Académique Documents

Professionnel Documents

Culture Documents

Lindquist1997 PDF

Transféré par

Fausto SalazarDescription originale:

Titre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Lindquist1997 PDF

Transféré par

Fausto SalazarDroits d'auteur :

Formats disponibles

In the Laboratory

Properties of Zeolite A Obtained from Powdered Laundry Detergent

An Undergraduate Experiment

Alison L. Smoot and David A. Lindquist

Department of Chemistry, University of Arkansas at Little Rock, Little Rock, AR 72204

Until recently, sodium tripolyphosphate (Na5P 3O10) was Since zeolite is the only insoluble component of detergent,

the preferred builder in laundry detergents. Since phos- it is isolated by filtering a solution of the detergent followed

phates stimulate growth of algae in wastewater they have by washing of the zeolite with water. The zeolite crystals

been replaced in most laundry detergents by the sodium used in detergents are very small (≈1 µm), so a fine filter

form of zeolite A (Na-A) (1). Zeolite A acts as a water soft- paper should be used. The weight percentage of Na-A in the

ener by cation exchange of its sodium ions for calcium and detergent may be determined. Since the zeolite is hygro-

magnesium ions. The utility of zeolites extends far beyond scopic, the powder should be heated to about 400 °C before

water softening. Zeolites are used in immense quantities as weighing.

catalysts for petroleum cracking and isomerization reac-

tions (2). Other applications include their use as desiccants, Water Softening Property of Na-A

selective adsorbents, and ion exchange materials. The water-softening property of Na-A can be demon-

In this experiment students are introduced to the strated by shaking a large stoppered test tube half-filled

myriad properties of zeolites using Na-A from detergent. with tap water, 0.25 g of zeolite, and a very small drop of

The appeal of this experiment is the study of a useful and liquid dish soap. The height of the suds layer formed in the

versatile material obtained from a common household prod- test tube will be greater than in a similar tube containing

uct. As an extension to the experiments described here one soapy water but no zeolite. The zeolite acts as a softener by

may synthesize Na-A to compare its properties with those exchanging the hard Ca2+ and Mg2+ ions of the tap water

of the commercial material (3). for Na+.

Na-A has a high ion exchange capacity because it is an

aluminum-rich zeolite containing approximately equal Desiccant Properties of Na-A

numbers of aluminum, silicon, and sodium atoms with an Na-A is hygroscopic, absorbing approximately 20 wt%

empirical formula of NaAlSiO4 . The composition of zeolite of water. This is quantified by first weighing a few grams of

A can be varied considerably to form silicon-rich material zeolite in a crucible after drying overnight at 400 °C. The dry

by using lesser quantities of aluminum during synthesis. zeolite in the crucible then is placed in a humid environment

Silicon-rich compositions have lower ion exchange capacity, and weighed again when the mass has equilibrated.

so they are not used in detergents.

The framework of zeolites is based on a simple motif of Ion Exchange Properties of Zeolite A

tetrahedrally coordinated aluminum and silicon atoms con- Detergent zeolite has an approximate empirical for-

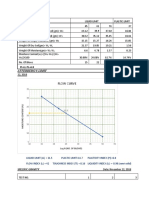

nected by bridging two coordinate oxygen atoms. Figure 1 mula of NaAlSiO4. If Na-A is placed in a solution rich in

is an illustration of the cubic unit Ca2+ ions, then ion exchange yields a zeolite formula of

cell of zeolite A (4). Each vertex in Ca0.5AlSiO4 . The degree of exchange can be quantified by

the figure represents an aluminum determining the decrease in Ca2+ solution concentration af-

or silicon atom and each line repre- ter ion exchange.

sents an Al–O–Si or Si–O–Si link- The Ca2+ solution for exchange is prepared by dissolv-

age. There are several types of zeo- ing approximately 15 g CaCl2·H2 O in 200 mL of distilled

lites, but all have the common fea- water. The solution is standardized by chelometric titration

ture of a network of internal pores. of Ca2+ with ethylenediaminetetraacetic acid (EDTA) (5). Ti-

