 pages2.5.4. Combined Stacker/Reclaimers and Their LimitationsMatheus Simões100% (1)

- Volume 5 Instruction Manual For Ship Unloader Stacker&Reclaimer Coal Handling System FinalDocument473 pagesVolume 5 Instruction Manual For Ship Unloader Stacker&Reclaimer Coal Handling System FinalVickySamsiadi75% (4)

- Shiploader Rev2 27may2010 PDFDocument24 pagesShiploader Rev2 27may2010 PDFYin ThoPas encore d'évaluation

- Elevator Belt and Splice Installation GuideDocument17 pagesElevator Belt and Splice Installation Guide4B Braime ComponentsPas encore d'évaluation

- Belt Conveyor: Installation, Operation Maintenance Safety ManualDocument13 pagesBelt Conveyor: Installation, Operation Maintenance Safety Manualsomjit saranai100% (2)

- L&T O&M ManualDocument156 pagesL&T O&M Manualranajoy71971Pas encore d'évaluation

- Japan Pipe Belt Conveyor Sy...Document7 pagesJapan Pipe Belt Conveyor Sy...salkan_rahmanovic810Pas encore d'évaluation

- Ijess Volume3, Issue6 ISSN: 2249-9482 Operation and Maintenance of Stacker Cum Relaimer in Coal Handling Plant in Thermal Power PlantDocument7 pagesIjess Volume3, Issue6 ISSN: 2249-9482 Operation and Maintenance of Stacker Cum Relaimer in Coal Handling Plant in Thermal Power Plantramanujam59Pas encore d'évaluation

- BWSR Safety Features PDFDocument3 pagesBWSR Safety Features PDFVijayakumarVageesanPas encore d'évaluation

- Safety Features For Reduction of Failure in Stacker Cum Reclaimer For Thermal Power PlantDocument3 pagesSafety Features For Reduction of Failure in Stacker Cum Reclaimer For Thermal Power PlantIjsrnet EditorialPas encore d'évaluation

- Long Belt Conveyor Operation Manual: I. FunctionDocument6 pagesLong Belt Conveyor Operation Manual: I. FunctionkhaiphuongPas encore d'évaluation

- Deck machinery and cargo handling equipmentDocument20 pagesDeck machinery and cargo handling equipmentMalik ForbesPas encore d'évaluation

- Choose Between Long-Stroke Sucker Rod Pumping Systems.: September 2015Document5 pagesChoose Between Long-Stroke Sucker Rod Pumping Systems.: September 2015Mohanad HussienPas encore d'évaluation

- VM TYPE Undercarriages CIPI2001Document30 pagesVM TYPE Undercarriages CIPI2001Edgar Revok VelazquezPas encore d'évaluation

- Rolling Technical Information H3 PDFDocument8 pagesRolling Technical Information H3 PDFswapneel_kulkarniPas encore d'évaluation

- 17ME64 DME Module 2Document21 pages17ME64 DME Module 2Shridhar ChinuuPas encore d'évaluation

- Energy Storage 101.Document65 pagesEnergy Storage 101.Durjoy ChakrabortyPas encore d'évaluation

- ST 14114Document8 pagesST 14114Durjoy ChakrabortyPas encore d'évaluation

- H2 KoreanDocument3 pagesH2 KoreanDurjoy ChakrabortyPas encore d'évaluation

- GEC-High Production CapabilityDocument1 pageGEC-High Production CapabilityDurjoy ChakrabortyPas encore d'évaluation

- Dec 08 - 08 - Sharma NPL - Emission Factors & Methodology (Compatibility Mode)Document44 pagesDec 08 - 08 - Sharma NPL - Emission Factors & Methodology (Compatibility Mode)Durjoy ChakrabortyPas encore d'évaluation

- Chemical & Process Technology: From Rs.2,879Document3 pagesChemical & Process Technology: From Rs.2,879Bhavana KewlaniPas encore d'évaluation

- TG SynchronizationDocument7 pagesTG SynchronizationDurjoy ChakrabortyPas encore d'évaluation

- Energies 09 00857Document20 pagesEnergies 09 00857Durjoy ChakrabortyPas encore d'évaluation

- Battery Components-REDoxDocument1 pageBattery Components-REDoxDurjoy ChakrabortyPas encore d'évaluation

- Cranes - Range Diagram and Lifting Capacity - RT665Document12 pagesCranes - Range Diagram and Lifting Capacity - RT665Bhavana Kewlani100% (1)

