Académique Documents

Professionnel Documents

Culture Documents

8 Green Roof Argument

Transféré par

Patricia OlgaCopyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

8 Green Roof Argument

Transféré par

Patricia OlgaDroits d'auteur :

Formats disponibles

6

ECOLOGY

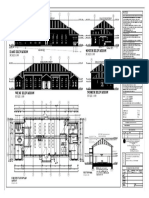

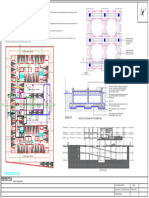

1 1:10 Detail of the Intensive Green Roof

The green roof 6

The option for the green roof was both its ecological value and its importance

drainage drainage

to physically integrate and link the building to hill and its surrounding weavy

landscape. It also helps to reduce the impact of climate change by keeping

the building cool in summer, soaking up heavy rainfall and absorbing carbon

dioxide from the atmosphere.

As 200kg/m2 soil will be used for construction, the roof may turn into an

interactive and useful space, giving the possibility to be planted. exterior concrete wall 150mm

5

ventilation air gap

Precedent study: Sharrow School near Sheffield

thermal insulation mineral wool 150mm

2 drainage

placed between steel square coloums.

2,000 square metres green roof Green roof: - soil and vegetation 200kg/m2

GLASS BARN LEVEL SC. 1:100

- filter layer

Rain harvesting system 35 roof terrace

- waterproof layer,copper foil protected

36 exibition space

5 glass workshop

6 glass fournace

13 elevator

15 courtayard

21 dinning room terrace

The Lake District is the wettest part in the UK, with average annual totals - thermal 5insulation

27 ramp to climb the house and the hill

32 hill corridor towards accomodation

33 artists accomodation

toilets, dishwasher exterior concrete wall 150mm

exceeding 2,000 mm/year. This drove the decision for the rain harvesting sys- washing machine 6

ventilation air gap with extruded polysthyrene 150mm

tem, using the green roof to soak the water. The system will be used to provide 15

5

32

thermal insulation mineral wool 150mm

placed between steel square coloums. -wood shuttering left in place as a finishing

water for the toilets and for the garden. drainage layer

33

STREAM ON SITE

The space allocated for this system is placed at the ground floor level attached

35

waterproofing membrane EPDM

480m2 protection concrete wall 100mm

to the concrete barn ( which contains all the toilets). The room can be accessed

13

thermal insulation, extruded polysthyrene: 180mm

polythylene membrane- vapor barrier

from the courtyard and collects the water from the concrete barn green roof. 36

structural reinforced concrete wall:250mm

(retaining wall poured in situ)

Roof surface:480m2, 60% efficiency of collection from 70% out of 480m2; 27

Roof surface of collection: 330m2

20

drainage layer

Amount of rain in Lake District: 2000mm/year surface of the green roof on my building protection waterproofing membrane EPDM

3

7

15

concrete wall 100mm

19 18

4

5

Water collection/year: 660 m3 x 60/100 = 400m3 that collects rain water

15

thermal insulation, extruded polysthyrene: 180mm

14

polythylene membrane- vapor barrier

Approximative water necessity for 1 day:

LONG SECTION THROUGH THE LIGHT ATRIUM SC.

structural reinforced concrete wall:250mm

LONG SECTION THROUGH THE LIGHT ATRIUM SC.100 (A1)

LONG SECTION THROUGH THE ATRIUM SC.1:100 (A1)

LANE ON THE HILL

possible location for the garden (retaining wall poured in situ)

- 6 toilets+ garden tap = 400L 6

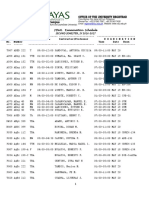

GRP Tank capacity: 2400L, 1200mm diameter and 2470mm length.

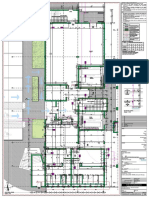

1 main public entrance 13 evevator

14 corridor

courtyard

2 workshop area

3 light atrium 15 interior courtyard

5

17 4 events room 16 water circuit system

15 5 glass workshop 17 corridor towards events room

6 glass fournance and accomodation

16 access 7 kitchen

8 pantry

9 toilets

18 plant room

19 dinning room

20 stair towards the exibition space

10 objects storage 21 terrace

toilets

11 glass storage 22 ramps to climb the hiill

dinning room

intensive Green Roof

12 metal storage and the house

18

9 8 7

kitchen

12 11 10 9

4 6

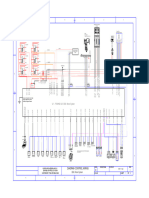

Besides the conventional system this one includes a header tank with a dual 13 14

19

given in bibliography 1

inlet. In case of pump failure the main water inlet opens.