The size and geometry of the pores tration procedures are found in most standard analytical

in a specific zeolite are defined by chemistry texts.

the crystal structure. The diameter Exchange then is performed using 100 mL of the stan-

of the eight-member ring entrance Figure 1. Zeolite A unit cell. dardized CaCl2 solution to which is added approximately 6

to the pores in zeolite A is 4.1 Å (2). g of accurately weighed Na-A dried overnight at 400 °C be-

The zeolite framework is neutral in charge if composed fore weighing. The mixture then is stirred for 30 min and

solely of silicon and oxygen. However, the zeolite framework the zeolite powder allowed to settle. An aliquot of the solu-

adopts one negative charge for each aluminum incorporated tion is titrated as before and the degree of ion exchange in

into the structure, since aluminum has a formal charge of the zeolite determined. For example, 6 g of Na-A (NaAlSiO4)

3+ whereas silicon is 4+. Additional cations are needed to will accommodate approximately 0.021 mol of Ca2+, corre-

accommodate the increasing charge with increasing alumi- sponding to a formula of Ca0.5AlSiO4 after exchange.

num content. In the case of Na-A, these additional cations

are sodium ions residing in the pores. Sodium ions can be Zeolite HA as a Dehydration Catalyst

readily exchanged for other cations small enough to fit into Zeolite A will catalyze the dehydration of an alcohol to

the pores (i.e., <4.1 Å in diameter). form an alkene. To make the zeolite catalytically active it is

converted to its acid form (H-A). The Na+ ions in Na-A are

Some Experiments Using Zeolite A first exchanged for NH4 + ions by stirring a mixture of a few

grams of zeolite in an ammonium chloride solution (10 g

Extracting Na-A from Detergent: NH4 Cl in 40 mL H2 O) for one hour. The supernatant solu-

Powdered laundry detergents specifying “aluminosili- tion is discarded and the zeolite filtered and washed. The

cates” on the ingredients list are those containing Na-A. NH4 + exchanged zeolite then is heated overnight in air at

Vol. 74 No. 5 May 1997 • Journal of Chemical Education 569

In the Laboratory

400 °C to drive off ammonia and make the protonated form The alkene is characterized by the infrared spectrum

of zeolite according eq 1. of the oil solution. The salient feature is the olefinic C–H

out-of-plane wagging vibration at 801 cm{1. The C=C stretch

400 °C at 1660 cm{1 is very weak. Primary and secondary alcohols

NH4+-A → H+-A + NH3 (1) may also be dehydrated by H-A, though not as easily as ter-

tiary alcohols owing to the stability of the tertiary

A few grams of zeolite (H-A) are placed in the middle carbocation intermediate. Most catalytic reactions using

section of a length of Pyrex glass tubing and held in place zeolites are designed to take place within the zeolite pores.

with a loose plug of glass wool on each side of the powder. The neopentyl alcohol molecule is too large to enter the H-

Using rubber tubing, one end of the glass tube is connected A pores, but the surfaces of the zeolite crystals are suffi-

to the outlet of a bubbler containing a tertiary alcohol such ciently active for dehydration.

as neopentyl alcohol. The inlet of the bubbler is connected

to a nitrogen cylinder. The downstream end of the catalyst Acknowledgment

tube is connected to the inlet of a second bubbler contain-

ing mineral oil. To run the reaction, a slow flow of nitrogen We wish to thank the Student Undergraduate Re-

gas is passed through the apparatus while the catalyst is search Fund (SURF) administered by the Arkansas Sci-

maintained at about 300 °C. The catalyst can be heated in ences Information Liaison Office (SILO) for financial sup-

a tube furnace or by wrapping the glass tube with a resis- port of this work.

tively heated electrical tape. The alkene is collected as a so-

lution in the mineral oil bubbler. Progress of the reaction is Literature Cited

noted by the sharp odor of alkene at the outlet and the wa- 1. Zeolites as Catalysts, Sorbents and Detergent Builders; Karge, H.

ter layer forming in the bottom of the oil bubbler. The dehy- G.; Weitkamp, J., Eds.; Elsevier Science: Amsterdam, 1989.

dration of neopentyl alcohol to 2-methyl-2-butene is shown 2. Hölderich, W.; Hesse, M.; Näumann, F. Angew. Chem. Int. Ed. Engl.