- EpcDocument18 pagesEpcDurjoy ChakrabortyPas encore d'évaluation

- Bridge Bearing PDFDocument7 pagesBridge Bearing PDFDurjoy ChakrabortyPas encore d'évaluation

- EpcDocument18 pagesEpcDurjoy ChakrabortyPas encore d'évaluation

- ACCDocument4 pagesACCDurjoy ChakrabortyPas encore d'évaluation

- Energies 09 00098Document14 pagesEnergies 09 00098dssrwrtgwtgPas encore d'évaluation

- A 240106Document6 pagesA 240106Durjoy ChakrabortyPas encore d'évaluation

- TechNote - DIS Daiki Japan Seawater Electrochlorination ProposalsDocument5 pagesTechNote - DIS Daiki Japan Seawater Electrochlorination ProposalsRomeo Jaka RPas encore d'évaluation

- Comparison of Counter Flow and Cross Flow CoolingDocument2 pagesComparison of Counter Flow and Cross Flow CoolingDurjoy ChakrabortyPas encore d'évaluation

- Glass Fibre Reinforced Products PDFDocument16 pagesGlass Fibre Reinforced Products PDFDurjoy ChakrabortyPas encore d'évaluation

- Coal FLowDocument28 pagesCoal FLowDurjoy ChakrabortyPas encore d'évaluation

- Fuel Audit Full Report PDFDocument198 pagesFuel Audit Full Report PDFDurjoy ChakrabortyPas encore d'évaluation

- The Dome Valve Is Normally ClosedDocument1 pageThe Dome Valve Is Normally ClosedDurjoy ChakrabortyPas encore d'évaluation

- LinksDocument1 pageLinksDurjoy ChakrabortyPas encore d'évaluation

- Restriction Orifice Diamater CalculationDocument1 pageRestriction Orifice Diamater CalculationDurjoy ChakrabortyPas encore d'évaluation

- Service Manual: Color Television Chassis No. SN-81Document2 pagesService Manual: Color Television Chassis No. SN-81Manuel SierraPas encore d'évaluation

- M14 Spring GuidesDocument4 pagesM14 Spring Guideswatch_sutPas encore d'évaluation

- Ev Pa2400t PDFDocument2 pagesEv Pa2400t PDFMuhiyadinPas encore d'évaluation

- Artistic Craft Centre (3) Project FileDocument9 pagesArtistic Craft Centre (3) Project Fileshubham shuklaPas encore d'évaluation

- Vermicomposting From Gondia Municipal Solid WasteDocument7 pagesVermicomposting From Gondia Municipal Solid WasteInternational Journal of Innovations in Engineering and SciencePas encore d'évaluation

- Sop 9Document11 pagesSop 9nemesis123Pas encore d'évaluation

- APT Axpert VM III 3.2 5.2KW Manual 20180122Document45 pagesAPT Axpert VM III 3.2 5.2KW Manual 20180122TariqMaqsood50% (2)

- CATALOG 2017 (Branch-Wise)Document33 pagesCATALOG 2017 (Branch-Wise)RajeevSangamPas encore d'évaluation

- 9415Document5 pages9415Fiaz juttPas encore d'évaluation

- July 2017Document96 pagesJuly 2017Pumper MagazinePas encore d'évaluation

- Rohan ResumeDocument2 pagesRohan ResumeRohanPas encore d'évaluation

- Evolution of Production and Operations ManagementDocument14 pagesEvolution of Production and Operations ManagementbashaprabhuPas encore d'évaluation

- Class3 MSW025-30F SpecsheetDocument4 pagesClass3 MSW025-30F SpecsheetgamunozdPas encore d'évaluation

- Volvo EC330Cl Excavator SpecsDocument12 pagesVolvo EC330Cl Excavator Specswalk111Pas encore d'évaluation

- BHATIDocument21 pagesBHATIKnowledge pediaPas encore d'évaluation

- A Range of Compact, Pressure Seal Gate Valves, Designed According To ASME B16.34Document4 pagesA Range of Compact, Pressure Seal Gate Valves, Designed According To ASME B16.34sureshisisis100% (2)

- DIY Filament Extruder Kit v2 - Store of WH HuangDocument5 pagesDIY Filament Extruder Kit v2 - Store of WH Huangeduardo toscanoPas encore d'évaluation

- Replacing SGDH in Field W MP940Document3 pagesReplacing SGDH in Field W MP940jroyal692974Pas encore d'évaluation

- DC MotorDocument4 pagesDC MotorNikhith ReddyPas encore d'évaluation