20

3

21

22

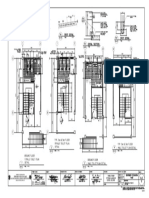

green roof soil and vegetation 200kg/m2

filter layer

1

GROUND FLOOR PLAN SC. 1:100 (A1)

waterproof layer, copper foil protected

thermal insulation with extruded polysthyrene: 150mm

position on the plan of the rainwater harvesting system wood shuttering

exterior concrete wall 150mm

left in place as a finishing

ventilation air gap

5

thermal insulation mineral wool 150mm

placed between steel square coloums. materials entrance

2

Geothermal energy

green roof soil and vegetation 200kg/m2

drainage layer

filter layer waterproofing membrane EPDM

Considering that the site, unlike urban sites is located in an wide landscape

protection concrete wall 100mm

waterproof layer,

thermal insulation, extruded copper

polysthyrene: 180mm

polythylene membrane- vapor barrier

foil protected

structural reinforced concrete wall:250mm 4

(retaining wall poured in situ)

area, with no trees besides the trees barrier nearby towards the West main thermal insulation with extruded polysthyrene: 150mm

storage room

wood shuttering left in place as a finishing

Road, it makes it possible in this case to use geothermal energy. The land-

scape provides advantages to use the surface type of underground pipes,

which is cheaper

and geothermal energy is a constant energy supply. green roof soil and vegetation 200kg/m2

filter layer

waterproof layer, copper foil protected aluminiun brackets with laminated safety

thermal insulation with extruded polysthyrene: 150mm

aluminiun track for glass louvres.

wood shuttering left in place as a finishing double glazing 10mm sun-screen toughen

glass

laminated timber beam.

Diagram of the dual in-let system,

similar position of the tank as in my case

diagramme from: http://www.rainharvesting.co.uk/pages/systems/systs_hdrtnk.html

Vous aimerez peut-être aussi

- Equids Zebras, Asses and Horses - IUCNDocument204 pagesEquids Zebras, Asses and Horses - IUCNringpiecePas encore d'évaluation

- Car Wash AssignmentDocument23 pagesCar Wash AssignmentTahir Yaqoob50% (2)

- Mill OptimizationDocument45 pagesMill OptimizationDSG100% (5)

- Green Building Code PHDocument322 pagesGreen Building Code PHdesignfrrPas encore d'évaluation

- CASE STUDY. Ground ImprovementDocument6 pagesCASE STUDY. Ground ImprovementRashdanPas encore d'évaluation

- Isha Fore Flower Sept 2019Document24 pagesIsha Fore Flower Sept 2019aaha74Pas encore d'évaluation

- QSC gx5 SH Ts SCHDocument1 pageQSC gx5 SH Ts SCHel pule100% (1)

- DAO 2010 21 Consolidated DAODocument144 pagesDAO 2010 21 Consolidated DAOcecilemarisgozalo98100% (2)

- SeparatorsDocument6 pagesSeparatorsKADİR durmaz100% (1)

- NRW Impact To The Service, Environment and FinancialDocument16 pagesNRW Impact To The Service, Environment and FinancialAkmalYahyaPas encore d'évaluation

- Drawing 1.Document1 pageDrawing 1.tiyaniPas encore d'évaluation

- Drawing 3.Document1 pageDrawing 3.tiyaniPas encore d'évaluation

- Drawing 2.Document1 pageDrawing 2.tiyaniPas encore d'évaluation

- Liquid Petroleum Gas (LPG) Systems: Installation NotesDocument3 pagesLiquid Petroleum Gas (LPG) Systems: Installation NotesSamaila Anthony MalimaPas encore d'évaluation

- Side Elevation Front Elevation Side Elevation Rear ElevationDocument1 pageSide Elevation Front Elevation Side Elevation Rear ElevationGary ChestersPas encore d'évaluation

- East Elevation South Elevation: Church HallDocument1 pageEast Elevation South Elevation: Church HallanzaniPas encore d'évaluation

- Polyethylene Fittings Price List Westwood - PricelistDocument64 pagesPolyethylene Fittings Price List Westwood - PricelistElvi PapajPas encore d'évaluation