1988, 27, 226–246.

below (eq 2). 3. Meise, W.; Schwochow, F. E. Advances in Chemistry 121; American

Chemical Society: Washington, DC, 1973; pp 169–178.

4. Broussard, L.; Shoemaker, D.P. J. Am. Chem. Soc. 1960, 82, 1041–

CH3 CH3 1051.

300 °C / N2 5. Harris, D.C. Quantitative Chemical Analysis; W. H. Freeman: San

CH3CH2 C OH

H+-A

CH3CH2 C + H2O (2) Francisco, 1982; p 284.

CH3 CH3

570 Journal of Chemical Education • Vol. 74 No. 5 May 1997

Vous aimerez peut-être aussi

- Why Men Want Sex and Women Need Love by Barbara and Allen Pease - ExcerptDocument27 pagesWhy Men Want Sex and Women Need Love by Barbara and Allen Pease - ExcerptCrown Publishing Group62% (34)

- Fortune Falls - Lou VaneDocument402 pagesFortune Falls - Lou VanetestePas encore d'évaluation

- IB Chemistry Extended EssayDocument30 pagesIB Chemistry Extended EssayPratyaksha Sinha100% (2)

- 4500 CL - CHLORIDEDocument2 pages4500 CL - CHLORIDEAndrés Osorio100% (1)

- Advanced Pharmaceutical analysisD'EverandAdvanced Pharmaceutical analysisÉvaluation : 4.5 sur 5 étoiles4.5/5 (2)

- The Way Out of Alcoholism by Jack BolandDocument38 pagesThe Way Out of Alcoholism by Jack BolandIma AardvarkPas encore d'évaluation

- Design and Details of Elevated Steel Tank PDFDocument10 pagesDesign and Details of Elevated Steel Tank PDFandysupaPas encore d'évaluation

- Pines 1968Document9 pagesPines 1968Alejo CastroPas encore d'évaluation

- Synthesis and Characterization of Porous Silica-Alumina XerogelsDocument6 pagesSynthesis and Characterization of Porous Silica-Alumina XerogelsIsna NurhidayatiPas encore d'évaluation

- Reaction TypesDocument10 pagesReaction TypesaqibazizkhanPas encore d'évaluation

- Toyoshima, Miyahara - 1975 - Catalysis and Coordinative Active Sites On Sulfurated Unsaturation ofDocument7 pagesToyoshima, Miyahara - 1975 - Catalysis and Coordinative Active Sites On Sulfurated Unsaturation ofDOUGLAS RAMON RODRIGUEZ ORDOÑEZPas encore d'évaluation

- Catalytic Hydrogenation by Using Raney NickelDocument5 pagesCatalytic Hydrogenation by Using Raney NickelSampotterPas encore d'évaluation

- imp-EVALUA TION OF DIFFERENT LEACHING SOLUTIONS FOR LEAD RECOVERYDocument5 pagesimp-EVALUA TION OF DIFFERENT LEACHING SOLUTIONS FOR LEAD RECOVERYThambik DuraiPas encore d'évaluation

- 1 s2.0 014424499500076I MainDocument7 pages1 s2.0 014424499500076I MainDebkrishna DeyPas encore d'évaluation

- Applied Surface ScienceDocument5 pagesApplied Surface ScienceGTheresiaPas encore d'évaluation

- My Note 28Document18 pagesMy Note 28TSZ YAN CHEUNGPas encore d'évaluation

- MASS PRODUCTION OF LiAl ALLOYS BY THE STEPDocument28 pagesMASS PRODUCTION OF LiAl ALLOYS BY THE STEPVenkiteshPas encore d'évaluation

- Diagrama de FlujoDocument2 pagesDiagrama de FlujoMariana PadillaPas encore d'évaluation

- Efectt of CaoDocument11 pagesEfectt of CaoAlfonso RamosPas encore d'évaluation

- Elias Lecture Silicones and Silicates Part 2Document27 pagesElias Lecture Silicones and Silicates Part 2Scribd_is_GreatPas encore d'évaluation

- United States Patent Office:) e C (O H2-CH-CH H-C E'sDocument4 pagesUnited States Patent Office:) e C (O H2-CH-CH H-C E'sAjeeth KumarPas encore d'évaluation

- Studies On The Solvent Extraction of Gold From Cyanide MediaDocument22 pagesStudies On The Solvent Extraction of Gold From Cyanide MediaMaiman LatoPas encore d'évaluation

- 5Document10 pages5Syahira YusofPas encore d'évaluation

- Ho2016 Enhancement of Hydrogen Generation Using WasteDocument7 pagesHo2016 Enhancement of Hydrogen Generation Using WasteNur FadhilahPas encore d'évaluation

- Alofano Como CatalizadorDocument10 pagesAlofano Como CatalizadorRenato Rovere HerreraPas encore d'évaluation

- Coflotation of Cs From Radioactive Process Waste WaterDocument8 pagesCoflotation of Cs From Radioactive Process Waste WaterPanagiotis XanthopoulosPas encore d'évaluation

- Electrolytic Production of Hydrometallurgical Reagents For Processing Manganese OresDocument4 pagesElectrolytic Production of Hydrometallurgical Reagents For Processing Manganese OresNeale NeelamegghamPas encore d'évaluation

- Lab 5 Synthesis of AlumDocument5 pagesLab 5 Synthesis of AlummohamedPas encore d'évaluation

- M1 L9 Zeolite Ion ExchangeDocument21 pagesM1 L9 Zeolite Ion Exchangegaurav toppoPas encore d'évaluation

- Hydroxyl Groups On Alumina Silica AluminaDocument10 pagesHydroxyl Groups On Alumina Silica AluminaParavastu VinuthaPas encore d'évaluation

- Effect On Aluminium Solubility When Acid Is Used To Neutralise ResidueDocument3 pagesEffect On Aluminium Solubility When Acid Is Used To Neutralise ResidueRogerio CannoniPas encore d'évaluation

- Ethers, Epoxides, and Sulfides: Organic Chemistry, 7Document34 pagesEthers, Epoxides, and Sulfides: Organic Chemistry, 7Elahine Yuliheht Orozco OcampoPas encore d'évaluation

- Ni/Ce-Al-O-A Catalyst: Imad Merhej Mouhamad Ali Ziwar Moulky Mouhamad KaddourDocument10 pagesNi/Ce-Al-O-A Catalyst: Imad Merhej Mouhamad Ali Ziwar Moulky Mouhamad KaddourziwarPas encore d'évaluation

- Ni/Ce-Al-O-A Catalyst: Imad Merhej Mouhamad Ali Ziwar Moulky Mouhamad KaddourDocument10 pagesNi/Ce-Al-O-A Catalyst: Imad Merhej Mouhamad Ali Ziwar Moulky Mouhamad KaddourziwarPas encore d'évaluation

- PW1. Javel WaterDocument3 pagesPW1. Javel WaterFariz AbdullayevPas encore d'évaluation

- Butan-1-Ol and Butan-2-Ol Dehydration On Nitrided Aluminophosphates: Influence of Nitridation On Reaction PathwaysDocument11 pagesButan-1-Ol and Butan-2-Ol Dehydration On Nitrided Aluminophosphates: Influence of Nitridation On Reaction PathwaysDiegowz FiguerzPas encore d'évaluation

- Synthesis of Zeolites by Alkaline ActivationDocument6 pagesSynthesis of Zeolites by Alkaline Activationnavri_nalhadPas encore d'évaluation

- 3 - K. J. Balkus. Chem. Educ. 68, 875, 1991Document3 pages3 - K. J. Balkus. Chem. Educ. 68, 875, 1991Gabriel ChavesPas encore d'évaluation