- Kafd A1 111 Comn NSF XXXXX WSP Phe DWG 00039Document1 pageKafd A1 111 Comn NSF XXXXX WSP Phe DWG 00039YazPas encore d'évaluation

- Niwaha IvanDocument1 pageNiwaha IvanTwebazibwe EdsonPas encore d'évaluation

- 200M3 IGNITION OIL TANK 2 (R-03) - ModelDocument1 page200M3 IGNITION OIL TANK 2 (R-03) - Modelery achjariPas encore d'évaluation

- 200M3 IGNITION OIL TANK3 (R-03) - ModelDocument1 page200M3 IGNITION OIL TANK3 (R-03) - Modelery achjariPas encore d'évaluation

- Ground Floor: Back Elevation Side ElevationDocument1 pageGround Floor: Back Elevation Side ElevationanzaniPas encore d'évaluation

- T7 Picking and Passivation Procedure (18 06 2019)Document6 pagesT7 Picking and Passivation Procedure (18 06 2019)Walid AmdouniPas encore d'évaluation

- Polypropylene Magnetic Drive Process PumpsDocument6 pagesPolypropylene Magnetic Drive Process Pumpsjagg_studPas encore d'évaluation

- Uio 66Document2 pagesUio 66Dwindi Agryanti JoharPas encore d'évaluation

- Enamelled WireDocument20 pagesEnamelled WireNesya LaxmithaPas encore d'évaluation

- Catalogue: A C Ompan y of Ha Wle German y GR OupDocument62 pagesCatalogue: A C Ompan y of Ha Wle German y GR OupAlvin TombarevicPas encore d'évaluation

- 9971-1120 All eDocument3 pages9971-1120 All emohamad eslamiPas encore d'évaluation

- LOS1-A-2202-OPS-PH1A - Rev 10 - Plan - Builders Work - Ground LevelDocument1 pageLOS1-A-2202-OPS-PH1A - Rev 10 - Plan - Builders Work - Ground LevelTosin FamuyiwaPas encore d'évaluation

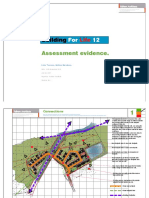

- Building: Assessment EvidenceDocument7 pagesBuilding: Assessment EvidencemalehalePas encore d'évaluation

- Pile FoundationDocument1 pagePile FoundationarchitecturebyamPas encore d'évaluation

- Tcbrochure enDocument4 pagesTcbrochure enyazedPas encore d'évaluation

- Deepak Filling Point-ModelDocument1 pageDeepak Filling Point-ModelPRUTHWIRAJ DAS [पृथ्वीराज दास]Pas encore d'évaluation

- Drawing 4.Document1 pageDrawing 4.tiyaniPas encore d'évaluation

- Ficha Tecnica CVT - 2M2® (Eng)Document3 pagesFicha Tecnica CVT - 2M2® (Eng)Ana María Molina MuñozPas encore d'évaluation

- 3,4 CoreDocument3 pages3,4 CoreNgô Trí DũngPas encore d'évaluation

- Fibre As An Ecosystem ServiceDocument9 pagesFibre As An Ecosystem ServiceSimi APas encore d'évaluation

- 03 180000 4800000253 SSJ Mec DRG 141004 - ADocument1 page03 180000 4800000253 SSJ Mec DRG 141004 - APalmacio DinolanPas encore d'évaluation

- Others - Daylight Analysis-1 PDFDocument1 pageOthers - Daylight Analysis-1 PDFرقيه العتومPas encore d'évaluation

- Current Set 4.1.21 PDFDocument21 pagesCurrent Set 4.1.21 PDFAkshay chavanPas encore d'évaluation

- 25 Favorite Christmas Duets For French HornDocument44 pages25 Favorite Christmas Duets For French HornRobin WinterfloodPas encore d'évaluation

- Branch Panel: Pp-Hvac-R1 Branch Panel: Pp-Hvac-R2 Branch Panel: Pp-Hvac-R3Document1 pageBranch Panel: Pp-Hvac-R1 Branch Panel: Pp-Hvac-R2 Branch Panel: Pp-Hvac-R3iunitedfactorysaPas encore d'évaluation

- Thermomechanical Processing of High T Superconducting Wire: Super BSCCO FamilyDocument15 pagesThermomechanical Processing of High T Superconducting Wire: Super BSCCO FamilyS. M. Habibul AhsanPas encore d'évaluation