- Experiment # 8 Synthesis and Reactivity of Tert-Butyl ChlorideDocument3 pagesExperiment # 8 Synthesis and Reactivity of Tert-Butyl ChlorideFon YeePas encore d'évaluation

- Jayasekera 1983 (Solvation of Ions V-Electrolytic Recovery of Ag From Non-Aq (DMS) Sol'ns)Document10 pagesJayasekera 1983 (Solvation of Ions V-Electrolytic Recovery of Ag From Non-Aq (DMS) Sol'ns)lakefieldPas encore d'évaluation

- EXPE8Document5 pagesEXPE8K-yanVehraaYomomaPas encore d'évaluation

- Experiment 5 PDFDocument4 pagesExperiment 5 PDFPeulh DialloPas encore d'évaluation

- Of Of: by John A. Scherrer. Rosemond K. Bell. and William D. MogermanDocument4 pagesOf Of: by John A. Scherrer. Rosemond K. Bell. and William D. MogermanMahmood UllahPas encore d'évaluation

- Hydrothermal Crystallization Mechanism oDocument3 pagesHydrothermal Crystallization Mechanism oPrakash MallaPas encore d'évaluation

- Lab 6-283gDocument11 pagesLab 6-283gAnonymous 4KuItFhPas encore d'évaluation

- ZeolitesDocument9 pagesZeolitesAhlan RiwahyuPas encore d'évaluation

- Chem 117 - Preparation of Potassium Aluminum SulfateDocument5 pagesChem 117 - Preparation of Potassium Aluminum Sulfatevinsmoke1Pas encore d'évaluation

- PREPARATION OF POTASSIUM ALUMINUM SULFATE, KAl (SO4) 2 - 12H2O (Alum)Document5 pagesPREPARATION OF POTASSIUM ALUMINUM SULFATE, KAl (SO4) 2 - 12H2O (Alum)vinsmoke1Pas encore d'évaluation

- PREPARATION OF POTASSIUM ALUMINUM SULFATE, KAl (SO4) 2 - 12H2O (Alum)Document5 pagesPREPARATION OF POTASSIUM ALUMINUM SULFATE, KAl (SO4) 2 - 12H2O (Alum)vinsmoke1Pas encore d'évaluation

- PREPARATION OF POTASSIUM ALUMINUM SULFATE, KAl (SO4) 2 - 12H2O (Alum)Document5 pagesPREPARATION OF POTASSIUM ALUMINUM SULFATE, KAl (SO4) 2 - 12H2O (Alum)vinsmoke1Pas encore d'évaluation

- Elimination Reactions On Solid Acid Catalysts Esterification of Ethanol With Acetic AcidDocument7 pagesElimination Reactions On Solid Acid Catalysts Esterification of Ethanol With Acetic AcidDemetrio RomeroPas encore d'évaluation

- Effects of Solvent Polarity On The Hydrogenation of Xylose: Jyri-Pekka Mikkola, Tapio Salmi and Rainer Sjo HolmDocument11 pagesEffects of Solvent Polarity On The Hydrogenation of Xylose: Jyri-Pekka Mikkola, Tapio Salmi and Rainer Sjo HolmEdgar Fernando Jerez GarciaPas encore d'évaluation

- Journal of Catalysis: Maxime Caillot, Alexandra Chaumonnot, Mathieu Digne, Jeroen A. Van BokhovenDocument10 pagesJournal of Catalysis: Maxime Caillot, Alexandra Chaumonnot, Mathieu Digne, Jeroen A. Van BokhovenAnonymous Wcj4C3jPas encore d'évaluation

- Esters From T H E Reactions of Alkyl Halides and Salts Carboxylic AcidsDocument3 pagesEsters From T H E Reactions of Alkyl Halides and Salts Carboxylic AcidsSrg9 3Pas encore d'évaluation

- Cloruros 2011Document7 pagesCloruros 2011Ysolina Vidal DurandPas encore d'évaluation

- Yu-Xie-Synthesis and Characterization of Monodispersed CopperDocument6 pagesYu-Xie-Synthesis and Characterization of Monodispersed CopperrobertsalazarruizPas encore d'évaluation

- Elias Lecture Silicates Part 2 Sept 2016Document34 pagesElias Lecture Silicates Part 2 Sept 2016m.aman.n0510Pas encore d'évaluation

- Catalytic Esterification of Benzyl Alcohol With Acetic Acid: Zeolites and Their Modified FormsDocument6 pagesCatalytic Esterification of Benzyl Alcohol With Acetic Acid: Zeolites and Their Modified FormsDatta Sai kalyanPas encore d'évaluation

- Chu Machen Ko 2016Document5 pagesChu Machen Ko 2016KaterinaPas encore d'évaluation

- 2011 - Nickel Nanoparticles in Hydrogen Transfer ReactionsDocument13 pages2011 - Nickel Nanoparticles in Hydrogen Transfer ReactionsMaría Andérez FernándezPas encore d'évaluation

- Ion Exchange Spent Catalyst Nguyen2013Document5 pagesIon Exchange Spent Catalyst Nguyen2013Michael ChandraPas encore d'évaluation

- Org Chem Lab ManualDocument62 pagesOrg Chem Lab ManualMaePas encore d'évaluation

- Haas 2012Document13 pagesHaas 2012Carlos AvenaPas encore d'évaluation

- The Chemistry of Fertilisers and Manure - Including Information on the Chemical Constituents and Types of Fertilisers and ManuresD'EverandThe Chemistry of Fertilisers and Manure - Including Information on the Chemical Constituents and Types of Fertilisers and ManuresÉvaluation : 5 sur 5 étoiles5/5 (1)

- Bis (Dimethylglyoximat0) Cobalt: ReferencesDocument10 pagesBis (Dimethylglyoximat0) Cobalt: ReferencesFausto SalazarPas encore d'évaluation

- Tautomerism of 1,2,3 - and 1,2,4-Triazole in The Gas Phase and in Aqueous Solution - JPC 1990Document3 pagesTautomerism of 1,2,3 - and 1,2,4-Triazole in The Gas Phase and in Aqueous Solution - JPC 1990Fausto SalazarPas encore d'évaluation

- An Advanced Inorganic Chemistry Experiment: Synthesis and Symmetry of Two Cobalt (III) Complexes With Tetradentate LigandsDocument2 pagesAn Advanced Inorganic Chemistry Experiment: Synthesis and Symmetry of Two Cobalt (III) Complexes With Tetradentate LigandsFausto SalazarPas encore d'évaluation

- Ring-Chain Tautomerism - Valters, Flitsch, 1985 PDFDocument284 pagesRing-Chain Tautomerism - Valters, Flitsch, 1985 PDFFausto SalazarPas encore d'évaluation

- Helvetica Chimica ActaDocument1 pageHelvetica Chimica ActaFausto SalazarPas encore d'évaluation

- Blatter 1990Document3 pagesBlatter 1990Fausto SalazarPas encore d'évaluation

- Chapter 9 Questions and AnswersDocument8 pagesChapter 9 Questions and AnswersFausto SalazarPas encore d'évaluation

- Some Observations On Molecular Orbital Theory PDFDocument5 pagesSome Observations On Molecular Orbital Theory PDFFausto SalazarPas encore d'évaluation

- Ionization Energies of Atoms and Atomic Ions PDFDocument9 pagesIonization Energies of Atoms and Atomic Ions PDFFausto SalazarPas encore d'évaluation

- Gravimetric Determination of Calcium As CaC2O4 - H2ODocument1 pageGravimetric Determination of Calcium As CaC2O4 - H2OFausto SalazarPas encore d'évaluation

- Video Questions Related To The Case of The Missing HareDocument2 pagesVideo Questions Related To The Case of The Missing HareFausto SalazarPas encore d'évaluation

- Introducing Copper As Catalyst For Oxidative Alkane DehydrogenationDocument10 pagesIntroducing Copper As Catalyst For Oxidative Alkane DehydrogenationFausto SalazarPas encore d'évaluation