- Legend: Key-Plan Distribution Special Systems ZonesDocument1 pageLegend: Key-Plan Distribution Special Systems ZonesDolyPas encore d'évaluation

- Modular MD: State-of-the-Art ICU Facilities For Rapid Medical ResponseDocument2 pagesModular MD: State-of-the-Art ICU Facilities For Rapid Medical ResponseakinravPas encore d'évaluation

- CorellaDocument2 pagesCorellamikey434Pas encore d'évaluation

- ATEE Educational Effects MatrixDocument1 pageATEE Educational Effects MatrixJannatPas encore d'évaluation

- Ampeg Svt-7 Pro 0032538-Xx Reva00 SCH PDFDocument1 pageAmpeg Svt-7 Pro 0032538-Xx Reva00 SCH PDFSlp Servicos e Produtos - AtendimentoPas encore d'évaluation

- To Main Board J13 To Output Board J5 5.5:1Document1 pageTo Main Board J13 To Output Board J5 5.5:1Dominik HamerskiPas encore d'évaluation

- The Millennium Tower Research PaperDocument4 pagesThe Millennium Tower Research PaperalaraPas encore d'évaluation

- 4.1 Catalogue Hang SangjinDocument77 pages4.1 Catalogue Hang SangjinKiến Huy LưuPas encore d'évaluation

- MFE Shell Plan - Signed OffDocument2 pagesMFE Shell Plan - Signed OffJuly FermiaPas encore d'évaluation

- Abfw 15-1552 - SID - DED - 01-02-OLFDocument1 pageAbfw 15-1552 - SID - DED - 01-02-OLFyonie prasetyoPas encore d'évaluation

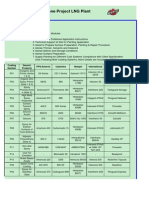

- Wheatstone Project LNG Plant: MR Number XX Title: Scope of WoDocument4 pagesWheatstone Project LNG Plant: MR Number XX Title: Scope of WoLegend AnbuPas encore d'évaluation

- A4 - Elevations and SectionsDocument1 pageA4 - Elevations and SectionsArjelyPas encore d'évaluation

- Stone Grinding Shed Detail Option-2-ModelDocument1 pageStone Grinding Shed Detail Option-2-ModelHabibur RahmanPas encore d'évaluation

- Vendor:: Issued For Detailed Engineering Phase English Language Shall GovernDocument1 pageVendor:: Issued For Detailed Engineering Phase English Language Shall GovernGustavo ChoquePas encore d'évaluation

- Zoning Rev1 25-Aug-20Document1 pageZoning Rev1 25-Aug-20ahmed yaqoobPas encore d'évaluation

- Peta Stack Out PLTM CIKANCANA-1.LAYDocument1 pagePeta Stack Out PLTM CIKANCANA-1.LAYmuzaka raiPas encore d'évaluation

- Dashboard ReportDocument140 pagesDashboard Reportm13naserrajaPas encore d'évaluation

- Ampeg Pf500 Main Power Supply 2034544-01-c02-SchDocument2 pagesAmpeg Pf500 Main Power Supply 2034544-01-c02-SchManuel CoutoPas encore d'évaluation

- Analysis Behind Casing: A Door To Improved Oil Recovery From A Carbonate Reservoir in IndiaDocument9 pagesAnalysis Behind Casing: A Door To Improved Oil Recovery From A Carbonate Reservoir in IndiaanoopscribdPas encore d'évaluation

- 1691873504-Brochure Pavani Royale - Availaible - 07!08!2023Document5 pages1691873504-Brochure Pavani Royale - Availaible - 07!08!2023miraj ahmedPas encore d'évaluation

- Spot Detail Det. Elevation of Ramp Spot Detail: A-6 5a A-6 5b 5b1Document1 pageSpot Detail Det. Elevation of Ramp Spot Detail: A-6 5a A-6 5b 5b1Jhn Cbllr BqngPas encore d'évaluation

- 2005 08 Os Fpso PSTR Mapa2Document1 page2005 08 Os Fpso PSTR Mapa2Juan de la Cruz Gil AlcocerPas encore d'évaluation

- Air On The G String HZ CDocument1 pageAir On The G String HZ Cfelistavelin8532Pas encore d'évaluation

- LWVP Standlake To NewbridgeDocument2 pagesLWVP Standlake To NewbridgeDaniel London CharlesPas encore d'évaluation

- Needs Analysis For Capacity Building of Artisanal Miners in Central AfricaDocument8 pagesNeeds Analysis For Capacity Building of Artisanal Miners in Central AfricanobleconsultantsPas encore d'évaluation