- Notes, MetalsDocument7 pagesNotes, MetalsindaiPas encore d'évaluation

- Class 7 Work Book Answers Acid Bases and SaltsDocument2 pagesClass 7 Work Book Answers Acid Bases and SaltsGaurav SethiPas encore d'évaluation

- Carbo Hi DratDocument11 pagesCarbo Hi DratILHAM BAGUS DARMA .NPas encore d'évaluation

- Injection Analyzer Electronic Unit enDocument67 pagesInjection Analyzer Electronic Unit enmayralizbethbustosPas encore d'évaluation

- Water TreatmentDocument13 pagesWater TreatmentBayuPas encore d'évaluation

- Guimbungan, Core Competency Module 1 - Part 3 PDFDocument11 pagesGuimbungan, Core Competency Module 1 - Part 3 PDFSharlyne K. GuimbunganPas encore d'évaluation

- Impact of Job Design On Employee Engagement: A Theoretical and Literature ReviewDocument6 pagesImpact of Job Design On Employee Engagement: A Theoretical and Literature ReviewAnonymous CwJeBCAXpPas encore d'évaluation

- RCMaDocument18 pagesRCMaAnonymous ffje1rpaPas encore d'évaluation

- 351 UN 1824 Sodium Hydroxide SolutionDocument8 pages351 UN 1824 Sodium Hydroxide SolutionCharls DeimoyPas encore d'évaluation

- DIP Lecture1Document12 pagesDIP Lecture1Manish SandilyaPas encore d'évaluation

- Transmission Lines SMART EDGE VILLARUEL For April 2024 v1Document89 pagesTransmission Lines SMART EDGE VILLARUEL For April 2024 v1mayandichoso24Pas encore d'évaluation

- An Enhanced Model of Thermo Mechanical Loading On A Vaccum Insulated GlazingDocument29 pagesAn Enhanced Model of Thermo Mechanical Loading On A Vaccum Insulated GlazingNguyễn SơnPas encore d'évaluation

- This Is No Way To Treat An Aorta.: Edwards EZ Glide Aortic CannulaDocument5 pagesThis Is No Way To Treat An Aorta.: Edwards EZ Glide Aortic CannulaAhmadPas encore d'évaluation

- ProAct ISCDocument120 pagesProAct ISCjhon vergaraPas encore d'évaluation

- MGMTDocument19 pagesMGMTMakrant MohanPas encore d'évaluation

- Jurnal Gerd PDFDocument6 pagesJurnal Gerd PDFdilaPas encore d'évaluation

- Lab CompilationDocument11 pagesLab CompilationJanita SiddiquiPas encore d'évaluation

- OM Mannual FOsDocument38 pagesOM Mannual FOsAbdulmuqtadetr AhmadiPas encore d'évaluation

- Preparing Polymers For The Jar TestDocument5 pagesPreparing Polymers For The Jar Testarvin4dPas encore d'évaluation

- HSN-Lube 2007 PDFDocument45 pagesHSN-Lube 2007 PDFCecilio Valderrama100% (3)

- Implementation of 5G - IoT Communication System 1 - RB - LAB EQUIPMENTDocument32 pagesImplementation of 5G - IoT Communication System 1 - RB - LAB EQUIPMENTMaitrayee PragyaPas encore d'évaluation

- Topic 7: Respiration, Muscles and The Internal Environment Chapter 7B: Muscles, Movement and The HeartDocument4 pagesTopic 7: Respiration, Muscles and The Internal Environment Chapter 7B: Muscles, Movement and The HeartsalmaPas encore d'évaluation

- Thermit Welding (GB) LTD Process ManualsDocument10 pagesThermit Welding (GB) LTD Process ManualsAntónio AlmeidaPas encore d'évaluation

- Leave of Absence Form (Rev. 02 072017)Document1 pageLeave of Absence Form (Rev. 02 072017)KIMBERLY BALISACANPas encore d'évaluation

- 1 SMDocument10 pages1 SMAnindita GaluhPas encore d'évaluation