- The City of Tomorrow: Le CorbusierDocument13 pagesThe City of Tomorrow: Le CorbusierJolar Marc GuevarraPas encore d'évaluation

- Lecture 31Document13 pagesLecture 31alfredomotaPas encore d'évaluation

- ﺭﻤﺘﻟﺍ لﻴﺨﻨ ﺩﻴﻤﺴﺘﻟ ﺔﻔﻴﻟﻭﺘ ﻡﻴﻴﻘﺘ ﻲﻓ ﺔﺴﺍﺭﺩ) dactylifeira .L (ﻑﻨﺼ ﻱﻭﺍﺭﻀﺨ ﻁﻴﻘﻨﺘﻟﺎﺒ ﻱﺭﻟﺍ ﻡﺎﻅﻨ ﺕﺤﺘDocument8 pagesﺭﻤﺘﻟﺍ لﻴﺨﻨ ﺩﻴﻤﺴﺘﻟ ﺔﻔﻴﻟﻭﺘ ﻡﻴﻴﻘﺘ ﻲﻓ ﺔﺴﺍﺭﺩ) dactylifeira .L (ﻑﻨﺼ ﻱﻭﺍﺭﻀﺨ ﻁﻴﻘﻨﺘﻟﺎﺒ ﻱﺭﻟﺍ ﻡﺎﻅﻨ ﺕﺤﺘdadaPas encore d'évaluation

- Forest Fires in Europe 2009Document86 pagesForest Fires in Europe 2009FG SummerPas encore d'évaluation

- Career Save GameDocument5 pagesCareer Save GameNemanja Cone RadicPas encore d'évaluation

- Client StoryDocument1 pageClient StorybernabethPas encore d'évaluation

- Limitations of The Ferrozine Method For Quantitative Assayof Mineral Systems For Ferrous and Total IronDocument8 pagesLimitations of The Ferrozine Method For Quantitative Assayof Mineral Systems For Ferrous and Total Ironmini2018Pas encore d'évaluation

- FINAL Exam, 2nd Semester, SY 2016-2017 - by SubjectDocument35 pagesFINAL Exam, 2nd Semester, SY 2016-2017 - by SubjectAliana Gene Sarmiento100% (8)

- Naturamin-WSP ING Resultados Stress Salino V1Document12 pagesNaturamin-WSP ING Resultados Stress Salino V1Petre Constantin100% (1)

- 3P Arctic: The Polar Petroleum Potential Conference & Exhibition Preliminary ProgramDocument14 pages3P Arctic: The Polar Petroleum Potential Conference & Exhibition Preliminary ProgramAAPG_Events100% (2)

- Uruk Countryside PDFDocument258 pagesUruk Countryside PDFSergio Andrés100% (1)

- Sugarcane Juice With Baking Soda As An AdmixtureDocument24 pagesSugarcane Juice With Baking Soda As An AdmixtureKleine Kristenne Pare DavidPas encore d'évaluation

- SaldaDocument2 pagesSaldaFarah SchmidtPas encore d'évaluation

- Linked FlupDocument38 pagesLinked FlupShirley MarayaPas encore d'évaluation

- Thomas P LeckyDocument5 pagesThomas P LeckycrnoblePas encore d'évaluation

- Filed Joint Industry Petitioners Tailoring and Timing Rule Brief 06202011Document199 pagesFiled Joint Industry Petitioners Tailoring and Timing Rule Brief 06202011National Association of Manufacturers (NAM)Pas encore d'évaluation

- Composting CalculationsDocument17 pagesComposting Calculationswilsonbravo30Pas encore d'évaluation

- Community Environment and Natural Resources Office: Page 1 of 3Document3 pagesCommunity Environment and Natural Resources Office: Page 1 of 3cenro alaminosPas encore d'évaluation

- Colorado Montrose Zoning PDFDocument2 pagesColorado Montrose Zoning PDFParkerPas encore d'évaluation

- Watershed Modeling Using Arc Hydro Tools. Geo HMS and HEC-HMS PDFDocument41 pagesWatershed Modeling Using Arc Hydro Tools. Geo HMS and HEC-HMS PDFdhydhy nunuPas encore d'évaluation

- Technical Guideline Number 01: Environmental Impact AssessmentDocument6 pagesTechnical Guideline Number 01: Environmental Impact Assessmentk.r.sureshbabuPas encore d'évaluation